The Benefits of CNC Machining Prototyping for Flashlight Manufacturers

CNC machining transforms how you approach prototyping. It reduces turnaround times, enabling rapid prototyping for faster market entry. Unlike traditional methods, CNC eliminates molds, saving time and effort. Its automated process ensures exceptional accuracy and tight tolerances, crucial for intricate flashlight designs. You can quickly modify designs by updating CAD files, streamlining innovation.

Key Takeaways

CNC machining speeds up prototyping, helping products reach the market faster.

Automated CNC tools improve precision and reduce mistakes, making better prototypes.

CNC machining allows custom designs, helping make flashlights for different needs.

Efficiency and Speed with CNC Machining

Rapid Prototyping for Faster Time-to-Market

CNC machining accelerates your prototyping process, helping you bring products to market faster. Unlike traditional methods, CNC eliminates the need for molds or other time-consuming prerequisites. You can simply update CAD files to modify designs and produce new prototypes quickly. This approach reduces lead times significantly, allowing you to test and refine flashlight designs without delays. Rapid prototyping with CNC ensures shorter product development cycles, keeping your projects on schedule and boosting overall efficiency.

Streamlined Processes with CNC Automation

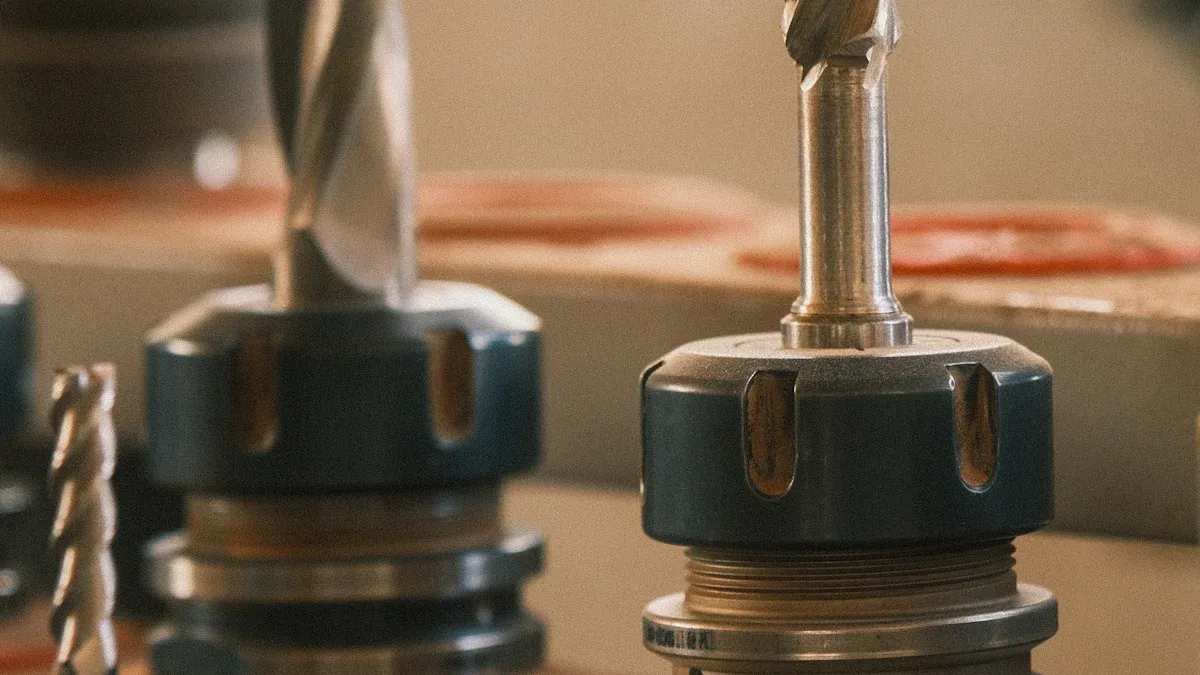

CNC automation simplifies the manufacturing process for flashlight prototypes. By minimizing design complexity, it enables quicker machine setups and reduces production timeframes. Automated systems eliminate the need for manual intervention, ensuring faster production cycles while maintaining machining precision. CNC technology uses computerized control systems to guide cutting tools with exact movements, delivering parts that meet tight tolerances. This streamlined approach enhances productivity and ensures high-quality results, making CNC machining an essential tool for digital manufacturing.

Reduced Manual Intervention and Errors

CNC machining reduces the risk of human error by automating critical processes. Manual intervention often leads to inconsistencies, but CNC ensures accuracy and consistency across all prototypes. Automation also improves efficiency by allowing machines to operate continuously without interruptions. This not only saves time but also enhances performance and productivity. With CNC, you can focus on innovation and design while the machines handle the precision work, ensuring reliable results every time.

Cost Savings Through CNC Prototyping

Minimizing Material Waste

CNC machining helps you reduce material waste during prototyping by optimizing the process from the start. It allows you to select the right workpiece size and refine 3D data before machining begins. This ensures that only the necessary amount of material is used, minimizing excess and lowering costs. By focusing on precision and efficiency, CNC machining not only saves resources but also enhances the overall quality of your prototypes. This approach supports sustainable practices while keeping your product development budget under control.

Eliminating Expensive Tooling Requirements

CNC eliminates the need for costly custom tooling, which can significantly reduce your production expenses. Several factors contribute to these savings:

Simplifying part designs shortens machining time and lowers costs.

