Anodized Aluminum: Why It Is Perfect for CNC Products

You need a material that combines strength, durability, and versatility for CNC machining. Anodized aluminum delivers all these qualities and more. Its surface hardness, comparable to ceramics, resists scratches and abrasions, making it perfect for aluminum parts exposed to friction or wear. The anodizing process creates a thick oxide layer, enhancing corrosion resistance and ensuring long-lasting performance. This material also retains its finish without peeling or chipping, making it easy to maintain. Whether for industrial or aesthetic applications, anodized aluminum stands out as a reliable and efficient choice.

Key Takeaways

Anodized aluminum is very strong. Its surface is three times harder than regular aluminum. This makes it great for tough jobs in planes and cars.

The anodizing process adds a protective layer. This layer stops rust and keeps it working well, even in bad weather.

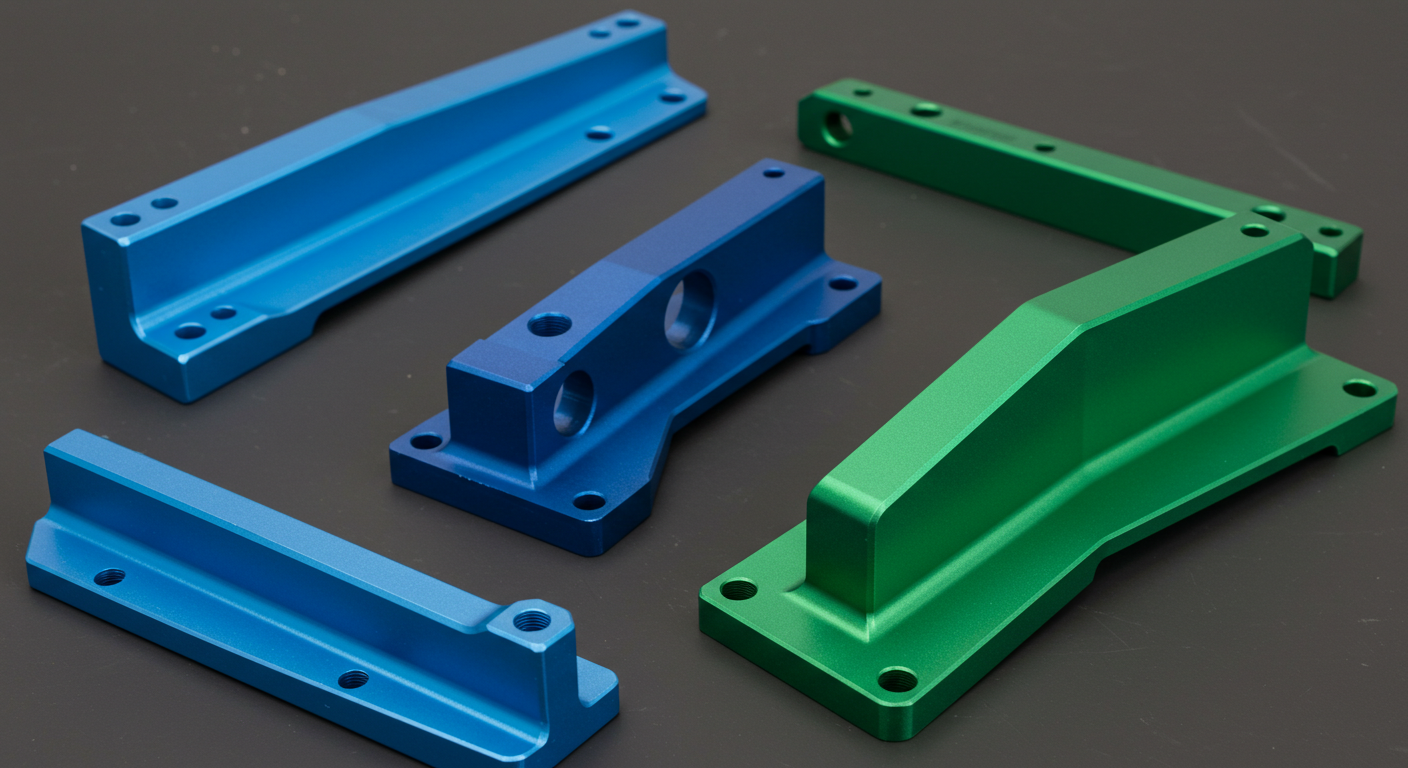

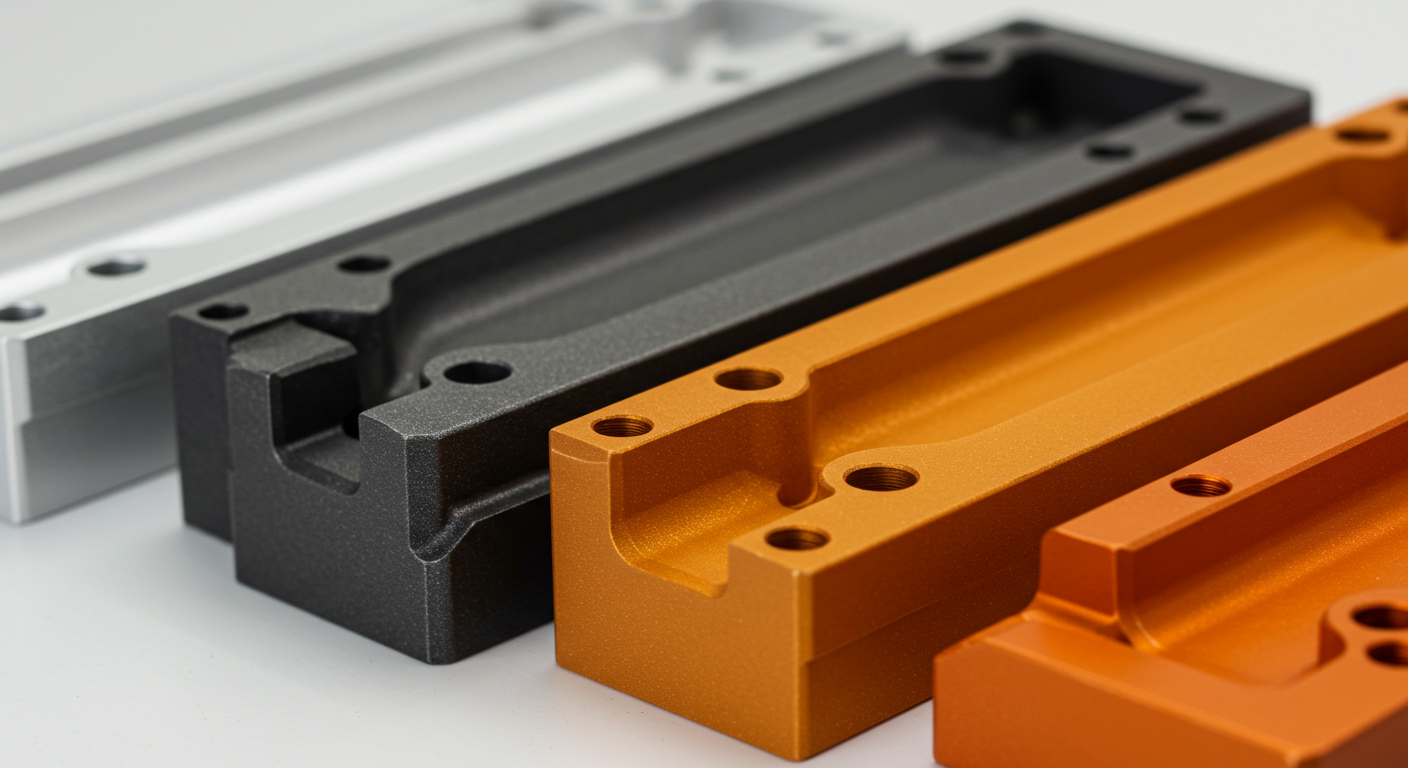

Anodized aluminum looks nice and comes in many colors and finishes. These colors stay bright and don’t peel or fade over time.

It is light but strong, which is perfect for detailed CNC designs. It gives both accuracy and dependability.

Using anodized aluminum lowers repair costs and makes CNC parts last longer. This makes it a smart and affordable choice for many uses.

Benefits of Anodized Aluminum for CNC Machining

Durability and Wear Resistance

Enhanced surface hardness for long-lasting CNC machined parts

Anodized aluminum offers exceptional durability, making it a reliable choice for CNC machining. The anodizing process creates a hardened surface that is three times stronger than untreated aluminum. This enhanced hardness ensures that your CNC machined parts can withstand demanding applications without compromising their structural integrity. Industries such as aerospace, automotive, and medical devices rely on anodized aluminum for its ability to endure high-stress environments. For example:

Aerospace components benefit from its lightweight yet durable properties.

