How to Use CNC Machining for Complex Part Geometries in Product Design

CNC machining offers unmatched high precision for creating intricate designs. Industries like aerospace and medical rely on this subtractive manufacturing technology for parts such as turbine blades and surgical tools. Recent trends show AI integration and eco-friendly practices are transforming machining processes, making it essential for modern product design and complex geometries.

Key Takeaways

CNC machining is very accurate and great for tricky designs. It is important for fields like airplanes and healthcare.

Picking the right material makes cutting easier and parts better. Metals like aluminum and brass work well for light parts.

Making part shapes simpler saves time and money. This helps make products easier to build and more dependable.

Key Design Considerations for CNC Machining of Complex Parts

Tool Access and Geometry Constraints

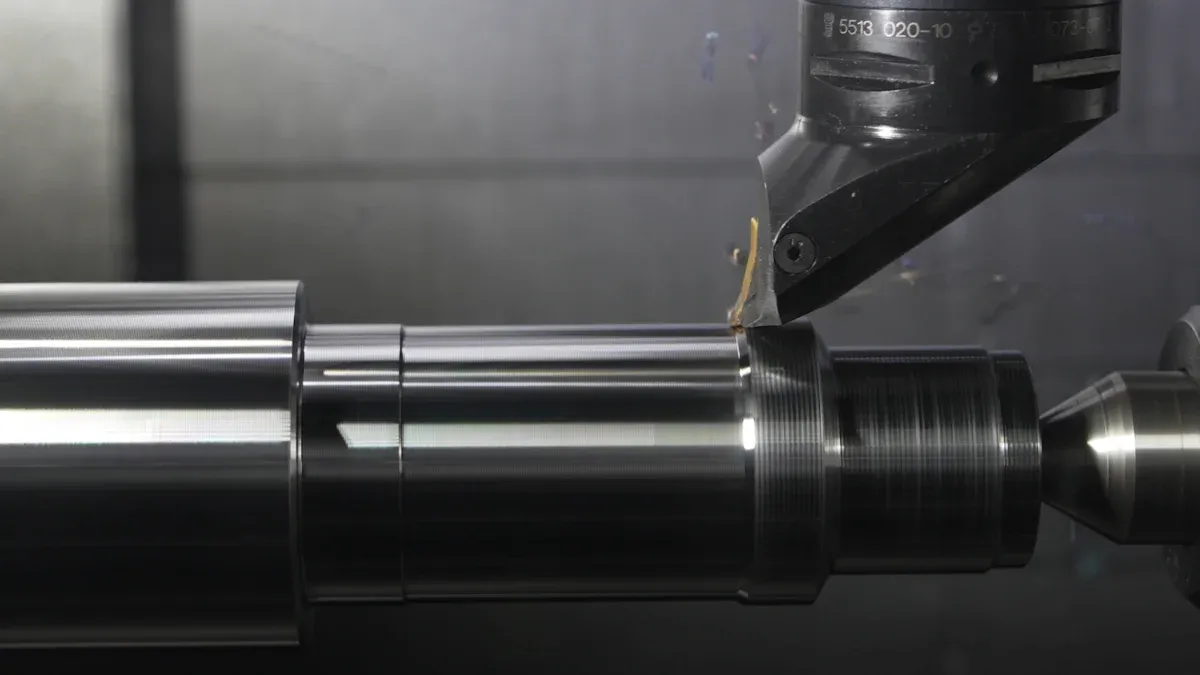

When designing parts for CNC machining, tool access plays a critical role in determining feasibility. Complex geometries, such as deep cavities, undercuts, or intricate internal features, can limit tool accessibility. If tools cannot reach certain areas, you may need to redesign the part or explore alternative manufacturing methods. Additionally, intricate designs often require multiple machining setups, increasing the risk of alignment errors.

To address these challenges, you should simplify geometries where possible and use advanced CAM software to simulate tool paths. This ensures that the design is both manufacturable and optimized for high precision. Keep in mind that tool accessibility directly impacts machining efficiency and part tolerances, so planning ahead can save time and costs.

Material Selection for Machinability

Choosing the right material is essential for achieving high dimensional accuracy and maintaining cost efficiency. Materials like aluminum and brass are highly machinable and ideal for applications requiring lightweight or durable components. Stainless steel offers strength and corrosion resistance, while titanium is perfect for high-performance parts in aerospace or medical industries. However, materials like titanium can pose machining challenges, such as increased tool wear.

You should also consider how material properties, such as thermal stability and mechanical strength, influence machining outcomes. For example, aluminum’s excellent thermal conductivity enhances heat dissipation, improving surface finishes and tool life. By selecting materials that balance machinability with performance requirements, you can optimize both accuracy and efficiency.

Tolerances and Surface Finish Optimization

Achieving tight part tolerances is crucial for components that require precise fits. Standard CNC machining tolerances typically range from +/- 0.1 mm to +/- 0.02 mm, depending on the material and geometry. For high-precision applications, tolerances as tight as +/- 0.005 in. (0.13 mm) are achievable. However, tighter tolerances often increase machining time and costs, so you should only specify them where necessary.

Surface finish optimization is another key consideration. Techniques like climb milling and high-speed machining can improve surface quality while reducing tool deflection. Post-processing methods, such as deburring and polishing, further enhance finishes. Using cutting fluids during machining also helps dissipate heat and achieve smoother surfaces. By combining proper machining techniques with post-processing, you can ensure both accuracy and high-quality finishes.

