How CNC Machining Can Improve the Durability of Your Products

CNC machining plays a vital role in creating durable products. Its precision ensures components fit perfectly, reducing stress points that lead to wear. By using robust materials and advanced techniques, it extends the lifespan of parts, saving you from frequent replacements. Industries like automotive and aerospace rely on CNC machining to meet strict durability standards. For example, lightweight aircraft components crafted with CNC machining withstand extreme conditions while maintaining performance. The process also minimizes maintenance costs by producing parts that resist wear and tear, ensuring reliability in demanding environments.

Key Takeaways

CNC machining makes products accurate, reducing mistakes and lasting longer.

Picking good materials is important; CNC uses strong ones like titanium and steel to make items tougher.

CNC machines work automatically, lowering human mistakes and keeping quality steady.

Coatings like anodizing and electroplating protect surfaces from damage and rust, making them last longer.

CNC machining helps industries like planes and cars by making safe, strong parts that work well.

Understanding CNC Machining and Its Role in Durability

What Is CNC Machining?

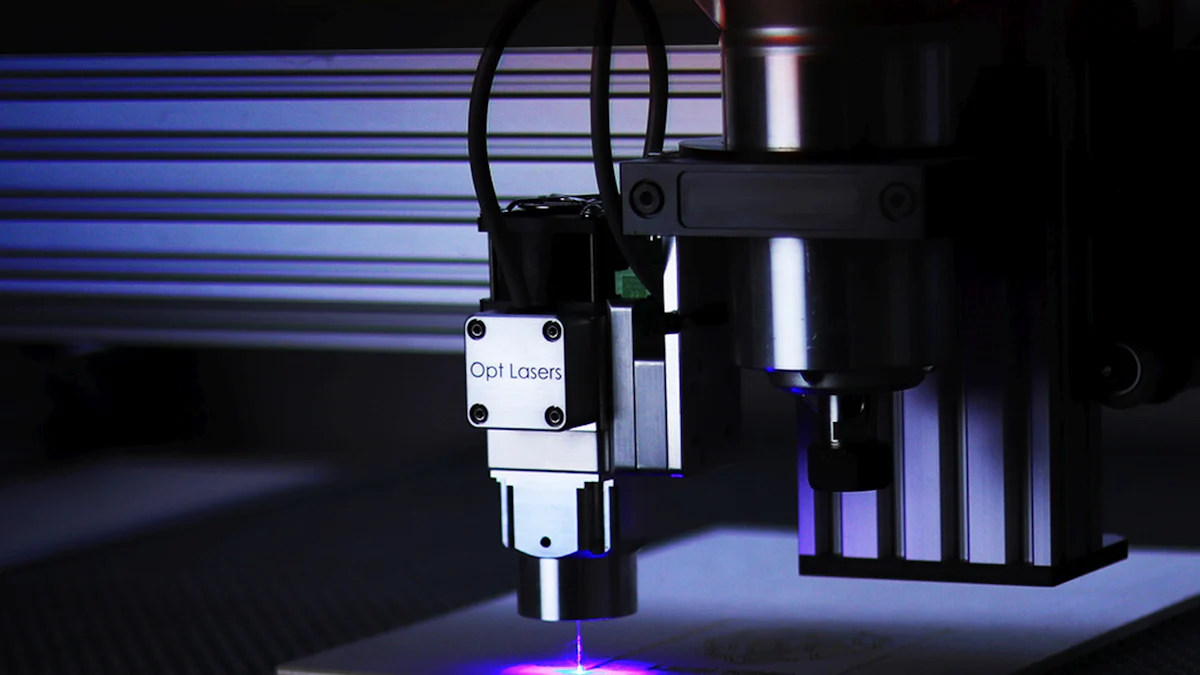

CNC machining is a manufacturing process that uses computer-controlled tools to create precise and complex parts. Unlike traditional methods, it relies on pre-programmed software to guide cutting, drilling, and shaping operations. This ensures unparalleled precision and consistency in every component produced. CNC machining services utilize advanced machinery to meet the demands of industries requiring high-quality, durable products. By crafting parts from robust materials, this process guarantees longevity and reliability. Whether you need intricate designs or tight tolerances, CNC machining delivers results that traditional methods cannot match.

