How Automation and Robotics Are Enhancing CNC Machining Efficiency

Automation and robotics have revolutionized CNC machining by enabling continuous operations and reducing inefficiencies. You can now achieve 24/7 production, maximizing machine utilization from 2,000 to 6,000 hours annually. Robots eliminate downtime by performing repetitive tasks without breaks, while automation enhances flexibility in production. These advancements significantly boost productivity and reduce operational costs.

Key Takeaways

Automation in CNC machining saves time by reducing breaks. It helps machines work longer and keeps production going nonstop.

Robots improve accuracy and speed by doing the same tasks perfectly. They lower mistakes made by people and make better products.

Using automation and robots together saves money. It cuts waste, uses materials better, and makes more products faster.

Understanding Automation in CNC Machining

What Is Automation in CNC Machining

Automation in CNC machining refers to the use of advanced technologies to perform tasks with minimal human intervention. It involves integrating systems that streamline operations, reduce errors, and enhance overall efficiency. Key components of automation in CNC machining include:

Automated tool changes that minimize downtime.

Predictive maintenance systems that prevent unexpected breakdowns.

Dimensional accuracy tools that ensure consistent quality.

Robotics that handle repetitive tasks with precision.

CNC machines come with different levels of software and automation. The level of automation specified can greatly enhance machining processes and consequently, the quality of manufactured components.

By adopting automation, you can achieve higher levels of efficiency and productivity, making it a cornerstone of modern manufacturing automation.

The Role of Robotics in Improving Precision and Productivity

Robotics plays a vital role in improving precision and productivity in CNC machining. Robots excel at performing tasks that require consistency and accuracy, such as:

Assembly: Ensuring precise and repeatable part assembly.

Machine Tending: Loading and unloading CNC machines to optimize workflow.

Quality Inspection: Conducting detailed inspections to maintain high standards.

Polishing and Finishing: Handling intricate finishing tasks with care.

Material Handling: Positioning large materials for machining.

High-Precision Milling: Executing tasks requiring extreme accuracy.

By delegating these tasks to robots, you can reduce human error, improve efficiency, and achieve superior results.

How Automation and Robotics Work Together

Automation and robotics complement each other to revolutionize CNC machining. Robots handle tasks like machine tending, tool changes, and material handling, while automation ensures seamless coordination between systems. For example, multi-axis CNC machines combined with robotics allow for complex designs with minimal waste. Systems like Tezmaksan Robotics’ CubeBOX automate loading, unloading, and quality inspections, enabling continuous operation. Advanced sensors in these systems ensure precision and consistency, which manual processes often struggle to achieve.

By integrating automation and robotics, you can achieve higher levels of efficiency, precision, and productivity, transforming your manufacturing processes.

Benefits of Automation in CNC Machining

Enhancing Efficiency and Reducing Downtime

Automation in CNC machining significantly enhances production efficiency by minimizing downtime. Automated systems reduce manual work, saving time on tasks like loading, unloading, and repositioning materials. Bar feeders ensure a steady supply of materials, keeping machines running without interruptions. Robotic arms streamline operations by performing intricate tasks such as tool changes, which maximizes production output. Predictive maintenance systems further improve efficiency by monitoring machine health in real-time. These systems identify potential issues early, preventing unexpected breakdowns and ensuring higher machine availability. By adopting automation, you can achieve faster production cycles and maintain consistent operational flow.

Improving Precision and Productivity

Automation and robotics play a crucial role in achieving high precision and boosting productivity in CNC machining. Automated systems eliminate human error, ensuring consistent and accurate execution of tasks. This is especially important for industries requiring tight tolerances. Advanced sensors and programming in robotic systems enhance precision by maintaining uniformity across repetitive operations. Tasks like automated tool changes and material handling are executed with unmatched accuracy, leading to superior product quality. By integrating automation, you can achieve higher productivity levels while maintaining the precision necessary for complex machining processes.

