How CNC Prototyping Allows for Faster Testing and Iteration of Product Designs

Imagine being able to test your product designs faster than ever before. That’s exactly what CNC machining offers. It powers rapid prototyping, letting you create high-precision prototypes in record time. This process reduces lead times, minimizes material waste, and supports a variety of materials. Industries like automotive, medical, and aviation rely on it to stay ahead. With the global CNC machine market projected to hit $128.86 billion by 2026, it’s clear this technology is transforming how products are developed.

Key Takeaways

CNC prototyping speeds up product creation by making exact models quickly.

It improves design accuracy, helping find mistakes early and fix them.

CNC machining saves money by using less material and simpler designs.

Understanding CNC Machining and Rapid Prototyping

What Is CNC Machining?

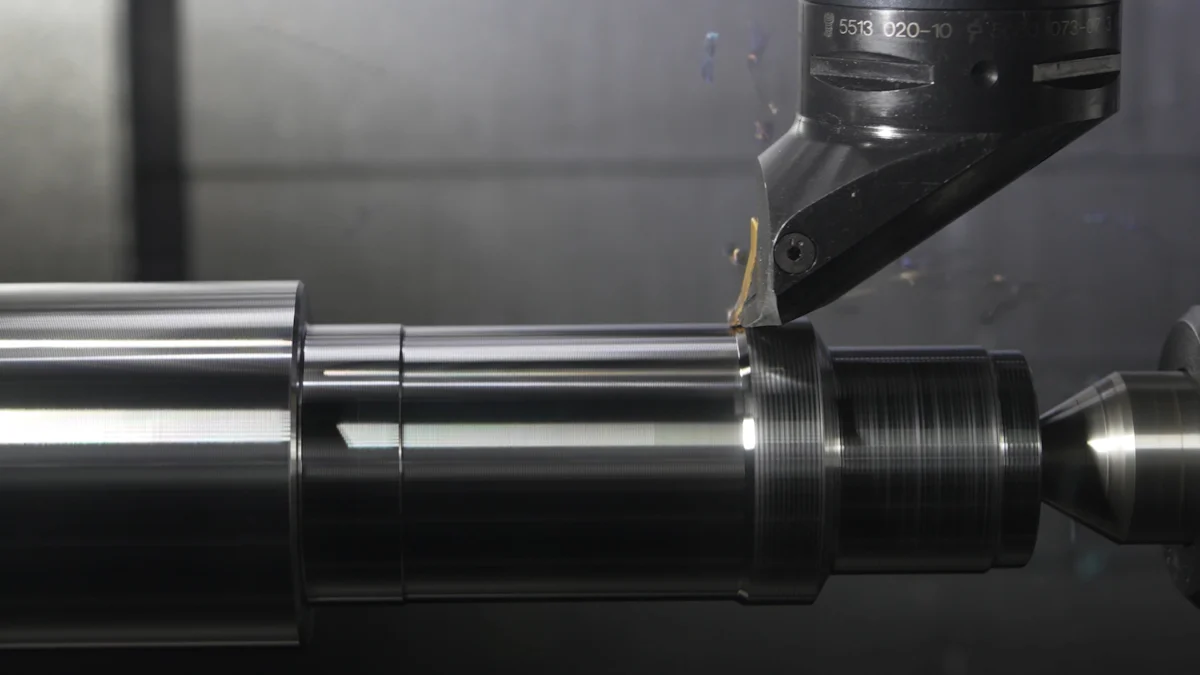

CNC machining, or Computer Numerical Control machining, is a manufacturing process where pre-programmed software controls the movement of tools and machinery. It’s like having a highly skilled craftsman who never makes mistakes. This technology excels at creating intricate and complex geometries with unmatched precision. Whether you’re working with metals, plastics, or composites, CNC machining delivers consistent results. Compared to other methods like 3D printing, CNC machining stands out for its accuracy and ability to handle a wider variety of materials. While it may take slightly longer to set up, the results are worth it.

Method | Turnaround Time |

|---|---|

CNC Machining | 5 days |

SLS (3D Printing) | Comparable |

The Role of Rapid Prototyping in Product Development

Rapid prototyping plays a critical role in product development. It allows you to bring your designs to life quickly and efficiently. By using CNC machining, you can test innovative ideas without committing to full-scale production. This process helps you avoid costly mistakes and ensures your designs meet quality standards. It’s a game-changer for industries that demand precision, like automotive and medical devices.

Why Prototyping Is Essential for Testing and Validation

Prototyping is your best friend when it comes to testing and validation. It helps you catch design flaws early and refine your product before mass production. With CNC machining, you can create prototypes that mimic the final product’s functionality and appearance. This makes it easier to gather feedback, test materials, and ensure everything works as intended. Prototypes also improve communication among stakeholders, reducing the risk of errors and delays.

Key Benefits of CNC Prototyping for Product Development

Speed and Efficiency in Prototype Production

CNC prototyping is a game-changer when it comes to speed and efficiency. You can produce functional prototypes in days instead of weeks, which keeps your product development cycles on track. For example:

Medical device companies have used CNC machining to quickly create high-fidelity prototypes of surgical tools, leading to faster FDA approvals.

Automotive manufacturers have produced over 70 components in just two weeks, reducing the risk of costly design flaws.

In consumer electronics, rapid prototyping has helped refine smartphone designs, ensuring user feedback is integrated before launch.

This speed allows you to test designs faster and make adjustments without delays, giving you a competitive edge in industries like aerospace and defense.

