Why CNC Customization Reduces Lead Times and Enhances Efficiency for Your Business

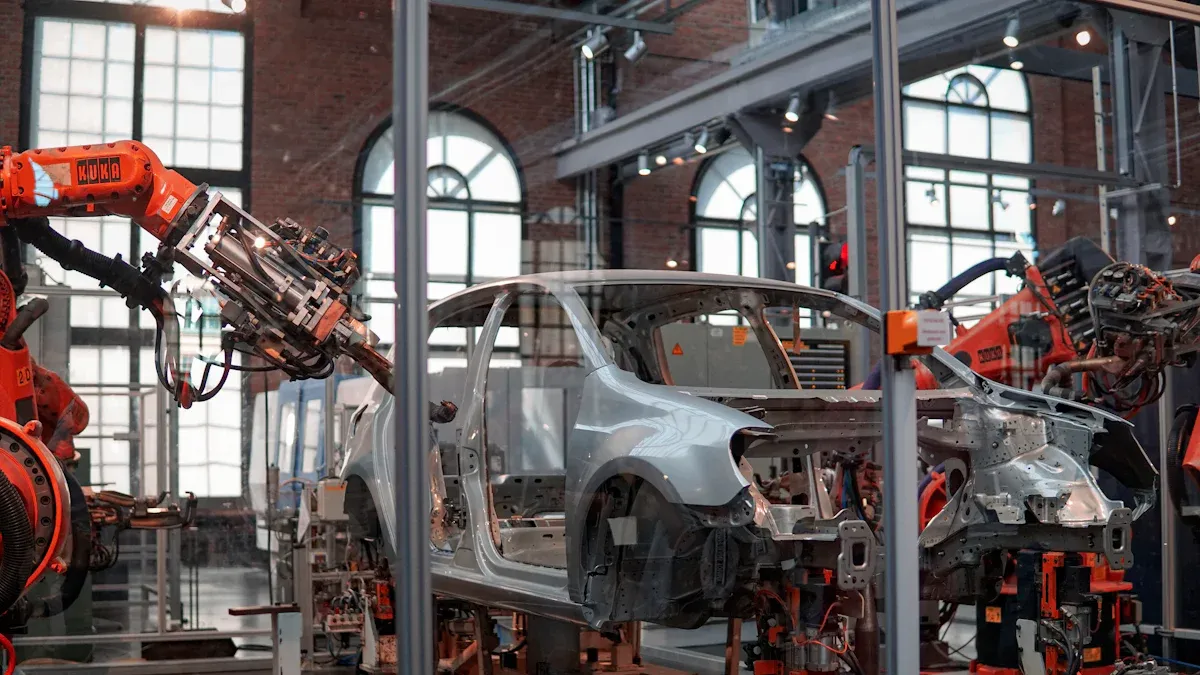

Imagine transforming your production process into a seamless, efficient operation. CNC customization empowers you to achieve this by combining precision and automation. Whether you're in electronics, medical devices, or aerospace, CNC machining delivers faster production cycles and consistent quality. For example, the automotive industry uses tailored CNC solutions to manufacture engine components with unmatched accuracy. This approach ensures your business stays ahead in a competitive market.

Key Takeaways

CNC customization makes production faster by using automated machines.

Machines can work nonstop to finish tasks on time.

CNC machining helps create and test designs quickly.

This improves creativity and makes product changes easier.

CNC machining reduces mistakes and waste, saving money and time.

It ensures good quality and helps businesses work better and greener.

Reducing Lead Time with CNC Machining

Faster Production Cycles Through Automation

Automation in CNC machining transforms your production process by eliminating delays caused by manual intervention. Machines operate continuously, even during off-hours, ensuring uninterrupted productivity. This capability allows you to meet tight deadlines without compromising quality.

Efficient Production with CNC Machining Services: Automated systems can operate around the clock with minimal human intervention, enabling rapid production without sacrificing quality.