Advanced Techniques in the CNC Machining Process

Multi-Axis Machining for Complex CNC Parts

Five-axis CNC machining offers advanced capabilities for creating intricate designs. This technology allows you to machine parts with high precision by moving the cutting tool and workpiece across multiple axes. Unlike traditional three-axis machines, five-axis CNC machining minimizes manual intervention. It enables the production of complex 3D shapes and contours, such as undercuts and hard-to-reach areas, without repositioning the workpiece.

You can achieve smoother surfaces and greater accuracy due to the continuous movement of the cutting tool. This reduces machining marks and eliminates the need for additional touch-ups. Industries like aerospace and medical rely on multi-axis capabilities to produce parts such as turbine blades, orthopedic implants, and surgical instruments.

Industry | Examples of Parts |

|---|---|

Automotive | Engine blocks, crankshafts, transmission components |

Aerospace | Turbine blades, intricate brackets, structural elements |

Medical Devices | Prosthetics, surgical tools, customized implants |

Handling Undercuts and Internal Features

Machining undercuts and internal features requires specialized tools and techniques. Tools like lollipop cutters and slot cutters allow you to access areas that traditional tools cannot reach. For example, lollipop cutters excel at machining curved undercut shapes, while slot cutters are ideal for creating recesses.

To handle these features effectively, follow these steps:

Evaluate the geometry to identify undercuts.

Select appropriate cutting tools based on material and profile.

Set up the CNC machine using CAD software.

Execute the machining process with precision.

Inspect the final part to ensure it meets specifications.

Techniques like back boring and thread milling also help you achieve high precision in aerospace and automotive applications. These methods ensure accuracy while maintaining the structural integrity of the part.

High-Speed Machining for Enhanced Efficiency

High-speed machining improves productivity by using higher spindle speeds and feed rates. This technique allows you to achieve high material removal rates while maintaining accuracy and quality. By reducing cycle times, you can process parts faster without compromising precision.

This method is particularly useful for machining lightweight materials like aluminum. It enhances surface finishes and extends tool life by dissipating heat more effectively. However, machining complex geometries may require advanced CAD/CAM software to simulate designs and address challenges like tool accessibility. Despite these limitations, high-speed machining remains a valuable tool for increasing efficiency in the CNC machining process.

Best Practices for Part Design in CNC Machining

Simplifying Geometries for Manufacturability

Simplifying part designs is one of the most effective ways to enhance manufacturability in CNC machining. By reducing complexity, you can minimize machining time and material waste. This approach aligns with design for manufacturability principles, which aim to streamline production and lower costs.

Some practical strategies include avoiding intricate features like undercuts and internal cavities unless absolutely necessary. For example, instead of designing parts that require 5-axis CNC machines, you can opt for simpler geometries that can be produced on 3-axis machines. This reduces manufacturing effort and cost. Additionally, incorporating aesthetic elements through post-processing rather than during machining can further decrease complexity.

Simplified designs not only save time but also improve lead times and product reliability. By focusing on efficient geometries, you create opportunities for optimization in both production and performance.

Collaborating with Machinists Early in the Design Phase

Engaging with machinists during the early stages of part design can significantly improve manufacturability. Their expertise helps you identify potential issues and refine your designs before production begins. Early collaboration also reduces delays and avoids costly design changes later in the process.

For instance, machinists can provide insights on material selection, tool accessibility, and tolerances. They can also help you adapt your designs to meet specific machining capabilities. Common challenges, such as undercuts or square corners, can be addressed more effectively with their input. For example, using channel tags instead of interior right angles simplifies machining.

By fostering open communication and sharing technical drawings early, you ensure that your designs align with machining requirements. This proactive approach leads to smoother production cycles and better outcomes.

Using CAD and Simulation Tools to Validate Designs

CAD and simulation tools play a crucial role in validating designs for CNC machining. These tools allow you to test and refine your designs before production, ensuring compatibility with machining processes. Using standard formats and protocols ensures consistency across tools and machines.

Simulation tools help you identify errors and discrepancies by comparing your designs with reference models. You can also perform test runs to collect data and optimize design parameters. For example, simulating tool paths can reveal potential issues with tool accessibility or material removal rates.

By leveraging these tools, you can adhere to design guidelines and create parts that meet both functional and manufacturability requirements. This step not only enhances accuracy but also reduces the risk of costly errors during production.

CNC machining empowers you to create intricate part geometries with exceptional precision and flexibility. By standardizing feature sizes and maintaining proper corner radii, you can enhance efficiency and reduce costs. Techniques like adaptive clearing and high-speed machining further optimize production workflows.

Product Design | Description |

|---|---|

Hakusaku Series | Aluminum saké glasses with thin rims (0.6mm) for aesthetics and functionality. |

BN! Lamp | Modular table lamp crafted with CNC milling for precise, interchangeable assembly. |

Explore CNC machining to unlock its potential in your designs.

FAQ

What is the best material for CNC machining complex parts?

The best material depends on your application. Aluminum offers excellent machinability, while titanium provides strength for aerospace. Choose based on performance needs and machinability.

How can you reduce CNC machining costs?

Simplify part designs, use standard tolerances, and select machinable materials. Collaborate with machinists early to optimize designs for efficiency.

Can CNC machines handle intricate internal features?

Yes, CNC machines can handle intricate features using specialized tools like lollipop cutters. Advanced techniques, such as multi-axis machining, improve precision for complex geometries.

💡 Tip: Always validate your designs with CAD tools to ensure compatibility with CNC machining processes.

See Also

Achieving Precision Parts Through Expert CNC Machining Techniques

Investigating CNC Machining Solutions for High-Precision Production

Grasping CNC Machining Fundamentals for Effective Parts Production

Excelling in CNC Milling for Accurate Parts Fabrication

Addressing Machining Challenges: NC Milling and CNC Engraving Solutions

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com