How CNC Services Can Customize Your Branding on Products

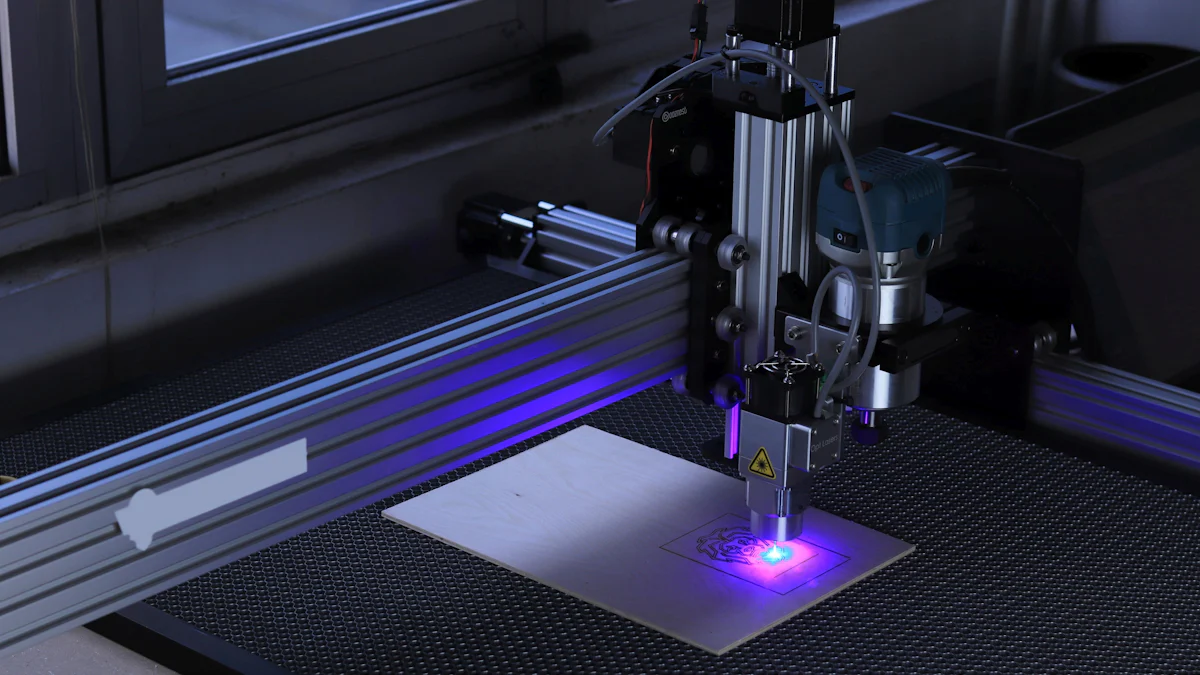

CNC machining gives you the ability to create precise and professional branding on your products. With custom CNC services, you can engrave logos, text, or intricate designs on materials like metal, plastic, or wood. Industries such as aerospace, medical, and electronics rely on CNC services for high-quality outputs. For example, CNC machining is used to craft implants in the medical field or airfoils in aerospace. This technology ensures your branding remains consistent and visually appealing, regardless of the material or complexity of the design.

Key Takeaways

CNC machines are very precise, accurate to 1/1000th of an inch. This makes your branding look clean and professional.

Keeping products the same is important for your brand. CNC services make sure every product looks exactly alike, no matter how many you order.

CNC machines can handle both small and big orders easily. This makes them great for different production needs.

CNC technology works with many materials, like metal and plastic. Picking the right material makes your products strong and look good.

Using custom CNC services can save money and cut waste. Automated machines give high-quality results while staying affordable.

Benefits of CNC Machining for Branding

Precision and Accuracy

When it comes to branding, precision is key. CNC machining offers greater precision than traditional methods, ensuring your designs are flawless. This technology achieves accuracy within 1/1000th of an inch, making it ideal for intricate logos or detailed patterns. Unlike manual processes, CNC machines rely on computerized numerical control, which eliminates human error and guarantees uniformity. Each product receives the same level of detail, ensuring high-quality outputs every time.

For example, CNC machining has been used to create products like the Hakusaku Series, a line of aluminum saké glasses with ultra-thin rims. These glasses demonstrate how precision machining can enhance both aesthetics and functionality. Whether you're engraving a logo or crafting a custom design, CNC services ensure your branding stands out with unmatched accuracy.

Consistency Across Products

Consistency is crucial for maintaining a professional brand image. Custom CNC services excel in delivering identical results across multiple products. The computer-controlled tools follow precise programming instructions, ensuring every item matches your original design. This level of consistency is difficult to achieve with traditional manufacturing methods, where variations can occur due to operator fatigue or skill differences.

