7075 Aluminum and its applications in CNC Machining

7075 aluminium stands out as a top choice for CNC machining due to its exceptional properties. Its high strength-to-weight ratio ensures durability without adding unnecessary weight. You benefit from its fatigue resistance, making it ideal for high-stress applications. Industries like aerospace and automotive rely on 7075 aluminium for critical components such as aircraft fuselages, wings, and lightweight car parts. Consumer electronics also use it for durable casings. The benefits of using aluminium include its machinability and moderate corrosion resistance, which enhance its versatility. These qualities make 7075 aluminium indispensable across various sectors.

Key Takeaways

7075 aluminum is strong but lightweight, perfect for planes and cars.

It is easy to cut and shape, making parts very precise.

It resists rust fairly well, but anodizing makes it better for tough conditions.

This aluminum is often used in gadgets for strong cases and parts.

Using 7075 aluminum is worth the cost for tough, reliable uses.

Overview of 7075 Aluminum

Composition and Alloying Elements

7075 aluminum alloy owes its remarkable properties to its unique composition. The primary alloying elements include:

Zinc: This element plays a key role in precipitation hardening, which significantly boosts the yield stress and ultimate tensile strength.

Magnesium: It enhances the mechanical properties and contributes to the overall strength of the alloy.

Copper: This element further strengthens the alloy, making it suitable for demanding applications.

These elements work together to create one of the strongest aluminum alloys available. The precise balance of these components ensures that 7075 aluminum alloy delivers exceptional performance in high-stress environments.

Mechanical Properties of 7075 Aluminum

When compared to other aluminum alloys, 7075 stands out for its superior mechanical properties. The table below highlights its tensile and yield strength:

Mechanical Property | 6061 Aluminum | 7075 Aluminum | Comments |

|---|---|---|---|

Tensile Strength | 290-310 MPa (42,000-45,000 psi) | 572 MPa (83,000 psi) | 7075 is significantly stronger than 6061. |

Yield Strength | ~240 MPa (35,000 psi) | ~503 MPa (73,000 psi) | 7075 has a higher yield strength. |

These figures demonstrate why 7075 aluminum alloy is a preferred choice for applications requiring high strength and durability.

Unique Characteristics of 7075 Aluminum

High Strength-to-Weight Ratio

7075 aluminum alloy offers an exceptional strength-to-weight ratio. This makes it ideal for industries like aerospace, where reducing weight without compromising strength is critical. You can rely on this alloy for lightweight yet robust components.

Corrosion Resistance

Although 7075 aluminium is more susceptible to corrosion than some other alloys, heat treatment can improve its resistance. This makes it suitable for environments where exposure to moisture or chemicals is a concern.

Heat Treatability

7075 aluminium responds well to heat treatment, which enhances its mechanical properties. This process allows you to tailor the alloy's strength and hardness to meet specific application requirements.

