3D Printing and CNC Hybrid Material Applications

You might already know that 3D printing and CNC machining are two powerful technologies shaping modern manufacturing. While 3D printing builds objects layer by layer, CNC machining removes material to achieve precise shapes. Together, they complement each other in several ways: 3D printing creates intricate designs, and CNC machining refines them with precision. This combination forms the foundation of hybrid manufacturing, where additive and subtractive processes work in harmony.

Hybrid manufacturing allows you to create complex parts with enhanced efficiency and cost-effectiveness. It also shortens production cycles by combining the flexibility of printing with the accuracy of CNC machining. Industries like aerospace, healthcare, and automotive rely on this approach to meet growing demands for innovation and customization.

Key Takeaways

Hybrid manufacturing mixes 3D printing and CNC machining. It helps make detailed parts faster and better.

This method saves time and money by using 3D printing's flexibility and CNC machining's accuracy together.

Hybrid manufacturing is eco-friendly. It cuts waste and uses materials wisely, helping the environment.

Industries like airplanes, healthcare, and cars use hybrid manufacturing. It helps them create new and custom products.

Using hybrid manufacturing helps businesses stay ahead. They can make high-quality, custom items for changing markets.

Overview of Hybrid Manufacturing

What is Hybrid Manufacturing?

Hybrid manufacturing combines additive and subtractive processes to create advanced manufacturing solutions. It integrates 3D printing and CNC machining into a single workflow, allowing you to produce parts with greater complexity and precision. This approach offers several key principles that set it apart from traditional methods:

Principle | Description |

|---|---|

Integration of Processes | Combines additive and subtractive methods for enhanced manufacturing capabilities. |

Complex Geometries | Enables production of intricate shapes that are difficult to achieve with traditional methods. |

Material Utilization | Maximizes material savings by combining additive and subtractive techniques. |

Precision Finishes | Achieves high surface quality and dimensional accuracy through CNC machining. |

Multi-material Capability | Allows for the use of different materials within a single part for optimized performance. |

By combining these principles, hybrid manufacturing enables you to achieve results that are difficult or impossible with standalone methods.

