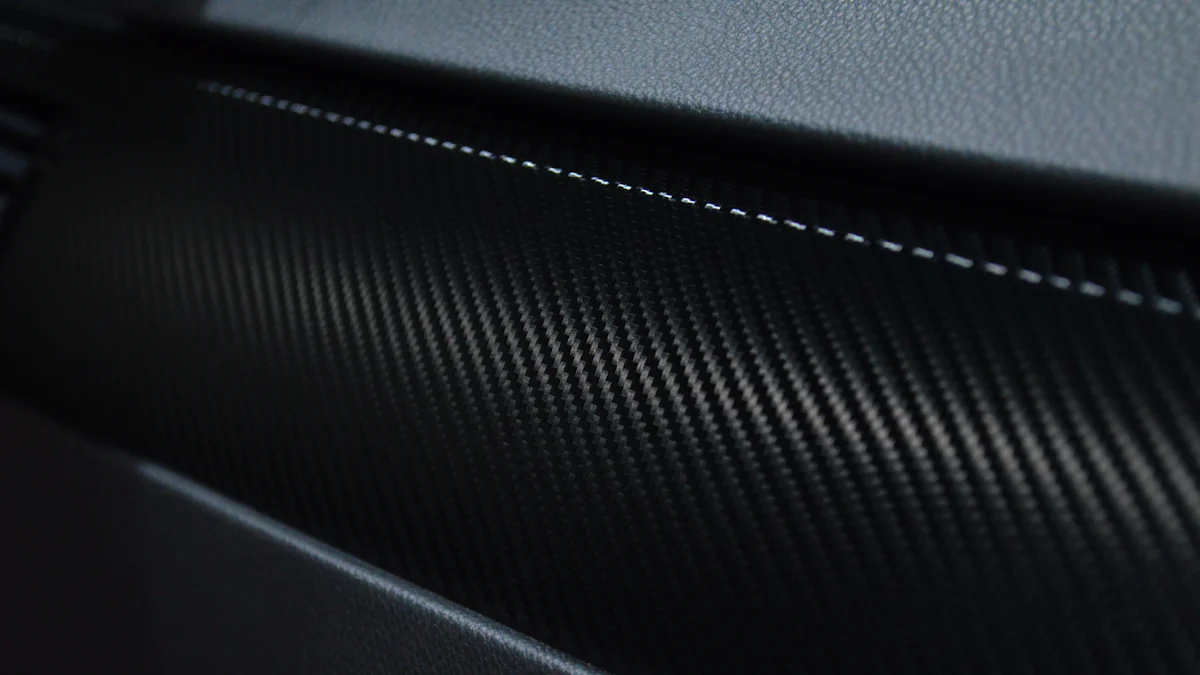

How CNC Handles Carbon Fiber Composites

CNC machining offers a precise and efficient way to work with carbon fiber composites. To achieve optimal results, you need to focus on key factors like tool selection, cutting parameters, and workholding techniques. Carbon fiber’s abrasive nature accelerates tool wear, while heat generated during machining can damage both tools and materials. Additionally, fine dust particles pose health risks, making dust extraction systems essential. Without proper precautions, issues like delamination and undersized machined features can arise. By addressing these challenges, you can ensure high-quality outcomes for your carbon fiber projects.

Key Takeaways

Pick the right tools. Use diamond-coated or carbide tools for strength when cutting carbon fiber. Sharp tools make clean cuts and avoid damage.

Adjust cutting settings. Set spindle speeds to 18,000–24,000 RPM. Use slower feed rates to lower heat and get a smooth finish.

Use good dust collectors. High-efficiency systems trap tiny dust, keeping you safe and your workspace clean.

Hold workpieces tightly. Use vacuum holders or special fixtures to stop movement or bending while cutting.

Check tool wear often. Look at tools regularly and replace them when needed. This keeps cuts precise and tools lasting longer for better results.

Key Factors for Successful CNC Machining of Carbon Fiber

Tool Selection

Choosing diamond-coated or carbide tools for durability

When machining carbon fiber, you need tools that can withstand its abrasive nature. Diamond-coated tools are an excellent choice due to their exceptional hardness and sharpness, which allow for clean and precise cuts. Polycrystalline diamond (PCD) tools, in particular, offer superior durability. They can operate at speeds up to three times faster than carbide tools and last up to 25 times longer. However, solid diamond PCD tools may dull quickly, leading to micro fiber pull-outs that can affect the final finish. Carbide tools are another reliable option, especially for less demanding applications, as they balance cost and performance effectively.

Maintaining sharp tools to ensure precision

Sharp tools are essential for achieving high-quality results when working with carbon fiber. Dull tools can cause fraying or delamination, compromising the structural integrity of your parts. Regularly inspect your tools and replace them as needed to maintain consistent performance. This practice not only ensures precision but also extends the lifespan of your equipment.