The Importance of Precision in Enhancing Durability

Precision and accuracy are critical for creating durable products. CNC machining ensures parts meet exact specifications, reducing the risk of defects. Tight tolerances improve functionality and extend the lifespan of components. For example, precision manufacturing allows parts to withstand extreme temperatures and high pressures without failure. This minimizes wear and tear, saving you money on maintenance and replacements. Additionally, maintaining precision reduces waste and rework, making the process more efficient. The importance of CNC machining lies in its ability to produce reliable parts that perform consistently under demanding conditions.

How CNC Machining Supports Modern Manufacturing Needs

CNC machining addresses the diverse needs of modern industries. In aerospace, it produces lightweight turbine blades and engine parts that meet strict safety standards. Automotive manufacturers rely on CNC machining services for engine components and custom car parts. The medical field benefits from precise surgical instruments and prosthetics. Even in energy and construction, CNC machining techniques create durable hydraulic components and pipe fittings. By offering versatility and precision, CNC machining supports industries that demand high-quality, long-lasting products. Its ability to handle complex designs and high-performance materials makes it indispensable in today’s manufacturing landscape.

Key Benefits of CNC Machining for Product Durability

Precision Manufacturing for Reliable Performance

CNC machining ensures your products perform reliably by delivering unmatched precision. Every component is crafted to exact specifications, eliminating inconsistencies that could compromise durability. This precision reduces stress points, which often lead to premature wear or failure. For example, in industries like aerospace and automotive, even minor deviations can result in significant performance issues. CNC machining services allow you to produce parts that meet tight tolerances, ensuring they function as intended under demanding conditions. By relying on CNC machining, you can achieve consistent performance and extend the lifespan of your products.

Material Optimization for Enhanced Strength

The choice of material plays a critical role in the durability of your products. CNC machining allows you to optimize materials for strength and performance.

The properties required for a part depend on its intended use and environment.

Strength, toughness, and wear resistance are essential for parts exposed to high stress.

Selecting materials that balance cost, performance, and machinability enhances durability.

Materials like steel, titanium, and certain plastics are popular in CNC machining for their strength and heat resistance. By carefully selecting the right material, you can create products that withstand extreme conditions while maintaining their structural integrity. CNC machining services give you the flexibility to work with these high-performance materials, ensuring your products remain durable and reliable.

Consistent Quality Across Production Runs

CNC machining ensures consistent quality in every production run. This consistency is vital for maintaining the durability of your products.

CNC machining services use advanced machines to meet exacting standards.

Accurate records of machining processes, such as tool changes and settings, ensure traceability.

Proper documentation helps identify and correct discrepancies before production continues.

By maintaining precise control over the manufacturing process, CNC machining eliminates variations that could weaken your products. This consistency allows you to deliver high-quality components that perform reliably, regardless of the production volume. The advantages of CNC machining lie in its ability to produce durable parts with the same level of precision every time.

Minimizing Human Error in Manufacturing

Human error is one of the most common causes of defects in traditional manufacturing. Mistakes during manual processes can lead to inconsistencies, weakened components, and even product failure. CNC machining eliminates this risk by automating production with computer-controlled precision. When you rely on CNC machining, you significantly reduce the chances of errors, ensuring your products meet the highest durability standards.

Automation in CNC machining ensures every step of the manufacturing process follows exact specifications. Unlike manual methods, where fatigue or misjudgment can result in costly mistakes, CNC machines operate with consistent accuracy. This precision not only improves the quality of your products but also minimizes waste and reduces operating costs over time. The table below highlights how CNC machining contributes to error reduction and durability:

Impact of CNC Machining | Description |

|---|---|

Fewer errors | CNC automation reduces the chances of production errors to almost zero, which proves cost-effective for the manufacturer as they can avoid fatal manufacturing errors, minimize waste, and reduce operating costs in the long run. |

Ensures Quality and Accuracy | Significant improvement in the quality and accuracy of the final product, leading to fewer defects and enhanced durability. |

By minimizing human error, CNC machining ensures your products maintain consistent quality across production runs. This consistency is especially critical in industries like aerospace and automotive, where even minor flaws can compromise safety and performance. With CNC machining, you can trust that every component will meet your exact requirements, enhancing the overall reliability and lifespan of your products.

