How CNC Machining Is Transforming the Automotive Manufacturing Industry

You’ve likely noticed how the automotive industry has evolved to produce vehicles with greater precision and efficiency. CNC machining plays a key role in this transformation. It automates production, reducing labor costs and lead times. By enhancing material efficiency, it minimizes waste while delivering high-quality parts that meet the demands of modern manufacturing.

Key Takeaways

CNC machines make parts automatically, cutting labor costs and time.

They are very precise, with accuracy up to ±0.0001 inches.

CNC machines use less material and save money, helping the environment.

What Is CNC Machining?

Overview of CNC Machining

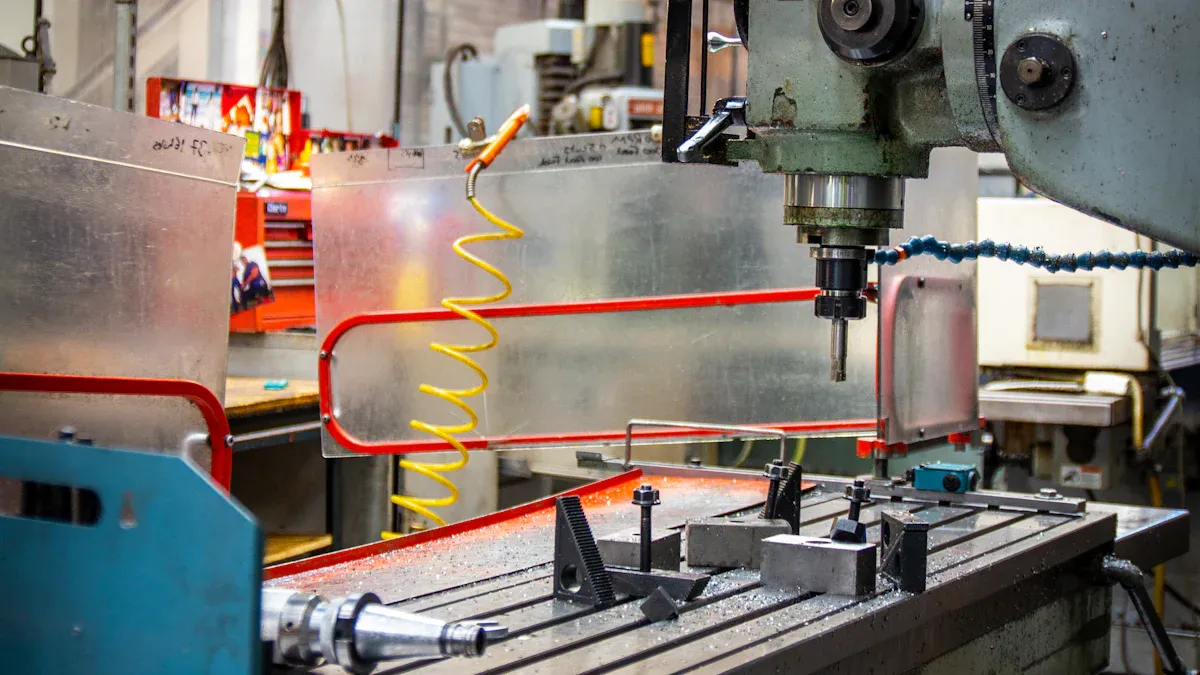

CNC machining, short for computer numerical control machining, is a manufacturing process that uses automated tools to shape materials into precise components. Unlike traditional methods, CNC machining relies on computer systems to control machine tools like lathes, mills, and drills. This technology enables you to produce complex parts with exceptional accuracy and repeatability.

The process begins with a CAD (Computer-Aided Design) model, which serves as a blueprint for the part. The computer system interprets this model and generates G-code, a programming language that directs the machine's movements. This automation ensures consistent quality, even for intricate designs.

How CNC Machining Works

CNC machining operates through a series of well-coordinated steps:

Computer System: Converts CAD models into G-code, which guides the machine's operations.

Machine Tool: Performs tasks like cutting, drilling, or milling to shape the material.

Cutting Tool: Removes material to achieve the desired design.

Key components of a CNC machine include the bed, which provides stability, and the machine control unit (MCU), which acts as the brain of the operation. The MCU decodes instructions, adjusts spindle speed, and manages tool changes. Other parts, like the chuck and tailstock, secure the material during machining.

