Why Aluminium CNC Parts Are Essential in Robotics and Automation

You rely on lightweight and durable materials to build efficient robotic systems. Aluminium CNC machining allows you to take advantage of aluminum's higher strength-to-weight ratio compared to steel, making it ideal for robotics. Its corrosion resistance and non-magnetic properties ensure durability and safety. With aluminium CNC machining, you can create precise, customizable components that enhance robotic performance and reliability.

Key Takeaways

Aluminum is light and strong, making it great for robots. It saves energy and helps robots move faster.

CNC machining is very accurate, making sure robot parts fit well. This helps robots work better.

Aluminum does not rust and handles heat well. This makes robot parts last longer and work in tough places.

Key Advantages of Aluminium in Robotics

Lightweight and Strength

You benefit from aluminum's exceptional strength-to-weight ratio when designing robotic systems. This material is three times lighter than iron or stainless steel, making it easier to handle and process. For example, a 2” x 2” x 8” block of aluminum weighs only 3.2 lbs, compared to over 9 lbs for steel of the same size. Its lightweight nature reduces the overall weight of robotic systems, improving energy efficiency and enabling faster movements. Aluminum's strength also makes it ideal for critical applications like robotic frames, automation systems, and material handling equipment, where durability and rapid motion are essential.

Corrosion Resistance

Aluminum naturally resists corrosion due to a protective oxide layer that forms on its surface. This property ensures that your robotic components remain durable even in challenging environments. Anodizing enhances this resistance, making aluminum less prone to rust than other metals. This feature is particularly valuable in environments with moisture, chemicals, or extreme temperatures, where other materials might degrade over time. By choosing aluminum, you ensure the longevity and reliability of your robotic systems.

Thermal and Electrical Conductivity

Aluminum's excellent thermal and electrical conductivity makes it a versatile choice for robotics. It efficiently dissipates heat, protecting sensitive components like motors and sensors from overheating. Its electrical conductivity also supports applications requiring effective signal transmission, ensuring smooth operation in automated systems.

High Machinability

You can easily machine aluminum into precise shapes and sizes, thanks to its high machinability. Techniques like backward extrusion create consistent workpieces with fewer defects. Selecting alloys such as A6042 and A6262 improves finishing quality and reduces chip size during machining. Proper tool maintenance further enhances the process, allowing you to produce high-quality components efficiently.

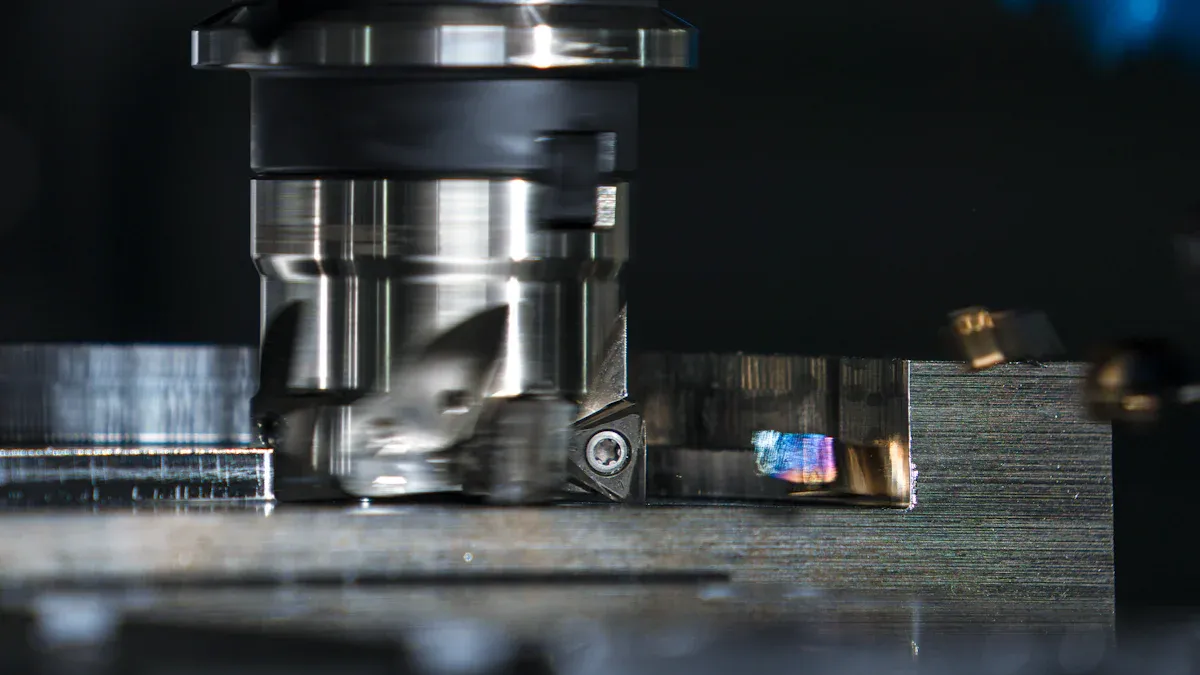

The Role of CNC Machining in Aluminium Robotics Parts

Precision and Tight Tolerances

CNC machining ensures exceptional precision, which is critical for creating reliable robot parts. You can achieve tolerances as tight as ±0.005" (0.13mm) or even ±0.001" (0.025mm), depending on the process. For example, milling and lathing consistently deliver these tolerances, making them ideal for high-performance robots. The table below highlights typical tolerances for various CNC processes:

CNC Process | Tolerance |

|---|---|

Router | ± 0.005" (0.13mm) |

Lathe | ± 0.005" (0.13mm) |

Milling (3-axis) | ± 0.005" (0.13mm) |

Milling (5-axis) | ± 0.005" (0.13mm) |

Engraving | ± 0.005" (0.13mm) |

Surface Finish | 125RA |

Precision cnc machining allows you to produce intricate components like gears, actuators, and sensors. These parts must fit perfectly to ensure smooth robotic motion and optimal performance. For instance, robotic arms require exact specifications to achieve seamless movement, while end effectors depend on precision to interact effectively with their environment.