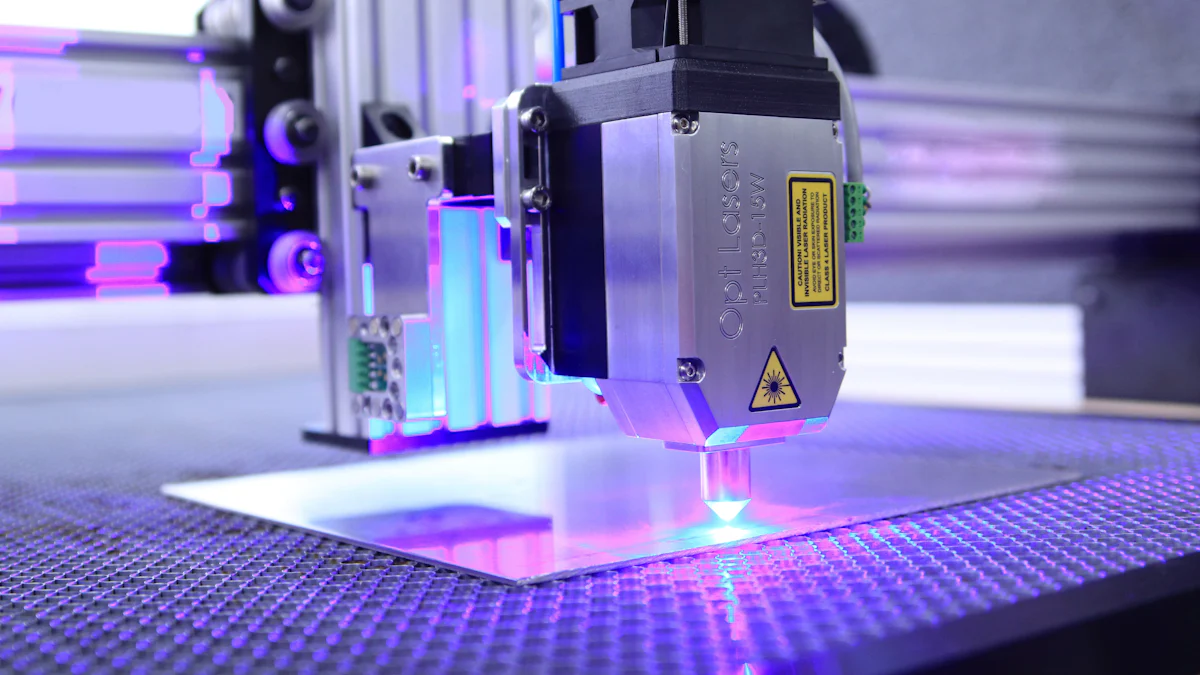

The Role of CNC Machining in Hybrid Manufacturing

CNC machining plays a critical role in hybrid manufacturing. It provides the precision needed to refine 3D-printed parts, ensuring high-quality finishes and dimensional accuracy. This eliminates the need to transfer parts between machines, saving time and reducing errors. You can rely on CNC machining for:

High precision in shaping and finishing parts.

Excellent surface quality for a polished final product.

Compatibility with a wide range of materials.

Strength and durability in the finished components.

By integrating CNC machining with 3D printing, you can produce complex parts more efficiently while maintaining superior quality.

How Hybrid Printing Enhances Manufacturing Processes

Hybrid printing combines the strengths of 3D printing and CNC machining to improve manufacturing processes. It allows you to create intricate designs that traditional methods cannot achieve. The combination of rapid prototyping and precise finishing reduces production time and costs. Key advantages include:

Enhanced design freedom for complex geometries.

Improved efficiency by streamlining production cycles.

Greater cost-effectiveness for intricate parts.

Increased functionality through material combinations.

For example, 3D printing can build internal structures, while CNC machining ensures precise external finishes. This synergy makes hybrid printing a powerful tool for modern manufacturing.

Key Benefits of Hybrid Manufacturing

Enhanced Design Freedom and Customization

Hybrid manufacturing gives you unmatched design flexibility. It allows you to create intricate geometries that traditional methods cannot achieve. For example, additive techniques can build sophisticated internal structures like lattices or fluid channels. You can then use subtractive methods to refine these designs with precision. This combination fosters innovation and enables the production of complex parts more easily.

You can alternate between printing and machining to improve the finishing of detailed internal features.

The speed of 3D printing, combined with the precision of CNC machining, enhances efficiency.

Hybrid printing supports the creation of intricate and complicated parts that were once impractical.

This design freedom opens doors to new applications, helping you push the boundaries of what’s possible in manufacturing.

Tip: Use hybrid manufacturing to experiment with multi-material designs for optimized performance.

Improved Efficiency and Cost-Effectiveness

Hybrid manufacturing streamlines production by combining the strengths of 3D printing and CNC machining. This approach reduces waste and optimizes material usage. You can produce parts with less material while maintaining the same functionality. Additionally, hybrid systems allow you to integrate bulk production's cost-effectiveness with the flexibility of on-demand manufacturing.

You can use different materials within a single build, enhancing efficiency.

The hybrid approach helps you optimize cash flow by reducing waste and material costs.

Combining additive and subtractive processes shortens production cycles, saving time and money.

By leveraging these benefits, you can achieve high-quality results without overspending.

Superior Material Properties and Durability

Hybrid manufacturing enhances the durability and performance of your parts. Additive processes allow you to build lightweight structures with internal reinforcements, while CNC machining ensures precise external finishes. This combination results in components with superior material properties.

For example, you can use hybrid printing to create parts with varying material densities, improving strength where needed. The ability to alternate between CNC machining and 3D printing ensures that your parts meet both functional and aesthetic requirements. This makes hybrid manufacturing ideal for industries requiring high-performance components, such as aerospace and automotive.