Why 7075 Aluminum is Ideal for CNC Machining

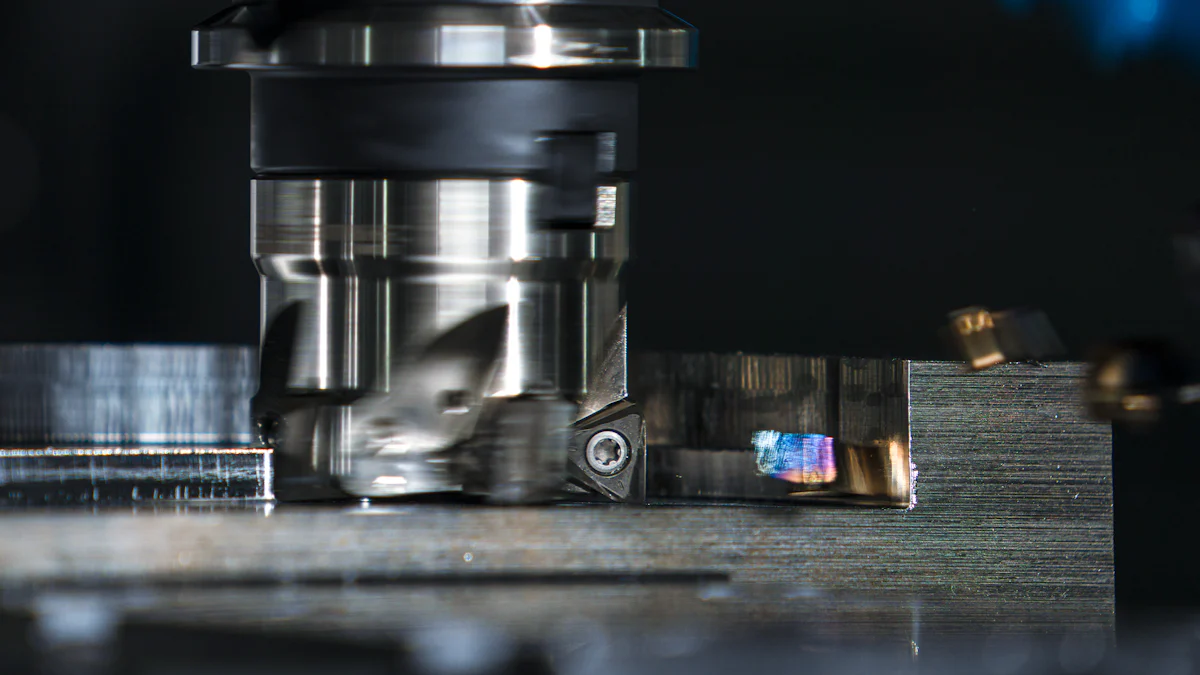

Machinability of 7075 Aluminum

Ease of Cutting and Shaping

7075 aluminum stands out for its excellent machinability, making it a preferred choice in CNC machining processes. Its alloying elements and heat treatment enhance its ability to be cut and shaped efficiently. You will find that it chips well at high speeds, which prevents cutting tools from clogging. The uniform dispersion of alloying elements during heat treatment further improves machining efficiency. These properties allow you to achieve precise cuts and shapes, even for complex designs.

Surface Finish Quality

Achieving a high-quality surface finish is crucial in CNC machining of aluminum, and 7075 excels in this area. The alloy's tensile strength of approximately 572 MPa ensures durability while maintaining a smooth finish. Proper chip control and the use of water-soluble coolants reduce heat buildup, enhancing the final surface quality. By using the right tools for machining aluminum and applying proper techniques, you can overcome challenges and achieve a polished, professional finish.

Property | Description |

|---|---|

Tensile Strength | Approximately 572 MPa, comparable to some steels, ideal for high-performance applications. |

Density | 2.81 g/cm³, significantly lighter than steel, suitable for weight-sensitive designs. |

Machinability | Good machinability, though challenges exist in achieving a smooth surface finish. |

Surface Finish Quality | Proper chip control and coolant application can enhance finish quality despite hardness. |

Strength and Durability in CNC Machining

7075 aluminum offers exceptional strength and durability, making it ideal for CNC machining processes. Its tensile strength of 572 MPa allows it to withstand heavy loads without deforming. This property makes it suitable for high-stress applications in industries like aerospace and automotive. Known as aircraft-grade aluminum, 7075 is commonly used for gears, shafts, and structural components. Its high hardness requires specialized cutting tools, but this ensures long-lasting performance in demanding environments.

Key Benefits of 7075 Aluminum in CNC Machining:

High tensile strength for load-bearing applications.

Lightweight nature for fuel efficiency and mobility.

Moderate corrosion resistance, which can be improved with anodizing or coatings.

Lightweight Nature for Precision Applications

The lightweight nature of 7075 aluminum makes it perfect for precision CNC machining applications. With a density of 2.81 g/cm³, it is significantly lighter than steel. This property allows you to design weight-sensitive components without compromising strength. In aerospace and automotive industries, this translates to improved fuel efficiency and enhanced mobility. The combination of high strength and low weight ensures that 7075 aluminum meets the demands of precision engineering.

Property | Value | Significance |

|---|---|---|

Tensile Strength | 572 MPa | High strength for load-bearing applications |

Density | 2.81 g/cm³ | Lightweight for fuel efficiency and mobility |

Applications of CNC Machined 7075 Aluminum

Aerospace Applications

Aircraft Structural Components

You will find 7075 aluminum widely used in the aerospace industry due to its exceptional strength and lightweight nature. CNC machining allows precise manufacturing of critical components such as aircraft wings and fuselages. These parts must endure high stress while maintaining minimal weight, making 7075 aluminum an ideal choice. Its high strength-to-weight ratio ensures that aircraft remain efficient and reliable during operation.

Common aerospace components made from CNC machined 7075 aluminum include:

Aircraft wings

Fuselage sections

Spacecraft Parts

7075 aluminum plays a vital role in space exploration. Its ability to withstand extreme stress and temperature variations makes it indispensable for spacecraft parts. You can rely on this alloy for components like engine parts in spacecraft, where precision and durability are critical. For example, 7075 aluminum has been used in the Space Shuttle and Saturn V rocket. Its lightweight strength ensures that spacecraft achieve optimal performance without unnecessary weight, which is crucial for space missions.

