5-Axis CNC Machines: Transforming Manufacturing

In the realm of modern manufacturing, the CNC machine has evolved to a new pinnacle with the advent of 5-axis technology. This cutting-edge innovation allows for unparalleled precision and efficiency in shaping raw materials. The significance of these machines cannot be overstated, as they revolutionize production processes across industries. Throughout this blog, we will delve into the intricate mechanics of 5-axis CNC machines, explore their myriad benefits, and uncover the diverse applications that showcase their versatility.

Mechanics of 5-Axis CNC Machines

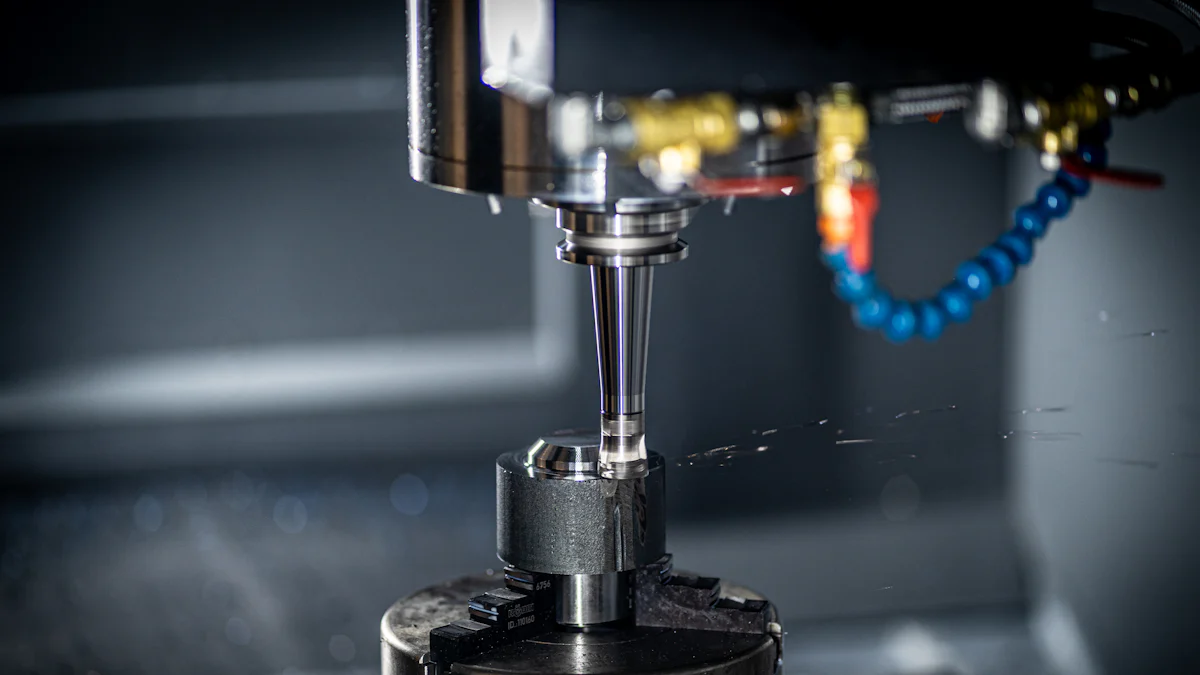

When delving into the Understanding CNC Machine aspect of 5-axis technology, it is crucial to grasp the intricate details that set these machines apart. The Basic Components form the foundation of these cutting-edge tools, comprising a spindle, which holds the cutting tool, and a worktable where the material is secured. Alongside this, the Linear Axes (X, Y, Z) facilitate movement in three directions, enabling precise cuts and shaping. Complementing these linear axes are the Rotary Axes (A, B) that introduce rotational capabilities to approach the workpiece from diverse angles.

Exploring further into How 5-Axis Works, one uncovers a symphony of precision and efficiency. The seamless coordination of Movement and Rotation allows for unparalleled flexibility in tool positioning. This dynamic movement ensures optimal Tool Access and Precision, granting manufacturers the ability to craft intricate designs with utmost accuracy.

