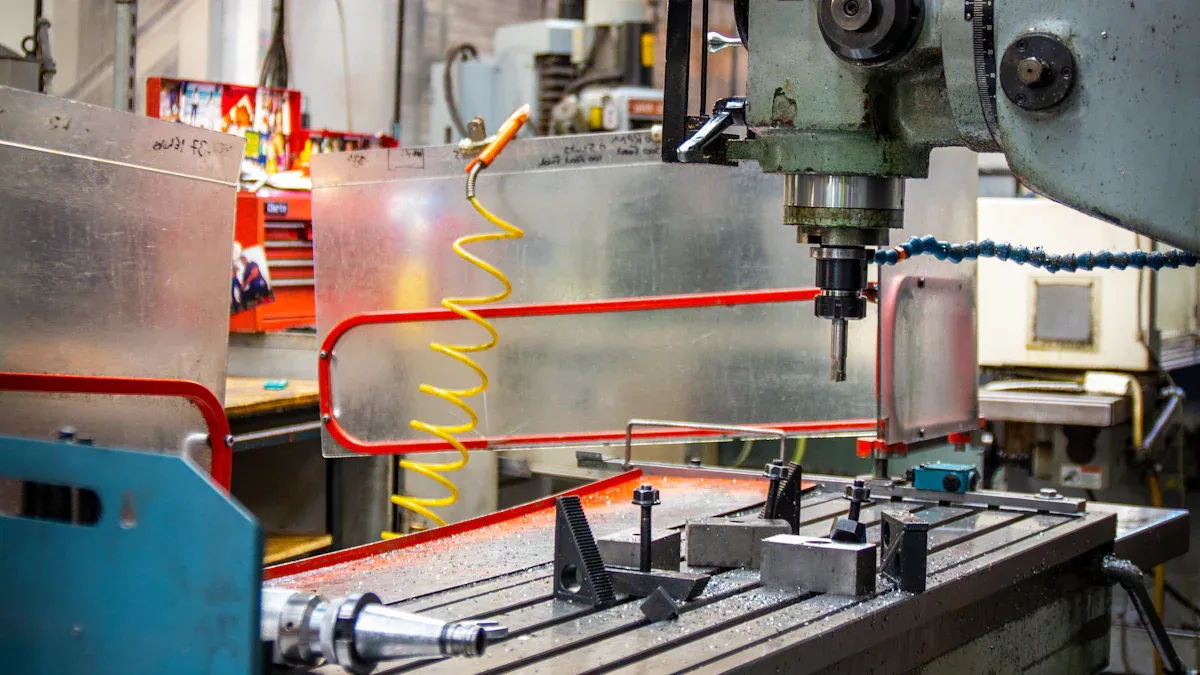

The Role of CNC Machining in Custom Furniture Manufacturing

CNC machining has transformed custom furniture manufacturing by delivering unmatched precision and efficiency. It achieves tolerances as fine as 0.001 inches, enabling intricate designs with exceptional accuracy. Unlike traditional methods, CNC ensures repeatability and consistency. This technology bridges craftsmanship and automation, producing high-quality furniture that meets modern demands for detail and durability.

Key Takeaways

CNC machines are very precise, making furniture with steady quality.

They help create detailed designs and custom pieces for customers.

CNC machines reduce waste and use materials more efficiently.

Key Benefits of CNC Machining

Precision and Accuracy in Furniture Manufacturing

CNC machining delivers unmatched precision and accuracy in furniture manufacturing. This technology ensures consistent quality by achieving tight tolerances and producing identical parts in large quantities. Manufacturers benefit from reduced errors, faster production speeds, and minimized rework costs.

High precision leads to consistent quality and tight tolerances.

Quick operation optimizes productivity and reduces production times.

Advanced monitoring ensures parts meet strict specifications.

Efficient material usage minimizes waste and lowers costs.

By automating processes, CNC machining parts maintain exact dimensions, ensuring perfect symmetry and reliable components. This level of precision enhances the overall quality of custom furniture production.

Design Flexibility for Custom Furniture

CNC woodworking offers unparalleled design flexibility, enabling the creation of intricate shapes, patterns, and textures. Designers can implement ornate carvings and detailed inlays with ease. A case study highlights how algorithmic design allows for dynamic and variable furniture designs, enhancing customization without increasing costs.

Generative design produces numerous geometric variations automatically.

CNC technology enables complex shapes and textures that traditional methods cannot achieve.

Unique customization tailors furniture to specific styles and spaces.