Automotive Applications

Performance Car Parts

In the automotive sector, CNC machined 7075 aluminum is a top choice for high-performance car parts. Its strength and machinability make it suitable for gears, shafts, and valve regulators. These components require durability and precision, which CNC machining delivers effectively. You can trust 7075 aluminum to enhance the performance and reliability of these parts.

Specific automotive components benefiting from 7075 aluminum include:

Gears and shafts

Valve regulators

Brackets, fittings, and casings

Lightweight Chassis Components

The lightweight nature of 7075 aluminum improves the performance of automotive chassis components. By using this alloy, you can design thinner and lighter chassis parts without compromising strength. This results in better fuel efficiency and acceleration, especially in high-performance vehicles. The strength-to-weight ratio of 7075 aluminum makes it a preferred material for creating durable yet lightweight designs.

Consumer Electronics Applications

Durable and Lightweight Casings

7075 aluminum is also popular in consumer electronics. Its durability and lightweight properties make it perfect for manufacturing casings for laptops, smartphones, and other devices. CNC machining ensures precise cuts and smooth finishes, giving these products a sleek and professional appearance. You can rely on this alloy for casings that protect delicate components while keeping devices portable.

High-Performance Components

In addition to casings, 7075 aluminum is used for high-performance components in electronics. Its strength and machinability allow for the creation of intricate parts that enhance the functionality of devices. Whether it’s heat sinks or structural supports, CNC machined 7075 aluminum ensures reliability and efficiency in consumer electronics.

Other Applications of CNC Machined Aluminum

Sporting Goods

CNC machined 7075 aluminium plays a vital role in the production of high-performance sporting goods. Its exceptional strength-to-weight ratio ensures that equipment remains durable without adding unnecessary bulk. You can find this alloy in a variety of sports products, including:

Bicycle frames designed for speed and endurance.

Baseball bats that deliver powerful hits while staying lightweight.

Archery bows and arrows, where precision and strength are critical.

Climbing gear, such as carabiners and harness components, ensuring safety and reliability.

The machinability of 7075 aluminium allows manufacturers to create intricate designs with precision. This ensures that sporting goods not only perform well but also meet the aesthetic and ergonomic needs of athletes. Whether you’re scaling a mountain or competing on the field, this alloy provides the reliability and performance you need.

Military and Defense Applications

7075 aluminium is a trusted material in military and defense applications due to its unmatched combination of strength, durability, and lightweight properties. You’ll find it used in:

Military-grade firearms like the M-16 and AR-15, where reliability in combat conditions is essential.

Portable equipment, as its lightweight nature reduces the burden on soldiers in the field.

Military vehicles and artillery components, offering durability and resistance to fatigue under extreme conditions.

Armor plating and structural elements, balancing protection with weight savings to improve mobility.

The ability of 7075 aluminium to withstand high stress and harsh environments makes it indispensable in defense. CNC machining ensures that each component meets the exacting standards required for military use. Whether it’s a firearm or a vehicle part, this alloy delivers the performance and reliability demanded by modern defense systems.

Comparison of 7075 Aluminum with Other Materials

7075 Aluminum vs. Other Aluminum Alloys

Comparison with 6061 Aluminum

When comparing 7075 aluminum to 6061 aluminum, you’ll notice significant differences in strength, machinability, and cost. The table below highlights these distinctions:

Property | 6061 Aluminum | 7075 Aluminum |

|---|---|---|

Strength | Lower tensile and yield strength | Higher tensile and yield strength |

Machinability | Easier to machine, softer and more ductile | Harder to machine, requires specialized tools |

Cost | More cost-effective, lower production complexity | More expensive due to higher strength and alloying elements |

6061 aluminum is easier to machine and more affordable, making it ideal for general-purpose applications. However, 7075 aluminum offers superior strength, which is critical for high-stress environments like aerospace and automotive industries.

Comparison with 2024 Aluminum

7075 aluminum also differs from 2024 aluminum in composition, strength, and corrosion resistance. The table below outlines these differences:

Property | 2024 Aluminum | 7075 Aluminum |

|---|---|---|

Composition | Aluminum, copper, magnesium, manganese | Aluminum, zinc, magnesium |

Strength | Good strength | Higher tensile strength |

Corrosion Resistance | Requires surface treatment | Better corrosion resistance |

Machinability | Easier to machine | More challenging to machine |

Applications | Aircraft structures, automotive parts | Aerospace applications, outdoor use |

While 2024 aluminum is easier to machine and suitable for many structural applications, 7075 aluminum excels in environments requiring higher strength and better corrosion resistance.

