5 Ways CNC Machines Adapt to Soft and Hard Material Processing

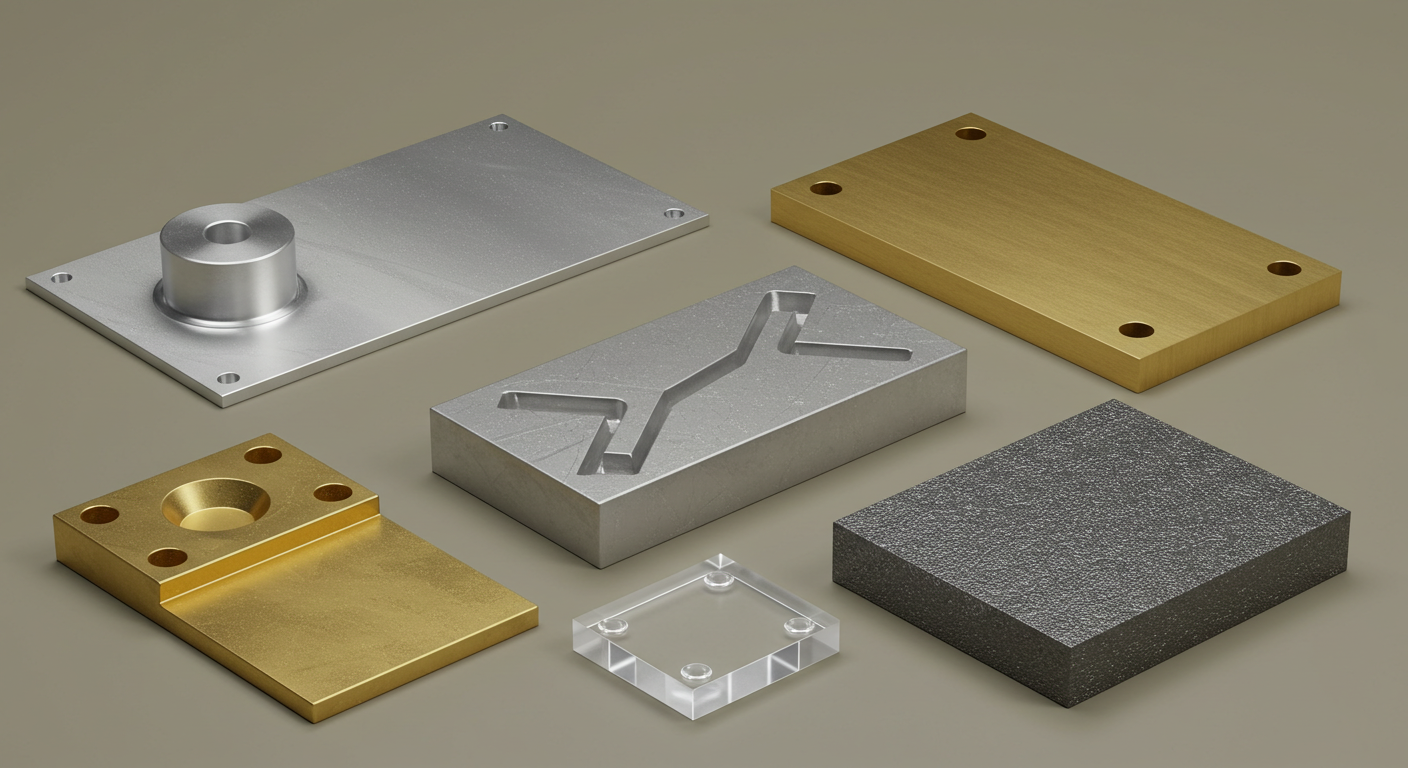

CNC machines revolutionize the manufacturing process by adapting to a wide range of materials, from soft plastics to hard metals. You can rely on their precision to minimize human error and achieve consistent, high-quality results. These machines excel in machining complex designs and geometries that traditional methods often cannot handle. Their efficiency reduces material waste, making them a sustainable choice for diverse applications. Whether you work with intricate components or large-scale projects, CNC machining ensures versatility and reliability across various applications in modern industries.

Key Takeaways

CNC machines help make things by working with soft and hard materials. They are very accurate and reduce mistakes.

Picking the right tools is important. Use high-speed steel for soft materials and tungsten carbide for hard metals to get the best results.

Change spindle speeds and feed rates based on material hardness. Faster speeds are good for soft materials, and slower speeds work better for hard metals.