In comparing 5-axis CNC Machines with their traditional counterparts, one can identify distinct advantages that propel manufacturing processes forward. The inherent benefits include enhanced versatility in machining complex geometries due to unrestricted tool movement (Advantages). However, it is essential to acknowledge certain limitations such as increased setup complexity when transitioning from traditional setups (Limitations).

The realm of 5-axis machining continues to evolve with advancements in automation and artificial intelligence. As explored in 5-Axis Machining in the Modeling, Simulation, and Training Cluster, autonomous machines and self-adjusting tooling systems are paving the way for a new era of manufacturing excellence.

Embracing the intricacies of 5-axis technology unveils a world where precision meets innovation. These machines stand as pillars of modern manufacturing, reshaping industries with their unparalleled capabilities.

Benefits of 5-Axis CNC Machines

Enhanced Precision

In the realm of precision engineering, CNC machine technology has reached new heights with the integration of 5-axis capabilities. This advancement allows for unparalleled accuracy in shaping raw materials, particularly when intricate designs and complex geometries are involved. The utilization of 5-axis technology enables manufacturers to achieve precision that was once deemed unattainable. By incorporating this cutting-edge approach, companies can produce components with intricate details and tight tolerances that meet the highest industry standards.

Complex Geometries

When it comes to machining intricate components with multifaceted shapes, traditional machining methods often fall short in delivering the required precision. However, with 5-axis CNC machines, manufacturers can navigate through complex geometries effortlessly. The ability to manipulate the cutting tool along five axes provides a level of flexibility that is unmatched by conventional machining processes. As a result, intricate parts such as aerospace components or medical devices can be manufactured with utmost precision and accuracy.

Reduced Errors

One of the key advantages of utilizing 5-axis CNC machines lies in their capability to minimize errors during the manufacturing process. By enabling continuous tool movement along multiple axes, these advanced machines significantly reduce the chances of human-induced errors that may arise from manual intervention. The seamless coordination between different axes ensures that each cut is executed with meticulous precision, leading to a substantial decrease in defects and rework. As a result, manufacturers can enhance their overall production quality while streamlining their operations.

Increased Efficiency

The integration of 5-axis technology in CNC machining not only enhances precision but also drives operational efficiency across manufacturing facilities. By leveraging the capabilities of these advanced machines, companies can optimize their production processes and achieve higher levels of productivity.

Reduced Setup Time

Traditional machining setups often require extensive time and effort to configure tools and equipment for specific tasks. In contrast, 5-axis CNC machines streamline this process by offering quick and efficient setup procedures. With the ability to access multiple sides of a workpiece without additional adjustments, manufacturers can significantly reduce setup times and increase overall throughput. This efficiency gain translates into cost savings and improved lead times for delivering high-quality products to customers.

Multi-Sided Machining

Another notable benefit of 5-axis CNC machines is their capacity for multi-sided machining, allowing manufacturers to complete complex parts in a single setup. This capability eliminates the need for multiple machine configurations or manual repositioning of workpieces, thereby enhancing workflow efficiency. By maximizing material utilization and minimizing idle time between operations, companies can achieve higher production rates while maintaining superior quality standards.

Cost-Effectiveness

In addition to enhancing precision and efficiency, 5-axis CNC machines offer significant cost advantages that contribute to overall operational profitability for manufacturing businesses.

Material Savings

The precise control provided by 5-axis technology enables manufacturers to optimize material usage during the machining process effectively. By minimizing waste and maximizing cutting efficiency, companies can reduce raw material costs while maintaining high production yields. This strategic approach not only leads to cost savings but also promotes sustainable practices within the manufacturing industry.

Labor Reduction

By automating intricate machining tasks that require high levels of precision, 5-axis CNC machines help reduce reliance on manual labor-intensive processes. The integration of advanced automation features allows operators to oversee operations more efficiently while ensuring consistent quality output. As a result, companies can reallocate resources effectively and focus on strategic initiatives that drive business growth.

