The Role of CAD/CAM Technology in CNC Machining Custom Robot Parts

Imagine creating robot parts with unmatched precision and speed. That’s exactly what CAD/CAM technology brings to CNC machining. It lets you design and manufacture custom robot parts with incredible accuracy. This technology doesn’t just save time—it ensures every piece fits perfectly, making your robotics projects more efficient and reliable.

Key Takeaways

CAD/CAM tools help make CNC machining more accurate for robot parts.

These tools cut mistakes and waste, saving time and money.

CAD/CAM is flexible and works with many materials for robots.

CAD/CAM Technology and Its Role in CNC Machining

Defining CAD and CAM

When you hear about CAD and CAM, you might wonder what they actually do. CAD, or computer-aided design, focuses on creating detailed 2D and 3D models. These models help you visualize and test your designs before they ever reach production. On the other hand, CAM, or computer-aided manufacturing, takes those CAD models and translates them into instructions for CNC machines. Think of it this way: CAD is the blueprint, and CAM is the builder. CAM generates cutting tool paths and outputs G-Code, which directs CNC machines to create parts with incredible precision. Together, CAD and CAM form a seamless bridge between design and manufacturing.

How CAD/CAM Software Integrates with CNC

Integrating CAD/CAM software with CNC machines might sound complex, but it’s all about creating a smooth workflow. First, the CAM software takes the geometric data from CAD files and develops toolpath logic. This logic is then post-processed into a set of instructions for the CNC machine. You can transfer these instructions directly or manually, depending on your setup. By automating this process, you reduce human error and speed up production. To make integration even smoother, you should use compatible software, prioritize automation, and ensure your team is trained to handle the system. This connection between design and machining ensures your custom robot parts are made with precision and efficiency.

The Importance of CAD/CAM in Custom Robot Parts Design

When designing custom robot parts, CAD/CAM software is your best friend. CAD lets you create detailed 3D models, ensuring every part fits perfectly. It also allows you to simulate and test your designs, so you can catch any issues early. CAM takes these designs and ensures they’re manufactured exactly as intended. This combination gives you the flexibility to customize parts for specific needs, whether it’s for a unique robot or a complex task. Plus, CAD/CAM software enhances collaboration by providing clear models that everyone can understand. With these tools, you can bring innovative ideas to life while maintaining the highest quality standards.