Additionally, CNC machining optimizes toolpaths and reduces cycle times. This is especially beneficial for high-volume production, where every second counts. Consider the following comparison:

Aspect | CNC Machining Automation | Traditional Methods |

|---|---|---|

Manual Intervention | Minimal | High |

Setup Times | Reduced | Longer |

Continuous Operation | Yes | No |

Cutting Speeds | Higher | Lower |

Multi-part Processing | Yes | No |

By leveraging automation, you can achieve faster production cycles, reduce lead time, and boost overall productivity.

Quick Prototyping for Rapid Iteration

CNC machining accelerates product development by enabling quick prototyping. You can transform CAD designs into physical prototypes with unmatched speed and precision. This process allows you to test, refine, and perfect your custom products efficiently.

Speed: Rapid conversion of designs into prototypes.

Accuracy: High precision ensures prototypes match final products.

Flexibility: Compatible with various materials and production volumes.

Cost-effectiveness: Eliminates the need for complex tooling.

Industries like medical, automotive, and aerospace rely on CNC machining for rapid iteration. For example:

Industry | Reason for Reliance |

|---|---|

Medical | High-quality prototypes with tight tolerances |

Automotive | Cost-effectiveness and speed in prototyping |

Aerospace | Need for high-quality prototypes with tight tolerances |

Quick prototyping not only reduces lead time but also enhances your ability to innovate and adapt to market demands.

Streamlined Processes for Fast Turnaround Times

CNC machining simplifies production with streamlined processes. By designing parts with specific machining techniques in mind, you can optimize speed and efficiency. For instance, 5-axis CNC machines eliminate the need for repositioning, allowing you to produce complex parts faster.

CNC turning offers quicker setup times compared to milling.

Automated machining ensures consistent quality, reducing the need for secondary operations.

Machines operate continuously, enabling fast turnaround times for both prototypes and production runs.

Companies like UPTIVE Advanced Manufacturing have demonstrated how CNC machining delivers fast turnaround times, helping businesses stay competitive. By adopting best practices for lowering lead time, you can meet customer expectations and scale your operations effectively.

Enhancing Efficiency Through Customization

Minimizing Errors with Precision Machining

CNC machining eliminates the guesswork from manufacturing. By automating processes, it reduces the need for manual labor and minimizes human error. This ensures faster production with fewer defects, which is especially important for mass production. The high precision of CNC systems allows you to achieve exact specifications by controlling tool movements through computer instructions. This results in consistent quality and fewer wasted materials.

For your business, fewer errors mean lower costs. Automated systems reduce labor expenses and optimize cutting paths, saving resources and improving productivity. With CNC machining, you can focus on delivering high-quality products without worrying about inconsistencies or defects.

Optimizing Material Usage to Reduce Waste

CNC machining takes material efficiency to the next level. Techniques like adaptive cutting and laser cutting ensure minimal waste by optimizing tool paths and enhancing accuracy. For example:

Adaptive cutting adjusts the tool's path in real-time, reducing waste and extending tool life.

Laser cutting achieves precise cuts at high speeds, leaving no room for imprecision.

Smaller cut widths conserve materials and improve cooling efficiency.

These methods not only save resources but also contribute to sustainability. By reducing waste, you lower costs and improve your environmental impact. Customers value businesses that adopt sustainable practices, giving you a competitive edge.

Ensuring Consistent Quality Across Production Runs

CNC machining guarantees consistent quality, even for complex designs. Automated processes ensure every part meets the same standards, eliminating inconsistencies. Advanced software like CAD and CAM enables precise execution of intricate designs. High-precision equipment achieves tight tolerances, ensuring your products meet exact specifications.

Quality control measures further enhance consistency. Real-time monitoring detects deviations early, while tools like geometric dimensioning and tolerancing (GD&T) ensure parts align with design requirements. With CNC machining, you can maintain high standards across all production runs, boosting customer satisfaction and loyalty.

Meeting Business Needs with CNC Customization

Tailored Designs for Unique Product Requirements

CNC machining empowers you to create products that meet your exact specifications. Whether you need intricate medical devices or durable automotive parts, CNC customization ensures precision and adaptability. For example:

Flexibility: A 3-axis milling machine works with diverse materials, from metals to plastics, making it ideal for both industrial and artistic applications.