Customization for Robotic Applications

CNC machining offers unmatched flexibility for creating custom robotic parts. You can design components tailored to specific needs, enhancing the performance and reliability of your robots. For example, custom aluminum extrusions provide a high strength-to-weight ratio, ideal for industrial robot parts. Mechanical arms used in manufacturing, welding, and assembly lines also benefit from precision cnc machining.

This customization addresses unique challenges in robot manufacturing, such as achieving tight tolerances and handling complex geometries. By using cnc machining, you can create parts that improve the accuracy and repeatability of robotic motion. This adaptability ensures your robots meet the evolving demands of automation and high-precision machining.

Superior Surface Finishes

CNC machining techniques deliver superior surface finishes, which enhance both the functionality and aesthetics of robot parts. Methods like grinding, reaming, and burnishing ensure smooth surfaces, reducing friction and wear. Anodizing, a popular surface treatment for aluminum, adds a protective oxide layer that improves corrosion resistance and durability.

For example, anodized aluminum can withstand salt spray testing for up to 1000 hours, compared to just 96 hours for untreated aluminum. This durability makes it ideal for industrial robot parts exposed to harsh environments. Additionally, surface finishes improve the visual appeal of components, making them suitable for high-performance robots in various applications.

Applications of Aluminium CNC Machining in Robotics

Robotic Arms and Joints

Robotic arms and joints demand materials that balance strength and weight. Aluminum CNC machining excels in this area. Aluminum alloys provide a high strength-to-weight ratio, making them ideal for reducing the overall weight of robotic arms. This lightweight property enhances energy efficiency and allows for faster, more precise movements. Additionally, aluminum's corrosion resistance ensures durability in environments exposed to moisture or harsh conditions. CNC machining services enable you to create these components with high precision, ensuring smooth and reliable operation. The high machinability of aluminum also reduces production time and costs, making it a cost-effective choice for manufacturing robotic arms and joints.

End-Effectors

End-effectors are critical robot components that interact with the environment. CNC machining ensures these parts meet exact specifications, which is essential for their functionality. You can achieve tight tolerances of +/- 0.015mm, allowing for precise and repeatable movements. CNC machining also delivers excellent surface finishes, with a roughness of about Ra 0.8μm, reducing friction and wear. These qualities make aluminum CNC machining perfect for creating end-effectors that require both durability and precision. Whether gripping, welding, or assembling, end-effectors benefit from the adaptability and accuracy of CNC machining services.

Motor and Sensor Housings

Motor and sensor housings protect vital robotic components. Aluminum's lightweight nature simplifies processing and reduces shipping costs. Its corrosion resistance ensures longevity, even in challenging environments. CNC machining allows you to produce housings with tight tolerances, ensuring optimal performance. For example, a tolerance of +/- 0.015mm guarantees that motors and sensors fit securely, enhancing the reliability of robot parts. The precision of CNC machining also supports the integration of complex designs, making it easier to house advanced electronics.

Structural Components

Structural components form the backbone of robotic systems. Aluminum alloys are favored for their high strength-to-weight ratio, which supports quick and efficient movements. CNC machining enables you to create precise parts like robot arms, frames, and mounting brackets. These components must meet exact specifications to ensure stability and functionality. Aluminum's thermal conductivity also helps dissipate heat from motors and electronics, improving performance. By using CNC machining, you can produce durable and lightweight structural components that enhance the efficiency of your robotic systems.

Aluminum CNC parts play a vital role in robotics and factory automation. Their lightweight nature and high strength-to-weight ratio reduce energy consumption and improve efficiency. CNC machining enhances precision, enabling the creation of intricate components essential for advanced robotic systems. Additionally, aluminum's recyclability and energy-efficient processing methods align with sustainability goals, making it a cornerstone of modern automation.

Long-term Benefits of Aluminum CNC Parts:

Property

Aluminum

Other Materials

Weight

Heavier than aluminum

Strength

Superior strength in 2000-7000 series

Varies, often lower than aluminum

Corrosion Resistance

Good due to natural oxide film

Generally prone to rust

Machinability

Good, suitable for complex machining

Poor for magnesium and titanium alloys

Processing Methods

Cutting, bending, welding

Limited options for some materials

By integrating aluminum CNC machining, you contribute to the development of eco-friendly robots that consume less energy. This innovation drives the robotics industry forward, ensuring both efficiency and sustainability.

FAQ

What makes aluminum better than other materials for robotic parts?

Aluminum offers a superior strength-to-weight ratio, excellent machinability, and corrosion resistance. These properties make it ideal for creating durable and lightweight robotic components.

How does CNC machining improve aluminum parts for robotics?

CNC machining ensures precision, tight tolerances, and smooth finishes. It allows you to create custom parts that enhance the performance and reliability of robotic systems.

Can aluminum CNC parts handle extreme environments?

Yes, aluminum resists corrosion and performs well in extreme temperatures. Anodized finishes further enhance its durability, making it suitable for harsh industrial conditions.

See Also

Uncovering The Benefits Of CNC Machining With Aluminum

Comprehensive Insights On CNC Turning For RC Car Parts

Achieving Excellence In Precision Parts Through CNC Machining

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com