Take the BN! Lamp as an example. This modular table lamp, crafted using CNC machining, features interchangeable components that fit together perfectly. Such precision ensures that every unit meets the same high standards, reinforcing your brand's reputation for quality. With CNC machining, you can trust that your branding will remain consistent, whether you're producing ten items or ten thousand.

Scalability for Different Order Sizes

CNC machining offers unmatched scalability, making it suitable for both small and large orders. The automated processes allow for continuous production without constant supervision, reducing lead times and ensuring efficiency. Whether you're creating a limited-edition product or fulfilling a bulk order, custom CNC machining adapts to your needs.

For large-scale orders, CNC machines maintain consistent quality by adhering to tight tolerances. They can handle oversized workpieces and intricate designs, making them versatile for industries like aerospace and automotive. Quality control plays a vital role in this process, identifying and correcting deviations before production is complete. This ensures that every product meets your specifications, enhancing your competitiveness in the market.

By choosing a CNC machining service, you gain the advantages of CNC machining, including cost savings, reduced material waste, and faster turnaround times. This flexibility supports your product development goals while maintaining the high standards your customers expect.

Versatility in Material Compatibility

CNC machining offers you the flexibility to work with a wide range of materials, making it an excellent choice for branding customization. Whether you need to engrave on metals, plastics, or other substrates, CNC technology adapts to your requirements. This versatility ensures that your branding aligns with the material best suited for your product.

When it comes to metals, CNC machining handles materials like aluminum, brass, copper, stainless steel, and steel with ease. Aluminum stands out for its lightweight nature and corrosion resistance, making it ideal for consumer goods or electronics. Brass and copper provide a polished, premium look, often used in decorative branding. Stainless steel and steel offer durability and strength, perfect for industrial or outdoor applications.

Plastics also play a significant role in CNC machining. Materials like ABS, PEEK, Acetal, nylon, polycarbonate, PVC, and polyethylene are frequently chosen for their unique properties. ABS, for instance, offers high impact strength and low heat conductivity, making it a popular choice for prototypes. PEEK, on the other hand, excels in demanding applications due to its abrasion resistance and low moisture absorption. You can rely on these plastics for lightweight, durable, and cost-effective branding solutions.

This material compatibility allows you to customize branding across industries. Whether you’re creating medical devices, automotive parts, or consumer products, CNC machining ensures your designs are both functional and visually appealing. By selecting the right material, you enhance the durability and aesthetic of your branded products, ensuring they leave a lasting impression.

Tip: Consult with your CNC service provider to determine the best material for your branding needs. Their expertise can help you achieve the perfect balance between functionality and design.

The Process of Custom CNC Machining for Branding

Design Creation

Creating a successful design for custom CNC machining begins with careful planning. The process ensures your branding aligns with your product design and meets your expectations. Here are the key steps involved:

G-Code Creation: A CAD model or technical drawing is converted into G-code, which serves as the programming language for CNC machines.

Material Preparation: The raw material is cut to size and securely fixed to the machine.

Roughing Passes: High-speed tools remove large portions of material to shape the initial design.

Finishing Passes: Smaller amounts of material are removed to achieve precision machining and a smooth finish.

Deburring: Sharp edges and imperfections are manually removed to enhance the final look.

Dimensional Inspection: Critical dimensions are measured to ensure the design meets quality standards.

Post-Processing: Surface finishes or coatings are applied to improve aesthetics and durability.

This structured approach ensures your branding transitions seamlessly from prototype to production, resulting in high-quality outputs that reflect your vision.

Material Selection

Choosing the right material is crucial for custom CNC machining. Several factors influence this decision:

Function and Environment: Consider how the product will be used and the conditions it will face.

Machinability: Select materials that are easy to cut and shape using CNC techniques.

Cost and Availability: Balance your budget with material accessibility.

Desired Finish and Aesthetics: Ensure the material supports the look and feel you want for your branding.

Design Complexity: Match the material to the intricacy of your design and required tolerances.

For example, metals like aluminum and stainless steel offer durability and a polished appearance, while plastics like ABS and PEEK are lightweight and cost-effective. By selecting the right material, you improve product development and ensure your branding stands out.

CNC Machining Techniques

Custom CNC machining employs various techniques to bring your branding to life. Electrical Discharge Machining (EDM) is particularly effective for creating textured surfaces or debossed logos. This method uses electrical discharges to shape the material, achieving intricate designs with precision. Other CNC techniques, such as milling and engraving, allow for detailed customization on a variety of surfaces.

These techniques ensure your branding remains consistent and professional, whether you're working on prototypes or transitioning from prototype to production. By leveraging computerized numerical control, you achieve unmatched accuracy and repeatability, making CNC machining an essential tool for modern manufacturing.