Use good cooling methods. Air cooling stops plastics from bending, and flood cooling keeps metals from getting too hot or rubbing too much.

Use the right way to hold materials. Vacuum fixtures hold soft materials, and vises keep hard metals steady for accurate machining.

Tool Selection in CNC for Different Materials

Choosing the right tools is critical in the material selection process for CNC machining. The tools you select must align with the properties of the material, whether you are working with soft metals or hard metals. This ensures precision, efficiency, and durability during machining.

Tools for Soft Materials

High-speed steel (HSS) tools for plastics and wood

High-speed steel (HSS) tools are a reliable choice for machining soft materials like plastics and wood. These tools are tough and can handle heavy cuts without chipping. Their versatility makes them ideal for rough milling applications. However, HSS tools wear faster when used on harder materials, so they are best suited for softer applications.

Carbide tools for aluminum and other soft metals

Carbide tools excel when machining soft metals such as aluminum. They are stronger than HSS tools and maintain their sharpness even at high temperatures. This makes them perfect for high-speed machining, delivering smooth and precise cuts. Carbide tools also resist overheating, which is essential when working with soft metals that tend to smear under heat.

Tools for Hard Metals

Diamond-coated tools for ceramics and composites

Diamond-coated tools are indispensable for machining hard metals, ceramics, and composites. These tools provide exceptional wear resistance and maintain their cutting edge longer than other options. Their durability ensures consistent performance, even when cutting through the toughest materials.

Tungsten carbide tools for steel and titanium

Tungsten carbide tools are the go-to choice for machining steel, titanium, and other hard metals. They offer excellent hardness and can withstand the high cutting forces required for these materials. Their ability to maintain sharpness under extreme conditions ensures a superior surface finish and prolonged tool life.

Role of Tool Geometry

Sharp edges for soft materials

When machining soft materials, sharp-edged tools are essential. They reduce the risk of smearing and ensure clean cuts. Tools with fewer flutes are preferable, as they allow for larger chip ejection, preventing clogging during high-speed operations.

Reinforced edges for hard materials

Hard metals demand tools with reinforced edges to handle the increased cutting forces. Ball end mills are particularly effective for roughing and finishing operations. Their design dissipates heat efficiently, ensuring precision and preventing tool wear.

By understanding the unique requirements of soft and hard materials, you can optimize your tool selection process. This ensures that your CNC machining projects achieve the desired results with minimal wear and maximum efficiency.

Speed and Feed Adjustments in CNC Machining

Spindle Speed Optimization

High speeds for soft materials to prevent melting or tearing

When machining soft materials like plastics, high spindle speeds are essential. These speeds prevent tearing and melting caused by prolonged tool contact. For example, acrylic requires speeds between 10,000 and 16,000 RPM, while polycarbonate performs best at 8,000 to 12,000 RPM. The table below highlights recommended spindle speed ranges for various materials:

Material | Spindle Speed (RPM) |

|---|---|

Acrylic | 10,000 - 16,000 |

Polycarbonate | 8,000 - 12,000 |

PVC | 8,000 - 14,000 |

Aluminum | 3,000 - 6,000 |

Steel | 1,500 - 3,000 |

Stainless Steel | 1,000 - 2,000 |

Titanium | 500 - 1,500 |

Lower speeds for hard metals to reduce tool wear

Hard metals like steel and titanium demand lower spindle speeds. These speeds minimize tool wear and maintain precision during machining. For instance, steel requires speeds between 1,500 and 3,000 RPM, while titanium operates best at 500 to 1,500 RPM. Lower speeds also help dissipate heat, ensuring the tool's longevity.

Feed Rate Adjustments

Faster feed rates for soft materials to enhance efficiency

Soft materials allow for faster feed rates, which improve efficiency and reduce machining time. Proper feed rates also prevent overheating, ensuring a smooth surface finish. Faster rates optimize productivity without compromising the quality of the final product.

Slower feed rates for hard materials to ensure precision

Hard materials require slower feed rates to achieve precision. These rates reduce strain on the tool and improve accuracy. A slower feed rate also enhances the surface finish, minimizing the need for additional post-processing.

Tip: Always balance the feed rate with the chip load to avoid excessive tool wear and ensure consistent results.

Balancing Parameters for Mixed Materials

Strategies for transitioning between soft and hard materials

When machining mixed materials, you must carefully balance spindle speed and feed rate. Gradually adjust these parameters to accommodate the material's hardness. For example, when transitioning from aluminum to steel, reduce the spindle speed and feed rate incrementally. This approach prevents tool damage and ensures a seamless machining process.