Note: Hybrid systems also allow you to experiment with advanced materials, further improving durability and functionality.

Sustainability Through Reduced Waste

Hybrid manufacturing plays a vital role in reducing waste, making it an environmentally friendly solution for modern industries. By combining additive and subtractive processes, you can optimize material usage and minimize waste. For instance, printing allows you to build parts layer by layer, using only the material needed. CNC machining then refines these parts with precision, reducing the need for additional resources. This streamlined approach eliminates the inefficiencies of traditional manufacturing methods.

You also benefit from enhanced production efficiency. Hybrid systems reduce the need for multiple machines, which minimizes errors and simplifies workflows. This optimization supports recycling efforts by allowing you to reuse leftover materials. As a result, you can significantly lower the environmental impact of your operations. For example, hybrid manufacturing helps reduce CO2 emissions by cutting down on energy-intensive processes.

This approach aligns with global sustainability goals, such as the United Nations' 17 Sustainable Development Goals. These goals emphasize the importance of reducing waste and conserving resources. By adopting hybrid manufacturing, you contribute to these objectives while improving your production processes. A leading consumer goods company demonstrated this by using advanced systems to monitor energy usage. They identified energy-intensive activities and made real-time adjustments, reducing greenhouse gas emissions and energy consumption.

Manufacturing accounts for 12% of emissions across American industries. In 2021 alone, it released 765 million metric tons of CO2 due to fossil fuel use and industrial processes. By adopting hybrid manufacturing, you can help lower these numbers. This method not only reduces waste but also supports a more sustainable future for the planet.

Tip: Use hybrid manufacturing to recycle materials and reduce your carbon footprint while maintaining high-quality production.

Applications of 3D Printing and CNC Hybrid Technologies

Aerospace Industry

You can see the aerospace industry embracing hybrid manufacturing to address its unique challenges. This technology allows you to create lightweight, high-strength components that meet strict performance standards. For example, hybrid manufacturing combines 3D printing for intricate geometries with CNC machining for precision. This approach optimizes the weight-to-strength ratio of parts, which is critical for aerospace applications.

Hybrid manufacturing also extends the lifecycle of expensive components. You can repair damaged parts by adding precise material layers, reducing the need for replacements. A notable example is the Dash 8-100 experimental aircraft, which integrates a hybrid-electric propulsion system and batteries. This project aims to improve fuel efficiency and reduce CO2 emissions by 30% compared to advanced turboprop aircraft. Flight testing is scheduled for 2024.

Application | Description |

|---|---|

Hybrid Manufacturing | Addresses complex production challenges, producing components like lattice structures and cooling systems for engines. |

Benefits | Enhances performance and fuel efficiency through precise control over material properties and geometry. |

Medical and Healthcare Applications

Hybrid manufacturing is revolutionizing healthcare by enabling real-time health monitoring and personalized treatments. Flexible hybrid electronics (FHE) play a significant role in this transformation. These devices are lightweight, comfortable, and conformable, allowing you to collect continuous health data. They facilitate early detection of health conditions and empower patients to manage chronic diseases.

Roll-to-roll (R2R) printing makes it possible to produce medical wearables cost-effectively and at scale. These wearables, equipped with FHE biosensors, capture extensive health data over long periods. This data provides valuable insights for wellness tracking and disease diagnosis. For instance, hybrid printing enables the creation of intricate designs for biosensors while CNC machining ensures their precision and durability. This combination enhances both functionality and patient comfort.

Automotive Sector

The automotive sector benefits significantly from hybrid manufacturing. You can use this technology to create parts with intricate geometries that traditional methods cannot achieve. Rapid prototyping through 3D printing, followed by CNC machining, reduces production time. This streamlined process improves efficiency and lowers costs.