Benefits of CAD/CAM in CNC Machining Custom Robot Parts

Precision and Accuracy in Manufacturing

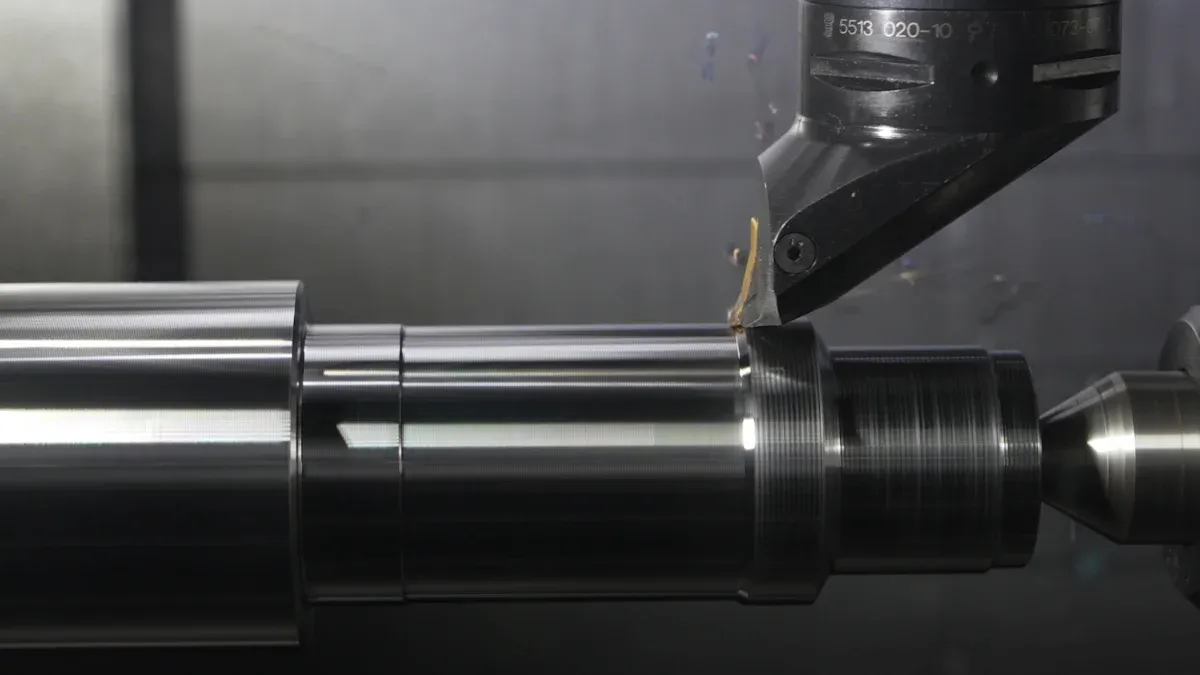

When it comes to cnc machining, precision is everything. CAD and CAM software work together to ensure your custom robot parts meet exact specifications. Advanced algorithms in these tools optimize toolpaths, making sure every cut is accurate. This means fewer errors and more consistent results. You can trust that the final product will match your design perfectly.

To measure this precision, manufacturers rely on accurate CAD models and CAM-generated toolpaths. These guide CNC machines to create parts that conform to blueprints. Regular assessments and calibration of measurement systems also help maintain accuracy. By tracking dimensions over time, you can ensure your parts consistently meet tolerance limits. This level of precision is what makes CAD/CAM essential for precision manufacturing.

Efficiency and Reduced Material Waste

Efficiency is another major benefit of CAD/CAM software in cnc machining. By simulating the manufacturing process, you can identify potential issues before production begins. This reduces errors and rework, saving both time and money. Automation also minimizes human error, improving the overall quality of your robot parts.

CAD and CAM tools optimize cutting paths to maximize material usage. This reduces raw material waste and lowers costs. For example, advanced models can anticipate problems and minimize defects, ensuring you get the most out of your materials. With less waste, you not only save money but also contribute to a more sustainable manufacturing process.

Material Compatibility and Design Flexibility

CAD/CAM software offers incredible flexibility when designing custom parts. Whether you’re working with aluminum, stainless steel, or other materials, these tools help you tailor designs to specific needs. For instance, lightweight aluminum is perfect for aerospace applications, while stainless steel provides strength and durability for demanding environments.

The software also considers mechanical properties like tensile strength and rigidity, ensuring your parts perform as intended. This flexibility allows you to create custom precision tooling for unique tasks. With CAD and CAM, you can design and manufacture robot parts that meet the exact requirements of your project.

