How CNC Machining Played a Crucial Role in the Development of a Robotics System

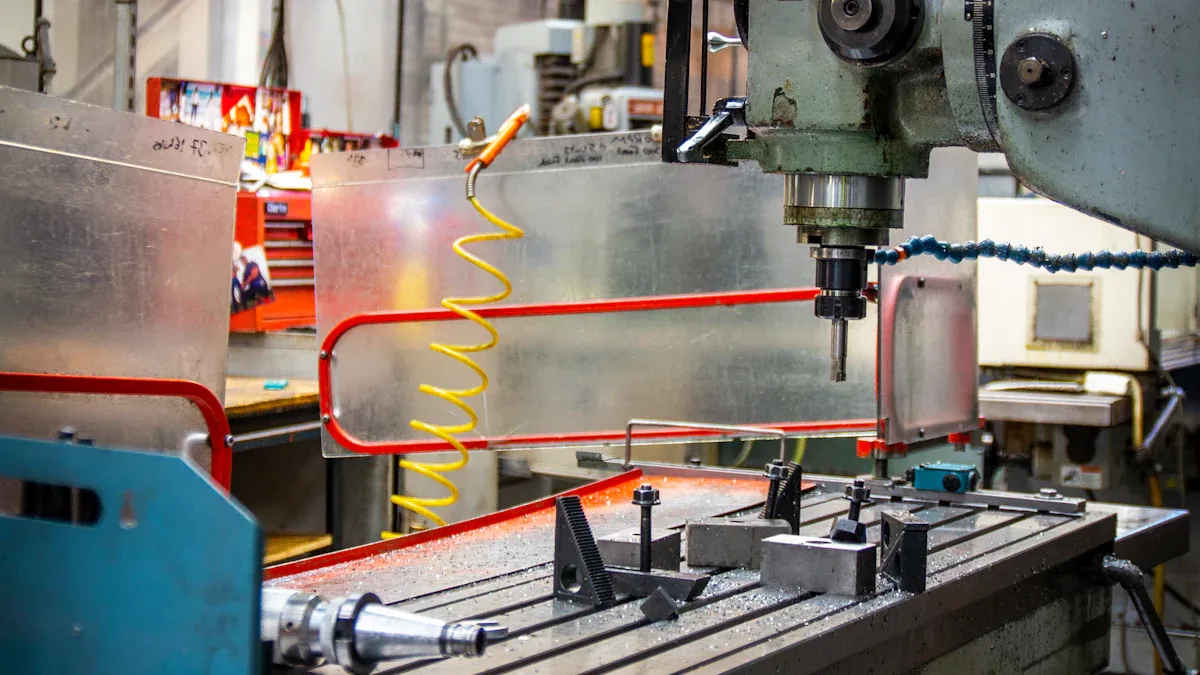

CNC machining has transformed how you approach robotics manufacturing. It enables the creation of intricate parts with unmatched precision. For example, CNC machines produce automotive prototypes and aerospace components with high accuracy. By automating repetitive tasks, CNC robotics boosts efficiency, reduces material waste, and ensures continuous operation, making it indispensable in modern manufacturing.

Key Takeaways

CNC machining makes robot parts very accurate, with errors as small as ±0.0002 inches for dependable parts.

Using CNC automation lowers mistakes made by people and speeds up production, making parts faster and more uniform.

Adding AI to CNC machines improves work by making tasks better and spotting repair needs early, keeping production steady.

CNC Machining and Its Role in Robotics

What Is CNC Machining?

CNC machining, or Computer Numerical Control machining, is a manufacturing process where pre-programmed software controls the movement of tools and machinery. This technology allows you to create parts with exceptional precision and repeatability. Unlike traditional machining, CNC eliminates the need for manual operation, ensuring consistent results. You can use CNC to cut, drill, mill, or shape materials into complex geometries that meet exact specifications.

The process works by converting digital designs into machine instructions. These instructions guide the tools to perform precise operations on materials like metals, plastics, or composites. For example, aluminum and stainless steel are commonly used in robotics due to their strength and corrosion resistance. CNC machining's ability to handle diverse materials makes it ideal for producing robotic components.

The Importance of CNC in Robotics Development

CNC machining plays a vital role in advancing robotics. It ensures that every component of a robot meets strict tolerances, enabling smooth movement and reliable performance. Precision is critical in robotics, as even minor deviations can disrupt functionality. CNC machining excels in creating intricate parts, such as gears and joints, that are essential for robotic systems.

Efficiency is another key advantage. CNC machines operate at high speeds, allowing you to produce large quantities of parts quickly. This capability supports the growing demand for robotics in industries like manufacturing and healthcare. Additionally, CNC machining's versatility lets you create components with complex geometries, which are often required for advanced robotic designs.

Modern CNC systems also integrate seamlessly with robotics. Features like predictive maintenance and real-time feedback enhance operational efficiency. By automating repetitive tasks, CNC machining reduces human error and accelerates production cycles. This integration ensures that robotics systems remain reliable and scalable, meeting the needs of modern industries.

