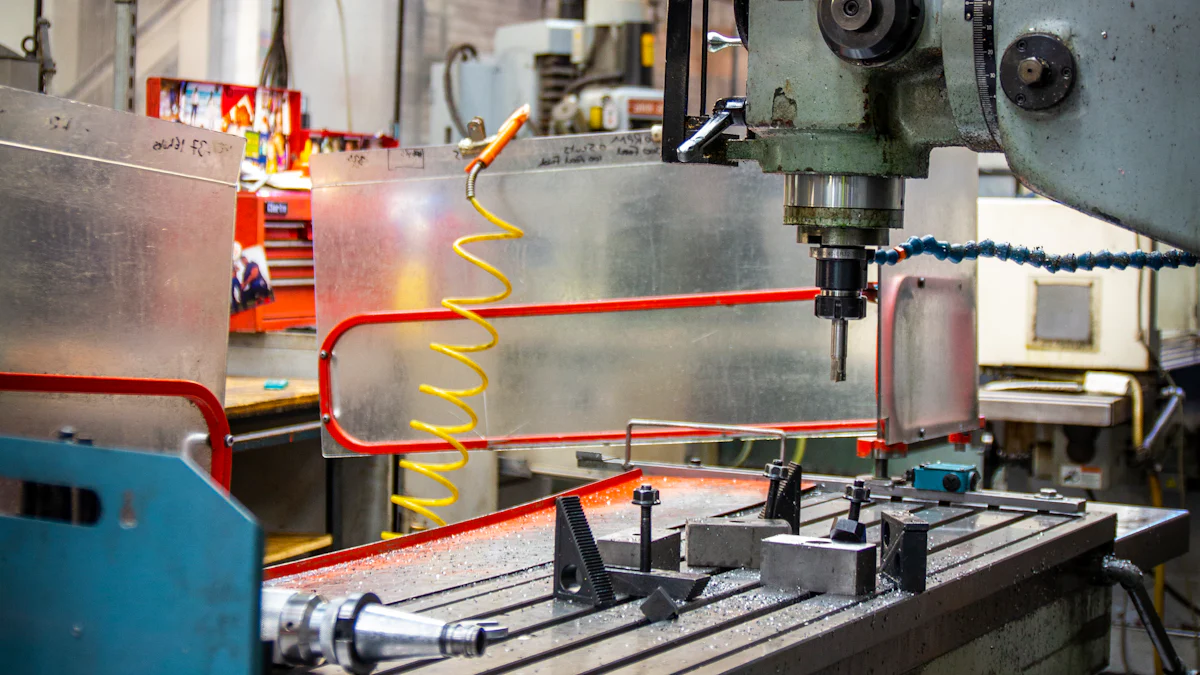

The Role of CNC in Manufacturing Aluminum Electronics Housings

CNC machining plays a vital role in creating aluminum housings for electronics. You benefit from its unmatched precision and efficiency, which ensure intricate designs meet exact specifications. Aluminum’s lightweight and durable nature makes it ideal for consumer electronic enclosures, while its high thermal conductivity protects sensitive components by dissipating heat effectively. CNC machining technology also offers faster production rates and cost-effectiveness compared to traditional methods. With computer-aided design, CNC processing consumer electronic products becomes seamless, delivering consistent quality and tight tolerances. This makes CNC machining of aluminum housing essential for modern applications of CNC in housing parts.

Key Takeaways

CNC machines are very accurate. They create detailed aluminum housings that follow strict rules.

Aluminum is light, strong, and spreads heat well. This makes it great for protecting delicate electronics.

CNC tools make prototypes quickly. This speeds up design and helps launch products faster.

CNC machining allows custom designs. This improves how products work for specific needs.

CNC uses eco-friendly methods like recycling aluminum and saving energy. This helps the planet while staying efficient.

Importance of CNC Machining in Aluminum Electronics Manufacturing

Applications of CNC Electronics Housings

Consumer Electronics and Devices

CNC machining plays a critical role in creating aluminum housings for consumer electronics. You’ll find these housings in products like laptops, smartphones, and gaming consoles. Their lightweight and durable nature ensures portability and long-lasting performance. CNC electronics also enable the production of heat sinks, which efficiently dissipate heat from components, preventing overheating. Additionally, CNC machining ensures precise fabrication of electronic switches, circuit boards, and connectors, guaranteeing reliable functionality and smooth finishes.

Industrial and Medical Equipment

In industrial and medical settings, CNC machining ensures the durability and reliability of aluminum housings. You benefit from its ability to produce components with tight tolerances, often within a few micrometers. This precision is essential for equipment like surgical instruments and diagnostic machines, such as MRI systems. Aluminum’s non-magnetic properties and machinability make it ideal for these applications. CNC machining also allows for the creation of complex geometries, enhancing the structural integrity of these critical devices.

