How CNC Lathes Differ from Turning Centers

CNC machines have revolutionized manufacturing, offering precision and efficiency. As the CNC market grows, understanding the differences between a CNC lathe and a turning center becomes crucial. You need to know these distinctions to make informed decisions in production. A CNC lathe focuses on turning operations, while a turning center offers advanced capabilities. This knowledge helps you choose the right tool for your needs, enhancing productivity and cost-effectiveness.

Understanding CNC Lathes

Definition and Functionality

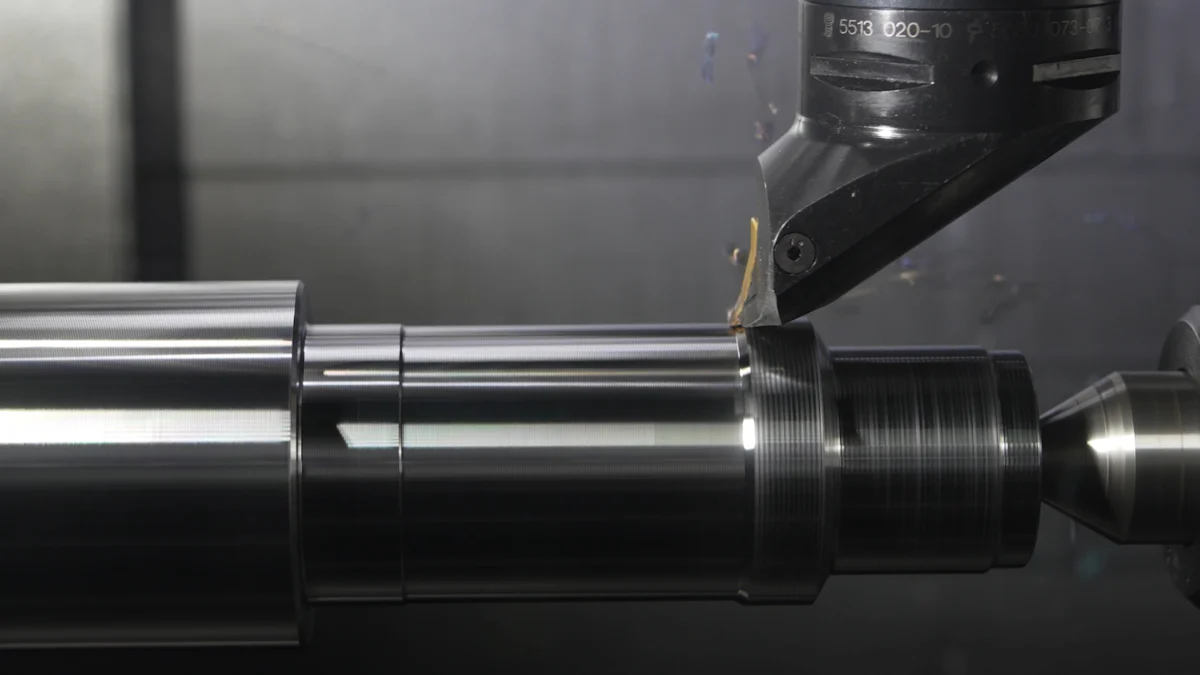

A CNC lathe stands as a cornerstone in the realm of precision machining. This machine automates turning operations with computerized controls, allowing you to achieve high precision and repeatability. You input a design into the machine's software, which translates it into precise movements. The workpiece mounts onto a spindle, rotating at variable speeds. As it turns, cutting tools move linearly and radially, shaving away material to form the desired shape. This process ensures accurate and consistent cuts, making CNC lathes essential for creating symmetrical components.

Basic Components

Every CNC lathe comprises several integral components that ensure smooth operations and high precision. Key parts include:

Spindle: Holds and rotates the workpiece.

Tool Turret or Carriage: Houses the cutting tools and moves them into position.

Control Panel: Allows you to input commands and monitor operations.

Bed: Provides a stable base for the machine.

These components work together to transform raw materials into finished products with precision and intricacy.

How CNC Lathes Operate

The operation of a CNC lathe begins with a design created using CAD (Computer-Aided Design) software. This design converts into G-code, the language of CNC machines. The G-code serves as a set of instructions, guiding the lathe on how to shape the raw material. The machine follows these coded instructions to turn the workpiece and shape it using tools. Multiple stages can be set simultaneously, ensuring accurate cut placement without needing to remove the component from the lathe.

Key Features

CNC lathes offer several key features that enhance their functionality and appeal.

Precision and Accuracy

CNC lathes excel in precision and accuracy. The automated system ensures high precision, repeatability, and efficiency. Feedback mechanisms maintain consistent cuts, making these machines ideal for producing intricate and symmetrical components.

Types of CNC Lathes

The world of CNC lathes is diverse, with each type tailored for specific needs. Some common types include:

Horizontal CNC Lathes: Suitable for general turning operations.

Vertical CNC Lathes: Ideal for large, heavy workpieces.

Swiss CNC Lathes: Designed for small, complex parts.

Understanding these differences helps you select the appropriate machine for your project.

Advantages of CNC Lathes

CNC lathes offer several advantages that make them a valuable addition to any manufacturing setup.

Cost-effectiveness

CNC lathes improve productivity by allowing operators to focus on other tasks while the machine works. This automation reduces labor costs and increases output, making CNC lathes a cost-effective solution for precision machining.

Ease of Use

The user-friendly interface of CNC lathes simplifies operation. You can easily input designs and monitor the machining process, reducing the learning curve and enabling efficient production.

