Why CNC Machining Is the Backbone of the Energy Industry's Production Processes

CNC machining plays a critical role in the energy industry by delivering unmatched precision and efficiency. You rely on CNC to produce components like wind turbine blades, reactor cores, and photovoltaic panel frames. These parts demand exact tolerances to ensure safety, durability, and optimal performance. CNC machining’s importance in the energy sector cannot be overstated.

Key Takeaways

CNC machining provides great accuracy and speed. It is key for making important energy parts like wind blades and reactor cores.

This technology changes easily to meet different needs. It helps quickly adjust designs and amounts, which is useful in the busy energy industry.

CNC machining cuts down on wasted materials and lowers worker costs. This makes it a smart and affordable option for big energy projects.

Overview of CNC Machining

What Is CNC Machining?

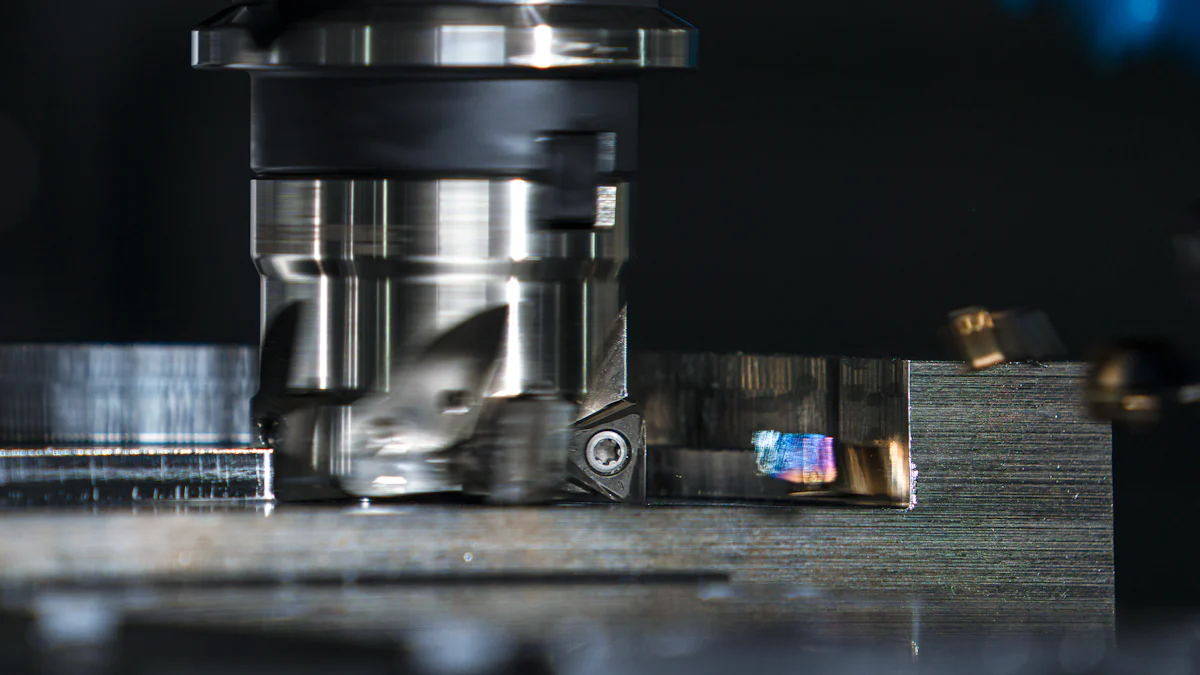

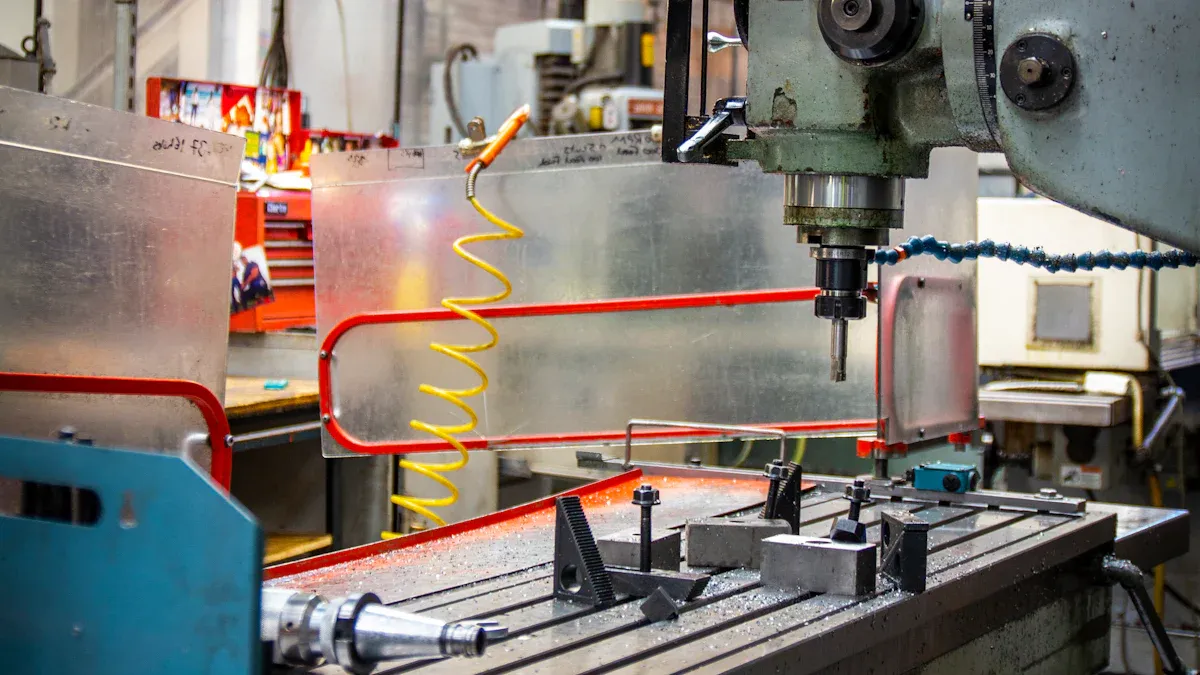

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses pre-programmed software to control machinery. You can think of it as a system where computers direct the movement of tools and equipment to create precise parts. Unlike manual machining, CNC eliminates human error by automating the process. This ensures consistent quality and accuracy, even for complex designs.

The history of CNC machining dates back to the 1940s when the need for automation in manufacturing became evident. Early developments, such as numerical control systems, laid the foundation for modern CNC technology. By the 1960s, computer control was introduced, revolutionizing the industry. Over the decades, advancements like microprocessors and CAD/CAM integration have made CNC machining more efficient and versatile. Today, it plays a vital role in industries like aerospace, automotive, and energy.

Core Capabilities of CNC

CNC machining offers a range of capabilities that make it indispensable for energy production. These features allow you to produce components with unmatched precision and efficiency. Below is a table highlighting the key functionalities of CNC:

