How CNC Machining Optimized the Production of Automotive Components

CNC machining has transformed how you manufacture automotive components. It achieves micrometer-level accuracy, reducing rework costs and ensuring precise assembly. This technology produces complex parts quickly while meeting strict safety and performance standards. For example, CNC machining creates engine components like cylinder heads and crankshafts, ensuring durability and smoother operation under extreme conditions.

Key Takeaways

CNC machining is very precise, making car parts accurate to ±0.001 inches. This ensures parts fit perfectly and work well.

CNC machines work fast and can run all day and night. This reduces waiting time and helps companies sell products quicker.

CNC machining uses less material and needs fewer workers, saving money. It also helps make prototypes quickly, saving time and materials.

What is CNC Machining?

Definition and Core Principles

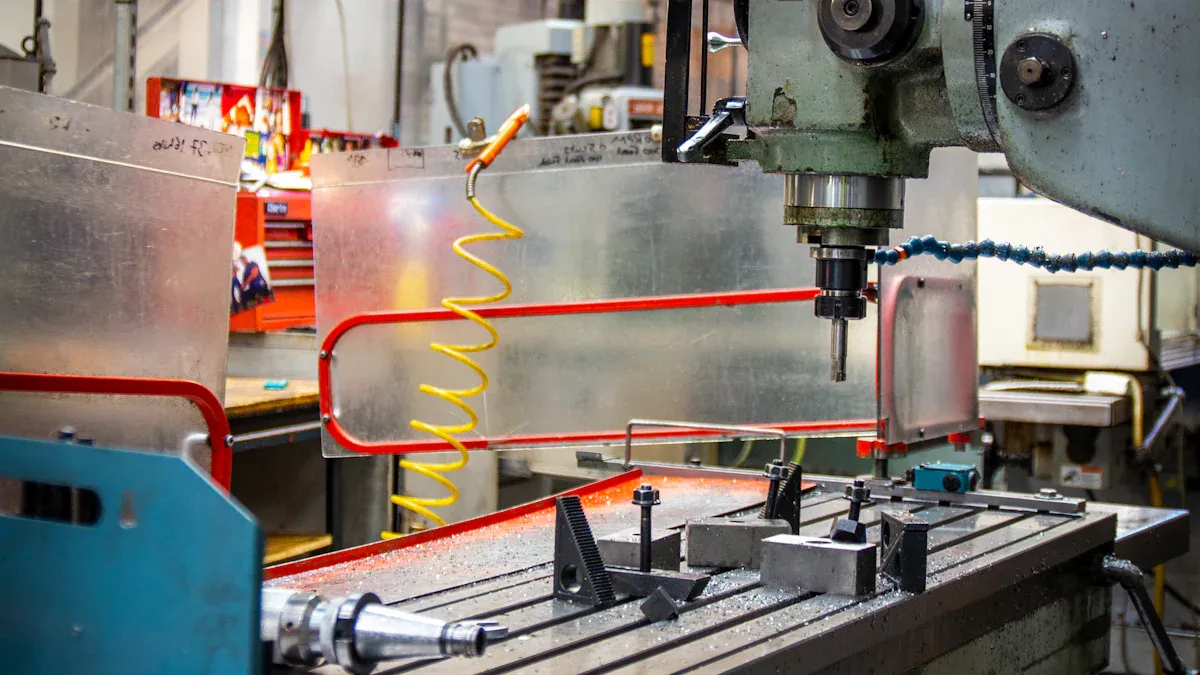

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses pre-programmed software to control machinery. This technology automates the production of parts by following precise digital instructions. You can think of it as a bridge between design and production, where computers guide tools like lathes, mills, and routers to shape raw materials into finished components.

The core principles of CNC machining make it ideal for automotive manufacturing. It ensures high precision, allowing you to create intricate parts with tolerances as tight as ±0.001 inches. Its versatility enables the production of a wide range of components, from engine pistons to custom interior trims. CNC machining also excels in efficiency, streamlining production and reducing lead times. Additionally, it guarantees repeatability, ensuring consistent quality across large production runs. These principles are essential for meeting the automotive industry's high standards for safety and performance.

Role of CNC Machining in Automotive Manufacturing

CNC machining plays a vital role in the automotive industry by producing components with exceptional accuracy and reliability. It allows you to manufacture complex parts like engine blocks, braking systems, and suspension components that require exact measurements. The process supports high-volume production while maintaining tight tolerances, which is crucial for ensuring vehicles operate safely and efficiently.

This technology also enhances the efficiency of automotive manufacturing. By automating production, CNC machining reduces manual labor and minimizes errors. It produces identical parts in large quantities, cutting down variability and inspection time. This consistency not only saves costs but also ensures that every component fits perfectly within the vehicle's systems. Whether you're creating gears, transmission parts, or custom designs, CNC machining delivers the precision and scalability needed to meet the demands of modern automotive manufacturing.

Benefits of CNC Machining for Automotive Industry

Enhanced Precision and Consistency

CNC machining ensures unmatched precision in producing automotive components. By following digital instructions, CNC machines eliminate variability, creating identical parts in large quantities. This consistency reduces inspection time and costs, making assembly seamless. For example, precision auto parts like cylinder heads and engine blocks are machined from solid aluminum with intricate designs. These designs ensure effective sealing and thermal management, which are critical for engine performance. CNC machining also enhances vehicle reliability by meeting strict industry standards for quality.

You can rely on CNC machining to produce parts like crankshafts and connecting rods with exact specifications. This precision ensures balance and durability, contributing to smoother engine operation. The integration of CNC machined parts in production lines has also reduced waste and improved productivity, ensuring every component fits perfectly.

