The Benefits of Outsourcing CNC Machining for Your Business

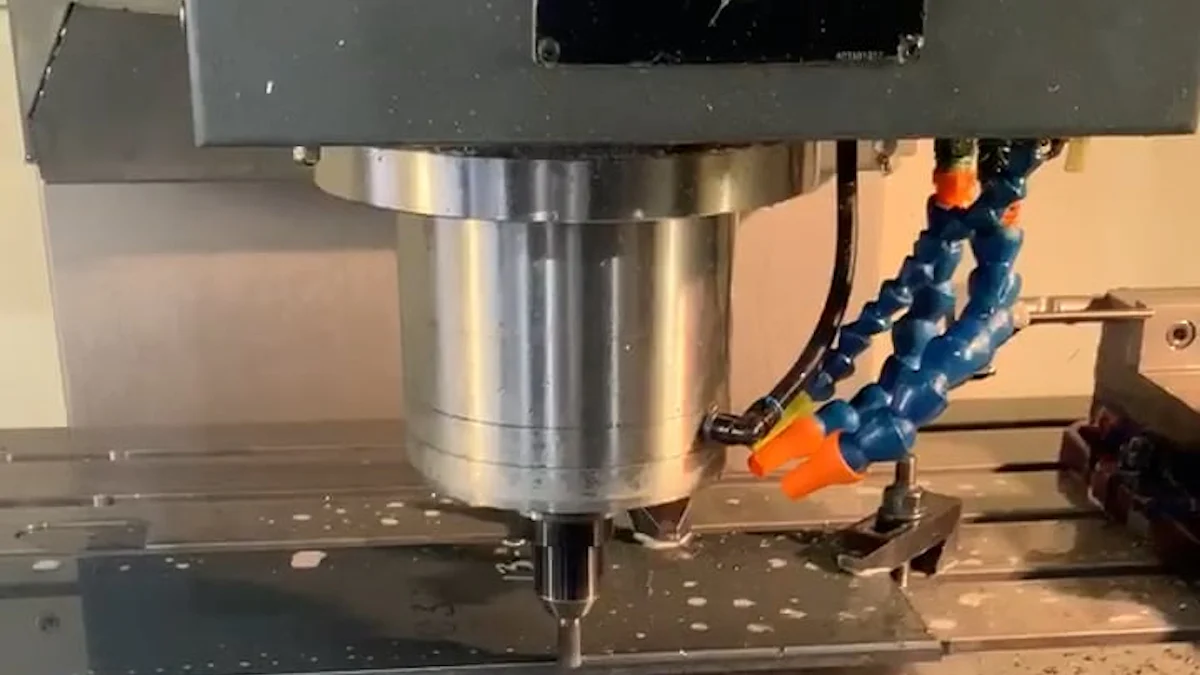

Outsourcing CNC machining can transform your business operations. It reduces costs, saves time, and ensures high-quality production without requiring heavy investments in equipment. You gain access to skilled professionals and advanced CNC machining services, which deliver precision and reliability. This approach also enhances efficiency by minimizing errors and material waste. By outsourcing, you can focus on strategic growth and innovation while adapting quickly to market demands. With agile manufacturing capabilities, you can modify designs faster and stay competitive in a fast-paced industry.

Outsourcing CNC machining empowers you to achieve consistent quality and drive business growth effortlessly.

Key Takeaways

Hiring others for CNC machining can cut costs by 20-30%. This lets you spend more on things like ads and new products.

Skilled workers and modern tools make great products without buying costly machines yourself.

Outsourcing lets you make more or less based on demand. This helps your business stay quick and competitive.

Giving machining tasks to others lets you focus on important work. You can create new ideas and grow your business without distractions.

Expert CNC services follow strict rules to ensure good quality. This means customers get reliable products every time.

Cost Savings with Outsourcing CNC Machining

Outsourcing CNC machining offers significant cost savings for your business. By partnering with experienced providers, you can reduce overhead costs, minimize labor expenses, and benefit from economies of scale. These savings allow you to allocate resources more effectively and focus on growing your business.