Cost Savings Through Waste Reduction

Automation in CNC machining offers substantial cost savings by reducing waste and optimizing material usage. Automated systems minimize errors, leading to fewer defective parts and less scrap. This not only conserves resources but also reduces labor costs associated with rework. Continuous operation of CNC machines further maximizes return on investment by increasing production volumes. Over time, these factors contribute to significant cost reductions, making automation a valuable investment for manufacturers. By leveraging automation, you can achieve sustainable production efficiency while maintaining profitability.

Technological Advancements Driving CNC Machining Efficiency

Artificial Intelligence (AI) in CNC Machining

Artificial intelligence is transforming CNC machining by streamlining processes and enhancing productivity. AI simplifies programming and toolpath definition, allowing you to achieve faster setups and reduced manual effort. It analyzes machining data to identify optimal paths, improving precision and minimizing errors. By automating NC machine programming, AI eliminates repetitive tasks, enabling continuous production and consistent results. You can also rely on AI to handle dangerous operations, enhancing workplace safety. These advancements not only boost efficiency but also ensure machines operate 24/7 without interruptions.

Internet of Things (IoT) and Smart CNC Systems

The Internet of Things enables smart CNC systems to revolutionize manufacturing. IoT allows real-time monitoring of CNC operations, giving you immediate control over processes. Predictive maintenance powered by IoT anticipates machine failures, reducing downtime and improving overall efficiency. Machines equipped with IoT can self-regulate and adjust operations based on live data, ensuring precision and automation. Remote monitoring capabilities let you track machine conditions from anywhere, facilitating timely inspections. Real-time alerts further enhance productivity by enabling proactive maintenance actions, ensuring uninterrupted workflows.

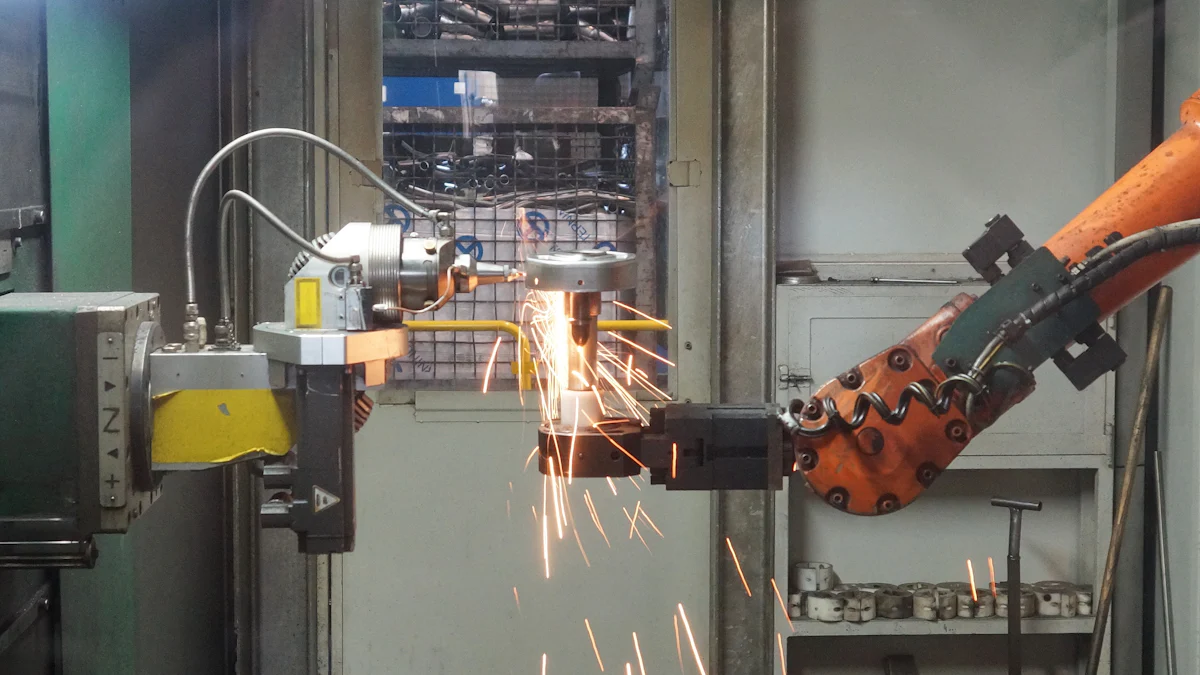

Advanced Robotics and Tooling

Robotics and advanced tooling are redefining CNC machining capabilities. Multi-axis machining centers, such as 5-axis and 6-axis systems, allow you to create intricate parts with fewer setups. Robotic arms provide flexibility for handling large or irregularly shaped workpieces, while robotic milling ensures precise cutting and shaping. Innovations like digital twin technology let you simulate and troubleshoot machining processes before production begins. High-performance cutting tools made from advanced materials improve durability and cutting speeds. These advancements reduce human error, enhance efficiency, and maintain the accuracy required for complex operations.