Role of CNC Machining in the Automotive Industry

CNC machining plays a vital role in the automotive industry by enabling the production of high-quality automotive parts. It allows you to create lightweight components for electric vehicles, precise sensors for autonomous driving, and intricate engine parts. Compared to traditional methods, CNC machining reduces material waste and ensures fewer defects, which is crucial for automotive reliability. Its flexibility also lets manufacturers switch between tasks quickly, minimizing downtime and boosting efficiency.

By integrating CNC machining into automotive production, you can achieve superior precision, lower costs, and faster turnaround times. This makes it an indispensable tool for meeting the demands of modern vehicle manufacturing.

Key Benefits of CNC Machining in Automotive Manufacturing

Precision and Accuracy in Automotive Parts Production

CNC machining delivers unmatched precision and accuracy, making it essential for producing high-quality automotive parts. This technology achieves tolerances as tight as ±0.0001 inches, ensuring components fit perfectly and function reliably. For example, CNC machining is used to create custom push rods, pistons, crankshafts, and exhaust pipes. These parts meet strict quality standards, enhancing engine performance and reliability. Additionally, CNC machining minimizes human errors, providing repeatable results critical for precision manufacturing. This level of enhanced precision ensures that even the most complex automotive parts meet the demands of modern vehicles.

Increased Efficiency and Reduced Lead Times

CNC machining significantly boosts productivity by automating processes. It reduces setup time and eliminates the need for extensive tooling, allowing you to produce complex parts quickly. Compared to traditional methods, CNC machining drastically shortens lead times, enabling faster production cycles. This increased efficiency ensures that manufacturers can meet tight deadlines without compromising quality. The ability to operate continuously further enhances productivity, making CNC machining a cornerstone of modern automotive manufacturing.

Cost-Effectiveness and Waste Minimization

The cost of CNC machining is offset by its ability to reduce material waste and improve efficiency. CNC machines use digital controls to cut materials precisely, minimizing excess material. This precision reduces waste and lowers production costs. Additionally, the durability of CNC-machined components, such as aluminum parts, decreases the need for frequent replacements, saving you money in the long run. By optimizing material usage, CNC machining supports sustainable manufacturing practices while maintaining cost-effectiveness.

Versatility in Auto Components Manufacturing

CNC machining offers unparalleled versatility and flexibility in auto components manufacturing. It works with a wide range of materials, including metals and plastics, to produce durable and reliable parts. For instance, it ensures precise fitting for interior and exterior components like dashboard frames and door panels. CNC machining also excels in creating suspension components, drive axles, and gearboxes with high accuracy. This versatility makes it ideal for both mass production and custom projects, such as limited-edition vehicles or electric cars requiring lightweight, precise parts.

Applications of CNC Machining in the Automotive Industry

Engine and Powertrain Components

CNC machining plays a critical role in producing high-performance engine and powertrain components. You can rely on this technology to manufacture essential parts like engine blocks, cylinder heads, and connecting rods. These components require exceptional precision and accuracy to ensure optimal engine performance and fuel efficiency. CNC machining achieves tolerances as tight as ±0.0001 inches, making it ideal for creating intricate designs such as intake manifolds and valves. The automation provided by CNC machining enhances productivity while maintaining consistency in part production. This ensures that every component meets strict quality control standards, which is vital for the automotive industry.

Chassis and Structural Automotive Parts

When it comes to chassis and structural parts, CNC machining ensures durability and reliability. This technology minimizes human errors and delivers repeatable results, which are essential for producing complex components like suspension systems and transmission components. By using CNC machining, you can achieve uniformity in parts, which enhances the structural integrity of vehicles. This precision not only improves quality but also ensures compliance with safety standards. The increased efficiency of CNC machining reduces labor costs and accelerates production, making it a cornerstone of modern auto components manufacturing.

Customization of Interior and Exterior Features

CNC machining offers unmatched versatility and flexibility for customizing interior and exterior automotive features. For example, you can use it to create dashboard frames and door panels with precise cutouts for instruments. Lightweight interior panels made from polymers and plastics are also fabricated using this technology. The ability to produce unique components or rare replacement parts makes CNC machining invaluable for specialized vehicle models.