This flexibility empowers custom woodworking to meet diverse customer preferences while maintaining efficiency.

Efficiency in CNC Woodworking Processes

CNC woodworking processes optimize efficiency by automating tasks and reducing manual labor. Automation ensures consistent results, even in small batch production. Faster production speeds reduce lead times, allowing manufacturers to meet tight deadlines. Additionally, CNC machines streamline operations, saving time and resources. This efficiency makes CNC machining a cornerstone of modern furniture manufacturing.

Material Versatility in CNC Machines

CNC machines handle a wide range of materials, making them ideal for custom furniture production. They process hardwoods like maple and walnut, softwoods such as pine, and engineered materials like MDF and plywood.

Material Type | Examples |

|---|---|

Hardwood | Hickory, Maple, Walnut |

Softwood | Pine, Cedar |

Engineered | Medium-density fiberboard (MDF), Plywood |

This versatility allows manufacturers to create diverse furniture designs while maintaining high quality.

Sustainability Through Waste Reduction

CNC machining supports sustainability by reducing waste in furniture production. Precise cuts and shapes ensure efficient material usage, converting more raw materials into usable parts. This approach minimizes scrap and lowers energy consumption. By reducing the need for manual labor, CNC woodworking aligns with sustainability initiatives, making it an eco-friendly choice for custom furniture production.

Applications of CNC Machines in Custom Furniture

Structural Components in Furniture Manufacturing

CNC machines play a vital role in crafting structural components for custom furniture. They enable the production of essential parts such as table frames, chair legs, and cabinet supports with unmatched precision. This ensures durability and consistency in furniture manufacturing. CNC woodworking also facilitates modular and flat-pack designs, which simplify assembly and save space.

Key benefits include:

Customization at scale, allowing designs tailored to customer preferences.

Efficient material utilization, reducing waste and promoting sustainability.

Fast prototyping, enabling quick testing and refinement of creative designs.

By combining automation and precision, CNC machining parts ensure high-quality structural elements for custom furniture production.

Decorative Elements with CNC Woodworking

CNC woodworking excels in creating intricate decorative elements that elevate furniture aesthetics. CNC technology enables the production of detailed patterns, such as floral designs and 3D textures, with flawless accuracy. Traditional woodworking often struggles to achieve this level of detail.

For example, CNC routers can craft inlays and recesses with perfect fits, enhancing the visual appeal of custom furniture. A tabletop featuring intricate floral inlays made from various wood species demonstrates the artistic potential of CNC machining. This approach not only enhances the furniture's aesthetic value but also increases its perceived quality.

Functional Features Enabled by CNC Machining

CNC machining enhances the functionality of custom furniture by enabling precise joinery and innovative designs. It allows for the creation of modular components, improving assembly and portability. CNC woodworking also supports advanced sanding and finishing processes, ensuring smooth surfaces and refined details.

Designers benefit from the flexibility of CNC machines, which allow for highly customizable designs tailored to individual needs. This technology ensures structural integrity and visual appeal while reducing production time. By combining automation and precision, CNC machining delivers functional and aesthetically pleasing furniture components.

Technological Capabilities of CNC Machines

Complex Design Execution in Custom Furniture

CNC woodworking has revolutionized the ability to execute intricate designs in custom furniture production. Advanced features like multi-axis machining allow CNC machines to create complex shapes and internal features that traditional methods cannot achieve. For example, multi-axis CNC machines can produce turbine blades with intricate cooling channels, demonstrating their capability to handle detailed designs. Enhanced precision and accuracy ensure tight tolerances, which are essential for creating furniture with intricate details.

The integration of advanced software further optimizes tool paths and machining strategies. This reduces the number of setups required, minimizing errors and shortening production times. The table below highlights key advancements in CNC technology that enable complex design execution:

Advancement Type | Description |

|---|---|

Multi-axis machining capabilities | Enables production of complex shapes and internal features that traditional machines cannot achieve. |

Enhanced precision and accuracy | Essential for applications requiring tight tolerances and intricate details. |

Increased efficiency and speed | Reduces the number of setups needed, minimizing errors and shortening production times. |

Advanced software integration | Optimizes tool paths and machining strategies, improving overall production efficiency. |

These advancements empower custom woodworking to achieve unparalleled design complexity while maintaining high quality.

Automation for Consistency in Furniture Manufacturing

Automation in CNC woodworking ensures consistency in custom furniture production. CNC machines guarantee that every part matches the design specifications with perfect accuracy. This high precision ensures tight tolerances and perfect alignment, which are critical for producing uniform furniture components.

