How to Ensure Quality Aluminum Parts with CNC Machining

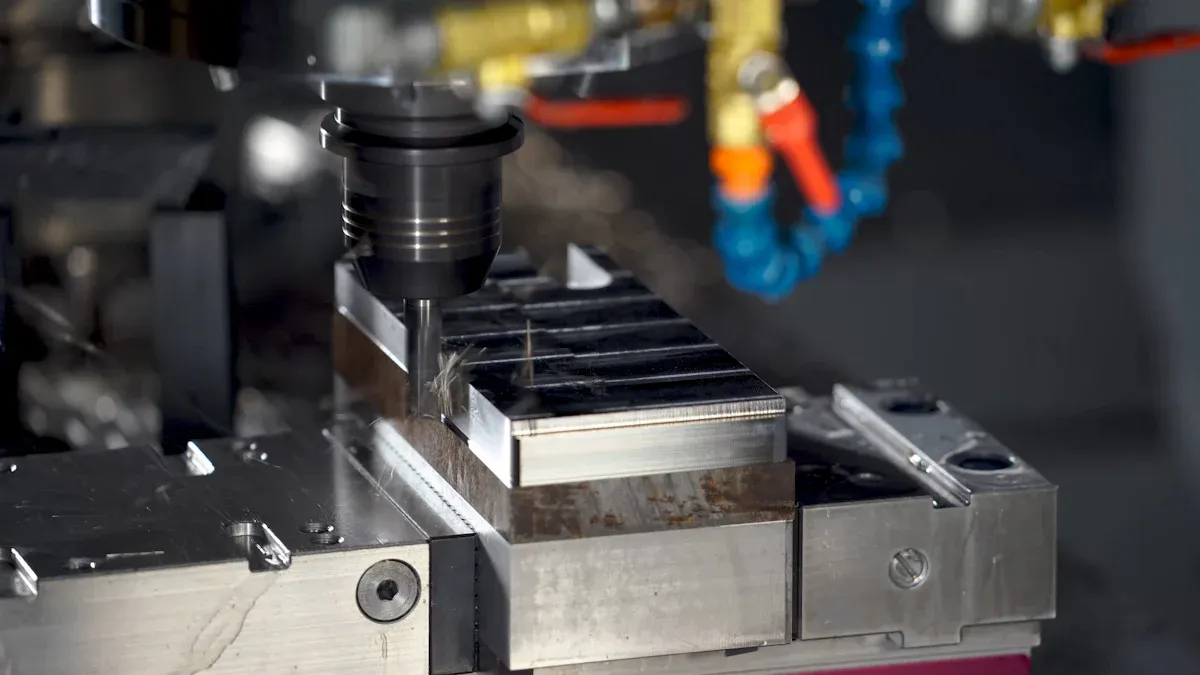

CNC machining delivers unmatched precision and efficiency for aluminum parts, particularly through Aluminium CNC Machining. This process achieves tolerances within microns, thanks to automation and CAD/CAM software. Aluminum’s machinability, strength-to-weight ratio, and corrosion resistance make it ideal for intricate designs. Additionally, its recyclability reduces environmental impact, making Aluminium CNC Machining both cost-effective and sustainable.

Key Takeaways

Pick the correct aluminum type for your project. Each type has special features that affect cutting and strength. For example, 6061 is flexible, while 7075 is very strong.

Get aluminum ready before cutting. Use strong tools, check machines, and use coolants to control heat. This improves the final product's quality.

Take care of machines often. Check oil and coolant daily. Do monthly and yearly maintenance to keep machines working well and making good parts.

Material Selection and Preparation in Aluminum CNC Machining

Choosing the Right Aluminum Alloy for Precision

Selecting the right aluminum alloy is crucial for achieving high precision in CNC machining. Each alloy offers unique properties that suit specific applications. For example:

6061: Lightweight and easy to machine, making it ideal for electronics and structural parts.