Reduced Overhead Costs

Setting up an in-house CNC machining facility requires substantial investment. You need to purchase expensive equipment, maintain it, and allocate space for operations. Outsourcing eliminates these costs entirely. By working with a professional CNC machining provider, you can reduce overhead expenses by 20-30%. This reduction frees up capital for other critical areas of your business, such as marketing or product development.

Minimized Labor Expenses

Hiring and training skilled machinists can strain your budget. Outsourcing CNC machining removes the need for these upfront costs. You gain access to a team of experts without the burden of recruitment or training. Additionally, outsourcing allows you to scale production quickly, ensuring you only pay for the labor you need. This flexibility helps you manage labor expenses effectively while maintaining high productivity. Access to specialized technology and skilled professionals further enhances efficiency, reducing overall labor costs.

Economies of Scale

Outsourcing CNC machining enables you to achieve economies of scale. Contract manufacturers use advanced technologies to streamline processes like deburring and finishing, saving time and money. They also handle large production runs efficiently, reducing unit costs. For example, producing 10 pieces can lower the unit cost from $40 to $12.5, while producing 100 pieces reduces it further to $8.79. These savings, often exceeding 60%, give your business a competitive edge. By outsourcing, you avoid the need for costly in-house equipment and training, allowing you to focus on strategic growth.

Outsourcing CNC machining not only reduces costs but also enhances your operational efficiency, helping you stay ahead in a competitive market.

Access to Expertise and Advanced CNC Machining Services

Outsourcing CNC machining gives you access to a wealth of expertise and cutting-edge technology. By partnering with experienced providers, you can ensure your projects are handled by skilled professionals using state-of-the-art equipment while adhering to industry standards. This combination guarantees high-quality components and reliable results.

Skilled Professionals

When you outsource CNC machining, you gain access to highly trained professionals with specialized certifications. These experts bring years of experience and technical knowledge to your projects, ensuring precision and efficiency. Many professionals hold certifications that validate their skills and commitment to excellence.

Certification | Types | How to Obtain | Impact |

|---|---|---|---|

NIMS Certifications | CNC Lathe Operator, CNC Programmer | Pass performance and theory assessments | Enhances credibility and career prospects |

PMPA Certification | Precision Machining | Complete coursework and pass an exam | Demonstrates commitment to high standards |

Mastercam Certification | CAD/CAM software | Complete training courses and pass tests | Opens doors to specialized roles in programming |

Haas Certification Program | Haas CNC machines | Online and hands-on training, culminating in a test | Enhances operational and troubleshooting skills |

These qualifications ensure that your projects are in capable hands, reducing errors and delivering consistent results.

State-of-the-Art Equipment

Outsourcing providers invest in the latest CNC machining technology, giving you access to advanced tools without the need for upfront investment. Modern equipment includes features like artificial intelligence for predictive maintenance and process optimization. Providers also use the Internet of Things (IoT) to enable real-time data sharing and improve production control. Some even offer hybrid machines that combine CNC machining with additive manufacturing, allowing for greater flexibility and efficiency.

This advanced technology ensures that your projects benefit from the highest levels of precision and innovation, resulting in high-quality components that meet your exact specifications.

Industry Knowledge and Compliance

Professional CNC machining services ensure compliance with industry standards, giving you peace of mind. Providers often hold certifications like ISO 13485, AS 9100, or IATF 16949, which demonstrate their commitment to quality. They conduct regular audits and quality checks to maintain these standards.

To ensure compliance, providers follow a structured approach:

Identify applicable regulatory standards.

Consult regulatory experts.

Develop a compliance management system.

Implement training programs.

Conduct regular reviews and audits.

Use compliance software tools.

Validate CNC machining capabilities.

Implement traceability.

By outsourcing, you can trust that your projects meet all necessary regulations, ensuring consistent quality and reliability.

Outsourcing CNC machining services connects you with skilled professionals, advanced equipment, and industry expertise, ensuring your business stays competitive and efficient.