7075 Aluminum vs. Steel in CNC Machining

When deciding between 7075 aluminum and steel for CNC machining, you should consider their unique advantages and disadvantages:

Advantages of 7075 Aluminum:

High strength-to-weight ratio

Lightweight, reducing overall part weight

Easier to machine due to lower density

Accepts finishes and coatings well

Disadvantages of 7075 Aluminum:

Higher cost compared to most steels

Lower corrosion resistance without treatment

Requires precision tools for machining

Steel, on the other hand, offers greater durability and resistance to bending or scratching. However, its heavier weight and longer machining times make it less suitable for weight-sensitive applications.

Cost and Performance Considerations

7075 aluminum costs more than other aluminum alloys like 6061 due to its superior mechanical properties. For example, sheet metal made from 7075 aluminum ranges from $2.50 to $3.00 per pound, compared to $1.50 to $2.00 per pound for 6061. Despite the higher upfront cost, 7075 aluminum’s strength and reliability make it a worthwhile investment for critical applications. Its lightweight nature also reduces operational costs in industries like aerospace, where weight savings translate to fuel efficiency.

Product Form | 6061 Aluminum Cost (USD/lb) | 7075 Aluminum Cost (USD/lb) |

|---|---|---|

Sheet Metal | $1.50 – $2.00 | $2.50 – $3.00 |

Bar Stock | $1.80 – $2.20 | $2.80 – $3.50 |

By choosing 7075 aluminum, you gain unmatched performance in high-stress environments, justifying its higher price for precision engineering projects.

7075 aluminum stands out as a premier material for CNC machining due to its exceptional properties. Its high tensile strength of 572 MPa ensures durability in load-bearing applications, while its lightweight density of 2.81 g/cm³ enhances mobility and fuel efficiency. The alloy’s moderate corrosion resistance, which can be improved with anodizing, and its good machinability make it ideal for precision CNC turning.

This aluminum alloy’s versatility drives its widespread use across industries. In aerospace, its strength and lightweight nature make it indispensable for aircraft components. Automotive manufacturers rely on it for performance car parts and lightweight chassis. In consumer electronics, it provides durable yet sleek casings and high-performance components. These qualities ensure that 7075 aluminum meets the demands of high-performance applications.

By choosing 7075 aluminum, you gain a material that combines strength, precision, and lightweight properties. Its unmatched performance makes it a top choice for manufacturers seeking reliable solutions for critical applications.

Property | Value | Significance |

|---|---|---|

Tensile Strength | 572 MPa | High strength for load-bearing applications |

Density | 2.81 g/cm³ | Lightweight for fuel efficiency and mobility |

Corrosion Resistance | Moderate | Can be improved with anodizing or coatings |

Machinability | Good | Suitable for precision CNC turning |

FAQ

What makes 7075 aluminum suitable for CNC machining?

7075 aluminum offers high strength, lightweight properties, and excellent machinability. These qualities make it ideal for creating precise and durable components. Its ability to maintain structural integrity under stress ensures reliable performance in demanding applications.

Can 7075 aluminum be anodized for better corrosion resistance?

Yes, you can anodize 7075 aluminum to improve its corrosion resistance. This process adds a protective oxide layer, enhancing durability in harsh environments. Anodizing also allows for aesthetic customization with various color options.

How does 7075 aluminum compare to steel in CNC machining?

7075 aluminum is lighter and easier to machine than steel. It provides a high strength-to-weight ratio, making it suitable for weight-sensitive designs. Steel, however, offers greater durability and scratch resistance, which may be necessary for specific applications.

Is 7075 aluminum cost-effective for CNC machining projects?

7075 aluminum costs more than other aluminum alloys, but its superior strength and lightweight properties justify the investment. For high-performance applications, the material's reliability and efficiency outweigh the higher initial expense.

What industries benefit most from CNC machined 7075 aluminum?

Industries like aerospace, automotive, and consumer electronics benefit significantly. Aerospace uses it for aircraft components, automotive for lightweight parts, and electronics for durable casings. Its versatility makes it valuable across various sectors.

See Also

A Comprehensive Look at CNC Machining 7075 Aluminum Alloy

Your 2024 Handbook for CNC Machining 6061 and 7075 Alloys

Discovering The Benefits Of Aluminum CNC Machining Solutions

The Complete Manual for CNC Turning RC Car Aluminum Components

Proven Strategies For Flawless CNC Machining Of Aluminum Parts

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com