Hybrid manufacturing also allows you to tailor parts for specific applications. For example, you can design components with unique properties, such as varying material densities, to enhance functionality. This approach is more economical than relying solely on CNC machining. By combining additive and subtractive processes, you can produce high-performance parts that meet the demands of modern vehicles.

Enhanced Design Freedom: Create intricate geometries for advanced automotive components.

Improved Efficiency: Reduce production time with rapid prototyping and precise finishing.

Greater Cost-Effectiveness: Save costs on complex parts compared to traditional methods.

Increased Functionality: Develop parts with unique properties tailored to specific needs.

Consumer Goods and Customization

Hybrid manufacturing has revolutionized the production of consumer goods by enabling unparalleled customization. You can now create intricate designs that were once impossible with traditional methods. By combining additive and subtractive techniques, hybrid manufacturing allows you to produce complex internal structures, such as lattices or fluid channels. This capability enhances the design possibilities for products like home appliances, electronics, and even fashion accessories.

Hybrid manufacturing merges 3D printing with CNC machining, giving you the ability to create highly detailed and precise components.

It supports agile production, letting you customize products without significantly increasing costs.

The combination of these technologies overcomes individual limitations, offering greater design freedom and precision.

For example, you can use hybrid manufacturing to produce personalized smartphone cases with intricate patterns or ergonomic furniture tailored to specific user needs. This approach fosters innovation in component architecture, making it essential for modern consumer goods.

Tip: Use hybrid manufacturing to experiment with multi-material designs, enhancing both functionality and aesthetics.

Emerging Industries Like Energy and Robotics

Hybrid manufacturing is driving innovation in emerging industries like energy and robotics. In the energy sector, you can develop advanced thermal management systems and protective coatings for critical components. These improvements enhance efficiency and durability, which are vital for renewable energy applications.

In robotics, hybrid manufacturing allows you to create lightweight yet strong parts with intricate geometries. This capability is essential for designing robotic arms, joints, and other components that require both precision and flexibility. By integrating additive and subtractive processes, you can achieve faster prototyping and higher production rates.

Aerospace benefits from hybrid manufacturing by producing lattice structures and cooling systems that reduce weight while maintaining strength.

Medical applications include crafting custom implants and advanced surgical instruments.

Heavy industries use hybrid manufacturing to refurbish large-scale equipment, ensuring precision and durability.

SmartZavod’s technology showcases the potential of hybrid manufacturing. It achieved a 50% reduction in cost per part, 70% less labor time, and 30% lower labor costs. This efficiency minimizes energy consumption and material waste, making hybrid manufacturing a sustainable choice for emerging industries.

Note: Manufacturing contributes to 12% of emissions in American industries. By adopting hybrid manufacturing, you can reduce waste and support sustainability goals.

Processes and Techniques in Hybrid Manufacturing

Material Deposition and Additive Manufacturing

Material deposition forms the foundation of additive processes in hybrid manufacturing. You can use techniques like Directed Energy Deposition (DED) to build parts layer by layer. DED focuses energy to melt metal powders, which are then deposited onto a surface. This method allows you to create near-net shapes that require minimal material waste. After deposition, you can refine the part using subtractive processes like CNC machining.

Hybrid systems often alternate between additive and subtractive technologies during production. This interleaved approach lets you machine intricate internal features while the additive process builds the part. For example, you can create complex geometries, such as internal cooling channels, that traditional methods cannot achieve.

Key processes in material deposition include:

Combining 3D printing with machining for metals like titanium or stainless steel.

Applying additive and subtractive processes in sequence for precision.

Making real-time adjustments during production to enhance accuracy.

This synergy ensures you achieve both design flexibility and high-quality results.