Aerospace and Automotive Electronics

CNC machining is indispensable in aerospace and automotive industries. Aluminum housings provide lightweight enclosures that improve fuel efficiency and performance. You’ll see these housings used in avionics, engine components, and structural parts. Aluminum’s corrosion resistance and excellent thermal conductivity further enhance its suitability for these demanding applications. CNC machining ensures these housings meet the exact specifications required for safety and efficiency.

Why Aluminum is Ideal for CNC Electronics

Lightweight and Durable Material

Aluminum’s lightweight nature makes it perfect for CNC machining in electronics. You can achieve durable housings without adding unnecessary weight. This property is especially beneficial for portable devices and applications where weight reduction is crucial, such as aerospace and automotive industries.

Superior Heat Dissipation Properties

Aluminum’s excellent thermal conductivity helps protect sensitive electronic components. It dissipates heat effectively, preventing overheating and extending the lifespan of devices. CNC machining allows for intricate designs, such as heat sinks, that maximize this property and enhance device performance.

Corrosion Resistance and Longevity

Aluminum resists corrosion, ensuring your electronics housings remain functional and visually appealing over time. This property, combined with CNC machining’s precision, results in housings that are both reliable and long-lasting. Whether for consumer devices or industrial equipment, aluminum ensures durability in various environments.

Advantages of Aluminum CNC Machining

Precision and Accuracy in Manufacturing

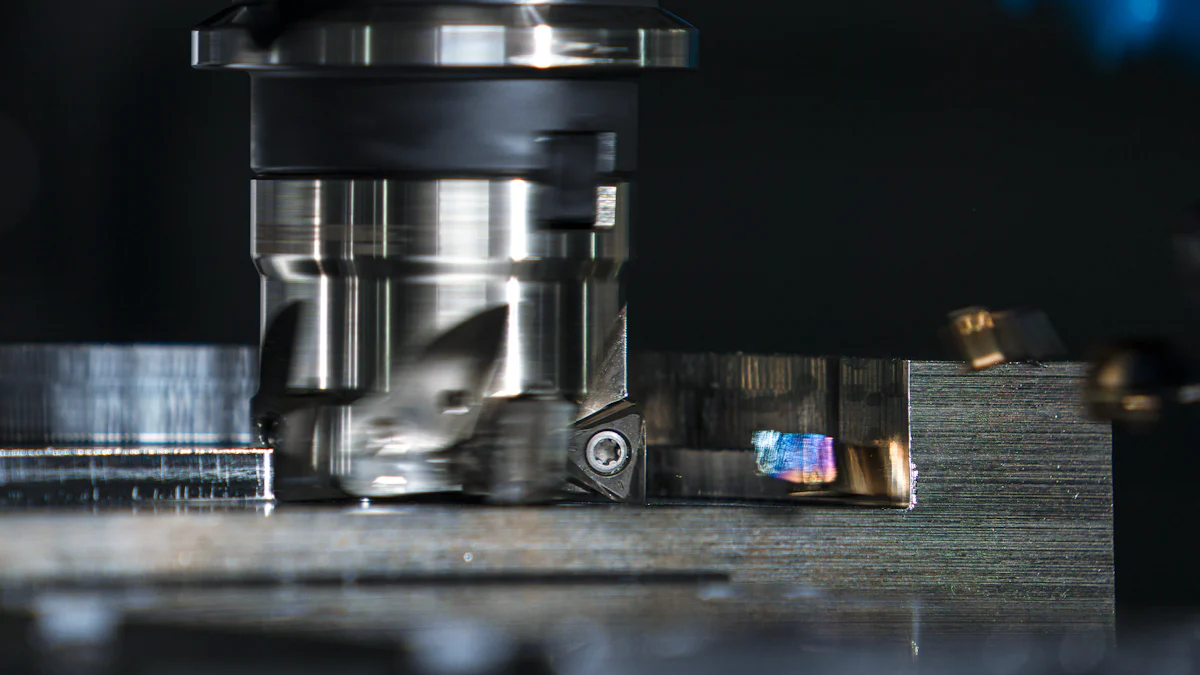

Achieving Tight Tolerances

CNC machining ensures that you achieve tight tolerances, which are essential for aluminum electronics housings. This level of precision allows you to meet the stringent standards required in the electronics industry. CNC milling and turning processes enable the creation of intricate shapes and features, such as heat sinks and mounting holes, that traditional methods cannot replicate. High-speed machining (HSM) further enhances precision by maintaining accuracy during rapid material removal. Additionally, CNC machining produces high-quality surface finishes, reducing the need for post-processing steps and saving you time.

CNC machining achieves intricate designs with unmatched precision.

Advanced techniques like cryogenic machining improve surface quality and tool life.