Faster Production Speed

CNC machining significantly boosts production speed compared to traditional methods. Once programmed, CNC machines operate autonomously, performing multiple operations simultaneously. This automation allows for 24/7 production without breaks, ensuring faster project completion. For instance, CNC machining reduces lead times by automating processes, enabling you to bring products to market quickly. The combination of speed and precision ensures high-quality components with minimal wastage, enhancing overall efficiency.

Advantage | CNC Machining | Traditional Methods |

|---|---|---|

Automation | Operates autonomously once programmed | Requires constant supervision |

Simultaneous Operations | Can perform multiple operations at once | Limited to one operation at a time |

Setup Time | Quick setup with reusable programs | Extensive setup required |

Production Speed | Faster project completion | Slower production rates |

Cost-Effectiveness in Manufacturing

CNC machining offers several cost-saving benefits for automotive manufacturers. By optimizing cutting paths, it minimizes material waste, especially when working with expensive metals like aluminum. This efficiency allows you to produce more parts per material unit, reducing costs over large production runs. Automation also lowers labor costs by reducing the need for manual intervention. Additionally, CNC machining enables quick prototyping, allowing you to validate designs before full-scale production, saving time and resources.

Benefit | Description |

|---|---|

Reduced Material Waste | CNC machining optimizes the cutting path, minimizing waste, especially in expensive metals. |

Lower Labor Costs | Automation reduces the need for manual labor, lowering operational costs per part. |

Increased Production Efficiency | Quick prototyping allows for efficient design validation before full-scale production. |

Enhanced Quality Control | Precise machining leads to high-quality components while keeping expenses in check. |

Customization for Complex Designs

CNC machining excels in creating complex and customized automotive designs. It allows you to produce intricate engine components like cylinder heads, intake manifolds, and engine blocks. These parts require detailed geometries and internal features, which CNC machining handles with ease. For example, piston clearance and ring gap tolerances are machined to within 0.0005 to 0.0015 inches, ensuring optimal engine performance.

This technology also supports the production of bespoke components for high-performance vehicles. You can create personalized interior trims or specialized performance parts tailored to customer specifications. CNC machining facilitates collaboration with OEMs to produce unique designs that integrate seamlessly into existing vehicle systems. Whether for motorsport or aftermarket parts, CNC machining ensures precision and quality in every component.

Applications of CNC Machining in Automotive

Engine and Transmission Components

CNC machining plays a critical role in producing engine and transmission components with unmatched precision. These components must meet tight tolerances to ensure optimal performance and durability. You can rely on CNC machining to manufacture parts such as:

Gearboxes, including gears, shafts, and housings, which are essential for smooth power transmission.

Hypoid and bevel gears, crafted with precision to improve vehicle handling.

Engine components like cylinder heads, blocks, and pistons, which require high accuracy for efficient operation.

The precision of CNC machining enhances engine efficiency by reducing friction and ensuring consistent part dimensions. This accuracy is vital for critical components where even minor deviations can impact safety and performance. By simplifying the production of complex parts, CNC machining ensures reliability and longevity in vehicles.

Interior and Exterior Automotive Parts

CNC machining is indispensable for creating both functional and aesthetic automotive parts. For interior components, it produces dashboard panels, control interfaces, and mounting locations with high-quality finishes. Exterior parts like door panels, fenders, and car body profiles are also crafted to exact specifications.

Here’s a breakdown of commonly machined parts:

Dashboard and center console with precise instrument holes and button placements.

Door panels and hoods, ensuring structural integrity and visual appeal.

Roof profiles, contributing to the aerodynamic design of vehicles.

CNC machining enhances these parts with techniques like polishing for smooth finishes, anodizing for corrosion resistance, and coating for durability. This ensures that every component meets both functional and aesthetic requirements.

Safety and Performance Systems

Safety-critical systems in vehicles demand the highest levels of precision and reliability. CNC machining ensures that components like engine pistons, brake systems, and motor housings meet exact specifications. This accuracy is crucial for maintaining vehicle safety and performance.

Key contributions of CNC machining to safety systems include:

High accuracy and repeatability, ensuring tight tolerances for optimal functionality.

Simplified production of complex geometries, vital for advanced safety features.

Enhanced reliability, reducing the risk of part failure under extreme conditions.

For electric vehicles, CNC machining produces rotor shafts and motor housings with precision, improving safety and efficiency. By meeting stringent quality standards, CNC machining ensures that every safety-critical component performs flawlessly.

CNC machining has become indispensable in the automotive industry due to its precision and efficiency. It ensures tight tolerances for critical components, enabling optimal performance and safety. By supporting rapid prototyping and handling complex geometries, CNC machining drives innovation and growth. Its adaptability makes it essential for modern vehicle designs and sustainable manufacturing.

FAQ

What materials can CNC machining handle?

CNC machining works with metals like aluminum, steel, and titanium. It also processes plastics such as ABS and polycarbonate, making it versatile for various automotive components.

How does CNC machining improve automotive safety?

CNC machining ensures precise dimensions for safety-critical parts like brake systems and engine pistons. This accuracy reduces the risk of part failure under extreme conditions.

Can CNC machining create custom automotive designs?

Yes, CNC machining supports custom designs. It produces intricate geometries for unique interior trims, performance parts, and bespoke components tailored to specific vehicle requirements.

See Also

Revolutionizing High-End Manufacturing With CNC Machining Technology

Impact of CNC Precision Parts Processing on Production Expenses

Streamlined CNC Machining Solutions for Accurate Manufacturing

Achieving Excellence in Precision Parts Through CNC Machining

Exploring CNC Machining's Role in Aerospace Precision Engineering

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com