Why Choosing the Right Alloy is Crucial for CNC Precision Machining

The alloy you choose directly impacts the success of CNC machining. Material properties like machinability, tensile strength, and thermal resistance determine how well a CNC Precision Part performs. For example, softer materials like aluminum are easier to machine, while tougher ones like titanium require more effort. Poor material selection can lead to inefficiencies, higher costs, and reduced product quality.

Key Takeaways

Picking the right alloy makes machining easier and faster.

Strong and durable materials help CNC parts last longer.

Alloys that resist heat and rust make parts last more.

Key Factors in Selecting Materials for CNC Machining

Machinability and Processing Efficiency

When choosing materials for CNC machining, machinability plays a vital role in determining efficiency. Materials with high machinability allow you to produce parts faster, reduce tool wear, and achieve superior surface finishes. For example:

Easier-to-machine materials extend tool life, lowering maintenance costs.

High machinability ensures smoother surfaces, reducing the need for rework.

Consistent machinability leads to predictable outcomes, improving quality control.

By selecting materials with good machinability, you can optimize production speed and minimize waste, making your machining process more efficient and cost-effective.

Strength and Durability for CNC Precision Parts

Strength and durability are critical for ensuring the longevity of CNC-machined parts. Different alloys offer varying levels of strength, making material selection essential for meeting application-specific requirements. For instance:

Alloy Type | Strength Characteristics | Applications |

|---|---|---|

Aluminum 6061 | Good strength-to-weight ratio, excellent machinability | General use |

Stainless Steel 2205 | Highest strength among common stainless steels, excellent corrosion resistance | Extreme environments, Oil & Gas |

Choosing the right alloy ensures your parts can withstand stress and maintain performance over time.

Thermal and Corrosion Resistance in Precision Machining

Thermal and corrosion resistance are essential for parts exposed to extreme conditions. Alloys like Aluminum MIC 6 can handle temperatures up to 427 °C, making them ideal for high-temperature applications. Corrosion-resistant materials, such as stainless steel, prevent rust and extend the lifespan of your components. By prioritizing these properties, you can enhance the durability and reliability of your CNC-machined parts.

Cost and Availability of Materials

Cost and availability significantly influence material selection. Affordable options like Aluminum 6061-T6 offer excellent machinability, reducing machining time and tool wear. However, stronger alloys like Aluminum 7075-T6 may require specialized equipment, increasing costs. Additionally, readily available materials ensure smooth production without delays, making them a practical choice for most projects.