Incorporating CNC machining into your manufacturing process not only improves durability but also boosts efficiency. You save time and resources by avoiding rework and defective parts. This makes CNC machining an essential tool for producing high-quality, long-lasting products.

CNC Machining Processes That Enhance Durability

The Role of Surface Treatment in Durability

Surface treatment plays a vital role in improving the durability of CNC-machined components. It enhances the material's resistance to wear, corrosion, and environmental factors. By applying specific treatments, you can significantly extend the lifespan of your products while maintaining their performance.

Here are some common surface treatments and their benefits:

Surface Treatment | Description | Benefits |

|---|---|---|

Anodizing | Forms an oxide layer on aluminum surfaces. | Improves durability and corrosion resistance; enhances visual attractiveness and coloring options. |

Type III Hardcoat Anodizing | Produces thick, durable oxide layers. | Increases wear and corrosion resistance; ideal for industrial and military applications. |

Electroplating | Covers substrate with a metal layer. | Increases corrosion resistance and wear protection; enhances appearance. |

Black Oxide Coating | Wear-resistant finish for steel and iron. | Improves lubricity and durability; provides an appealing dark surface. |

By selecting the right surface treatment, you can optimize your product design for durability and functionality. For example, anodizing is ideal for lightweight aluminum parts, while black oxide coating works well for steel components. These treatments ensure your products withstand harsh conditions without compromising their structural integrity.

Multi-Axis Machining for Complex and Robust Designs

Multi-axis machining allows you to create intricate and durable product designs. Unlike traditional methods, this process uses advanced CNC machining equipment to handle complex geometries with precision.

Here’s how multi-axis machining enhances durability:

Reduced Setup Time: Completing complex parts in a single setup minimizes errors and speeds up production.

Complex Geometries with Precision: Multi-axis machines produce intricate shapes with high accuracy, essential for industries like aerospace and medical devices.

Improved Surface Finish and Tool Life: Optimal tool positioning reduces wear, extending tool life and improving surface finishes.

This process enables you to optimize product design by incorporating robust features that enhance strength and functionality. For example, aerospace components often require intricate shapes to reduce weight while maintaining durability. Multi-axis machining ensures these designs meet exact specifications, resulting in reliable and long-lasting products.

Heat Treatment for Improved Material Properties

Heat treatment is a critical step in CNC machining that enhances the mechanical properties of materials. By altering the microstructure, you can improve strength, hardness, and flexibility, making your products more durable.

Benefit | Description |

|---|---|

Increased Strength | Heat treatment enhances the strength of materials, allowing them to withstand higher stress levels. |

Increased Flexibility | Tempering reduces brittleness, increasing flexibility and ductility, which is crucial for many applications. |

Increased Wear Resistance | Hardened metals resist wear, making them suitable for high-stress applications like gears and tools. |

Surface Modification | Heat treatment can harden the surface while keeping the core softer, improving wear and impact resistance. |

For example, gears and cutting tools benefit from heat treatment as it increases their wear resistance. This process also allows you to tailor material properties to specific applications, ensuring your product design meets the required performance standards. By incorporating heat treatment into your CNC machining workflow, you can produce components that excel in durability and reliability.

Leveraging High-Performance Materials

The materials you choose play a crucial role in determining the durability of your products. CNC machining gives you the flexibility to work with high-performance materials that offer exceptional strength, wear resistance, and longevity. These materials ensure your components can withstand demanding environments without compromising performance.

Each material brings unique properties that make it suitable for specific applications. For example, carbon steel offers excellent machinability and becomes even stronger after heat treatment. This makes it ideal for structural components and mechanical fasteners. Titanium, on the other hand, combines a high strength-to-weight ratio with corrosion resistance, making it perfect for aerospace and biomedical applications. Stainless steel provides unmatched wear and corrosion resistance, making it a popular choice for medical equipment and marine environments. Aluminum, known for its lightweight and high machinability, is widely used in automotive and aerospace industries.