Quality Control and Finishing

Quality control plays a vital role in custom CNC machining. It ensures that your branding meets the highest standards and delivers high-quality outputs. The process begins with material inspection. This step confirms that raw materials are free from defects and meet the required specifications for dimensional accuracy and material properties. By starting with flawless materials, you set the foundation for exceptional results.

During machining, in-process monitoring keeps the production on track. Key parameters like cutting speed and tool wear are closely tracked. This allows for immediate adjustments if any deviations occur, ensuring consistent quality throughout the process. Statistical process control (SPC) further enhances this step by analyzing data to identify trends or potential issues before they escalate. These proactive measures help maintain precision and reliability in your branding.

Once machining is complete, a final inspection ensures that every detail aligns with your design. Advanced equipment measures dimensional accuracy and surface finish, confirming that the finished product meets your specifications. This step guarantees that your branding looks professional and functions as intended.

Finishing touches elevate your branding to the next level. Techniques like polishing, coating, or painting enhance the appearance and durability of your products. These processes ensure that your branding not only stands out visually but also withstands wear and tear over time. Regular machine maintenance also supports this by keeping CNC machines in peak condition, preventing quality issues during production.

Investing in quality control training for employees ensures that your team understands quality standards and inspection techniques. This knowledge helps maintain consistency and excellence in every project. With custom CNC machining, you can trust that your branding will achieve the precision and professionalism your business deserves.

Practical Applications of Custom CNC Services

Logos and Company Names

Custom CNC services allow you to engrave logos and company names with precision and professionalism. This capability ensures your branding remains consistent across all products, whether you’re creating promotional items or high-end merchandise. CNC machines can handle intricate designs, making them ideal for crafting detailed logos on materials like metal, wood, or plastic.

For example, you can use CNC machining to create branded plaques for a trade show booth or engrave your company name on premium corporate gifts. These applications not only enhance your brand visibility but also leave a lasting impression on clients and customers. By leveraging CNC technology, you ensure your branding looks polished and professional, helping you achieve successful marketing displays.

Custom Text and Messages

CNC machining offers unmatched flexibility for engraving custom text and messages. Whether you need to personalize a product or adapt to changing design requirements, CNC services make it possible. Advanced CNC cutter tools allow you to modify existing designs or create new ones with ease. This adaptability is especially valuable for industries requiring frequent updates, such as event planning or product prototyping services.

You can engrave intricate designs on materials like wood, metal, glass, or stone. For instance, floral motifs on wooden jewelry boxes or geometric patterns on metal plaques add a unique touch to your products. These personalized elements enhance the uniqueness of your offerings, making them stand out in competitive markets.

Unique Patterns and Designs

CNC machining enables the creation of unique patterns and designs that elevate your products. Whether you’re working with glass, metal, stone, or wood, CNC machines bring your creative vision to life. For example:

Material | Unique Designs |

|---|---|

Glass | Custom etchings, monograms, intricate patterns, company logos |

Metal | Detailed engravings for jewelry, decorative elements for home decor |

Stone | Intricate motifs on tiles, personalized engravings on countertops |

Wood | Intricate carved furniture, customized sculptures and decorative items |

These designs are perfect for applications like architectural elements, decorative items, or even physical prototypes. For instance, intricate wooden furniture or custom stone tiles can transform a trade show booth into a visually stunning display. CNC services also support rapid prototyping, accelerating prototyping processes for creative projects. By using CNC technology, you can achieve designs that are both functional and visually appealing.

Tip: Collaborate with your CNC service provider to explore creative possibilities for your branding. Their expertise can help you achieve designs that align with your brand identity.

Branding Across Industries

CNC machining plays a vital role in branding across multiple industries. Its precision, consistency, and adaptability make it a preferred choice for businesses aiming to enhance their brand identity. You can use this technology to meet the unique demands of your industry while maintaining high-quality standards.

Industries That Benefit from CNC Branding

Industry | Benefits |

|---|---|

Aerospace | Requires high accuracy and repeatability; tolerances of ±0.0001” for critical parts. |

Defense | Needs strict adherence to quality and delivery; vital components must be reproduced identically. |

Electronics | Handles miniaturization; maintains tight tolerances for small components in high volume. |

In the aerospace industry, branding often involves engraving logos or serial numbers on critical parts. These components demand extreme precision, as even the smallest error can affect performance. CNC machining ensures your branding meets the tight tolerances required, enhancing both functionality and aesthetics.

The defense sector relies on CNC machining for its ability to reproduce components with exact specifications. You can engrave identification marks or serial numbers on equipment, ensuring traceability and compliance with strict regulations. This consistency reinforces your brand’s reputation for reliability and quality.