6082: Known for its strength and corrosion resistance, often used in transport and construction.

7075: Offers the highest strength-to-weight ratio, perfect for aerospace components.

2024: Combines strength and durability, commonly used in military and commercial aircraft.

When choosing an alloy, you should consider factors like machinability, strength, and corrosion resistance. For instance, 6061 is highly machinable and versatile, while 7075 excels in strength but may require more effort to machine. Balancing these factors ensures the final product meets your precision and performance requirements.

Preparing Aluminum for Optimal CNC Machining Results

Proper preparation of aluminum materials enhances the quality of CNC machining. Start by selecting cutting tools made from carbide or high-speed steel. These tools reduce wear and ensure clean cuts. Next, check the CNC machine for proper functioning to avoid defects during machining.

Using coolants or lubricants is essential to manage heat and prevent thermal deformation. Smaller cuts also help minimize heat generation, improving part quality. Additionally, ensure proper chip evacuation by using suitable cutting fluids. This prevents tool damage and ensures a smooth surface finish.

To avoid common defects like deformation or poor surface finishes, apply stress-relieving treatments before machining. Optimizing cutting parameters, such as feed rates and speeds, further reduces internal stress and enhances precision. By following these steps, you can achieve consistent results and maintain high precision in your aluminum CNC machining projects.

Achieving Precision in Aluminum CNC Machining

Tight Tolerances and Dimensional Accuracy

Achieving tight tolerances is essential for producing high-quality aluminum parts. CNC machining allows you to achieve tolerances as tight as ±0.0005 inches, ensuring ultimate precision. Typical tolerance limits hover around ±0.005 inches, but advanced techniques and skilled operators can push this to ±0.001 inches. These strict tolerance levels enhance the performance and durability of parts, especially in industries like aerospace and medical devices. For example, aerospace components with tight tolerances can withstand higher stress and fatigue loads, improving safety and reliability.

Dimensional accuracy depends on several factors, including the aluminum alloy's properties. Alloys with consistent chemical compositions and low thermal expansion coefficients help maintain accuracy during machining. Additionally, controlling environmental factors like temperature prevents thermal expansion or contraction, ensuring consistent results. By focusing on these aspects, you can achieve superior precision in your CNC machining projects.