Here’s a quick overview of some commonly used high-performance materials in CNC machining:

Material | Key Properties | Applications |

|---|---|---|

Carbon Steel | Good machinability, heat treatment improves properties, cost-effective | Mechanical fasteners, structural components |

Titanium | High strength-to-weight ratio, corrosion-resistant, biocompatible | Aerospace, military, biomedical applications |

Stainless Steel | Excellent wear and corrosion resistance, strength, tough but hard to machine | Medical equipment, outdoor enclosures, marine |

Aluminum | High machinability, lightweight, corrosion-resistant, various grades available | Automotive engine parts, aerospace frames |

By leveraging these materials, you can design products that excel in both performance and durability. CNC machining allows you to precisely shape these materials, ensuring every component meets your exact specifications. This precision not only enhances the strength of your products but also reduces the risk of failure in critical applications.

When you select the right material for your project, you maximize the benefits of CNC machining. Whether you need lightweight parts for aerospace or corrosion-resistant components for marine use, high-performance materials ensure your products stand the test of time.

Real-World Applications of Durable CNC-Machined Products

Aerospace Components for Extreme Conditions

CNC machining plays a critical role in manufacturing aerospace components that endure extreme conditions. You can rely on this technology to produce parts with unmatched precision and durability. Aircraft components must withstand high stress, temperature fluctuations, and intense vibrations. CNC machining ensures these parts meet stringent safety and performance standards.

Some examples of aerospace components crafted with CNC machining include:

Landing gear components like braces and torque links.

Engine parts such as compressors, turbines, and combustion chambers.

Structural elements like fuselage sections, bulkheads, and wing spars.

Moving parts, including gears, shafts, and housings.

These high-quality components are essential for maintaining aircraft reliability and safety. For instance, turbine discs and compressor rotors require high precision to function efficiently under extreme pressure. By using CNC machining, you can create successful products designed with CNC machining that meet the rigorous demands of the aerospace industry.

Medical Devices with High Precision and Longevity

Medical devices demand exceptional accuracy and durability to ensure patient safety and effective treatment. CNC machining excels in producing these devices by adhering to precise specifications. This precision minimizes risks associated with poorly made medical tools.

Here’s how CNC machining benefits medical devices:

It ensures patient safety by reducing the likelihood of defects.

It allows for the creation of custom implants tailored to individual anatomies.

It guarantees the strength and longevity of devices used within the human body.

For example, surgical instruments and prosthetics require high precision to perform reliably. CNC machining enables you to produce these tools with the exact dimensions needed for their intended use. This process ensures that medical devices remain durable and effective, even under repeated use.

Automotive Parts for Safety and Reliability

In the automotive industry, CNC machining ensures the production of parts that prioritize safety and reliability. You can use this technology to create components that withstand operational stresses without failure.

Some automotive parts that benefit from CNC machining include:

Transmission components like gears and clutches.

Cylinder heads, which require high precision for optimal engine performance.

Starter motors, where tightly machined parts ensure consistent operation.

Drive axles, which must accurately transmit power from the engine to the wheels.

CNC machining allows you to produce high-quality components that meet the rigorous demands of automotive applications. For example, cylinder heads with complex features rely on CNC machining for their precise construction. This precision ensures your vehicle operates safely and efficiently, even under challenging conditions.

Industrial Equipment Built to Last

Industrial equipment often operates in harsh environments, facing heavy loads, high temperatures, and constant wear. You need components that can endure these challenges without frequent breakdowns. CNC machining ensures industrial equipment meets these demands by delivering precision-crafted parts designed for durability.

CNC machining creates components with exact specifications, ensuring a perfect fit and reducing stress points.

The process uses robust materials like hardened steel and titanium, which resist wear and deformation under extreme conditions.

Durable CNC-machined parts minimize the need for replacements, saving you time and maintenance costs.

For example, hydraulic cylinders used in construction machinery rely on CNC machining for their pistons and rods. These parts must withstand immense pressure without bending or cracking. CNC machining ensures they meet the required strength and tolerance levels, allowing the equipment to perform reliably over time.

You also benefit from the consistency CNC machining provides. Every part produced matches the same high-quality standard, ensuring your equipment operates smoothly. This consistency is critical for industrial applications where even minor defects can lead to costly downtime.

Surface treatments further enhance the durability of CNC-machined components. Processes like hardening or coating protect parts from corrosion and abrasion, extending their lifespan. For instance, gears in manufacturing equipment often receive heat treatment to improve wear resistance, ensuring they function efficiently for years.