Cooling and Lubrication for Material Hardness

Cooling for Soft Materials

Air cooling for plastics to prevent deformation

When machining soft materials like plastics, heat buildup can lead to deformation. Air cooling offers an effective solution by dissipating heat without introducing moisture. This method ensures the material retains its shape and strength during machining. To further prevent deformation, you should use appropriate coolants, such as water-based options, which help dissipate heat efficiently. However, avoid excessive coolant flow, as it may cause thermal shock and cracking.

Technique | Description |

|---|---|

Use appropriate coolants | Water-based coolants are commonly used for plastics to dissipate heat. |

Avoid excessive coolant flow | Excessive flow can cause thermal shock and lead to cracking. |

Minimal lubrication for wood to avoid swelling

Wood requires minimal lubrication during machining to maintain its structural integrity. Excessive lubrication can cause swelling, compromising the material's strength. Instead, you should rely on dry machining techniques or use lubricants sparingly to achieve a smooth finish without damaging the wood.

Cooling for Hard Metals

Flood cooling for metals to reduce heat and friction

Flood cooling is essential when machining hard metals. It reduces heat and friction, which helps maintain the tool's strength and prolongs its life. This method also ensures a consistent surface finish by preventing overheating during machining.

High-pressure coolant systems for deep cuts

High-pressure coolant systems are highly effective for machining hard metals with high hardness, such as titanium and stainless steel. These systems improve chip control, extend tool life, and allow for deeper cuts. They can increase cutting speed by up to 20% in aerospace materials like titanium while maintaining the same cutting distance. This makes them indispensable for high-strength materials.

Benefits of high-pressure coolant systems:

Improved chip control for all materials.

Increased tool life for difficult-to-machine metals.

Up to 50% increase in cutting capability at the same parameters.

Eco-Friendly Solutions

Environmentally safe coolants and lubricants

Traditional coolants often have a significant environmental impact. For example, CFCs and HCFCs contribute to ozone depletion and global warming. Eco-friendly alternatives, such as natural refrigerants like ammonia and CO2, offer negligible ozone depletion potential and significantly lower global warming potential. By switching to these options, you can reduce your environmental footprint while maintaining machining efficiency.

Type of Coolant | Ozone Depletion Potential (ODP) | Global Warming Potential (GWP) |

|---|---|---|

CFCs | Significant | 10,900 |

HCFCs | Moderate | 1,810 |

Natural Refrigerants (e.g., Ammonia, CO2) | Negligible | 0 or significantly lower |

HFOs | Zero | Significantly lower than HFCs |

Eco-friendly coolants not only protect the environment but also enhance workplace safety by reducing exposure to harmful chemicals.

Material-Specific Programming in CNC

Programming for Soft Materials

Lower cutting forces in G-code

When programming for soft materials, you must prioritize lower cutting forces in the G-code. This approach minimizes the risk of deforming the material during the machining process. By reducing cutting forces, you can achieve smoother finishes on machined parts like plastics or wood. Adjusting the G-code to include lighter cuts ensures that the material retains its structural integrity while maintaining high accuracy.

High-speed machining strategies

Soft materials benefit from high-speed machining strategies. These strategies involve faster spindle speeds and feed rates, which reduce machining time and improve efficiency. For example, when machining complex parts made of aluminum, high-speed strategies allow you to maintain precision while producing a clean surface finish. This method also prevents issues like melting or tearing, which are common with softer materials.

Programming for Hard Metals

Toolpath strategies like trochoidal milling

Trochoidal milling is an effective toolpath strategy for machining hard metals. This technique uses circular toolpaths with minimal radial stepovers, which reduces cutting forces and vibrations. By lowering these forces, you can achieve a better surface finish and extend the life of your tools. Trochoidal milling also enhances the process by allowing you to machine complex parts with greater efficiency and precision.

Adjusting depth of cut and step-over values

Hard metals require careful adjustments to the depth of cut and step-over values in your CNC programming. Smaller depths of cut reduce the strain on tools, while optimized step-over values ensure consistent material removal. These adjustments help you maintain accuracy and prevent tool wear, especially when machining tough materials like titanium or steel.

Simulation and Testing

Verifying programs with CAM software before machining

Simulation and testing play a crucial role in CNC programming. Using CAM software to verify your programs before machining offers several advantages:

Improves safety by reducing the risk of accidents.

Detects potential collisions before actual machining.

Identifies programming errors, such as syntax issues.

Saves costs by preventing collisions and reducing downtime.

Provides a safe training environment for operators.