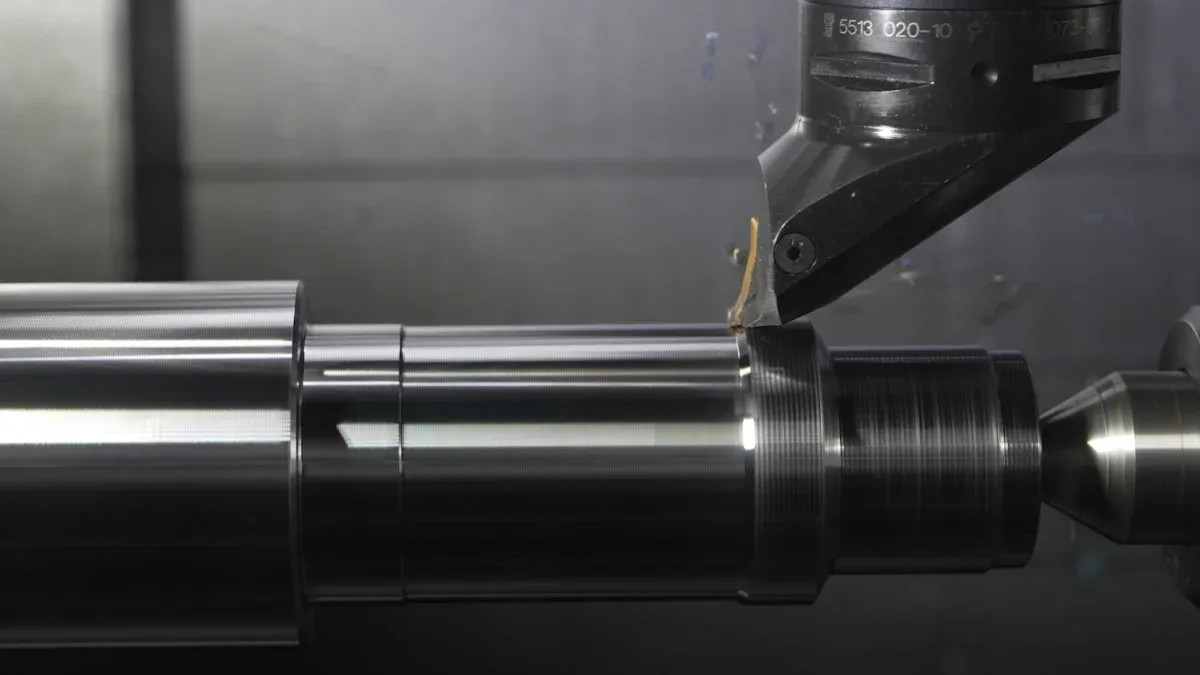

Tool Selection for High-Quality Aluminum Machining

The right tools play a critical role in achieving high precision and accuracy. Carbide tools are ideal for CNC machining aluminum due to their durability and ability to handle high temperatures. For CNC turning, sharp tools reduce cutting forces, resulting in smoother finishes. Tools with coatings like Titanium Diboride (TiB2) prevent aluminum from sticking, further enhancing surface quality.

You should also consider tool geometry. Tools with sharper angles and multiple flutes efficiently evacuate chips, reducing heat buildup and preventing re-cutting. This not only improves the machining process but also extends tool life. By selecting advanced cutting tools, you can achieve consistent performance and superior precision across production batches.

Toolpath Optimization for Enhanced Precision

Optimizing toolpaths is one of the most effective ways to enhance precision in CNC machining. Reduced machining time is a key benefit, as optimized paths minimize unnecessary movements and tool changes. This not only speeds up production but also reduces costs. Additionally, optimized toolpaths improve tool life by reducing wear, leading to fewer replacements and lower maintenance expenses.

Precise optimization ensures a smoother surface finish, which is crucial for industries like automotive and aerospace. It also minimizes material waste, making the process more cost-effective and environmentally friendly. By leveraging innovations enhancing CNC precision, you can achieve accuracy and consistency in every part you produce.

Ensuring Quality in Aluminum CNC Machining

Inspection Techniques for Consistent Quality

Inspection plays a vital role in maintaining product quality during aluminum CNC machining. By using advanced tools and methods, you can ensure consistent quality and defect-free aluminum components. Several techniques are commonly employed:

Micrometers and Calipers: These tools provide precise dimensional measurements, ensuring parts meet exact specifications.

Coordinate Measuring Machines (CMMs): These machines use probes to collect data points, offering accurate three-dimensional measurements.

Surface Finish Inspections: Visual inspections and surface roughness testers help assess surface quality and detect imperfections.

Non-Destructive Testing (NDT): Techniques like ultrasonic testing and X-ray inspection identify internal defects without damaging the part.

Advanced imaging technologies, such as high-resolution scanners, further enhance quality control. These systems capture detailed images of aluminum parts, allowing software to detect even minor deviations. This is especially critical in industries like aerospace, where precision and product quality are paramount.

Process Monitoring to Maintain Standards

Real-time process monitoring ensures consistent quality throughout the machining process. Tools like real-time monitoring systems track production data, enabling immediate corrective actions. For example, monitoring parameters such as spindle speed, feed rate, and coolant flow helps detect deviations early.

Tool condition monitoring systems assess tool wear, ensuring optimal performance and reducing the risk of defects. Environmental monitoring tools, such as temperature and humidity sensors, maintain stable machining conditions, which is essential for achieving high surface quality.