Feature Type | Description |

|---|---|

Interior Parts | Dashboard frames and door panels, ensuring perfect fit and compliance with safety standards. |

Customized Components | Production of unique components or rare replacement parts for specialized vehicle models. |

This versatility allows manufacturers to meet diverse customer demands while maintaining improved quality and functionality.

Prototyping and Innovation in Auto Components Manufacturing

CNC machining accelerates prototyping and innovation in the automotive industry. You can quickly create functional prototypes to test performance and make necessary design adjustments. This process reduces the overall development cycle, helping you bring products to market faster. CNC machining supports rapid design iterations, which is critical for developing bespoke parts for high-performance vehicles. By enabling prototyping and mass production, this technology fosters innovation and ensures that new designs meet the highest standards of accuracy and consistency.

Future Trends and Innovations in CNC Machining

Integration with Smart Manufacturing and AI

The integration of CNC machining with smart manufacturing and AI is reshaping the automotive industry. AI enhances productivity by optimizing machining paths, reducing cycle times, and improving overall efficiency. For example, real-time quality monitoring uses machine vision to ensure consistent accuracy during production. AI also predicts tool wear, preventing interruptions and maintaining smooth operations.

Smart factories are emerging as a result of combining AI, IoT, and data analytics. These technologies provide real-time insights into manufacturing processes, enabling you to make informed decisions. AI-assisted design further streamlines production by minimizing manual adjustments. With these advancements, CNC machining is driving increased productivity and delivering high-quality vehicles with precision.

Advancements in Sustainable Manufacturing Practices

CNC machining is contributing significantly to sustainability in automotive manufacturing. By using materials more effectively, it reduces waste and promotes eco-friendly practices. Automated procedures also lower energy consumption, which decreases the carbon footprint of production. For instance, advanced CAD/CAM software optimizes material usage, ensuring minimal waste during machining.

Sustainable CNC machining integrates environmentally friendly processes, such as energy-efficient machining techniques. These practices not only support sustainability but also align with the growing demand for greener automotive solutions. By adopting these methods, you can achieve both cost savings and environmental benefits.

Use of Advanced Materials in Automotive Parts Production

The use of advanced materials in CNC machining is transforming the production of automotive and aerospace components. Aluminum alloys, known for their lightweight and corrosion resistance, are widely used in engine parts and body panels. Steel alloys provide strength and durability, making them ideal for drivetrain components.

Magnesium and titanium alloys are gaining popularity for their exceptional strength-to-weight ratios. These materials are critical for applications where weight reduction is essential, such as high-performance vehicles. Plastics like ABS and PVC are also used for lightweight and durable interiors. By leveraging these materials, CNC machining ensures the production of high-quality vehicles with improved fuel efficiency and performance.

CNC machining stands as a cornerstone of innovation in automotive manufacturing. Its precision and adaptability drive advancements in safety, performance, and sustainability.

Key Contributions:

Enables rapid prototyping, accelerating design iterations and fostering innovation.

Produces critical components like engine blocks, brake systems, and suspension parts with unmatched accuracy.

Future developments include lightweight materials for EVs and IoT integration for real-time monitoring.

These advancements ensure CNC machining remains vital for next-generation vehicles.

As technology evolves, you can expect CNC machining to redefine automotive manufacturing, delivering safer, more efficient, and sustainable vehicles.

FAQ

What makes CNC machining better than traditional manufacturing methods?

CNC machining offers unmatched precision, faster production, and reduced waste. It automates processes, ensuring consistent quality and enabling the creation of complex automotive parts efficiently.

Can CNC machining handle custom automotive designs?

Yes, CNC machining excels at customization. You can create unique interior and exterior features, rare replacement parts, or prototypes for specialized vehicles with high accuracy and flexibility.

Tip: Use CNC machining for prototyping to test designs quickly and improve innovation in automotive manufacturing.

Is CNC machining suitable for electric vehicle components?

Absolutely! CNC machining produces lightweight, precise parts like battery housings and motor components. These are essential for improving electric vehicle performance and energy efficiency.

See Also

CNC Machining Innovations Shaping Precision Manufacturing Today

Exploring CNC Technology Advancements in Modern Manufacturing

Comparing CNC and Traditional Manufacturing Across Various Sectors

CNC Machining's Role in Transforming Toy Production Techniques

Exploring CNC Precision Machining Benefits and Future Directions

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com