Real-World Applications of Automation in CNC Machining

Automated Material Handling

Automated material handling systems streamline workflows in CNC machining by efficiently managing the movement of raw materials and finished parts. Robotic arms and conveyors can load and unload materials with precision, reducing manual labor and minimizing errors. These systems ensure that materials are always in the right place at the right time, which keeps production lines running smoothly. For instance, automated pallet changers allow you to switch between workpieces quickly, maximizing machine uptime. By integrating automation into material handling, you can achieve faster production cycles and maintain consistent quality across operations.

Robotic Quality Control and Inspection

Robotic systems enhance quality control and inspection processes by delivering consistent and accurate results. These systems reduce defects and improve overall product quality by integrating seamlessly with CNC machining operations. Key benefits include:

Adaptive control that adjusts machining parameters in real-time based on sensor feedback.

Autonomous process control (APC), which uses real-time data to ensure consistent quality without human intervention.

Automated inspection technologies that identify defects early, preventing costly rework.

By leveraging robotics for quality control, you can maintain high standards while reducing the time and effort required for manual inspections.

Lights-Out Manufacturing for 24/7 Operations

Lights-out manufacturing enables CNC machining facilities to operate autonomously without human supervision. This approach offers several advantages:

Savings in labor costs by minimizing the need for human intervention.

Increased capacity and productivity through additional machining hours.

Energy efficiency, as automated systems consume less energy for cooling and lighting, especially during nighttime operations.

Consistency in production, with reduced variations caused by external factors.

With lights-out manufacturing, you can maximize output, reduce costs, and maintain uniform production quality, making it a game-changer for modern manufacturing.