Applications of 5-Axis CNC Machines

Aerospace Industry

In the realm of precision engineering, CNC machine technology has reached new heights with the integration of 5-axis capabilities. This advancement allows for unparalleled accuracy in shaping raw materials, particularly when intricate designs and complex geometries are involved. The aerospace industry stands as a testament to the transformative power of 5-axis CNC machines in revolutionizing component manufacturing processes.

Component Manufacturing

The utilization of 5-axis CNC machines in aerospace component manufacturing has redefined the standards of precision and efficiency. These advanced machining tools enable manufacturers to craft intricate components with unparalleled accuracy, meeting the stringent requirements of aerospace applications. By leveraging the flexibility provided by five-axis capabilities, companies can produce complex parts that adhere to strict tolerances and geometric specifications.

Material Utilization

Efficient material utilization is a cornerstone of sustainable manufacturing practices within the aerospace industry. With 5-axis CNC machines, manufacturers can optimize material consumption by minimizing waste during the machining process. The precise control offered by these advanced tools ensures that raw materials are utilized effectively, leading to cost savings and environmental benefits. By maximizing material utilization, companies can enhance their operational efficiency while reducing their ecological footprint.

Automotive Industry

The automotive sector is another domain where 5-axis CNC machines have made a significant impact on production processes. From engine parts to custom components, these advanced machining tools have revolutionized manufacturing practices, enabling companies to achieve unprecedented levels of precision and customization.

Engine Parts

In the automotive industry, precision engineering is paramount to ensure optimal performance and reliability of engine parts. 5-axis CNC machines play a crucial role in manufacturing engine components with intricate designs and tight tolerances. By harnessing the capabilities of five-axis machining, companies can produce high-quality engine parts that meet the demanding requirements of modern vehicles.

Custom Components

Customization is a key driver in the automotive industry, where unique designs and specialized components are essential for vehicle innovation. 5-axis CNC machines empower manufacturers to create custom automotive parts with exceptional precision and detail. Whether producing bespoke interior elements or specialized exterior components, these advanced machining tools offer unparalleled flexibility in realizing creative automotive concepts.

Medical Device Manufacturing

Precision instruments and custom implants form the backbone of medical device manufacturing, where quality and accuracy are paramount for patient safety and treatment efficacy. The integration of 5-axis CNC machines in this sector has revolutionized the production of medical devices, enabling manufacturers to deliver cutting-edge solutions with unmatched precision.

Precision Instruments

The creation of precision instruments requires meticulous attention to detail and uncompromising accuracy. 5-axis CNC machines provide medical device manufacturers with the capability to fabricate intricate instruments such as surgical tools and diagnostic equipment with exceptional precision. By leveraging five-axis technology, companies can ensure that every instrument meets rigorous quality standards for clinical use.

Custom Implants

Custom implants tailored to individual patient needs represent a significant advancement in medical device manufacturing. With 5-axis CNC machines, manufacturers can produce patient-specific implants with precise dimensions and complex geometries. This level of customization enhances treatment outcomes and patient comfort by ensuring optimal fit and functionality for each implant recipient.

In the realm of modern manufacturing, 5-axis CNC machines stand as pillars of precision and efficiency, reshaping industries with unparalleled capabilities. The significance of these advanced tools is undeniable, streamlining manufacturing processes and enhancing a CNC Machinist's skill set. As innovations in precision CNC machining continue to shape the future of manufacturing, the proficiency gained from 5-axis technology opens doors to higher wages and career advancement opportunities.

See Also

The Evolution of CNC Machining in Precision Manufacturing

Discovering Precision Manufacturing with CNC Machining Services

The Role of CNC Technology in Manufacturing Advancements and Applications

Uncovering 7 Major Advantages of CNC Machining in Advanced Manufacturing

Diving into Precision Manufacturing and Metal Cutting with CNC Machining

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com