Cutting Parameters

Optimal spindle speeds and feed rates for carbon fiber

To machine carbon fiber effectively, you must optimize spindle speeds and feed rates. Higher spindle speeds, ranging from 18,000 to 24,000 RPM, combined with lower feed rates, help prevent excessive heat buildup. For example, a feed rate of 4.570 mm/min works well for many applications. Starting with a feed rate of 0.076 mm per tooth for a 6.3 mm two-flute cutter is also recommended. These settings reduce the risk of material damage and ensure a smooth finish.

Spindle Speed (RPM) | Feed Rate (mm/min) |

|---|---|

18,000 - 24,000 | 4.570 |

Managing heat and preventing material contamination

Heat management is critical when machining carbon fiber. Excessive heat can weaken the material and contaminate the surface. Use coolants or a cold air gun to dissipate heat and remove debris. High-speed machining techniques also minimize tool contact time, reducing heat generation. Additionally, a dust collection system is essential to capture fine particles and maintain a clean work environment.

Workholding Techniques

Securing carbon fiber parts to prevent movement

Proper workholding ensures stability during machining. Carbon fiber components are delicate and prone to damage if they shift. Vacuum workholding or custom fixtures can keep parts secure. For thin carbon fiber sheets, consider using backing plates. These provide extra support and prevent vibrations, which can lead to delamination.

Avoiding deformation during machining

To minimize deformation, optimize your cutting parameters and use appropriate workholding methods. Adjust spindle speed, feed rate, and depth of cut to suit your specific application. Monitor tool wear closely, as worn tools can damage the material. Vacuum fixtures or custom supports can also help maintain the integrity of your parts throughout the process.

Challenges of Machining Carbon Fiber and How to Overcome Them

Dust Generation

Health risks associated with carbon fiber dust

Machining carbon fiber generates fine dust particles that pose significant health risks. Inhaling this dust can lead to respiratory issues like bronchitis or long-term lung diseases. Skin and eye contact with the dust often causes irritation, redness, or itching. To protect yourself, always wear personal protective equipment (PPE). Use N95 respirators or masks with HEPA filters to prevent inhalation. Safety goggles and long-sleeved clothing shield your skin and eyes from exposure. Proper ventilation systems, such as Local Exhaust Ventilation (LEV), help capture airborne contaminants and maintain a safer workspace.

Implementing effective dust extraction systems

Effective dust extraction systems are essential for managing carbon fiber dust. High-efficiency systems capture dust directly at the source, reducing its dispersion. Portable units or central systems with cyclone separators work well for CNC setups. HEPA filtration systems remove fine particles from the air, ensuring clean and breathable conditions. Dust collection shrouds around the cutting area further minimize dust spread. Wet methods, like using water or coolant during machining, suppress dust and reduce inhalation risks.

Tool Wear

Abrasive nature of carbon fiber and its impact on tools

Carbon fiber’s abrasive nature accelerates tool wear. Its sharp, brittle fibers quickly dull conventional tools, leading to frequent replacements and higher costs. This wear reduces machining precision and increases downtime. You must choose tools designed for durability to combat this challenge.

Strategies to extend tool life, such as using high-quality tools

Using diamond-coated or polycrystalline diamond (PCD) tools significantly extends tool life. These materials resist wear and maintain sharpness longer. Optimize cutting speeds and feed rates to reduce stress on tools. Employ cooling methods like spray mist or air cooling to dissipate heat and maintain tool performance. Regular maintenance and timely replacement of tools ensure consistent results. Fully synthetic coolants also help control dust and improve tool longevity.

Delamination

Causes of delamination during machining

Delamination occurs when the layers of carbon fiber separate during machining. This issue arises from improper machining parameters, such as incorrect cutting speeds or feed rates. Dull tools and excessive heat generation also contribute to delamination. Carbon fiber’s inherent brittleness makes it more prone to this problem, especially under mechanical stress.

Cause of Delamination | Description |

|---|---|

Improper Machining Parameters | Incorrect speeds, feed rates, or depths of cut increase stress on the material. |

Suboptimal Tool Selection | Tools not suited for carbon fiber exacerbate delamination risks. |

Inherent Brittleness | Carbon fiber’s natural brittleness makes it susceptible to layer separation. |

Dull Tools | Worn tools tear fibers, causing separation. |

Excessive Heat Generation | High temperatures weaken the bond between layers. |

Mechanical Stress | Excessive force during machining leads to layer separation. |

Techniques to minimize delamination risk, such as proper cutting parameters

To minimize delamination, adjust your cutting parameters carefully. Lower cutting speeds and moderate feed rates reduce stress on the material. Use sharp, high-quality tools designed for carbon fiber. Employ specific techniques like pre-drilling to prevent fiber pullout. Backing plates provide additional support, reducing vibrations and the risk of layer separation. Maintaining a cutting speed between 50 to 100 meters per minute helps avoid excessive heat, preserving the material’s integrity.

Is CNC Machining the Best Option for Carbon Fiber Projects?