Using standardized components removes the need for specialized tools.

Optimizing tool paths through efficient strategies reduces machine time.

Automation minimizes manual finishing, cutting down on labor costs.

Continuous improvement practices lead to ongoing cost reductions.

By adopting CNC machining, you can streamline your processes and focus on delivering high-quality flashlight prototypes without the burden of excessive tooling expenses.

Long-Term Cost Efficiency in Production

CNC machining offers long-term cost benefits by improving productivity and reducing waste. Its automated systems ensure consistent accuracy, which minimizes errors and rework. Over time, this leads to significant savings in both materials and labor. Additionally, CNC machining supports scalability, allowing you to transition seamlessly from prototyping to full-scale production. This adaptability ensures that your manufacturing processes remain efficient and cost-effective as your business grows.

Design Flexibility and Innovation

Testing and Refining Complex Geometries

CNC machining empowers you to test and refine intricate flashlight designs with ease. This process allows you to bring innovative ideas to life by enabling rapid prototyping of complex geometries. You can create intricate flashlight casings and test their functionality and aesthetics without compromising quality.

CNC machining supports the development of advanced flashlight geometries.

It ensures high-quality finishes, which are essential for both performance and appearance.

The process allows for quick iterations, helping you refine designs efficiently.

By leveraging CNC machining, you can explore creative possibilities and ensure your flashlight designs meet the highest standards of functionality and durability.

Quick Iterations for Design Modifications

CNC technology simplifies the process of making design modifications. You can quickly update CAD files and produce new prototypes without delays. This capability enhances your product development process by allowing you to test multiple iterations in a short time.

For flashlight manufacturers, this means you can adapt to market demands and refine your designs to achieve optimal performance. The ability to make quick adjustments ensures that your prototypes align with your vision and meet customer expectations. CNC machining boosts productivity by streamlining the design iteration process, saving you time and resources.

Customization for Diverse Market Needs

CNC machining offers unmatched customization options, enabling you to cater to diverse market demands. For example, aluminum flashlight casings can be tailored with various finishes and anodizing colors. This flexibility allows you to create products that stand out in the market while maintaining superior quality.

The design process also considers practical aspects like airflow to prevent heat build-up, ensuring optimal performance in high-temperature conditions. CNC machining supports digital manufacturing by enabling intricate designs that enhance both functionality and aesthetics. With this technology, you can deliver customized solutions that meet the unique needs of your customers.

Superior Accuracy and Quality

High Precision for Intricate Flashlight Components

CNC machining delivers production-quality accuracy, making it ideal for intricate flashlight components. You can achieve tolerances as tight as ±0.005 mm, ensuring every detail of your design is captured. This level of precision is essential for creating complex geometries, such as aluminum flashlight casings, that require both functionality and aesthetic appeal.

CNC machining achieves precision up to ±0.01 mm (±0.0004").

Advanced CAD/CAM software enhances the accuracy of intricate designs.

By leveraging this technology, you can produce high-quality prototypes that meet exact specifications, ensuring your flashlight components perform as intended.

Consistency Across Prototypes

CNC ensures consistency across all prototypes, which is crucial for testing and validation. Once programmed, CNC machines replicate designs with unmatched precision, producing identical parts every time. This repeatability allows you to test different materials or variations without compromising quality.

CNC machines quickly switch between designs and materials while maintaining consistent results.

Each prototype is an exact replica of the original design, ensuring reliable testing.

This consistency streamlines your prototyping process, saving time and resources while maintaining high standards.

Durability and Reliability in Prototyping

CNC machining uses a subtractive process, starting with a solid block of material and removing excess to create the desired design. This method ensures prototypes can withstand rigorous testing before moving to mass production. Selecting the right material, such as aluminum or titanium, enhances durability and reliability.

Choosing materials based on strength, heat resistance, and machinability ensures your prototypes meet project demands.

By focusing on precision and material selection, CNC machining helps you create robust prototypes that perform reliably in real-world conditions.

CNC machining prototyping transforms flashlight manufacturing by offering speed, cost efficiency, and precision. You can minimize design complexity, reduce production time, and maintain quality with standard tolerances. Long-term advantages include customization, enhanced durability, and improved heat dissipation. Partnering with experienced manufacturers ensures optimized processes, helping you stay competitive and deliver superior products.

FAQ

What materials work best for CNC machining flashlight prototypes?

Aluminum and titanium are ideal. Aluminum offers lightweight durability, while titanium provides superior strength. Both materials ensure precision and reliability for intricate flashlight components.

How does CNC machining improve flashlight design testing?

CNC machining allows you to create precise prototypes for testing. You can evaluate functionality, durability, and aesthetics before production, ensuring your flashlight meets performance standards.

Can CNC machining handle custom flashlight designs?

Yes! CNC machining supports customization. You can create unique designs, add finishes, or modify geometries to meet specific market demands. This flexibility ensures your product stands out.

💡 Tip: Always consult with your CNC provider to optimize designs for machining efficiency and cost-effectiveness.

See Also

Utilizing CNC Machining for Outdoor and Tactical Flashlight Parts

Addressing Issues: Improving CNC Prototyping Precision and Speed

Understanding CNC Machining: Tolerances, Prototyping, and Material Choices

Investigating CNC Machining Solutions for Accurate Manufacturing Needs

Streamlined CNC Machining Services for High-Precision Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com