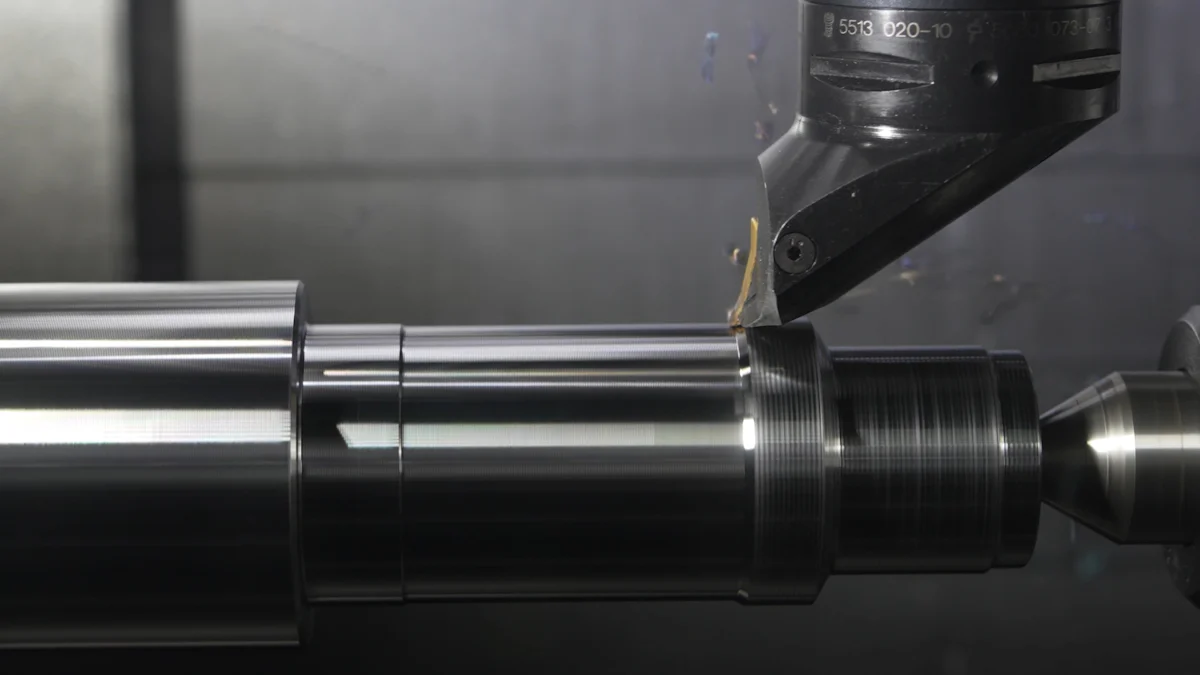

Precision Machining and Subtractive Manufacturing

Precision machining refines the additive components of hybrid manufacturing. You can rely on this process to meet rigorous standards for industries like aerospace and healthcare. It ensures functional integrity and exceptional surface quality.

Benefits of precision machining include:

Producing a better surface finish.

Reducing machining time and tool wear.

Achieving a higher material removal rate.

Addressing the limitations of standalone additive processes.

For example, you can use CNC machining to craft critical features like tight tolerances or smooth surfaces. This dual-process approach enhances the durability and functionality of your parts.

Post-Processing for Surface Finishing

Post-processing ensures your hybrid-manufactured parts meet aesthetic and functional requirements. Techniques like vibration-assisted laser beam machining improve surface finish by reducing particle deposition. Laser-assisted mechanical machining decreases cutting forces and tool wear, making it ideal for difficult-to-machine materials.

Technique | Advantages |

|---|---|

Vibration-Assisted Laser Beam Machining | Improves surface finish; increases heat transfer, reducing particle deposition. |

Laser-Assisted Mechanical Machining | Reduces tool wear; decreases cutting forces; high material removal rate; good surface finish. |

Laser-Assisted Advanced Machining | Achieves superior surface finish; reduces cutting forces; effective for difficult-to-machine materials. |

Directed Energy Deposition and Mechanical Machining | Combines additive and subtractive processes for smooth surface finish. |

By using these techniques, you can ensure your parts are both visually appealing and structurally sound.