Real-World Applications of CAD/CAM in Robotics

Examples of Custom Robot Parts Manufactured with CNC

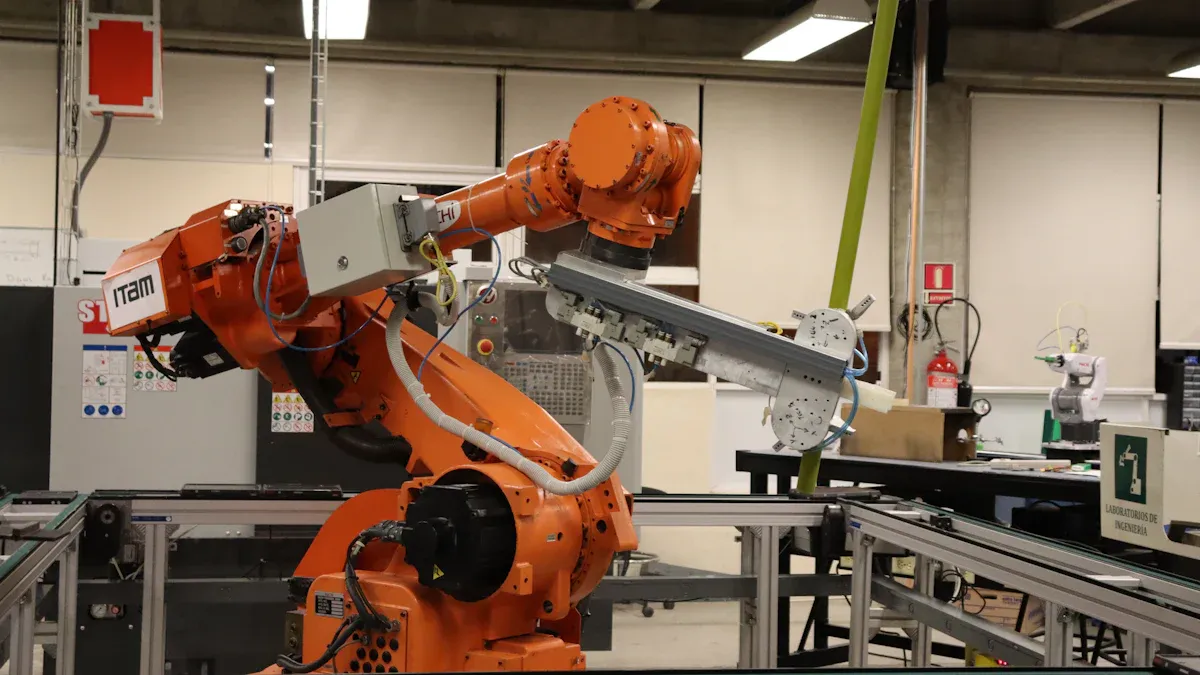

When you think about custom robot parts, CNC machining powered by CAD/CAM software is the go-to solution. It’s used to create everything from precision gears to lightweight frames. For example, you can design intricate robotic arms with CAD, ensuring they meet exact specifications. CAM then translates these designs into precise instructions for CNC machines, which carve out the parts with unmatched accuracy.

Another great example is end-effectors, the tools robots use to interact with their environment. Whether it’s a gripper for delicate tasks or a welding tool for heavy-duty jobs, CAD/CAM software helps you customize these parts to fit specific needs. This level of customization ensures your robots perform efficiently, no matter the task.

Impact of CAD/CAM on Robotics Industry Advancements

CAD/CAM technology has revolutionized the robotics industry. By addressing technical gaps, it has paved the way for new products and improved production quality. For instance, integrating CAD/CAM with inventory management and quality control systems optimizes the manufacturing process. This makes it easier for you to produce high-quality robot parts while reducing costs.

Here’s how CAD/CAM is reshaping the industry:

It enhances productivity by automating complex tasks.

It supports the creation of intricate components, freeing up labor for other essential tasks.

It enables integrated programming for CNC and robots, streamlining modern manufacturing processes.

These advancements don’t just improve efficiency—they also drive long-term growth in the robotics sector.

Emerging Trends in CAD/CAM and CNC for Robotics

The future of CAD/CAM and CNC machining looks exciting, especially for robotics. Advanced automation is leading the way, with collaborative robots (cobots) working alongside humans to boost productivity. IoT and Industry 4.0 are also making waves, allowing you to monitor machines in real time and predict maintenance needs.

Other trends include:

AI and machine learning for smarter decision-making.

Additive and hybrid manufacturing, combining 3D printing with CNC machining for complex designs.

Enhanced simulation tools that let you test designs virtually, reducing errors before production.

These innovations are transforming how you design and manufacture custom robot parts, making the process faster, smarter, and more efficient.

CAD/CAM technology plays a vital role in CNC machining for custom robot parts. It ensures precision, efficiency, and flexibility throughout the process.

"Using CAD, we were able to design the part to exact specifications. The CAM software then helped us create an efficient machining plan, which our CNC machines followed to produce the part with high precision."

Looking ahead, advancements like AI-driven CAD-CAM and IoT integration will revolutionize robotics manufacturing.

FAQ

What is the main advantage of using CAD/CAM software in CNC machining?

It simplifies the process by automating design and machining tasks. This ensures precision, reduces errors, and speeds up manufacturing for custom robot parts.

Can CAD/CAM software work with different materials?

Yes, it supports various materials like aluminum and stainless steel. You can tailor designs to meet specific project requirements, ensuring compatibility and flexibility.

How does CAD/CAM software improve efficiency in CNC machining?

It optimizes cutting paths and simulates processes before production. This reduces material waste, minimizes errors, and saves time during manufacturing.

See Also

Achieving Excellence in CNC Machining for Precision Parts

Exploring Key Processes in CNC Precision Machining Techniques

Unveiling the Secrets of CNC Precision Parts Programming

Fulfilling Standards for CNC Machining of Precision Components

The Impact of CNC Technology on Precision Manufacturing Advancements

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com