Feature | Description |

|---|---|

Precision | CNC machining delivers exceptional precision and consistency, achieving tolerances within mere microns, critical for industries like aerospace and medical devices. |

Multi-axis capabilities | CNC machines equipped with multi-axis functionality can create intricate parts with complex geometries without extensive manual intervention, enhancing design capabilities. |

Scalability | CNC technology adapts to varying production needs, allowing for modifications in designs or production volumes without significant delays, supporting responsiveness in fast-paced markets. |

Material versatility | CNC machining can work with a wide range of materials, optimizing workflows for different materials and reducing downtime during material switching. |

Digital integration | Modern CNC systems integrate with digital technologies, enabling real-time monitoring and data analysis, which enhances productivity and decision-making in manufacturing processes. |

These capabilities make CNC machining a cornerstone of the energy industry. Whether you need to produce turbine components or solar panel frames, CNC ensures precision, scalability, and material flexibility. Its ability to adapt to changing demands makes it an essential tool for modern energy systems.

CNC Machining in the Energy Industry

Oil & Gas Applications

CNC machining plays a pivotal role in the oil and gas sector by producing components that meet the industry's demanding standards. You rely on CNC to manufacture pipeline fittings, valves, and compressor parts with precise tolerances. These components ensure safety and efficiency in transporting and processing hydrocarbons. For example, CNC machining creates durable pump and valve components capable of withstanding high pressures and extreme conditions. Drilling rig parts, such as drill bits and safety valves, also benefit from CNC's precision, enabling reliable performance in challenging environments.