You can rely on CNC processes to deliver consistent results for complex geometries.

Consistency in High-Volume Production

CNC machining excels in maintaining consistency, even in high-volume production. Once programmed, CNC machines replicate designs with exact accuracy, ensuring every aluminum housing meets the same specifications. This reliability is crucial for industries like consumer electronics, where uniformity directly impacts product performance. CNC machining also supports rapid prototyping, enabling you to bring new products to market faster.

CNC machines ensure uniformity across large production runs.

Automation minimizes errors, enhancing reliability and efficiency.

You can meet market demands quickly with CNC’s high-volume capabilities.

Efficiency and Speed in CNC Processes

Faster Prototyping and Iterations

CNC machining significantly reduces the time required for prototyping. Traditional methods often involve manual labor, which slows down the process. With CNC, you can quickly create prototypes, test designs, and make adjustments. This efficiency allows you to refine your aluminum housings without delays, ensuring they meet both functional and aesthetic requirements.

CNC machining operates continuously, unlike traditional methods that require human intervention. This constant operation reduces project timelines from weeks to days.

Reduced Lead Times for Production

CNC machining’s automation accelerates production cycles. Once the parameters are set, CNC machines operate without frequent interruptions, minimizing downtime. This capability ensures you can produce large quantities of aluminum housings efficiently, meeting tight deadlines. High-speed machining also contributes to faster material removal, further reducing lead times.

CNC machines run 24/7, ensuring uninterrupted production.

Automation enhances speed and quality, reducing overall lead times.

Faster production cycles help you meet market demands promptly.

Customization and Design Flexibility

Tailored Solutions for Specific Applications

CNC machining offers unparalleled customization for aluminum electronics housings. Whether you need enclosures for laptops, medical devices, or automotive components, CNC allows you to tailor designs to specific requirements. This flexibility ensures your housings align with the unique needs of each application, enhancing performance and functionality.

CNC machining enables custom designs for consumer electronics like smartphones and tablets.

You can create specialized enclosures for medical equipment, such as ventilators and imaging devices.

Tailored solutions improve the efficiency and reliability of your products.

Easy Modifications and Updates

CNC machining simplifies the process of modifying and updating designs. By using CAD software, you can easily adjust dimensions, shapes, and features like cutouts or mounting holes. This adaptability ensures your aluminum housings remain up-to-date with evolving technological and aesthetic trends.

CNC machining begins with a detailed 3D model, which serves as the blueprint for production. You can modify this model effortlessly, ensuring the final product meets your exact specifications. This capability allows you to stay ahead in a competitive market.

Material and Surface Considerations in Aluminum CNC Machining

Common Aluminum Grades for CNC

6061 Aluminum for Versatility

6061 aluminum is one of the most versatile materials for CNC machining. You’ll find it lightweight, easy to machine, and weldable, making it ideal for a wide range of applications. Its excellent corrosion resistance ensures durability in environments prone to moisture or chemicals. This grade is perfect for structural components and electronics housings that require both strength and a clean surface finish.

7075 Aluminum for Strength

When you need high strength, 7075 aluminum stands out. It offers an exceptional strength-to-weight ratio, making it suitable for high-stress applications like aerospace and automotive electronics. Although it’s slightly harder to machine than 6061, its superior strength makes it worth the effort. You’ll often see 7075 used in CNC precision turning parts where durability is critical.

5052 Aluminum for Corrosion Resistance

5052 aluminum excels in environments where corrosion resistance is a priority. It’s highly suitable for marine and chemical applications, where exposure to harsh elements is common. This grade also offers good workability and weldability, making it a reliable choice for CNC machining projects that demand longevity and resistance to wear.

Surface Finishes for Aluminum Electronics Housings

Anodizing for Durability and Aesthetics

Anodizing enhances the durability and appearance of aluminum electronics housings. It creates a tough oxide layer that resists corrosion, scratches, and wear. This finish also allows you to customize the housing with various colors, making it ideal for consumer electronics. Anodized aluminum performs well in harsh environments, ensuring long-lasting protection for sensitive components.

Powder Coating for Enhanced Appearance

Powder coating provides a smooth, durable finish that resists scratches and corrosion. This surface treatment is perfect for exterior components, as it offers both protection and an attractive appearance. You can rely on powder coating to enhance the visual appeal of aluminum housings while ensuring their longevity.

Polishing for Electrical Conductivity

Polishing improves the electrical conductivity of aluminum surfaces, making it essential for certain electronic applications. This finish also enhances the housing’s aesthetic appeal by creating a sleek, reflective surface. Polished aluminum is often used in components where both functionality and appearance matter.

Surface finishes not only protect aluminum electronics housings but also improve their performance and lifespan. Choosing the right finish ensures your CNC-machined parts meet both functional and aesthetic requirements.