Optimizes toolpaths for better accuracy.

Enhances productivity by decreasing setup time.

By simulating the machining process, you can ensure that your programs are error-free and optimized for the material being used. This step is essential for achieving high-quality results in machined parts.

Workholding Strategies for Material Stability

Securing Soft Materials

Vacuum fixtures for plastics and thin materials

When machining soft materials like plastics or thin sheets, vacuum fixtures provide excellent stability. These fixtures use suction to hold the material firmly in place, ensuring precision during machining. They are particularly effective for lightweight or delicate materials that might deform under traditional clamping methods. Vacuum fixtures also allow for unobstructed access to the workpiece, making them ideal for intricate designs.

Soft jaws for delicate materials

Soft jaws offer a reliable solution for securing delicate materials. Made from soft metals like aluminum, they conform to the shape of the workpiece, reducing the risk of damage. These jaws are perfect for complex shapes and provide a secure grip without leaving marks. However, they are less durable for high-volume machining. The table below highlights additional workholding strategies for soft materials:

Workholding Strategy | Description |

|---|---|

Milling Vise | Popular for various materials, using jaws to keep parts immobile. |

Soft Jaws | Ideal for complex shapes, made from soft metals like aluminum. |

Clamps | Useful for securing parts alongside other workholding methods. |

Clamping Hard Metals

Vises and clamps for metals

Vises and clamps are essential for machining hard metals. They provide a strong grip, ensuring the workpiece remains stable under high cutting forces. You can use adjustable vises to accommodate different sizes and shapes, making them versatile for various applications. Clamps work well as supplementary tools, enhancing the overall stability of the setup.

Magnetic workholding for ferrous materials

Magnetic workholding systems excel when machining ferrous metals. These systems provide consistent clamping pressure and full surface support, reducing chatter and allowing for higher speeds and feeds. Smooth-surfaced workpieces benefit the most, as they maximize exposure to magnetic flux. Additionally, the absence of jaws simplifies the setup process and eliminates interference on the sides of the workpiece.

Preventing Material Movement

Techniques to reduce vibration and ensure stability

Preventing material movement is crucial for achieving precision. You can follow these techniques to minimize vibrations:

Optimize cutting parameters like speed, feed rate, and depth of cut.

Use sharp, well-maintained tools to reduce cutting forces.

Secure the workpiece with proper clamping methods.

Implement damping materials to absorb vibrations.

Maintain machine rigidity through regular maintenance.

These strategies ensure stability, improve surface finish, and extend tool life during cnc machining.

CNC machines excel in modern manufacturing due to their ability to adapt to various materials and machining requirements. Their versatility stems from several factors:

Automation reduces human error and enhances speed.

High precision ensures tight tolerances for complex parts.

Faster production increases output through continuous operation.

Consistency delivers identical parts, reducing defects.

Flexibility allows quick reprogramming for different parts.

This adaptability improves production efficiency and product quality. You can rely on CNC machining to produce consistent, high-quality results while minimizing waste and setup time. These features make CNC machines indispensable in achieving precision and efficiency across diverse material types.

FAQ

What materials can you process with CNC machines?

You can process a wide range of materials, including plastics, wood, aluminum, steel, titanium, and ceramics. Each material requires specific tools, speeds, and cooling techniques to ensure precision and efficiency during machining.

How do you choose the right tool for CNC machining?

You select tools based on the material's hardness and properties. For soft materials, high-speed steel or carbide tools work best. For hard metals, tungsten carbide or diamond-coated tools provide durability and precision.

Why is cooling important in CNC machining?

Cooling prevents overheating, which can damage tools and materials. For soft materials, air cooling or minimal lubrication works well. Hard metals require flood cooling or high-pressure systems to reduce heat and friction during machining.

Can CNC machines handle mixed materials in one project?

Yes, CNC machines can process mixed materials by adjusting spindle speeds, feed rates, and tool selection. Transitioning between materials requires careful programming to maintain precision and avoid tool damage.

How do you ensure stability during CNC machining?

You can use vacuum fixtures, soft jaws, or magnetic workholding systems to secure materials. Reducing vibrations through optimized cutting parameters and proper clamping techniques ensures stability and precision.

See Also

Mastering Five Key CNC Drilling Skills for Accuracy

Five Important Uses of CNC Technology You Should Understand

Investigating CNC Machining Solutions for Accurate Production

Upcoming Trends in CNC Milling: Innovations and Uses

Understanding CNC Machining: Accurate Manufacturing and Cutting Techniques

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com