Scalability and Flexibility in CNC Machining

Outsourcing CNC machining gives your business the agility to adapt to changing demands and market conditions. Whether you need to scale production up or down or create custom parts for specific applications, outsourcing provides the flexibility to meet your goals without overextending your resources.

Adjusting Production to Demand

Market demand can fluctuate unexpectedly, and your ability to respond quickly determines your success. Outsourcing CNC machining allows you to adjust production levels effortlessly. You can scale up during peak seasons or reduce output during slower periods without investing in additional equipment or labor. Contract machining companies have the infrastructure to handle both small and large production runs efficiently. This flexibility ensures you only pay for what you need, helping you optimize costs while meeting customer expectations.

Adapting to Market Changes

The market evolves rapidly, and staying competitive requires adaptability. Outsourcing CNC machining equips you to respond to sudden shifts in demand or industry trends. Providers often have advanced equipment and skilled teams ready to pivot production as needed.

You can scale production without significant investments in labor or machinery.

Providers handle quick transitions between small and large production runs.

Outsourcing ensures your business remains competitive during fluctuating market conditions.

This adaptability strengthens your position in the market, enabling you to meet customer needs promptly and efficiently.

Customization for Specific Needs

Every business has unique requirements, and outsourcing CNC machining ensures you can meet them with precision. Providers offer a wide range of services tailored to your needs, from precision turning to advanced wire EDM cutting.

Service Type | Description |

|---|---|

Turning | Precision turning services for various components. |

Milling | Comprehensive milling solutions for complex parts. |

Wire EDM | Advanced wire EDM cutting for intricate designs. |

EDM | Electrical discharge machining for high precision. |

Surface Grinding | Surface grinding services for smooth finishes. |

Outsourcing also supports industries like automotive, aerospace, and medical, delivering high-quality custom parts that meet strict standards. Whether you need lightweight aerospace components or durable automotive parts, outsourcing ensures your specifications are met with accuracy and efficiency.

By outsourcing CNC machining, you gain the flexibility to adapt, scale, and customize your production processes, giving your business a competitive edge.

Improved Focus on Core Business Activities

Outsourcing CNC machining allows you to concentrate on what truly matters—your core business activities. By delegating complex manufacturing tasks to experts, you can free up valuable resources, enhance operational efficiency, and drive innovation that propels your business forward.

Freeing Up Internal Resources

When you outsource CNC machining services, you eliminate the need to invest in expensive equipment or maintain a dedicated machining facility. This decision saves you from the costs of owning and maintaining specialized machinery. You also avoid hiring and training CNC machinists, which reduces labor expenses significantly.

Outsourcing minimizes overhead costs, including rental fees, maintenance, and repair expenses. It also reduces the need for storage space for raw materials or finished goods. These savings free up your internal resources, allowing you to allocate them to areas like product development, marketing, or customer service. By outsourcing, you can focus on growing your business without the distractions of managing in-house machining operations.

Enhancing Operational Efficiency

Outsourcing CNC machining improves your operational efficiency by streamlining production processes. Professional providers use advanced tools and techniques to deliver high-quality results with minimal waste. Their expertise ensures precision and consistency, reducing the risk of errors or delays.

You no longer need to worry about managing complex machining tasks or maintaining equipment. Instead, you can rely on experienced professionals to handle these responsibilities. This shift allows you to optimize your workflow and focus on delivering value to your customers. Enhanced efficiency translates to faster turnaround times and improved customer satisfaction, giving your business a competitive edge.

Driving Innovation and Strategic Growth

Outsourcing CNC precision machining creates opportunities for innovation and growth. By freeing up your time and resources, you can focus on developing new products, exploring emerging markets, or refining your business strategy.

Professional CNC machining providers often offer insights and recommendations based on their industry expertise. These insights can inspire innovative ideas and help you stay ahead of market trends. With fewer operational burdens, you can dedicate more energy to strategic initiatives that drive long-term success. Outsourcing empowers you to think big and take your business to the next level.