The Future of CNC in Electronics Manufacturing

Emerging Trends in CNC Technology

Automation and AI in CNC Processes

Automation and artificial intelligence (AI) are transforming CNC machining in the electronics industry. Automated systems handle tasks like part loading and tool changes, reducing labor costs and increasing efficiency. AI algorithms optimize machining parameters, predict maintenance needs, and improve quality control. These advancements ensure that CNC machining delivers consistent results while minimizing downtime.

Digital twin technology is another game-changer. It allows you to create virtual prototypes, test designs, and optimize processes before physical production begins. This innovation reduces errors and accelerates development cycles, making it invaluable for consumer electronics development.

Multi-Axis CNC Machines for Complex Designs

Multi-axis CNC machines are revolutionizing the manufacturing of intricate aluminum electronics housings. These machines enable you to process complex geometries with precision, eliminating the need for multiple setups. By using multi-axis technology, you can achieve tighter tolerances and smoother finishes, which are essential for high-performance electronics. This capability supports the growing demand for compact and lightweight designs in the electronics industry.

Innovations in Aluminum CNC Electronics

Lightweight and Compact Housing Designs

Advancements in aluminum CNC machining are driving the creation of lightweight and compact electronics housings. Aluminum’s excellent strength-to-weight ratio and high thermal conductivity make it ideal for portable devices. CNC machining ensures precise fabrication, allowing you to produce intricate components that enhance functionality. Faster production times and design flexibility further support innovation in consumer electronics development.

Sustainable and Eco-Friendly Manufacturing

Sustainability is becoming a priority in CNC machining. Manufacturers are adopting energy-efficient machine tools and recycling aluminum scraps to reduce waste. Eco-friendly coatings and green materials are also being used to minimize environmental impact. These efforts align with the electronics industry’s push for sustainable practices, ensuring that aluminum CNC electronics remain both efficient and environmentally responsible.

Challenges and Opportunities in CNC Manufacturing

Balancing Cost and Scalability

Balancing cost and scalability is a critical challenge in CNC machining. Aluminum’s machinability allows for faster production and lower costs, making it a top choice for electronics manufacturing. By leveraging CNC technology, you can achieve high-precision components with tight tolerances, meeting the exact specifications required for scalable production.

Adapting to Rapid Technological Advancements

The electronics industry evolves rapidly, and CNC machining must keep pace. Companies like Apple and Tesla use CNC to produce high-quality components for their products, ensuring precision and scalability. By adopting advanced technologies like AI and multi-axis machining, you can stay competitive and meet the demands of modern electronics manufacturing.

CNC machining has revolutionized aluminum electronics housing manufacturing. You benefit from its unmatched precision and efficiency, which enable the creation of intricate components that meet industry standards. The evolution of CNC has addressed challenges like chip formation and thermal buildup, ensuring high-quality production. Its rapid prototyping capabilities drive innovation, while sustainable practices like recycling aluminum and using energy-efficient tools reduce environmental impact. As CNC technology advances, you can expect even greater strides in efficiency, sustainability, and design flexibility, making it indispensable for the electronics industry.

FAQ

What makes CNC machining ideal for aluminum electronics housing?

CNC machining ensures precision and consistency, which are essential for aluminum electronics housing. It allows you to create intricate designs with tight tolerances. This process also supports high-volume production, ensuring every housing meets exact specifications while maintaining durability and functionality.

How does aluminum benefit electronics enclosures?

Aluminum offers excellent thermal conductivity, lightweight properties, and corrosion resistance. These qualities make it perfect for electronics enclosures. It protects sensitive components from heat and environmental damage while ensuring the enclosure remains durable and visually appealing over time.

Can CNC machining handle custom housing designs?

Yes, CNC machining excels at creating custom housing designs. You can tailor dimensions, shapes, and features to meet specific requirements. This flexibility ensures your housing aligns with the unique needs of your application, whether for consumer devices or industrial equipment.

What surface finishes work best for aluminum enclosures?

Anodizing, powder coating, and polishing are popular surface finishes for aluminum enclosures. Anodizing enhances durability and aesthetics, powder coating provides a smooth and protective layer, and polishing improves electrical conductivity while adding a sleek appearance.

Is CNC machining cost-effective for aluminum housing production?

CNC machining offers cost-effective solutions for aluminum housing production. Its automation reduces labor costs and ensures consistent quality. High-speed machining minimizes lead times, making it an efficient choice for both prototyping and large-scale manufacturing.

See Also

Understanding CNC Technology and Precision Engineering in Electronics

Benefits of Utilizing Aluminum CNC Machining Solutions

CNC Precision Parts Processing: Key to Manufacturing Success

Your 2024 Handbook for CNC Machining Aluminum Alloys

Streamlined CNC Machining Services for Accurate Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com