Automotive engine parts resist wear under extreme temperatures.

Medical devices maintain their functionality even after repeated sterilization.

Resistance to scratches and abrasions for extended lifespan

The anodized finish protects aluminum parts from scratches and abrasions, extending their lifespan significantly. Hard coat anodizing, in particular, provides superior wear resistance. Abrasion tests show that hard anodized aluminum loses only 1.0-1.5 mg per 1000 cycles, compared to 20-35 mg for regular anodizing. This durability reduces maintenance needs and ensures your CNC machined parts remain in excellent condition over time.

Corrosion Resistance

Protection against moisture, chemicals, and environmental factors

Anodized aluminum excels in environments where moisture, chemicals, or other corrosive elements are present. The anodizing process forms a protective oxide layer that shields the material from oxidation and degradation. This makes it ideal for industries like aerospace and electronics, where components must endure extreme conditions. For instance, anodized aluminum in aerospace applications resists corrosion while maintaining a high strength-to-weight ratio.

Ideal for outdoor and high-humidity CNC applications

The corrosion resistance of anodized aluminum makes it perfect for outdoor and high-humidity environments. Whether used in yacht hulls to combat saltwater exposure or in commercial kitchen equipment for its non-reactive surface, anodized aluminum ensures long-lasting performance. Its ability to withstand harsh conditions without compromising functionality makes it a preferred material for CNC machining.

Aesthetic Versatility

Customizable anodized finish with a wide range of colors

Anodized aluminum offers unmatched aesthetic versatility. You can choose from a variety of colors, including gold, black, blue, and natural silver, to match your design needs. Products like the Apple MacBook and Tesla Model S showcase how anodized finishes enhance both appearance and functionality. The anodized finish not only adds visual appeal but also provides a durable surface that resists fading and peeling.

Retains visual appeal over time without fading or peeling

The anodized finish ensures that your aluminum parts maintain their aesthetic quality over time. Unlike painted surfaces, anodized aluminum does not peel or chip. This makes it an excellent choice for applications requiring both durability and style, such as architectural cladding in buildings like the Burj Khalifa or signage in the London Underground.

Lightweight Strength

High strength-to-weight ratio for precision machining

Anodized aluminum offers a remarkable strength-to-weight ratio, making it a standout material for CNC machining. This property ensures that you get lightweight yet durable aluminum parts, perfect for applications where weight savings are critical. For instance, anodized aluminum outperforms stainless steel 316L in this aspect, providing greater strength while being significantly lighter. This makes it ideal for industries like aerospace, where reducing weight without compromising strength is essential.

You can also rely on anodized aluminum for its cost-effectiveness. High-strength aluminum alloys provide an affordable alternative when stiffness and weight savings are priorities. The material’s durability further enhances its value, as it withstands demanding environments and maintains its performance over time. Whether you need CNC machined parts for industrial machinery or consumer products, anodized aluminum delivers exceptional results.

Suitable for complex and intricate CNC designs

The lightweight nature of anodized aluminum makes it highly suitable for intricate CNC designs. Its machinability allows you to create detailed and precise components without sacrificing strength. This is particularly beneficial for industries requiring complex geometries, such as electronics and medical devices.

Anodized aluminum’s great strength-to-weight ratio ensures that even the most delicate designs remain robust and reliable. Additionally, the material’s enhanced surface hardness, achieved through the anodizing process, provides added durability. You can trust anodized aluminum to maintain the integrity of your CNC machined parts, even in high-stress applications.

By choosing anodized aluminum, you gain access to a material that combines lightweight properties with exceptional strength. This unique balance makes it a preferred choice for CNC machining across various industries.

How Anodizing Enhances Aluminum's Properties

Formation of a Protective Oxide Layer

Electrochemical process that strengthens and protects the surface

The anodizing process transforms aluminum into a more durable material by forming a protective oxide layer. This process involves submerging aluminum parts in a sulfuric acid electrolyte bath and applying an electric current. The current triggers a chemical reaction, creating a thicker aluminum oxide layer on the surface. This layer significantly enhances the material's resistance to corrosion and wear, making it ideal for CNC machining applications. You can rely on this process to strengthen aluminum parts and extend their lifespan in demanding environments.