Accuracy: CNC systems achieve tight tolerances, essential for industries like aerospace and healthcare.

Versatility: From engine components to surgical tools, CNC machining delivers high-quality, customized solutions.

Industries Benefiting from Tailored CNC Solutions:

Automotive: Engine components and chassis parts.

Aerospace: Safety-critical components with tight tolerances.

Medical: Biocompatible implants and surgical instruments.

By leveraging CNC machining, you can meet unique product requirements while maintaining exceptional quality and efficiency.

Scalability to Handle Demand Surges

CNC machining offers scalability for any project, allowing you to adapt to fluctuating demands effortlessly. Automated systems operate 24/7 with minimal supervision, ensuring rapid production without compromising quality. This capability makes it easier to meet tight deadlines during demand surges.

"CNC manufacturing is built for efficiency. Automated systems can operate around the clock with minimal human intervention, enabling rapid production without sacrificing quality."

Additionally, CNC technology supports both high-volume production and single-unit manufacturing. You can adjust production volumes or modify designs without delays, ensuring your business remains agile and competitive. Industries like electronics, firearms, and medical devices rely on CNC machining for its scalability and precision.

Industry | Benefits of CNC Machining |

|---|---|

Electronics | Handles specialized materials with tight tolerances for small components, ensuring high process reliability. |

Medical | Ensures impeccable precision for medical devices, with fast prototyping and scalability for high-volume production. |

Aerospace | Achieves high accuracy and repeatability, essential for critical aeronautical parts with strict compliance needs. |

Flexibility for Complex and Specialized Projects

CNC customization provides unmatched flexibility, enabling you to tackle even the most complex projects. Tailored solutions optimize machines for specific tasks, enhancing efficiency and precision. For example, CNC lathes can be customized to meet industry-specific requirements, such as biocompatibility for medical devices or high-speed machining for aerospace components.

With CNC machining, you can handle intricate designs, tight tolerances, and specialized materials. This flexibility allows you to innovate and deliver products that stand out in competitive markets. Whether you're developing prototypes or scaling production, CNC customization ensures your business stays ahead.

Tip: By investing in CNC customization, you can reduce waste, improve efficiency, and achieve higher returns on investment.

CNC machining transforms your business by reducing lead times and boosting efficiency. Customized solutions optimize tasks, ensuring faster cycles and higher precision. You can adapt to market demands, scale production, and explore innovative product development methods.

Advantage | Description |

|---|---|

Enhanced Efficiency and Productivity | Customized machines are optimized for specific machining tasks, resulting in faster cycle times and increased throughput. |

Improved Product Quality and Precision | Tailored solutions ensure precise machining and tighter tolerances, leading to higher product quality and consistency. |

Cost-Effectiveness and ROI | Customization eliminates unnecessary features and optimizes machine performance, resulting in reduced operating costs and improved return on investment. |

Tip: Adopting CNC machining ensures you stay competitive by meeting customer needs and delivering exceptional products.

FAQ

What industries benefit the most from CNC customization?

CNC customization benefits industries like aerospace, automotive, medical, and electronics. These sectors demand precision, scalability, and efficiency for complex designs and high-quality production.

How does CNC machining improve sustainability?

CNC machining reduces waste by optimizing material usage and cutting paths. This efficiency lowers costs and supports eco-friendly practices, helping your business meet sustainability goals.

Can CNC customization handle small production runs?

Yes! CNC machining excels at both small and large production runs. Its flexibility allows you to produce prototypes or limited batches without compromising quality or efficiency.

Tip: Start small with CNC customization to test its benefits for your business. Scale up as you see results!

See Also

Streamlined CNC Machining Solutions For Accurate Production

Investigating CNC Machining Options For Precision Production

The Impact Of CNC Machining On Precision Manufacturing

CNC Precision Parts Production: Affecting Manufacturing Expenses

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com