Future Trends in Automation for CNC Machining

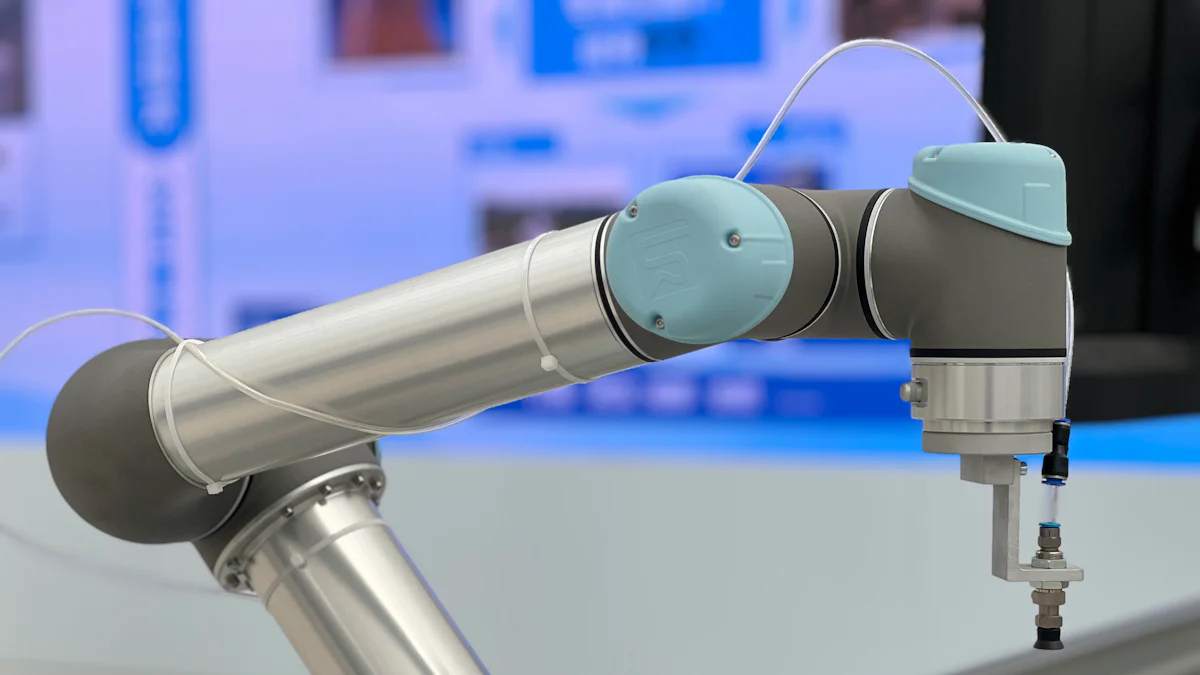

Collaborative Robots (Cobots) in CNC Processes

Collaborative robots, or cobots, are transforming CNC machining by working alongside humans to enhance flexibility and efficiency. These robots perform tasks such as loading and unloading machines, conducting real-time inspections, and supporting tool changes. By taking over repetitive tasks, cobots allow you to focus on more complex operations, improving overall productivity.

Cobots are particularly beneficial in environments requiring high precision and adaptability. For example:

They reduce downtime by streamlining machine tending processes.

They ensure consistent quality through precise handling of materials.

They adapt quickly to changes in production requirements, making them ideal for dynamic manufacturing setups.

Since their invention in 1996, cobots have become a staple in CNC machining, helping you achieve higher efficiency and operational excellence.

Predictive Maintenance with Machine Learning

Machine learning is revolutionizing predictive maintenance in CNC machining systems. By analyzing data, it anticipates equipment failures and optimizes maintenance schedules. This approach reduces downtime and ensures consistent production quality.

Key benefits of predictive maintenance include:

Anticipating failures to prevent unexpected breakdowns.

Reducing unplanned downtime, which can disrupt production.

Enhancing productivity by maximizing machine uptime.

Improving decision-making with accurate data insights.

Real-time monitoring also ensures product quality by detecting deviations early. With predictive maintenance, you can maintain smooth operations and extend the lifespan of your equipment.

Expanding Automation in Custom Manufacturing

Expanding automation in custom manufacturing presents both challenges and opportunities. High equipment costs and skilled labor shortages can hinder adoption. However, automation addresses these issues by reducing dependency on manual labor and improving workplace safety.

Opportunities include:

Enhanced efficiency and precision in manufacturing processes.

Economic growth driven by increased demand for CNC machining automation.

Advanced fixturing and setup that ensure consistent product quality.

Balancing production speed and accuracy remains a challenge, but integrating automation with CNC systems can help you achieve both. By overcoming these hurdles, you can unlock the full potential of custom manufacturing.

Automation and robotics are reshaping cnc machining by driving efficiency, precision, and productivity. Robotics streamline workflows through material handling and additive manufacturing, while IoT sensors enable real-time monitoring and predictive maintenance. AI optimizes processes by analyzing data and boosting machine productivity. Future CNC systems will handle complex geometries, enhancing speed and reducing costs.

FAQ

What industries benefit the most from CNC machining automation?

Industries like aerospace, automotive, medical, and electronics benefit significantly. Automation ensures precision, reduces errors, and enhances productivity, making it ideal for sectors requiring high-quality, complex components.

How does automation reduce CNC machining costs?

Automation minimizes material waste, reduces labor costs, and prevents downtime through predictive maintenance. These factors collectively lower operational expenses and improve your return on investment.

Can small manufacturers adopt CNC automation effectively?

Yes, small manufacturers can adopt scalable automation solutions like cobots or modular systems. These technologies enhance efficiency without requiring significant upfront investments, making them accessible for smaller operations.

See Also

Streamlined CNC Machining Solutions for Accurate Production

Exploring CNC Technology's Role in Modern Manufacturing Innovations

The Impact of CNC Technology on Precision Manufacturing Excellence

Improving CNC Prototyping: Boosting Accuracy and Operational Efficiency

Recent Developments in CNC Machining for Precision Engineering

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com