Prevents oxidation and degradation of CNC machined parts

The protective oxide layer acts as a barrier against oxidation and environmental damage. It prevents the degradation of CNC machined parts, ensuring they maintain their structural integrity over time. This makes anodized aluminum a reliable choice for industries requiring durable and long-lasting components, such as aerospace and automotive.

Improved Wear Resistance

Hard anodized aluminum for superior durability

Hard anodized aluminum offers enhanced durability, making it suitable for high-demand applications. Its hardness and corrosion resistance make it a versatile material for industries like aerospace, automotive, electronics, and medical devices. For example:

Aerospace components like brackets and frames withstand high stress.

Automotive parts such as pistons and heat sinks remain lightweight yet durable.

Electronics benefit from housings that manage heat and resist corrosion.

Medical devices use sterilizable and durable materials for critical applications.

Reduces maintenance and replacement costs in CNC applications

Hard anodizing reduces maintenance costs by extending the service life of aluminum parts. Its wear resistance minimizes the need for frequent replacements or repairs. The corrosion-resistant oxide layer protects the material from damage, ensuring long-term performance. This durability makes hard anodized aluminum a cost-effective solution for CNC machining.

Enhanced Surface Quality

Scratch-resistant and easy-to-clean anodized finish

An anodized finish improves the surface quality of aluminum parts. It creates a scratch-resistant layer that protects against wear and tear. The finish is also easy to clean, making it ideal for applications requiring low maintenance. You can choose from various finishes, such as matte, glossy, or textured, to enhance the visual appeal of your products.

Better adhesion for coatings, paints, and adhesives

The porous nature of the anodized layer allows coatings, paints, and adhesives to adhere more effectively. This results in a more even and durable finish, which is valuable for applications like architectural components and consumer electronics. The improved adhesion also enhances the structural integrity of assemblies, ensuring strong and reliable connections over time.

Applications of Anodized Aluminum in CNC Machining

Aerospace Components

Lightweight and durable parts for high-performance applications

You can rely on anodized aluminum for aerospace components due to its lightweight and durable nature. This material offers a high strength-to-weight ratio, making it ideal for high-performance parts. For example:

NASA uses anodized aluminum in the International Space Station (ISS) for trusses, handrails, and structural components.

Aircraft panels, frames, and landing gear benefit from its strength and reduced weight, ensuring efficiency and reliability.

The use of aerospace-grade aluminum alloys ensures that these parts meet the demanding requirements of the industry. This combination of strength and weight savings makes anodized aluminum a preferred choice for high-performance parts in aerospace applications.

Resistance to extreme environmental conditions

Anodized aluminum performs exceptionally well in extreme environments. The anodizing process creates a protective oxide layer that enhances corrosion resistance and durability. This layer shields the material from high temperatures, humidity, and corrosive elements. Its ability to withstand high-velocity air and extreme conditions ensures longevity and reduces maintenance needs. For instance, anodized aluminum components in aircraft endure high-altitude environments while maintaining their structural integrity. This high corrosion resistance makes it a reliable material for aerospace-grade applications.

Automotive Parts

Corrosion-resistant and visually appealing components

In the automotive industry, anodized aluminum offers both functionality and style. Its corrosion resistance protects aluminum parts from moisture, salt, and chemicals, ensuring durability in harsh road conditions. Tesla, for example, uses anodized aluminum extensively in its Model S vehicles. This material enhances the range and efficiency of electric vehicles while providing a sleek, corrosion-resistant finish. Common automotive applications include engine components, exterior trim, and interior parts.

Long-lasting parts for high-stress environments

Anodized aluminum ensures longevity for automotive components exposed to high stress. The hard anodized layer minimizes abrasion and wear, making it suitable for critical parts like wheels and brake calipers. Additionally, chassis and body panels benefit from its lightweight yet durable properties. This durability reduces maintenance costs and extends the lifespan of automotive parts, making anodized aluminum a cost-effective choice for high-performance vehicles.

Electronics and Consumer Goods

Sleek designs with durable anodized finishes

Anodized aluminum is a popular choice for electronics and consumer goods due to its sleek appearance and durability. You’ll find it in products like Apple’s MacBook laptops and iPhones, where it provides a premium finish and scratch resistance. Its lightweight nature also enhances portability, making it ideal for devices like laptops and MP3 players. The anodized finish ensures these products maintain their aesthetic appeal over time.

