Why CNC Machining Is Perfect for Complex Designs with Tight Tolerances

When manufacturing complex designs, achieving tight tolerances requires unmatched precision. CNC machining excels in this area by automating processes and eliminating human error. Unlike traditional machining, which depends on operator skill, CNC ensures consistent results.

Method | Precision and Consistency |

|---|---|

CNC Machining | Offers unparalleled precision and consistency, producing parts with tight tolerances. |

Traditional Machining | Depends heavily on the operator’s skill, which may introduce variability in precision. |

CNC machines precisely control cutting tools and workpieces. Automated systems maintain accuracy and repeatability, even for intricate geometries. This makes CNC machining the ideal choice for high-quality production.

Key Takeaways

CNC machines do tasks automatically, lowering mistakes and giving steady results.

They use smart programs and live checks to stay precise, perfect for exact designs.

These machines handle many materials, making them flexible for different needs.

They can quickly test new ideas, helping products get made faster and cheaper.

CNC machines work well for small or big jobs, keeping things fast and high-quality.

Precision and Accuracy in CNC Machining

Achieving High Precision

Role of computer control in eliminating human error

CNC machining relies on computer control to deliver unmatched precision. Unlike traditional methods, where human intervention can introduce variability, CNC machines automate tasks with exact programming. This automation ensures consistent results, even for complex designs. Real-time monitoring systems further enhance accuracy by detecting and correcting errors during the machining process. Sensors continuously track operations, ensuring every cut meets the desired specifications.

By reducing manual labor, CNC machining minimizes errors caused by fatigue or distraction. The built-in quality control measures also play a vital role in maintaining dimensional accuracy. These features make CNC machining the go-to solution for producing high-precision parts.

Advanced tooling for exact measurements

The tools used in CNC machining are designed for precision. High-precision measurement instruments, such as calipers and coordinate measuring machines (CMM), verify that parts meet exact dimensions. Proper workpiece setup and effective fixturing techniques prevent movement during machining, ensuring tight tolerances. Regular calibration of CNC machines further enhances their ability to produce accurate results.

Stable environmental conditions also contribute to precision. Temperature fluctuations can cause materials and machinery to expand or contract, leading to deviations. CNC machining addresses this by maintaining controlled environments, ensuring consistent quality in every production run.

CNC Machining Tolerances

Importance of calibration and real-time monitoring

CNC machining tolerances are among the tightest in the manufacturing industry. Regular calibration ensures that machines operate at peak accuracy, while real-time monitoring systems adjust operations to maintain precision. Feedback mechanisms detect errors early, reducing waste and ensuring high-quality production.

The table below highlights the typical tolerances achievable with CNC machining:

Processes | Tolerance Standards |

|---|---|

Milling (3-axis, 5-axis) | ± 0.13 mm or 0.005” |

Lathe | ± 0.13 mm or 0.005” |

Router | ± 0.13 mm or 0.005” |

Engraving | ± 0.13 mm or 0.005” |

Screw Machining | ± 0.13 mm or 0.005” |

These tolerances ensure that CNC machining meets the demands of industries requiring high-precision parts.

Industries requiring tight tolerances

Certain industries rely heavily on CNC machining for its ability to achieve tight tolerances. The aerospace sector demands components that can withstand extreme conditions, such as high pressure and temperature. Similarly, the medical field requires precise parts for devices like implants and surgical tools. Automotive, defense, and electronics industries also benefit from CNC machining's precision and reliability.

By meeting these stringent requirements, CNC machining has become indispensable in producing high-quality, high-precision parts for critical applications.