Benefits of Using the Right Alloy in CNC Precision Machining

Enhanced Precision and Performance in CNC Machining

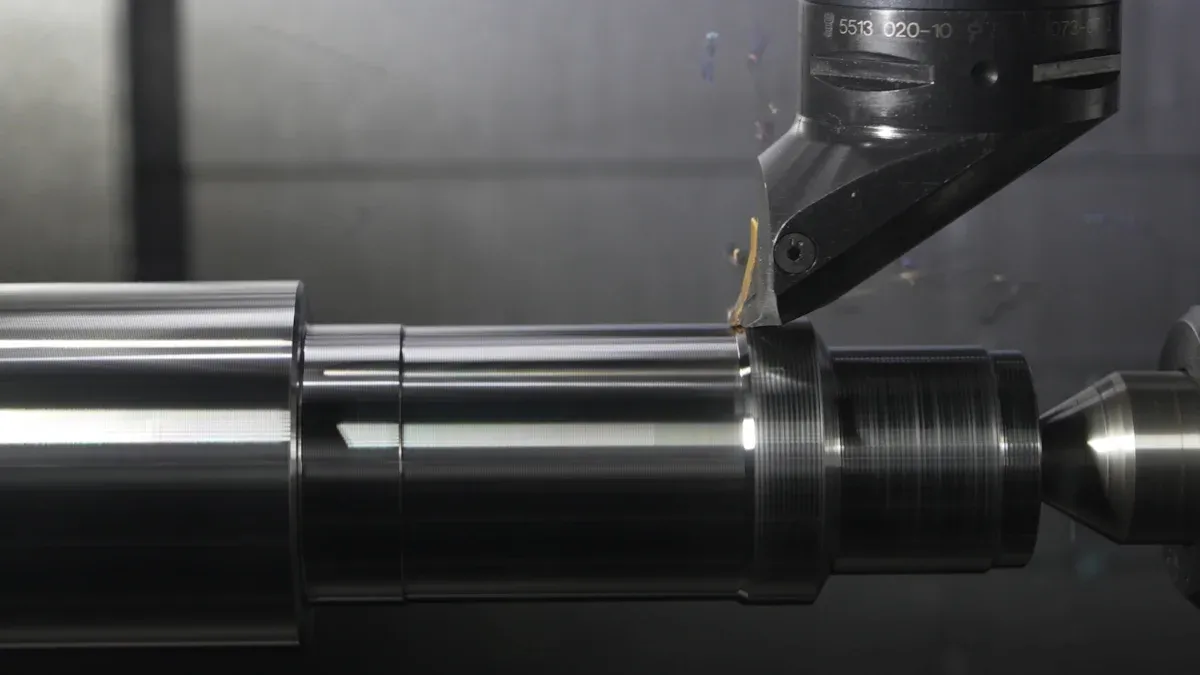

Choosing the right alloy directly impacts the precision and performance of your CNC precision part. Alloys with optimal machinability ensure smooth chip formation, which allows for easier cutting and shaping. This results in a superior surface finish and reduces the need for additional polishing. For example, aerospace applications often require high-strength, corrosion-resistant alloys to meet strict performance standards. By selecting the appropriate material, you can achieve the desired mechanical properties, such as tensile strength and fatigue resistance, ensuring your parts perform reliably in demanding environments.

Factor | Description |

|---|---|

Chip Formation | Influences how easily the alloy can be cut and shaped. |

Tool Wear | Affects the longevity of cutting tools based on the alloy's composition. |

Surface Finish | Determines the quality of the final product, which is influenced by the alloy used. |

Reduced Tool Wear and Maintenance Costs

The right alloy minimizes tool wear, which reduces maintenance costs and extends the lifespan of your equipment. For instance, aluminum components are easier to machine than harder metals like titanium, leading to less wear on cutting tools. Corrosion-resistant alloys, such as stainless steel, also reduce degradation over time, lowering the frequency of repairs. Durable materials ensure your CNC machining process remains efficient and cost-effective.

Benefit | Explanation |

|---|---|

Durability | Aluminum components last longer, reducing the frequency of replacements and repairs. |

Corrosion Resistance | This property minimizes degradation over time, leading to lower maintenance needs. |

Machinability | Easier to machine than harder metals, allowing for efficient production and less wear on equipment. |

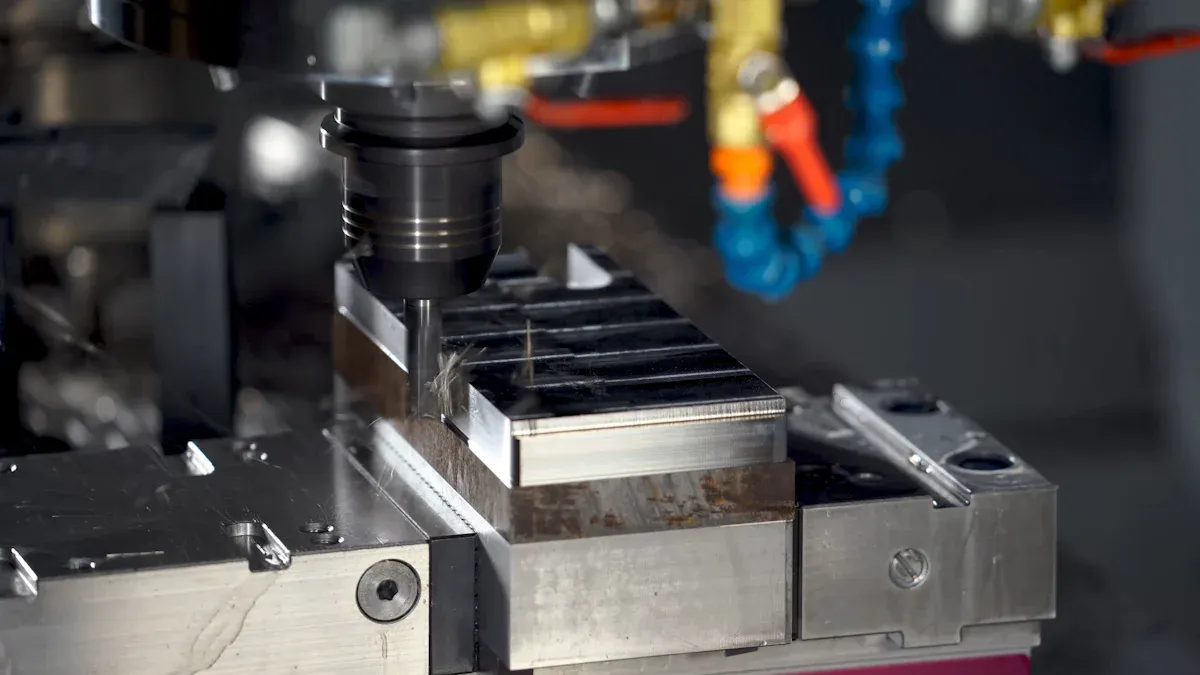

Improved Efficiency and Production Speed

Using alloys with high machinability improves production speed and reduces waste. Materials like aluminum allow for faster machining, as they require less cutting force and generate minimal heat. This efficiency translates to shorter production cycles and higher output. Additionally, selecting CNC materials that are readily available ensures uninterrupted workflows, saving you time and resources.

High-performance alloys may provide superior properties but come at a higher cost.