Heat dissipation properties for electronic devices

The heat dissipation properties of anodized aluminum make it essential for electronic devices. The anodizing process increases the surface area, improving heat transfer and cooling efficiency. This material is commonly used in heat sinks and protective enclosures for smartphones, laptops, and computers. Its ability to manage heat effectively ensures the reliability and performance of electronic devices, even under heavy use.

Medical Equipment

Biocompatible and hygienic surfaces for medical devices

When it comes to medical devices, anodized aluminum stands out as an exceptional material. Its biocompatibility ensures safety for patients, making it a preferred choice for tools and equipment that come into direct contact with the human body. The anodizing process creates a thick alumina layer, which acts as a barrier against corrosion and prevents aluminum from leaching into the body. This feature is critical, as aluminum in high doses can be toxic.

You’ll also appreciate how anodized aluminum provides a smooth, non-porous surface. This minimizes the adhesion of bacteria and pathogens, making it easy to clean and sterilize. For medical environments where hygiene is paramount, this property is invaluable. Additionally, the porous nature of the anodized layer allows for further treatments, such as protective coatings, to enhance its biocompatibility.

The lightweight nature of aluminum adds to its appeal. It reduces the overall weight of medical devices, improving usability for healthcare professionals. Whether for surgical instruments or diagnostic tools, anodized aluminum ensures a balance of safety, hygiene, and practicality.

Precision CNC machined parts for critical applications

In the medical field, precision is non-negotiable. Anodized aluminum excels in CNC machining, allowing you to create intricate and accurate components for critical applications. Its machinability ensures that even the most complex designs can be achieved without compromising strength or durability.

The anodizing process enhances the material’s strength and corrosion resistance, making it ideal for medical devices exposed to sterilization processes or harsh environments. For example, surgical tools and implants benefit from the durability and reliability of anodized aluminum. Its non-reactive surface also supports chemical bonding, ensuring compatibility with other materials used in medical assemblies.

By choosing anodized aluminum for CNC machining, you gain access to a cost-effective solution. The material’s affordability, combined with its superior properties, makes it a practical choice for producing high-quality medical equipment. Whether you need lightweight surgical instruments or durable diagnostic devices, anodized aluminum delivers unmatched performance.

Comparison of Anodized Aluminum with Other Materials

Anodized Aluminum vs. Stainless Steel

Lightweight and cost-effective alternative for CNC machining

When comparing anodized aluminum to stainless steel, you’ll notice a significant difference in weight. Anodized aluminum is much lighter, making it ideal for applications where reducing weight is critical, such as aerospace and automotive industries. This lightweight property also makes it easier to handle and transport. Additionally, anodized aluminum is more cost-effective. Its lower raw material costs and efficient anodizing process make it a better choice for large-scale CNC machining projects. Replacing damaged aluminum parts is also less expensive compared to stainless steel, saving you money in the long run.

Easier to machine and customize with an anodized finish

Anodized aluminum offers superior machinability compared to stainless steel. You can achieve intricate designs and precise cuts more easily, which is essential for CNC machining. The anodized finish also provides a smooth, customizable surface. You can choose from a wide range of colors and finishes to match your design needs. In contrast, stainless steel, while durable, is harder to machine and offers fewer aesthetic options.

Feature | Anodized Aluminum | Stainless Steel |

|---|---|---|

Appearance | Wide range of colors; smooth and even finish; popular for decorative applications. | Natural metallic luster; various finishes; conveys durability and strength. |

Corrosion Resistance | Protective anodized layer; good for outdoor use but can degrade in harsh chemicals. | Excellent corrosion resistance due to chromium; suitable for food and marine applications. |

Strength and Durability | Lightweight; good strength but less than stainless steel; may deform under heavy loads. | High strength and durability; withstands heavy loads and mechanical stresses. |

Cost | Generally less expensive; cost-effective for large-scale applications. | More expensive due to raw material costs and complex manufacturing processes. |

Thermal Conductivity | Excellent heat conductor; suitable for heat sinks. | Lower thermal conductivity; may be advantageous in certain heat-resistant applications. |

Weight | Lightweight; beneficial for aerospace and automotive industries. | Relatively heavy; can be advantageous for stability in heavy-duty applications. |

Anodized Aluminum vs. Plastics

Superior strength, durability, and heat resistance

Anodized aluminum outperforms plastics in strength and durability. Its hard, long-lasting finish resists peeling, chipping, and scratches, making it ideal for high-performance applications. You’ll also benefit from its excellent heat resistance, which allows it to perform well in environments where plastics might warp or degrade. This makes anodized aluminum a better choice for industrial and transportation components.