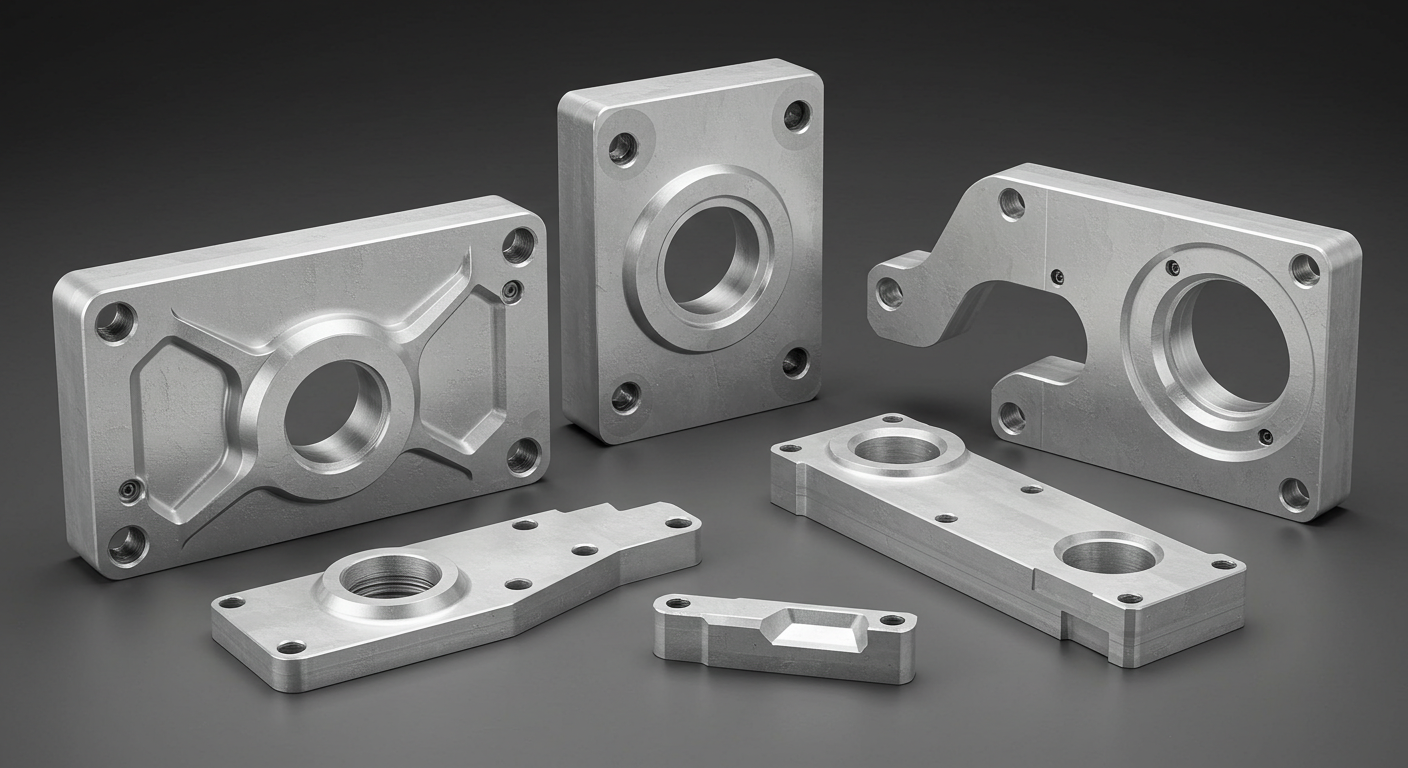

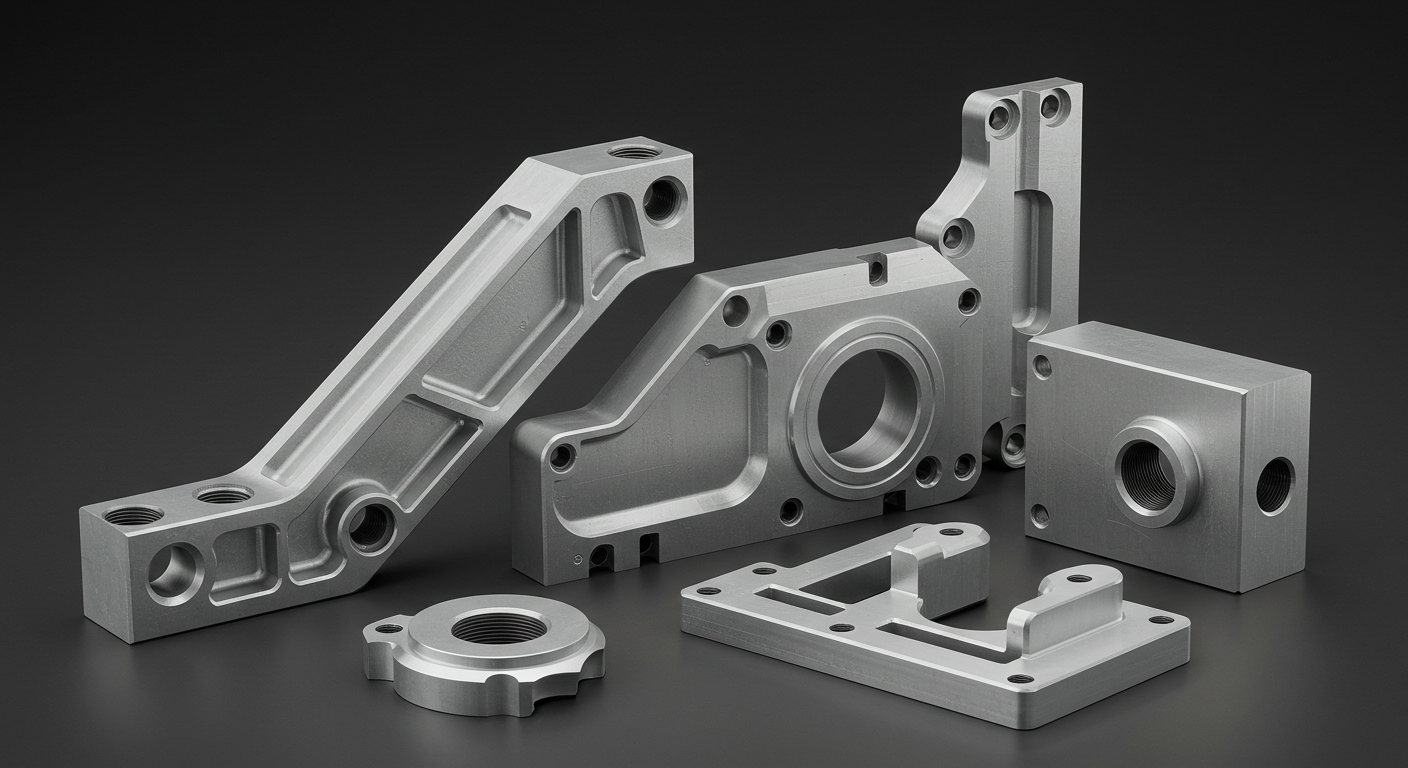

CNC Machining for Complex Designs

Capabilities for Intricate Geometries

Multi-axis machining for complex shapes

CNC machining stands out for its ability to handle complex geometries with unmatched precision. Multi-axis CNC machines, such as 5-axis and 6-axis systems, allow cutting tools to approach the workpiece from multiple angles. This eliminates the need for repositioning, reducing errors and improving accuracy. These machines excel at creating intricate shapes and internal features that traditional 3-axis machines cannot achieve.

Multi-axis machining also enhances surface finishes and extends tool life by maintaining optimal tool positioning. This capability is essential for industries like aerospace and medical devices, where high-quality parts with tight tolerances are critical. By using advanced CNC technology, you can produce complex components efficiently and with consistent results.

Examples of intricate products

CNC machining enables the production of highly detailed parts that meet strict specifications. For example, turbine blades require precise geometry to ensure optimal performance in extreme conditions. Similarly, prototypes for new products often feature intricate designs that demand high accuracy. CNC machines can handle these challenges, delivering parts that match digital models with exceptional quality.

Flexibility in Design Adjustments

Rapid prototyping and iterative processes

CNC machining supports rapid prototyping, allowing you to quickly create and test designs. This process ensures prototypes closely match digital specifications, enabling faster iterations. CNC machines produce prototypes with tight tolerances, making them ideal for testing and evaluation. Automated processes ensure repeatability, so each prototype maintains consistent quality.

The ability to make quick alterations minimizes waste and reduces costs. CNC machining also supports small batch production, making it a cost-effective solution for iterative design processes. By leveraging this technology, you can accelerate product development and gain a competitive edge.

Adapting to custom requirements

CNC machining adapts easily to custom requirements, offering solutions tailored to your needs. For instance, specialized tools can be designed for specific applications to enhance performance. Material optimization ensures the best machinability, reducing production time and costs. Advanced programming with CAD/CAM software optimizes tool paths, improving efficiency and reducing errors.

This flexibility allows CNC machining to handle a wide range of projects, from simple parts to highly complex geometries. Whether you need custom tooling, process optimization, or material-specific solutions, CNC technology ensures precision and quality in every production run.

Material Versatility in CNC Machining

Wide Range of Materials

Metals (e.g., aluminum, titanium, stainless steel)

CNC machining supports a variety of metals, making it ideal for industries requiring durable and high-performance components. Metals like aluminum, titanium, and stainless steel offer unique benefits. Aluminum provides lightweight strength, titanium excels in high-stress environments, and stainless steel resists corrosion. These properties make metals suitable for aerospace, automotive, and medical applications.