Automation and Software Integration in Hybrid Systems

Automation and software integration play a vital role in hybrid manufacturing. They streamline workflows, reduce errors, and improve overall efficiency. By automating repetitive tasks, you can focus on more strategic activities, boosting productivity. Software tools also help you refine designs and optimize production processes, ensuring high-quality results.

Modern hybrid systems rely on advanced software to manage complex operations. For example, Enterprise Resource Planning (ERP) systems provide live access to production schedules and inventory levels. This real-time data helps you make informed decisions and avoid delays. Cloud technology further enhances efficiency by allowing you to access data instantly, eliminating the need for manual synchronization.

ERP systems improve decision-making with live production data.

Automation reduces time spent on routine tasks like data entry.

Cloud platforms ensure seamless data sharing across teams.

Software integration also enhances the precision of hybrid manufacturing. Advanced tools refine CAD models and toolpaths, ensuring accurate machining and printing. Predictive adjustments allow you to fine-tune operations, minimizing waste and errors. Modeling the production sequence helps you foresee challenges and optimize workflows.

Use manufacturing software to refine designs and toolpaths.

Make predictive adjustments to improve accuracy.

Model production sequences to identify and resolve potential issues.

By combining automation with software integration, you can achieve faster production cycles and higher-quality outputs. These technologies not only simplify complex processes but also empower you to adapt quickly to changing demands. Hybrid systems equipped with automation and smart software represent the future of efficient and innovative manufacturing.

Tip: Leverage cloud-based tools to monitor and adjust your hybrid manufacturing processes in real time. This ensures maximum efficiency and minimal downtime.

Challenges and Future Outlook

Current Limitations of Hybrid Manufacturing

Hybrid manufacturing offers many benefits, but it also faces several challenges. The initial financial investment for hybrid systems is significant. These platforms often cost more than traditional manufacturing methods. Maintenance can also be more complex and expensive compared to standalone systems.

Material compatibility remains a major hurdle. You may find it difficult to optimize processes for different materials, which limits flexibility. Additionally, vibration-assisted processes, while useful, can reduce machining accuracy due to vibratory movements. These limitations highlight the need for further advancements to make hybrid manufacturing more accessible and efficient.

High initial costs for hybrid platforms.

Complex and expensive maintenance requirements.

Challenges in material compatibility and process optimization.

Reduced machining accuracy in vibration-assisted processes.

Addressing Material Compatibility Challenges

Material compatibility is a critical factor in hybrid manufacturing. To overcome this challenge, you should focus on research and development. Exploring new materials and refining existing processes will expand the range of compatible materials. This will also improve the flexibility of hybrid systems.

By enhancing process parameters, you can achieve better results with a wider variety of materials. This approach broadens the application possibilities for hybrid manufacturing. For example, industries can use advanced materials to create parts with unique properties, improving both performance and durability. Continued innovation in this area will help you unlock the full potential of hybrid systems.

Advancements in Hybrid Manufacturing Technologies

Recent advancements have significantly improved hybrid manufacturing technologies. The integration of additive manufacturing with CNC machining has enhanced efficiency. New hybrid platforms now support a wider range of materials, making them suitable for diverse applications. These systems also save time and reduce costs, giving you a competitive edge.

SmartZavod’s hybrid solution demonstrates these advancements. It reduced costs per part by 50% and labor time by 70%, while also lowering energy consumption. These improvements show how hybrid systems can meet original specifications while being more efficient. The hybrid manufacturing market is expected to grow rapidly, driven by these innovations.

Integration of additive and subtractive processes.

Enhanced material compatibility for various applications.

Development of advanced platforms that improve efficiency and reduce costs.

Tip: Stay updated on emerging technologies to leverage the full potential of hybrid manufacturing.

The Role of Hybrid Manufacturing in Industry 4.0

Hybrid manufacturing plays a vital role in Industry 4.0 by integrating advanced digital technologies with traditional manufacturing processes. This approach transforms how you produce goods, making operations more efficient, precise, and flexible. By combining additive and subtractive methods with real-time data, hybrid systems create a smarter and more adaptive manufacturing environment.