Component Type | Description |

|---|---|

Pipeline fittings and valves | Manufactured to precise tolerances, minimizing leaks and increasing safety in pipeline systems. |

Compressor and pump components | Essential for the transportation and processing of oil and gas, benefiting from high precision. |

Pump and Valve Components | Must meet high standards of precision to handle pressure and flow of hydrocarbon products. |

Drilling rig components | Includes drill bits and safety valves, requiring exceptional precision for extreme drilling conditions. |

CNC machining addresses key challenges in oil and gas production. It enables rapid prototyping for tools tailored to specific geological conditions. Durable machined parts reduce maintenance needs, ensuring continuous operations and minimizing downtime.

Renewable Energy Industry Applications

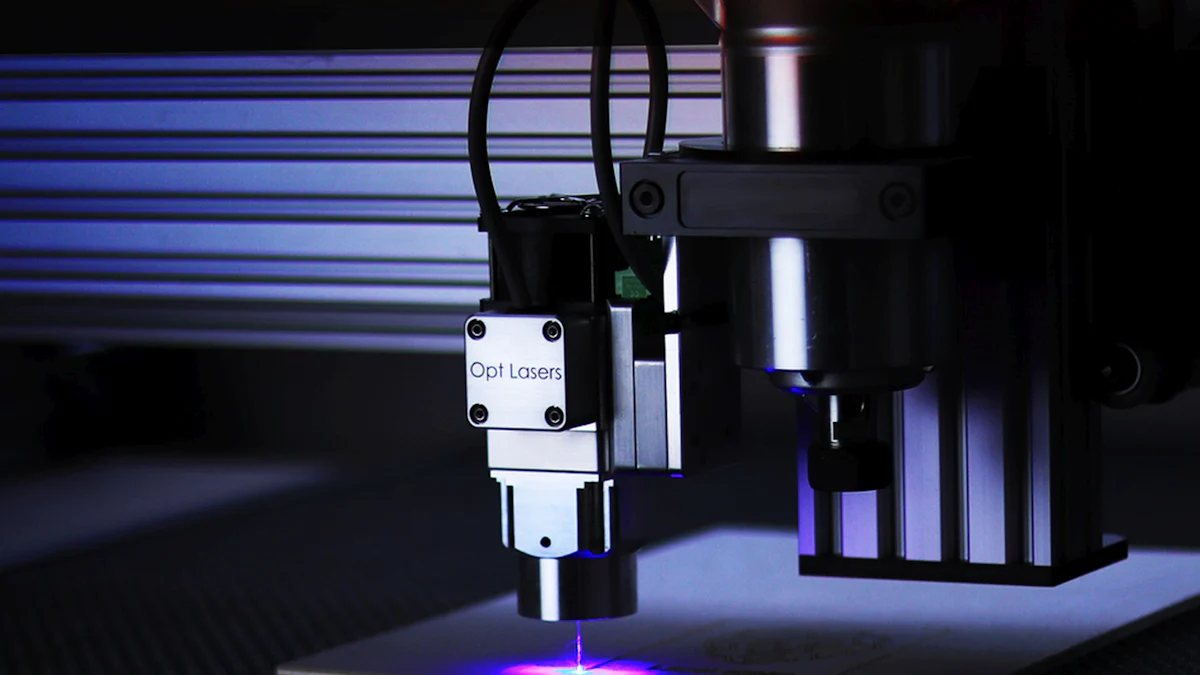

CNC machining for renewable energy systems ensures the production of high-quality components critical for sustainability. You can see its impact in wind turbines, where CNC creates aerodynamic blades and precise gearboxes. Solar panel frames and photovoltaic cell housings also rely on CNC for structural integrity and heat dissipation.

Application Area | Description |

|---|---|

Wind Turbine Blades | CNC machining creates precise aerodynamic shapes for efficient energy capture. |

Key Wind Turbine Components | Essential parts like gear housings, gearboxes, and rotors require high precision from CNC machining. |

Solar Panel Frames | CNC machining produces frames and mounting systems that ensure optimal heat dissipation and structural integrity. |

PV Cell Frames | Lightweight and durable frames protect photovoltaic cells from environmental hazards. |

CNC machining contributes to renewable energy production by minimizing material waste and enabling custom solutions. Its scalability and energy efficiency make it indispensable for manufacturing renewable energy components. This highlights CNC's role in renewable energy as a driver of sustainability and innovation.

Nuclear Energy Applications

In the nuclear energy sector, CNC machining ensures the safety and reliability of critical components. Reactor assemblies, safety mechanisms, and core components require exact specifications to maintain operational integrity. You depend on CNC's precision to create parts that meet stringent safety standards.