The table below highlights common materials used in CNC machining and their specific applications:

Material | Benefits | Applications/Industries Used |

|---|---|---|

Alloy Steel | High strength, heat treatable, enhanced formability | Automotive, aerospace, energy companies, high-stress applications |

Low Carbon Steel | Good formability and weldability, excellent machinability | Rivets, gears, shafts, higher stress applications |

Stainless Steel | Better weldability and formability, corrosion resistant | Medical, aerospace, food-handling equipment, machinery parts |

Brass | Low friction coefficient, high corrosion resistance | Medical equipment, consumer goods, electrical hardware |

Plastics | Cost-effective, good flame resistance, impact strength | Insulators, bearings, aerospace, automotive, medical, electronics |

Plastics and composites for lightweight applications

Plastics and composites are essential for lightweight applications. CNC machining processes these materials with precision, ensuring high-quality results. Plastics like ABS and polycarbonate are cost-effective and durable, while composites offer strength without added weight. These materials are widely used in aerospace, automotive, and electronics industries, where reducing weight improves performance.

Ensuring Design Flexibility

Switching materials without compromising precision

Switching between materials in CNC machining requires careful planning to maintain precision. Different materials have unique properties, such as hardness and thermal expansion rates, which can affect machining accuracy. To address these challenges:

Select tools designed for specific material properties.

Adjust machining parameters to account for variations in hardness and elasticity.

Monitor material composition to ensure consistent machining behavior.

By understanding how materials interact with the machining process, you can achieve high-quality components that meet tight tolerances.

Industries benefiting from material versatility

Many industries benefit from the material versatility of CNC machining. Aerospace companies rely on CNC to produce lightweight, high-strength parts like turbine blades. The medical field uses CNC for custom implants and surgical tools, ensuring precision and biocompatibility. Automotive manufacturers value CNC for its ability to handle diverse materials, creating durable and reliable components.

Industry | Benefits of CNC Machining |

|---|---|

Aerospace | High-precision components tailored to specific needs |

Automotive | Ability to handle a wide range of materials for quality parts |

Medical | Production of custom components with exact specifications |

Marine | Versatile manufacturing for various applications |

CNC machining's adaptability makes it indispensable for industries requiring innovative and precise solutions.

Consistency and Repeatability with Tight Tolerances

Uniformity Across Production Runs

Automated processes for identical results

CNC machining ensures uniformity across production runs by relying on automated systems. These systems follow precise programming to replicate designs with minimal variation. Advanced tools like Coordinate Measuring Machines (CMMs) inspect dimensions with high precision, ensuring every part meets exact specifications. Non-destructive testing (NDT) methods further verify structural integrity without damaging components.

To maintain consistency, you can implement quality control at multiple stages of production. Early detection of issues reduces waste and ensures that all parts adhere to tight tolerances. Regular machine maintenance also prevents breakdowns, sustaining high-quality output. Additionally, collaborating with suppliers guarantees the consistent quality of raw materials, which is critical for achieving repeatable results.

Tip: Accurate documentation of processes and materials supports traceability, making it easier to identify and resolve inconsistencies.

Quality control measures in CNC machining

Quality control plays a vital role in CNC machining. Inspections at various stages ensure that parts meet design requirements. Tools like micrometers and calipers measure dimensions accurately, while regular checks account for tool wear and machine calibration. Advanced inspection techniques, such as CMMs and NDT, detect defects and confirm compliance with specifications. These measures help you maintain precision and consistency, even in high-stakes industries.

Importance of Consistency for Tight Tolerances

Reducing variability in critical applications

Consistency is essential for applications requiring tight tolerances. By reducing variability, CNC machining ensures that parts fit together seamlessly and function as intended. This level of precision is crucial in industries like aerospace, where components must withstand extreme conditions. Similarly, the medical field depends on accurate machining to produce implants and surgical tools that meet strict safety standards.

Implementing stringent quality assurance measures minimizes defects and improves efficiency. This approach ensures that your final products meet the highest standards of reliability and precision, helping you stay competitive in demanding markets.

Case studies of consistent production in high-stakes industries

Many industries rely on CNC machining for consistent production. In the oil and gas sector, high-precision components like valves and pump parts must perform reliably under extreme conditions. The defense industry uses CNC machining to produce durable parts for military equipment, including aircraft and naval vessels.

Consumer goods manufacturers depend on CNC for intricate components in items like smartphones and appliances. Similarly, industrial equipment producers achieve high precision and consistency for custom parts. These examples highlight how CNC machining supports critical applications across diverse industries.