In electronics, miniaturization is key. CNC machining excels at creating detailed branding on small components, such as circuit boards or device casings. You can achieve intricate designs that maintain clarity, even at a microscopic scale. This capability helps your products stand out in a competitive market.

By leveraging CNC technology, you can adapt your branding to the specific needs of your industry. Whether you work in aerospace, defense, or electronics, CNC machining ensures your designs are precise, professional, and impactful. This versatility allows you to strengthen your brand identity while meeting the technical demands of your field.

Tip: Collaborate with a CNC service provider to explore how this technology can address your industry’s unique branding challenges. Their expertise can help you achieve results that align with your goals.

Why Choose Custom CNC Machining for Branding

Cost-Effectiveness

Custom CNC machining offers significant cost savings for your branding needs. The automated nature of CNC machines reduces labor costs by minimizing manual intervention. This efficiency allows you to produce high-quality branded products without overspending. Additionally, CNC machining optimizes material usage, which reduces waste and further lowers expenses.

For large-scale production, CNC technology ensures consistent quality across all items. This consistency eliminates the need for costly rework or replacements. Even for small orders, the precision of CNC machining ensures you get value for your investment. By choosing custom CNC services, you can achieve professional results while staying within your budget.

Customization Flexibility

Custom CNC machining provides unmatched flexibility for your branding projects. You can quickly adapt designs to meet changing market demands or customer preferences. CNC technology supports rapid prototyping, allowing you to test multiple design iterations efficiently. This iterative process helps you refine your product design and create a market-ready product faster.

CNC machining enables you to experiment with innovative branding ideas.

Rapid prototyping improves product reliability and quality during development.

You can refine components quickly, ensuring your branding aligns with your vision.

This flexibility enhances your competitiveness by allowing you to respond to trends and customer feedback. Whether you need intricate logos or unique patterns, custom CNC services make it possible to bring your ideas to life.

Professional Results

Custom CNC machining ensures your branding looks polished and professional. The precision machining capabilities of CNC technology allow you to achieve intricate designs with flawless accuracy. This level of detail enhances the visual appeal of your products, making them stand out in competitive markets.

CNC machines maintain tight tolerances, ensuring every product meets your exact specifications. This consistency reinforces your brand’s reputation for quality and reliability. Additionally, CNC machining supports a wide range of materials, enabling you to choose the best option for your branding. Whether you work with metal, plastic, or wood, CNC technology delivers results that elevate your brand image.

By investing in custom CNC services, you gain access to advanced manufacturing techniques that enhance your product development process. This approach not only improves the aesthetics of your branding but also strengthens your competitiveness in the market.

CNC services offer a reliable way to customize your branding with precision and efficiency. Custom CNC machining ensures consistent results across products, enhancing your brand’s visibility and reputation. Businesses using custom CNC services benefit from tailored solutions, quick turnaround times, and durable materials. CNC machining service also improves production speeds and product quality, helping you strengthen your brand identity. By investing in custom CNC machining, you gain peace of mind knowing skilled professionals handle your project. Contact a CNC machining service provider today to bring your branding vision to life.

FAQ

What is CNC machining, and how does it work?

CNC machining uses computer-controlled tools to cut, engrave, or shape materials. You provide a digital design, and the machine follows precise instructions to create your product. This process ensures accuracy and consistency, making it ideal for branding and manufacturing.

Can CNC services handle small or intricate designs?

Yes, CNC machines excel at creating intricate designs. They achieve high precision, even for small or detailed logos, patterns, or text. This makes them perfect for branding projects requiring fine details or complex shapes.

What materials can CNC machines work with?

CNC machines work with metals like aluminum, brass, and stainless steel, as well as plastics like ABS and PEEK. They also handle wood, glass, and stone. You can choose the material that best suits your branding needs.

How long does it take to complete a CNC branding project?

The timeline depends on the complexity of your design and the order size. Simple projects may take a few days, while larger or intricate designs might require more time. Your CNC service provider can give you an accurate estimate.

Is CNC machining cost-effective for small businesses?

Yes, CNC machining reduces labor costs and material waste, making it affordable for small businesses. It ensures high-quality results, even for small orders, helping you achieve professional branding without overspending.

Tip: Always discuss your project details with your CNC provider to get the best results within your budget and timeline.

See Also

Discovering CNC Services for Accurate Manufacturing Solutions

Tianjie CNC: Transforming Industries Through Precision Machining Solutions

Streamlined CNC Machining Solutions for Accurate Production Needs

Tailored CNC Milling Solutions: Perfecting Precision Engineering Methods

CNC Precision Parts Processing: Key Influence in Manufacturing Sector

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com