Precision and Accuracy in Design Iterations

CNC machining ensures unmatched precision, which is critical for design validation. It uses advanced computer programs to translate CAD files into machine instructions, achieving tolerances as tight as ±0.01 mm. This level of accuracy is perfect for creating high-fidelity prototypes that mimic the final product. Whether you’re working on intricate aerospace turbine blades or complex medical devices, CNC machining delivers consistent results. Its ability to handle complex geometries also makes it ideal for iterative design processes, where every detail matters.

Cost-Effectiveness in the Development Process

CNC prototyping saves money in several ways. By simplifying designs, you can reduce machining time and material waste. Using standardized components lowers costs while maintaining quality. For instance:

Cost-Saving Strategy | Description |

|---|---|

Economies of Scale | Bulk production spreads costs over more units, reducing the cost per part. |

Minimal Post-Processing | Simpler finishes cut down on additional expenses. |

Design Simplification | Shorter machining times lower material and labor costs. |

These strategies make CNC prototyping a cost-effective choice for creating high-quality prototypes without breaking the bank.

How CNC Prototyping Enhances the Iterative Design Process

Rapid Feedback and Design Adjustments

CNC prototyping makes it easy to gather early feedback on your designs. You can quickly produce a prototype, test it, and identify areas for improvement. This rapid feedback loop allows you to make timely adjustments, improving functionality and efficiency. CNC machining excels at handling complex geometries, so even intricate parts can be revised and tested without delays. Unlike 3D printing, CNC machining offers greater material versatility, letting you experiment with different options to find the best fit for your product development needs.

With CNC turning, you can update design programs and produce revised prototypes in no time. This flexibility ensures rapid iterations, helping you refine your designs faster. Reduced lead times also mean you can validate your prototypes sooner, keeping your project on track.

Testing and Validation of Functionality

Testing and validation are crucial for ensuring your product works as intended. CNC prototyping allows you to create high-fidelity prototypes that closely mimic the final product. This makes it easier to conduct design validation testing and production validation testing. You can test functionality under real-world conditions, ensuring your product meets performance standards.

User feedback plays a big role here. By testing prototypes early, you can gather insights and make necessary adjustments. CNC machining’s precision ensures that every iteration aligns with your design goals, reducing the risk of errors during mass production.

Accelerating Time-to-Market for Products

CNC prototyping significantly shortens the time-to-market for your products. By streamlining the manufacturing process, it eliminates unnecessary delays. You can test, validate, and optimize your designs faster, giving you a competitive edge. The efficiency of CNC machining ensures that every prototype meets your expectations, reducing the need for rework.

This approach not only speeds up testing and validation but also enhances design optimization. With faster time-to-market, you can launch products sooner and stay ahead in competitive industries like consumer electronics and medical devices.

Real-World Applications of CNC Prototyping

Automotive Industry Innovations

CNC prototyping has revolutionized the automotive industry. You can now create customized parts with unmatched precision, meeting specific customer demands effortlessly. This technology allows you to modify designs without costly tooling changes, making it ideal for innovation in car design.

Here’s how CNC machining supports automotive advancements:

It produces critical engine components like cylinder heads, pistons, and camshafts with exceptional accuracy.

High-precision gears and transmission parts benefit from its reliability.

Lightweight chassis and suspension components improve vehicle performance and stability.

Electric vehicles and advanced driver-assistance systems rely on CNC prototypes for custom parts.

By using CNC prototyping, you can test and refine designs faster, ensuring functionality and durability in every component.

Advancements in Consumer Electronics

In consumer electronics, CNC prototyping plays a key role in creating sleek, functional designs. You can quickly produce prototypes for devices like smartphones, laptops, and wearables. This lets you gather user feedback early and make necessary adjustments.

CNC machining excels at handling intricate details, so you can experiment with different materials and finishes. For example, smartphone manufacturers use CNC prototypes to refine designs and ensure functionality before mass production. This process helps you stay ahead in a competitive market by launching products that meet user expectations.

Medical Device Development and Testing

CNC prototyping has transformed medical device development. You can now accelerate testing and validation cycles, reducing time-to-market for life-saving devices. The flexibility of CNC machining allows you to create complex geometries and make quick design changes based on user feedback.

Here’s why CNC prototyping is essential in this field:

It enables the development of patient-specific devices, improving personalized care.

Prototypes comply with safety and performance standards, ensuring functionality under real-world conditions.

Material selection considers biocompatibility and sterilization compatibility, meeting regulatory requirements.

By identifying design flaws early, you can optimize devices for better patient outcomes and faster regulatory approval.

CNC machining has transformed how you design and test products. Its speed and precision let you iterate faster, reducing errors and downtime.

🚀 With CNC, you can explore complex designs, automate processes, and work with diverse materials. Emerging trends like multi-axis machining and hybrid manufacturing promise even greater innovation in the future.

This technology ensures your ideas reach the market faster and better than ever.

FAQ

What materials can you use with CNC prototyping?

You can work with metals, plastics, wood, and composites. CNC machines handle a wide range of materials, making them versatile for different industries and applications.

How does CNC prototyping compare to 3D printing?

CNC prototyping offers better precision and material variety. It’s ideal for functional prototypes, while 3D printing excels at creating complex shapes quickly with fewer material options.

💡 Tip: Use CNC prototyping when you need high accuracy or durable materials for testing.

Is CNC prototyping suitable for small businesses?

Absolutely! CNC prototyping is cost-effective and scalable. It helps small businesses test designs without committing to expensive tooling or large production runs.

See Also

Improving CNC Prototyping: Boosting Precision And Productivity

Optimizing Product Creation Through Effective Prototyping Solutions

Grasping Rapid Prototyping: Key Materials, Speed, And Standards

Excelling In CNC Machining: Precision, Prototyping, And Material Choices

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com