Cost-Effectiveness of CNC Machining for Complex Projects

Balancing Cost and Efficiency

Reduced waste through precise material usage

CNC machining reduces material waste by optimizing resource utilization. Machines follow exact specifications, ensuring precise cuts that align with your design requirements. This precision minimizes errors during production, leading to less material being scrapped. Additionally, CNC machining automates repetitive tasks, maintaining consistency and efficiency. By controlling cutting speeds and tool paths, CNC machining achieves precise material removal, reducing waste compared to traditional methods.

Sustainable practices in CNC machining further enhance cost-effectiveness. Manufacturers can reuse materials and adopt closed-loop systems to minimize excess material sent to landfills. These efforts not only reduce environmental impact but also lower material costs, making CNC machining an economical choice for complex projects.

Faster production times compared to manual methods

CNC machining significantly speeds up production compared to manual methods. Automated processes eliminate the need for constant human intervention, allowing machines to operate continuously. This efficiency reduces lead times, enabling you to meet tight deadlines without compromising quality. CNC machines also optimize cutting paths, ensuring faster and more accurate production.

Rapid prototyping capabilities further enhance production speed. You can quickly create and test designs, making adjustments as needed. This streamlined process accelerates product development, saving both time and money. By leveraging CNC machining, you can achieve faster production cycles while maintaining high precision.

Long-Term Benefits

Lower maintenance costs due to durable parts

CNC machining produces durable parts that require minimal maintenance. The precision of CNC technology ensures components fit perfectly, reducing wear and tear over time. High-quality materials and accurate machining processes enhance the longevity of parts, lowering replacement costs.

Automated systems also reduce labor expenses by minimizing the need for manual intervention. This efficiency translates into long-term savings, making CNC machining a cost-effective solution for complex projects. By investing in CNC technology, you can reduce maintenance costs and improve the overall reliability of your products.

Scalability for small and large production runs

CNC machining offers scalability for both small and large production runs. The adaptability of CNC machines allows you to efficiently manage varying production volumes. Whether you need a single prototype or mass production, CNC machining ensures consistent quality and precision.

This scalability supports quick transitions from prototyping to full-scale production. Continuous and repeatable operations enhance output, making CNC machining suitable for industries like automotive and aerospace. By choosing CNC machining, you can maximize economic benefits and meet the demands of diverse production scales.

CNC machining stands out as the gold standard for manufacturing complex designs. Its automation and advanced programming consistently meet extreme precision needs. You can rely on CNC machining to handle intricate geometries and produce custom machined parts with high levels of accuracy. Modern CNC machines also improve efficiency, making them ideal for industries requiring reliable and high-quality production.

Key reasons why CNC machining excels:

Automation reduces human error and ensures consistent results.

Precision machining works with diverse materials and complex shapes.

Advanced technology enhances speed and operational efficiency.

Aspect | CNC Machining | Traditional Machining |

|---|---|---|

Precision and Consistency | Unparalleled precision and consistency | Varies based on operator skill |

Speed and Efficiency | Significantly faster production times | Slower due to manual operations |

Complexity | Capable of producing complex parts | Limited by manual capabilities |

For businesses seeking cost-effective solutions, CNC machining delivers unmatched precision and versatility, ensuring optimal performance across industries.

FAQ

What makes CNC machining better than traditional machining?

CNC machining automates processes, ensuring precision and consistency. Unlike traditional methods, it eliminates human error and handles complex designs with ease. You can achieve faster production times and tighter tolerances, making it ideal for industries requiring high-quality components.

Can CNC machines work with all materials?

CNC machines support a wide range of materials, including metals, plastics, and composites. You can switch between materials without losing precision. This versatility makes CNC machining suitable for industries like aerospace, medical, and automotive.

How does CNC machining ensure tight tolerances?

CNC machining uses advanced programming, real-time monitoring, and precise tooling to maintain tight tolerances. Regular calibration and quality control measures ensure every part meets exact specifications. You can rely on CNC for consistent results across production runs.

Is CNC machining cost-effective for small projects?

Yes, CNC machining is cost-effective for small projects. Its rapid prototyping capabilities and minimal material waste reduce costs. You can also scale production easily, making it a practical choice for both small and large runs.

What industries benefit most from CNC machining?

Industries like aerospace, medical, automotive, and electronics benefit greatly. You can produce high-precision parts, custom components, and intricate designs. CNC machining ensures reliability and quality, even for critical applications.

Tip: Always consult with a CNC machining expert to choose the right materials and processes for your project.

See Also

Streamlined CNC Machining Solutions for Accurate Production

Excelling in CNC Machining for High-Precision Components

The Impact of CNC Machining on Precision Manufacturing Innovations

Recognizing the Significance of Precision in CNC Machining

Investigating CNC Machining Options for Precision Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com