Automation also eliminates variability in production, making it ideal for small batch production or large-scale manufacturing. By maintaining uniformity, CNC machining enhances the overall quality of custom furniture. This combination of automation and precision allows manufacturers to meet customer demands for consistent and reliable products.

Waste Minimization with CNC Woodworking

CNC woodworking employs specific techniques to minimize waste, promoting sustainability in material use. Sawing optimizes material usage by cutting wood into precise shapes and dimensions. Nested-based manufacturing arranges multiple design components on a single sheet of wood, significantly reducing scrap material. Precision joinery creates seamless connections between wooden components, ensuring durability and minimizing excess material during assembly.

These techniques not only reduce waste but also contribute to sustainability in material use. By maximizing the efficiency of raw materials, CNC machining supports eco-friendly practices in custom furniture production. This approach aligns with modern demands for sustainable and high-quality woodworking solutions.

Future Trends in CNC Machining for Furniture Manufacturing

AI Integration in CNC Machines

Artificial intelligence (AI) is reshaping the future of CNC machining in furniture manufacturing. AI technologies enhance efficiency by automating repetitive tasks, allowing human workers to focus on creative and complex aspects of custom furniture design. Predictive maintenance powered by AI prevents costly equipment breakdowns, ensuring consistent production flow and reducing downtime.

AI also improves quality control through real-time monitoring and early defect detection. This capability enhances product quality and strengthens brand reputation. For example, AI-powered systems can analyze intricate woodworking patterns during production, ensuring flawless execution. These advancements make AI a critical component of CNC technology, driving innovation and reliability in custom woodworking processes.

Advancements in Sustainable CNC Woodworking

Sustainability in material use is becoming a priority in CNC woodworking. CNC machines now contribute to a circular economy by reducing waste and enabling the use of recycled or reclaimed wood. Businesses increasingly adopt sustainable wood materials, such as reclaimed timber, to meet consumer demand for environmentally responsible manufacturing.

CNC technology optimizes material usage by minimizing errors and utilizing even the smallest offcuts. This precision aligns with eco-friendly practices, appealing to customers seeking sustainable products. For instance, a custom dining set crafted from reclaimed wood demonstrates how CNC machining combines sustainability with high-quality craftsmanship. These advancements highlight the growing role of CNC machines in promoting sustainable woodworking practices.

Emerging Technologies for Enhanced Customization

Emerging technologies are revolutionizing customization at scale in CNC machining. Five-axis machining offers greater flexibility and precision, enabling the creation of complex designs that meet unique customer preferences. Advanced CNC software further enhances customization by optimizing processes, reducing errors, and minimizing material waste.

The integration of Industry 4.0 technologies, such as the Internet of Things (IoT), allows real-time monitoring and communication between CNC machines. This connectivity improves production control and efficiency, essential for small batch production and custom orders. As these technologies evolve, they will continue to expand the possibilities for custom furniture manufacturing, ensuring tailored solutions for diverse customer needs.

CNC machining has transformed custom furniture manufacturing by combining precision, efficiency, and sustainability. Its impact can be summarized as follows:

Precision and Accuracy: CNC machining ensures seamless assembly with high-precision parts.

Customization and Design Flexibility: It enables intricate patterns and complex shapes.

Minimal Waste and Cost-Effectiveness: CNC reduces material waste and optimizes production costs.

Businesses can leverage CNC to improve production processes:

It ensures perfect accuracy in every part.

Automation reduces labor costs and speeds up production.

CNC supports sustainability by minimizing waste and enabling eco-friendly practices.

As technology advances, CNC will continue to drive innovation and sustainability in the furniture industry. Manufacturers and designers should explore its potential to enhance their projects and meet modern demands.

FAQ

What types of furniture can CNC machining create?

CNC machining can produce tables, chairs, cabinets, and decorative pieces. Its precision allows for both structural components and intricate designs.

How does CNC machining improve sustainability in furniture production?

CNC machining reduces waste by optimizing material usage. It also supports the use of reclaimed wood and eco-friendly practices.

Can CNC machines handle small batch production?

Yes, CNC machines excel in small batch production. They ensure consistent quality and precision, even for limited quantities.

See Also

Discovering CNC Machining Solutions for Accurate Production

Streamlined CNC Machining Options for Exact Manufacturing

Perfecting CNC Machining Techniques for Precise Component Production

The Impact of CNC Machining on Advanced Precision Production

Recognizing the Significance of Accurate CNC Machining in Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com