Balancing material costs with performance characteristics is essential for efficiency.

Proper spindle speed, feed rate, and tool diameter enhance machining speed and tool life.

Application-Specific Benefits of Precision Machining

Different industries benefit from precise alloy selection tailored to their needs. For example, aerospace relies on nickel-chromium alloys for high strength and corrosion resistance. Automotive applications use cast alloys with silicon and copper for durability. In medical fields, stainless steel offers corrosion resistance and ease of sterilization. By choosing the right alloy, you can meet the specific demands of industrial applications and ensure long-lasting performance.

Application Area | Alloy Type | Benefits |

|---|---|---|

Aerospace | Nickel-Chromium, Iron-Chromium-Aluminum | High strength and corrosion resistance |

Automotive | Cast Alloys (10% Silicon, 2.5% Copper) | Durability and wear resistance |

Medical | Stainless Steel | Corrosion resistance and ease of sterilization |

Marine | Aluminum Alloys with Silicon Doping | Strength and corrosion resistance |

Electronics | Gold, Silver, Palladium, Nickel | Conductivity and durability |

By prioritizing alloy selection, you can optimize your CNC machining process for specific applications, ensuring your CNC precision part meets industry standards.

Common Alloys for CNC Machining and Their Applications

Aluminum Alloys for Lightweight and Versatile CNC Precision Parts

Aluminum alloys are among the most popular materials for CNC machining due to their lightweight nature, excellent machinability, and versatility. These alloys are ideal for applications requiring a high strength-to-weight ratio. For example:

6061: Commonly used in aircraft parts, structural components, and electronics due to its versatility and ease of machining.

7075: Known for its exceptional strength, this alloy is often used in aerospace applications like gears and missile parts.

2024: Preferred for automotive and military applications because of its fatigue resistance.

Aluminum Alloy | Applications | Properties |

|---|---|---|

6061-T6 | Automotive parts, bicycle frames | Versatile, easy to machine, good strength-to-weight ratio |

7075-T6 | Aircraft fittings, missile parts | Excellent strength-to-weight ratio, high hardness |

2024-T4 | Aircraft fuselage, transport vehicles | Moderate to high strength, good fatigue resistance |

These alloys offer a balance of strength, durability, and machinability, making them some of the best aluminum alloys for CNC machining.

Stainless Steel for Corrosion Resistance and Strength

Stainless steel is a top choice for CNC machining when corrosion resistance and strength are critical. Grades like 304 and 316 excel in harsh environments, making them suitable for industries such as food processing and medical devices. Stainless steel also offers superior tensile strength, allowing it to withstand significant stress without deforming. This makes it ideal for precision parts in aerospace and automotive applications.

Tip: The best stainless steel alloys, such as 316, provide enhanced corrosion resistance, ensuring long-lasting performance in demanding conditions.

Titanium for High-Performance Aerospace and Medical Applications

Titanium stands out for its high strength-to-weight ratio and corrosion resistance. It is about half as heavy as steel but offers comparable strength, making it indispensable in aerospace and medical fields. Titanium’s biocompatibility also makes it perfect for implants and prosthetics. For example, titanium alloys like Ti-10V-2Fe-3Al are widely used in high-stress environments due to their fracture toughness and stress corrosion resistance.

Brass and Copper for Electrical and Decorative Uses

Brass and copper are valued for their machinability, corrosion resistance, and aesthetic appeal. Brass is commonly used in decorative elements, musical instruments, and watch components. Copper, with its excellent thermal and electrical conductivity, is ideal for electrical applications. These materials combine functionality with visual appeal, making them versatile choices for CNC machining projects.

Selecting the right alloy is essential for the success of any cnc machining project. It ensures precision, durability, and cost-efficiency. By evaluating properties like machinability, strength, and corrosion resistance, you can optimize production and reduce long-term costs. For example:

Improved machinability speeds up production.

Reduced tool wear lowers maintenance expenses.

Enhanced durability minimizes rework and replacements.

Prioritizing alloy selection helps you meet industry standards and achieve reliable results in every cnc machining project.

FAQ

What is the most machinable alloy for CNC machining?

Aluminum alloys, especially 6061, are highly machinable. They allow faster cutting, reduce tool wear, and produce smooth surfaces, making them ideal for CNC machining projects.

How does alloy selection affect CNC machining costs?

Choosing the right alloy improves machinability, reduces tool wear, and minimizes rework. These factors lower production costs and enhance the efficiency of your CNC machining process.

Can CNC machining handle high-strength alloys like titanium?

Yes, CNC machining can process high-strength alloys like titanium. However, it requires specialized tools and techniques to ensure precision and maintain tool longevity.

See Also

Discovering the Benefits of CNC Machining with Aluminum

Recognizing the Significance of Precision in CNC Machining

Grasping Essential Material Needs for CNC Precision Machining

Excelling in CNC Machining for High-Precision Parts

Key Elements Influencing CNC Precision Parts Processing Costs

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com