Closed-loop feedback systems take monitoring a step further by automatically adjusting machining parameters based on sensor data. This reduces errors and ensures defect-free aluminum components. By integrating these tools, you can maintain high product quality and improve overall efficiency in CNC machining.

The Role of Operators and Maintenance in CNC Machining

Skilled Operators and Their Impact on Precision

Skilled operators are essential for achieving precision and efficiency in CNC machining. Their expertise ensures that aluminum parts meet exact specifications and maintain high quality. To excel in this role, operators must possess several key qualifications:

A strong understanding of machining principles.

Proficiency in CNC machine operation.

Knowledge of materials science, especially aluminum alloys.

A commitment to ongoing training and improvement.

Operators also need to master CNC machine tools and familiarize themselves with the operating interface. They should understand the entire process, from starting the machine to completing the machining cycle. Safety simulation training prepares them to handle unexpected situations, while process simulations help identify potential issues before production begins.

Your skilled operators directly influence the efficiency of the manufacturing process. They inspect cutting edges, check tool lengths, and ensure proper configurations. Their attention to detail reduces errors and enhances the precision of aluminum components. By combining traditional machining knowledge with CNC programming expertise, operators play a pivotal role in delivering consistent results.

Machine Maintenance for Sustained Quality

Regular maintenance is critical for sustaining the quality and efficiency of CNC machining. Daily tasks include checking lubrication levels, replenishing coolant, and emptying the chip hopper. Monthly maintenance involves cleaning air filters, inspecting coolant systems, and greasing chains or conveyors. Annually, you should remove and clean the coolant tank, test hydraulic oil, and calibrate the machine to maintain accuracy.

Frequency | Maintenance Tasks |

|---|---|

Daily | Check lubrication levels; replenish if needed; Grease parts that look dry; Check coolant concentration and fill levels; Empty chip hopper; Check levels of hydraulic system; Wipe down all surfaces. |

Monthly | Clean/replace air filters; Check and clean coolant filters; Clean radiators and cooling fans; Review oil fill checklists for unusual oil consumption; Remove and clean chuck and jaws; Grease and adjust chains or conveyors. |

Yearly | Remove coolant tank completely; Test hydraulic oil for contaminants; Drain and clean lubrication unit; Check headstock for tapering; Inspect chuck cylinder; Run backlash program. |

Proactive maintenance protects your investment and ensures consistent performance. Regular calibration keeps the machine accurate, while inspections prevent unexpected breakdowns. Addressing common issues like vibration, overheating, or incorrect settings enhances the operational lifespan of CNC equipment. By maintaining your machines, you create a reliable manufacturing environment that consistently produces high-quality aluminum parts.

CNC machining ensures precision and quality for aluminum parts by leveraging advanced technology and expert operators. You can achieve superior results by focusing on material selection, machining accuracy, and quality assurance. Partnering with a reliable CNC provider reduces costs, minimizes waste, and guarantees dimensional accuracy, surface finish quality, and corrosion resistance for your projects.

FAQ

What makes aluminum CNC machining ideal for precision parts?

Aluminum CNC machining offers unmatched precision due to aluminum's machinability and CNC's advanced technology. This combination ensures tight tolerances and high-quality parts for various industries.

How do CNC machining services ensure consistent quality?

CNC machining services use advanced inspection techniques, real-time monitoring, and skilled operators. These measures maintain high standards and deliver reliable aluminum parts for your projects.

Why choose CNC machining services for aluminum parts?

CNC machining services provide expertise, advanced equipment, and efficient processes. This ensures precise, durable, and cost-effective aluminum parts tailored to your specific needs.

See Also

Top Strategies for Flawless CNC Machining of Aluminum Parts

Achieving Excellence in CNC Machining for Precision Parts

Ensuring Compliance in CNC Precision Machining Processes

Understanding the Benefits of Aluminum CNC Machining Services

Enhancing Quality Through Advanced CNC Precision Machining Techniques

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com