CNC machining is crucial for creating reactor assemblies and safety mechanisms in the nuclear energy sector.

The precision of CNC-machined parts is essential for the safe operation of nuclear reactors.

Reactor core components must be manufactured to exact specifications to ensure safety and integrity.

CNC machining in the energy industry supports the production of durable, high-performance components. Its applications in oil and gas, renewable energy, and nuclear power demonstrate its versatility and importance in meeting the demands of modern energy systems.

Benefits of CNC Machining in Energy Production

Precision and Accuracy

CNC machining delivers unparalleled precision, making it indispensable for energy production systems. You can rely on CNC to achieve tolerances as tight as a few microns, ensuring components fit perfectly and function reliably. This level of precision is critical in high-stakes applications like nuclear energy, where even minor errors can lead to catastrophic failures. For example, CNC machining ensures the exact aerodynamic profiles of wind turbine blades, enhancing energy efficiency and performance.

Precision Metric | Description |

|---|---|

Tolerances | As tight as a few microns, critical for safe operation of energy systems. |

Applications | Used in wind, solar, and nuclear energy where precision is vital. |

CNC machining also enables the creation of intricate designs, such as cooling channels in turbine blades, which improve performance and durability. The importance of precision in energy production cannot be overstated.

Cost-Effectiveness

The automation and repeatability of CNC machining significantly reduce labor costs and material waste. You benefit from its efficiency, especially in large-scale energy projects where budget management is crucial. For instance, CNC machining minimizes waste by optimizing tool paths, ensuring consistent quality while lowering production costs. This makes it an economical choice for manufacturing high-quality components like solar panel frames and wind turbine parts.

Scalability for Energy Systems

CNC machining adapts seamlessly to the growing demand for energy system components. Whether you need small production runs or large-scale manufacturing, CNC processes accommodate both efficiently. For example, CNC machining has been used to produce gate valves for hydroelectric generators and high-pressure storage tanks for hydrogen fueling stations. Its ability to quickly adjust production volumes ensures you can meet market demands without delays.

CNC machining supports scalability by accommodating varying production volumes.

It enables the rapid production of components like solar panel frames, accelerating renewable energy projects.

Advanced CNC technology ensures reliability in extreme conditions, such as geothermal plants.

Durability of Components

CNC machining enhances the durability of energy components by using high-performance materials and precise techniques. You can trust CNC to manufacture components like turbine housings, heat exchangers, and pump parts that withstand harsh environments. Materials such as titanium alloys and carbon fiber composites ensure long-term reliability and resistance to corrosion.

Material/Technique | Contribution to Durability |

|---|---|

Titanium Alloys | Exceptional corrosion resistance and durability in harsh environments. |

Carbon Fiber Composites | High-performance materials that ensure long-term reliability. |

CNC Machining Precision | Enables the creation of complex geometries for optimal performance. |

By producing durable, high-quality components, CNC machining supports the sustainability and efficiency of energy systems, ensuring long-lasting performance.

CNC machining remains vital to the energy industry, offering unmatched precision, efficiency, and scalability. Its applications in oil and gas, renewable energy, and nuclear power drive innovation and sustainability. Advancements like AI integration, energy-efficient operations, and complex component designs will shape the future of CNC machining, ensuring its continued impact on energy production.

FAQ

What makes CNC machining essential for the energy industry?

CNC machining ensures precision, durability, and scalability. You can rely on it to produce components that meet the rigorous demands of energy systems, ensuring safety and efficiency.

Tip: CNC machining's adaptability makes it ideal for both traditional and renewable energy applications.

Can CNC machining handle complex designs for energy components?

Yes, CNC machining excels at creating intricate geometries. Multi-axis capabilities allow you to manufacture complex parts like turbine blades and reactor cores with unmatched accuracy.

How does CNC machining contribute to sustainability in energy production?

CNC machining minimizes material waste and optimizes energy use. You can achieve efficient production while reducing environmental impact, supporting the shift toward sustainable energy solutions.

Note: Using CNC for renewable energy components, like wind turbines and solar panels, further enhances sustainability efforts.

See Also

Comparing CNC And Traditional Manufacturing Across Various Sectors

How CNC Processing Influences Six Key Industries Today

Understanding CNC Technology's Role In Modern Manufacturing Innovations

Discovering Seven Essential Advantages Of CNC Machining Techniques

The Transformation Of Precision Manufacturing Through CNC Machining

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com