Better environmental stability for long-term use

Unlike plastics, anodized aluminum offers increased corrosion resistance and better environmental stability. It withstands harsh conditions, extending the lifespan of aluminum parts. Additionally, anodized aluminum is easy to clean and maintain. A simple wash with mild soap and water restores its original finish, ensuring long-term usability.

Anodized aluminum resists peeling and chipping.

It offers superior wear resistance, making it suitable for demanding applications.

Its corrosion resistance ensures durability in harsh environments.

It is well-suited for industrial and transportation uses.

Anodized Aluminum vs. Untreated Aluminum

Enhanced corrosion and wear resistance with anodizing

Untreated aluminum lacks the protective oxide layer that anodizing provides. This layer significantly improves corrosion resistance, protecting the material from rust and environmental damage. Anodized aluminum also becomes harder, offering better wear resistance. You’ll find it more durable against scratches and nicks, making it ideal for CNC machining applications in harsh conditions.

Improved aesthetic and functional properties for CNC machined parts

Anodizing enhances both the appearance and functionality of aluminum. You can choose from a variety of colors and finishes, allowing you to customize your aluminum parts to meet specific design requirements. The anodized layer also improves thermal conductivity, making it suitable for heat dissipation applications. Additionally, the process is environmentally friendly, avoiding the use of heavy metals or toxic chemicals.

Anodized aluminum is harder and more durable than untreated aluminum.

It resists corrosion and environmental degradation.

The anodized layer enhances thermal conductivity and heat dissipation.

You can achieve a wide range of colors and finishes for aesthetic flexibility.

Anodized aluminum stands out as the perfect material for CNC machining. Its durability and corrosion resistance ensure long-lasting performance, even in demanding environments. The anodizing process enhances the natural properties of aluminum, making it ideal for creating precise and reliable aluminum parts. You can use this material across industries, from aerospace to consumer electronics, thanks to its strength and aesthetic versatility. Compared to other options, anodized aluminum offers an unmatched balance of performance, cost-effectiveness, and adaptability, making it the top choice for CNC applications.

FAQ

What is anodized aluminum, and why is it used in CNC machining?

Anodized aluminum is aluminum treated with an electrochemical process to create a protective oxide layer. This layer enhances durability, corrosion resistance, and aesthetics. You’ll find it ideal for CNC machining because it combines strength, lightweight properties, and machinability, making it suitable for precision parts.

How does anodizing improve aluminum’s corrosion resistance?

The anodizing process forms a thick oxide layer on the aluminum surface. This layer acts as a barrier, preventing moisture, chemicals, and environmental factors from causing damage. You can rely on anodized aluminum for long-lasting performance in harsh conditions, including outdoor and high-humidity environments.

Can anodized aluminum be customized for different applications?

Yes! Anodized aluminum offers a wide range of color and finish options. You can choose matte, glossy, or textured finishes to match your design needs. Its aesthetic versatility makes it perfect for industries like electronics, automotive, and architecture, where both functionality and appearance matter.

Is anodized aluminum environmentally friendly?

Anodized aluminum is eco-friendly. The anodizing process doesn’t use heavy metals or toxic chemicals. Additionally, aluminum is recyclable, so you can reduce waste and environmental impact by choosing this material for CNC machining projects.

How does anodized aluminum compare to untreated aluminum?

Anodized aluminum is stronger, more durable, and resistant to corrosion compared to untreated aluminum. The anodized layer also improves wear resistance and aesthetics. You’ll find it better suited for demanding applications, as it lasts longer and maintains its appearance over time.

See Also

Benefits of Utilizing Aluminum CNC Machining Services Explored

A Comprehensive Look at Anodizing CNC Machined Aluminum Heat Sinks

CNC Machining Process and Uses of Aluminum Alloy 7075 Explained

Your 2024 Resource for CNC Machining Aluminum Alloys 6061 and 7075

Top Strategies for Achieving Scratch-Free CNC Machined Aluminum Parts

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com