By outsourcing CNC machining, you unlock the potential to focus on your strengths, improve efficiency, and innovate for the future.

Ensuring Quality and Reliability with CNC Machining Services

Outsourcing CNC machining services ensures your business achieves consistent quality and reliability. Professional providers follow strict standards and implement advanced processes to deliver exceptional results. This commitment to quality helps you meet customer expectations and maintain a competitive edge.

Consistent Quality Standards

You can rely on professional CNC machining providers to maintain consistent quality standards. Many providers hold ISO 9001 certification, which demonstrates their dedication to quality management and compliance with customer and regulatory requirements. They also conduct inspections at multiple stages of production. Machine operators perform initial checks, in-process probing ensures accuracy during machining, and the quality control department verifies the final product.

Providers use advanced metrology tools like coordinate measuring machines (CMMs) to achieve tight tolerances. These tools ensure every part meets your exact specifications. By outsourcing, you benefit from improved quality control without investing in expensive equipment or additional resources.

Reliable Turnaround Times

Outsourcing CNC machining guarantees faster delivery of machine parts. Providers streamline their processes to meet deadlines without compromising quality. Their expertise and advanced equipment allow them to handle large production runs efficiently. You can trust them to deliver parts on time, even for complex projects. This reliability helps you maintain smooth operations and meet customer demands promptly.

Robust Quality Assurance Processes

Professional CNC machining providers implement robust quality assurance processes to ensure precision and reliability. They monitor machines and equipment continuously to improve performance. Statistical Process Control (SPC) techniques identify potential issues early, preventing defects. Providers also document every step of the process, including material certificates and inspection reports, to ensure transparency.

Data integrity is a priority. Providers ensure all data is attributable, legible, contemporaneous, original, and accurate. They also make it complete, consistent, durable, and available for future reference. These measures guarantee improved quality control and consistent results for your business.

Partnering with professional CNC machining services ensures you receive high-quality, reliable components that meet your exact needs.

Outsourcing CNC machining offers unmatched advantages for your business. You save costs, access advanced technology, and scale production effortlessly. Companies like Catalyst Engineering have doubled production speed and cut overhead by up to 30%. By delegating complex tasks, you focus on growth and innovation while meeting market demands with precision. Outsourcing ensures high-quality results without the burden of expensive equipment or labor. Take the next step to streamline your operations and boost profitability. Partner with professional CNC machining providers today and unlock your business’s full potential.

FAQ

What is CNC machining, and why should you outsource it?

CNC machining uses computer-controlled tools to create precise parts. Outsourcing lets you avoid costly equipment investments and access expert services. You save time, reduce expenses, and ensure high-quality results without managing complex manufacturing processes in-house.

How do I choose the right CNC machining provider?

Look for providers with certifications like ISO 9001 or AS 9100. Check their experience, equipment, and customer reviews. Ask about their quality assurance processes and turnaround times. A reliable provider ensures consistent results and meets your specific needs.

Can outsourcing CNC machining handle custom designs?

Yes! Outsourcing supports custom designs with precision. Providers use advanced tools like CAD/CAM software and wire EDM to create intricate parts. They tailor services to your specifications, ensuring your unique requirements are met efficiently and accurately.

Is outsourcing CNC machining cost-effective for small businesses?

Absolutely! Outsourcing eliminates the need for expensive equipment and skilled labor. You only pay for what you need, reducing overhead costs. Small businesses benefit from economies of scale, allowing them to compete with larger companies without overspending.

How does outsourcing improve production scalability?

Outsourcing gives you the flexibility to adjust production levels based on demand. Providers handle both small and large runs efficiently. You can scale up during peak seasons or reduce output during slow periods without additional investments in equipment or labor.

💡 Tip: Start small with a trusted provider to test their capabilities before scaling up your operations.

See Also

Discovering CNC Machining Solutions for Accurate Production

Streamlined CNC Machining Solutions for Exact Manufacturing

Uncovering Benefits of Aluminum CNC Machining Solutions

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com