Advantages of CNC Machining

High precision and repeatability for complex designs

CNC machining allows you to achieve exceptional precision when working with carbon fiber. Computer-controlled machines cut, mill, or drill carbon fiber materials with tight tolerances, enabling the creation of intricate geometries. This technology enhances the material's potential, making it possible to manufacture complex designs with high repeatability. Whether you're prototyping or producing parts in bulk, CNC machining ensures consistent results. Its ability to minimize material waste further adds to its efficiency, especially when working with expensive carbon fiber composites.

Versatility in processing carbon fiber sheets

CNC machining adapts to various project needs, whether you're working with thin sheets for lightweight aerospace components or thick sheets for automotive structural parts. This versatility makes it a preferred choice for a wide range of applications. By using carbide or diamond-coated tools, you can machine carbon fiber effectively, ensuring durability and precision. CNC machining also supports customization, allowing you to tailor designs to specific requirements.

Limitations of CNC Machining

High initial setup costs and tool maintenance

CNC machining requires a significant upfront investment. Setup costs range from $100 to $200 per job, while tooling costs can vary between $50 and $300 per tool. These expenses can add up, especially for complex projects. Regular tool maintenance is also necessary due to the abrasive nature of carbon fiber, which accelerates wear. You must carefully evaluate your budget and compare these costs with alternative methods to determine feasibility.

Potential challenges with large-scale projects

For large production runs, CNC machining may not always be the most cost-effective option. Methods like compression molding or filament winding often provide better efficiency for high volumes. Additionally, while CNC machining handles a wide range of carbon fiber thicknesses, it may struggle with extremely thick parts. Dust generation, tool wear, and delamination also pose challenges that require careful management to ensure successful machining.

Limitation | Description |

|---|---|

Project Volume | Other methods like compression molding may be more cost-effective for large runs. |

Material Thickness | CNC machining has limitations with extremely thick carbon fiber parts. |

Project Budget | High setup and tooling costs make CNC machining a significant investment. |

Challenges | Issues like dust, tool wear, and delamination must be addressed for successful machining. |

Additional Considerations

Evaluating project size and complexity

When deciding if CNC machining suits your project, consider factors like part complexity, production volume, and material thickness. CNC machining excels at creating intricate geometries and details, making it ideal for low-to-medium volume projects. However, extremely thick carbon fiber parts may require alternative methods. Toolpath design also impacts the final strength of your parts, while additional post-processing might be necessary to achieve the desired surface finish.

Availability of skilled operators and advanced equipment

The success of CNC machining depends on skilled operators and advanced equipment. Experienced machinists optimize cutting parameters and ensure proper workholding, which are crucial for high-quality results. Advanced CNC machines designed for composite materials, equipped with high-quality cutting tools and cooling mechanisms, help manage the unique properties of carbon fiber. Choosing a provider with expertise in carbon fiber machining can prevent issues like delamination and excessive tool wear.

CNC provides an effective solution for machining carbon fiber composites when you follow the right precautions. Always wear personal protective equipment, use proper ventilation systems, and handle waste safely to minimize health risks. CNC machining ensures precision and durability, offering resistance to wear and corrosion. Experts and CNC services enhance project success by using advanced machines, strict quality control, and customization capabilities. Although initial costs may seem high, the long-term benefits of CNC machining, such as low maintenance and superior performance, make it a worthwhile investment. Consult professionals to achieve the best results for your projects.

FAQ

What makes carbon fiber difficult to machine?

Carbon fiber’s abrasive nature wears down tools quickly. Its brittleness increases the risk of delamination. Dust generated during machining poses health risks and requires proper extraction systems. You must also manage heat to prevent material damage.

Can you use standard CNC tools for carbon fiber?

Standard tools wear out quickly when machining carbon fiber. You should use diamond-coated or carbide tools. These materials resist wear and maintain sharpness, ensuring precision and durability during machining.

How do you prevent delamination while machining carbon fiber?

To avoid delamination, use sharp tools and optimize cutting parameters. Lower cutting speeds and moderate feed rates reduce stress on the material. Backing plates and pre-drilling techniques also help maintain the material’s integrity.

Is CNC machining suitable for all carbon fiber projects?

CNC machining works well for low-to-medium volume projects and intricate designs. However, for large-scale production or extremely thick parts, alternative methods like compression molding may be more efficient.

What safety precautions should you take when machining carbon fiber?

Always wear personal protective equipment, including N95 masks and safety goggles. Use dust extraction systems to capture fine particles. Ensure proper ventilation and handle waste safely to minimize health risks.

See Also

Grasping Material Needs for CNC Precision Machining Success

The Impact of CNC Technology on Precision Manufacturing Excellence

Enhancing Processing Standards Through CNC Precision Machining Techniques

Exploring Key Processes in CNC Precision Machining Operations

Addressing Machining Challenges: NC Milling Versus CNC Engraving

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com