You can benefit from hybrid manufacturing's ability to enhance operational efficiency. Hybrid machines allow you to save time by streamlining production steps. They also reduce costs by minimizing material waste and energy consumption. These advantages give you a competitive edge in a fast-evolving market.

Tip: Use hybrid systems to monitor production in real time and make adjustments instantly. This ensures consistent quality and reduces downtime.

Hybrid manufacturing aligns perfectly with the principles of Industry 4.0. It enables real-time monitoring of processes, allowing you to track performance and identify inefficiencies. Digital tools integrated into hybrid systems help you optimize workflows and improve precision. For example, software can analyze production data and suggest adjustments to enhance accuracy.

Hybrid manufacturing integrates digital technologies with production.

It improves efficiency, precision, and flexibility.

Real-time monitoring creates an adaptive manufacturing environment.

By adopting hybrid manufacturing, you can future-proof your operations. The ability to combine 3D printing and CNC machining with smart technologies ensures you stay ahead of industry trends. This approach not only boosts productivity but also positions you as a leader in innovation.

Note: Leveraging hybrid manufacturing in Industry 4.0 helps you reduce costs, improve efficiency, and maintain a competitive advantage.

Hybrid manufacturing transforms modern industries by enabling the creation of complex designs that traditional methods cannot achieve. Additive techniques allow you to build intricate internal structures, while CNC machining ensures precision and durability. This combination fosters innovation and enhances existing parts by adding precise material layers, making it ideal for repairing expensive components.

By integrating 3D printing and CNC machining, you gain design freedom, improved efficiency, and cost savings. These technologies complement each other, allowing you to produce high-quality, customized parts tailored to specific needs. Hybrid systems also support the use of diverse materials, enabling unique properties for specialized applications.

Adopting hybrid manufacturing empowers you to stay competitive in a fast-evolving market. It offers a sustainable, efficient, and innovative approach to production, making it a valuable solution for industries seeking to push the boundaries of possibility.

Tip: Start exploring hybrid manufacturing today to unlock its full potential and revolutionize your production processes.

FAQ

What is hybrid manufacturing, and how does it work?

Hybrid manufacturing combines 3D printing and CNC machining in one process. You use 3D printing to build complex shapes and CNC machining to refine them. This integration allows you to create parts with intricate designs and precise finishes, improving efficiency and reducing waste.

Why should you consider hybrid manufacturing for your business?

Hybrid manufacturing offers design flexibility, cost savings, and improved efficiency. You can produce high-quality parts faster while reducing material waste. This approach also supports customization, making it ideal for industries like aerospace, healthcare, and automotive.

Can hybrid manufacturing work with different materials?

Yes, hybrid systems support various materials, including metals, plastics, and composites. You can combine materials in a single part to achieve unique properties. However, you may need to optimize processes for specific material combinations to ensure compatibility.

How does hybrid manufacturing contribute to sustainability?

Hybrid manufacturing reduces waste by using only the material needed for each part. Additive processes minimize excess material, while subtractive methods refine parts efficiently. This approach lowers energy consumption and supports recycling, helping you reduce your environmental impact.

What industries benefit the most from hybrid manufacturing?

Industries like aerospace, healthcare, and automotive gain the most from hybrid manufacturing. You can create lightweight, durable components for aerospace, custom implants for healthcare, and intricate automotive parts. Emerging fields like robotics and renewable energy also leverage hybrid systems for innovation.

Tip: Explore hybrid manufacturing to unlock new possibilities in your industry!

See Also

Exploring Innovations and Diverse Uses of CNC Milling

Clarifying Myths Surrounding CNC Milling and Design Usability

Understanding CNC Machining: Key Factors in Prototyping and Materials

The Impact of CNC Machining on Precision Manufacturing Techniques

CNC Technology in Manufacturing: Trends and Practical Applications

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com