Exploring Turning Centers

Definition and Functionality

A turning center represents a significant advancement in CNC machining technology. Unlike traditional lathes, turning centers offer enhanced capabilities, allowing you to perform a variety of operations beyond simple turning. These machines integrate computer numerical control (CNC) to automate complex tasks, ensuring precision and efficiency. As the workpiece rotates, the turning center uses a single-point cutting tool to shape the material. This process, controlled by sophisticated software, guarantees meticulous precision in component production.

Basic Components

Turning centers consist of several key components that contribute to their advanced functionality:

Spindle: Rotates the workpiece at high speeds.

Turret: Holds multiple cutting tools for automatic tool changes.

Control Panel: Facilitates input of commands and monitoring of operations.

Bed: Provides a stable foundation for the machine.

These components work in harmony to deliver precise and efficient machining processes.

How Turning Centers Operate

Turning centers operate by utilizing CNC technology to control the movement of the cutting tools and the workpiece. The machine follows a set of programmed instructions, often derived from CAD designs, to execute various operations such as drilling, boring, and reaming. With live-tooling features, turning centers can perform these tasks even when the workpiece remains stationary. This versatility allows you to achieve complex machining tasks with ease and accuracy.

Key Features

Turning centers boast several key features that set them apart from traditional lathes.

Multi-functionality

Turning centers excel in multi-functionality. They can perform a wide range of operations, including turning, milling, drilling, and tapping. This capability makes them ideal for producing complex parts that require multiple machining processes.

Advanced Capabilities

Advanced capabilities define turning centers. Equipped with multiple axes, these machines offer enhanced flexibility and precision. You can utilize live tools with powered rotary tool turrets, sub-spindles, and Y-axes to achieve intricate machining tasks. This level of sophistication ensures that turning centers meet the demands of modern manufacturing.

Advantages of Turning Centers

Turning centers provide several advantages that enhance their appeal in the manufacturing industry.

Versatility

Versatility is a hallmark of turning centers. Their ability to perform various operations on a single machine reduces the need for multiple setups, saving time and resources. This versatility allows you to handle diverse projects efficiently.

Efficiency in Complex Operations

Turning centers excel in handling complex operations. Their advanced features and computer control enable you to execute intricate machining tasks with precision and speed. This efficiency translates into higher productivity and reduced production times, making turning centers a valuable asset in any manufacturing setup.

Comparative Analysis of CNC Lathe and Turning Center

Feature Comparison

Operational Differences

When you compare a CNC lathe to a turning center, you'll notice distinct operational differences. A CNC lathe primarily focuses on turning operations. It rotates the workpiece while stationary tools shape it. This setup suits simpler tasks and smaller production runs.

In contrast, a turning center offers more versatility. Equipped with multiple axes, it can perform turning, drilling, milling, and tapping. This multi-functionality allows you to complete complex parts in one setup, enhancing efficiency and reducing production time.

Technological Advancements

Turning centers represent an evolutionary leap in machining technology. They incorporate advanced features like automated tool changing and live rotating tools. These enhancements enable you to handle intricate components with precision. The protective enclosures and efficient chip removal systems further streamline operations, making turning centers a powerful choice for modern manufacturing.

Application Comparison

Industries Using CNC Lathes

CNC lathes find their place in industries where precision and simplicity are key. You often see them in automotive and aerospace sectors, producing symmetrical components like shafts and bushings. Their cost-effectiveness and ease of use make them ideal for small to medium-sized production runs.

Industries Using Turning Centers

Turning centers cater to industries requiring complex and high-volume production. You’ll find them in medical device manufacturing, electronics, and heavy machinery. Their ability to perform multiple operations on a single machine makes them indispensable for projects demanding versatility and precision.

Cost and Investment Considerations

Initial Costs

Investing in a CNC lathe typically involves lower initial costs. This makes it a suitable option if you have budget constraints or need a machine for straightforward tasks. However, a turning center requires a higher upfront investment due to its advanced capabilities and features.

Long-term Investment

While turning centers demand more initial capital, they offer significant long-term benefits. Their efficiency and ability to handle complex operations can lead to higher production rates and reduced labor costs. This makes them a wise investment if you aim for scalability and diverse manufacturing capabilities.

Making an Informed Decision

Factors to Consider

Production Needs

When choosing between a CNC lathe and a turning center, consider your production needs. Think about the complexity of the parts you plan to produce. If your projects involve simple, symmetrical components, a CNC lathe might suffice. However, if you require multi-functional capabilities for complex parts, a turning center offers more flexibility. Evaluate the size and material of the parts as well. Larger or more intricate pieces may benefit from the advanced features of a turning center.

Budget Constraints

Budget plays a crucial role in your decision. CNC lathes generally have lower initial costs, making them suitable if you're working with limited funds. They provide a cost-effective solution for straightforward tasks. On the other hand, turning centers require a higher investment but offer long-term benefits. Their ability to handle diverse operations can lead to increased productivity and reduced labor costs over time. Weigh the initial expense against potential future savings.

Understanding the key differences between CNC lathes and turning centers is crucial for making informed decisions in manufacturing. CNC lathes excel in precision and cost-effectiveness, focusing on turning operations. In contrast, turning centers offer versatility and advanced capabilities, handling complex tasks efficiently.

"Precision and accuracy are critical aspects in CNC turning to avoid functional or safety issues."

Before choosing, assess your specific needs. Consider the complexity of your projects, production volume, and budget constraints. This evaluation ensures you select the right tool, optimizing productivity and investment.

See Also

Exploring CNC Precision Machining: Unveiling CNC Turning Process

Exploration of CNC Machining: Techniques in Turning and Milling

Becoming a CNC Turning Expert: All You Must Understand

Guide for CNC Turning Beginners: Decoding Precision Machining

Impact of CNC Technology on Precision Manufacturing Evolution

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com