By incorporating CNC machining into your manufacturing process, you ensure your industrial equipment is built to last. The precision, material strength, and advanced treatments offered by CNC machining give you reliable components that stand up to the toughest conditions. This investment in quality translates to long-term performance and reduced operational costs.

The Future of Durable Product Manufacturing with CNC Machining

Innovations in CNC Technology

Advancements in CNC technology are transforming how you approach product design and manufacturing. The integration of IoT devices into CNC machining services has revolutionized production. These devices generate vast amounts of data, enabling you to predict maintenance needs and optimize processes. By analyzing this data, you can prevent costly delays and ensure your products remain durable.

New materials also play a significant role in enhancing durability. Ceramics offer exceptional hardness and heat resistance, making them ideal for electronics and medical devices. Advanced alloys, such as titanium-aluminum mixes, provide strength and lightweight properties crucial for aerospace and automotive industries. Composites like carbon fiber-reinforced plastics deliver high strength-to-weight ratios, perfect for creating durable yet lightweight components. These innovations allow you to push the boundaries of product design while maintaining reliability.

Cost-Effectiveness and Long-Term Value

CNC machining services offer unmatched cost-effectiveness and long-term value. Automation reduces production errors, saving you money on waste and rework. Operators can manage multiple machines simultaneously, lowering per-part labor costs. CNC machines run continuously, increasing production capacity and minimizing downtime.

Precision is another key advantage. CNC machining produces parts with exact specifications, reducing defects and warranty claims. This precision also minimizes material waste, lowering raw material costs. By optimizing cutting paths and improving cycle times, you can achieve better resource utilization. These benefits make CNC machining services an excellent investment for creating durable products while controlling costs.

Sustainability Through Waste Reduction

Sustainability is becoming a priority in manufacturing, and CNC machining supports this goal through waste reduction. Lean manufacturing principles align production with demand, reducing material usage and energy consumption. Sustainable materials and renewable energy sources further minimize environmental impact.

Efficient material usage is another strategy you can adopt. Reusing materials and implementing closed-loop systems reduce waste significantly. Process optimization, powered by advanced software, enhances productivity and reduces downtime. By incorporating these practices, CNC machining services help you create durable products while promoting environmental responsibility.

CNC machining stands as a cornerstone of durable product manufacturing. Its precision-driven processes, like material optimization and surface treatment, ensure your products achieve exceptional longevity. By investing in CNC machining, you gain access to high-performance components that reduce maintenance costs and extend product lifespan. This technology also provides a competitive edge through scalability, faster production, and lower operational costs. Whether you aim to enhance product quality or meet sustainability goals, CNC machining empowers you to deliver reliable, long-lasting solutions that excel in demanding conditions.

FAQ

What industries benefit the most from CNC machining?

CNC machining supports industries like aerospace, automotive, medical, and construction. You can use it to create durable, high-precision components for demanding applications. Its versatility also makes it ideal for custom parts in electronics, energy, and consumer goods manufacturing.

How does CNC machining improve product durability?

CNC machining enhances durability by ensuring precision, material optimization, and consistent quality. You can rely on its processes, like heat treatment and surface finishing, to strengthen materials and protect components from wear, corrosion, and environmental damage.

Can CNC machining handle custom designs?

Yes, CNC machining excels at producing custom designs. You can create intricate geometries and complex shapes with multi-axis machining. This flexibility allows you to meet unique specifications while maintaining high precision and durability.

Is CNC machining cost-effective for small production runs?

CNC machining is cost-effective for small runs due to its precision and automation. You save money by reducing waste and rework. Additionally, the ability to produce consistent, high-quality parts ensures long-term value for your investment.

What materials work best with CNC machining?

CNC machining supports a wide range of materials, including metals like aluminum, titanium, and stainless steel, as well as plastics. You can choose materials based on your product’s requirements, such as strength, heat resistance, or corrosion resistance.

Tip: Consult with your CNC machining provider to select the best material for your application.

See Also

Streamlined CNC Machining Solutions For Accurate Production

The Impact Of CNC Machining On Precision Manufacturing

Achieving Excellence In CNC Machining For Precision Parts

Investigating CNC Machining Options For Precision Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com