Key Benefits of CNC Machining in Robotics

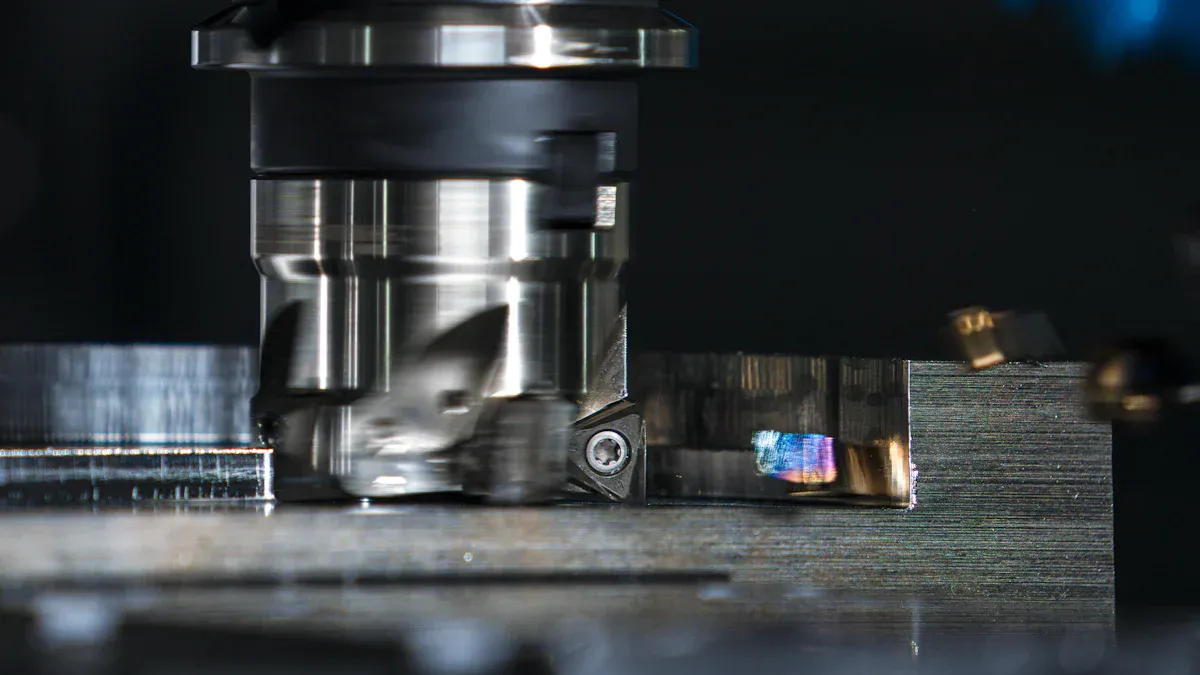

Precision and Accuracy in Robotics Manufacturing

CNC machining ensures enhanced precision and accuracy in robotics manufacturing, which is critical for creating reliable components. You can achieve tolerances as tight as ±0.0002 inches, ensuring consistent quality and performance. This level of dimensional accuracy minimizes errors and guarantees that robotic parts meet exact specifications. Additionally, CNC systems produce components with a superior surface finish, reducing friction and wear over time.

Feature | Description |

|---|---|

Dimensional Accuracy | Achieves tolerances as tight as ±0.0002 inches, ensuring consistent quality and performance. |

High Precision Machining | Programmed to achieve accuracy within ±1 mm, minimizing errors and ensuring precise specifications. |

Superior Surface Finish | Produces components with a surface roughness of 0.8 μm RA or lower, reducing friction and wear. |

This precision allows you to create intricate parts like gears, actuators, and sensors, which are essential for smooth robotic operations.

Efficiency and Scalability in Production

CNC robotics enhances efficiency by automating repetitive tasks and reducing human error. You can produce large quantities of parts quickly, meeting tight deadlines without compromising quality. CNC systems also support scalability, allowing you to increase production volumes as demand grows.

The integration of CNC machining with robotics enables continuous operation, maximizing output and minimizing downtime. Automation features, such as material handling and tool changes, further streamline the production process. This successful implementation of CNC robotics ensures that you can meet industry demands while maintaining high standards of accuracy and reliability.

Cost-Effectiveness and Material Optimization

CNC machining optimizes material usage, reducing waste and lowering costs. By maximizing raw material utilization and minimizing off-cuts, you can significantly decrease production expenses. CNC robotics also reduces the need for rework, saving time and resources.

CNC robotics maximizes the use of raw materials by optimizing machining parameters and tool usage.

Efficient material utilization minimizes off-cuts and scrap, reducing waste and lowering material costs.

Consistency and precision reduce the need for rework, enhancing production efficiency.

Additionally, automation through CNC machining lowers labor costs. A single operator can manage multiple machines, further improving cost efficiency. Over time, the benefits of CNC robotics, such as reduced errors and extended equipment lifespan, lead to substantial long-term savings.

Technological Advancements in CNC Robotics and Automation

AI Integration and Smart Manufacturing

AI has transformed CNC robotics and automation by enhancing efficiency and precision. You can now rely on AI to optimize tool paths and predict wear and tear in real-time. This capability ensures consistent results and reduces downtime. AI also analyzes performance data, helping you fine-tune machine operations for better productivity.

In smart manufacturing, AI integration allows CNC systems to adapt to changing production needs. For example, AI-powered systems can predict maintenance requirements, preventing unexpected breakdowns. This proactive approach extends the lifespan of automated CNC equipment and minimizes disruptions. By incorporating AI, you can achieve higher production capacity and maintain consistent quality in robotics manufacturing.

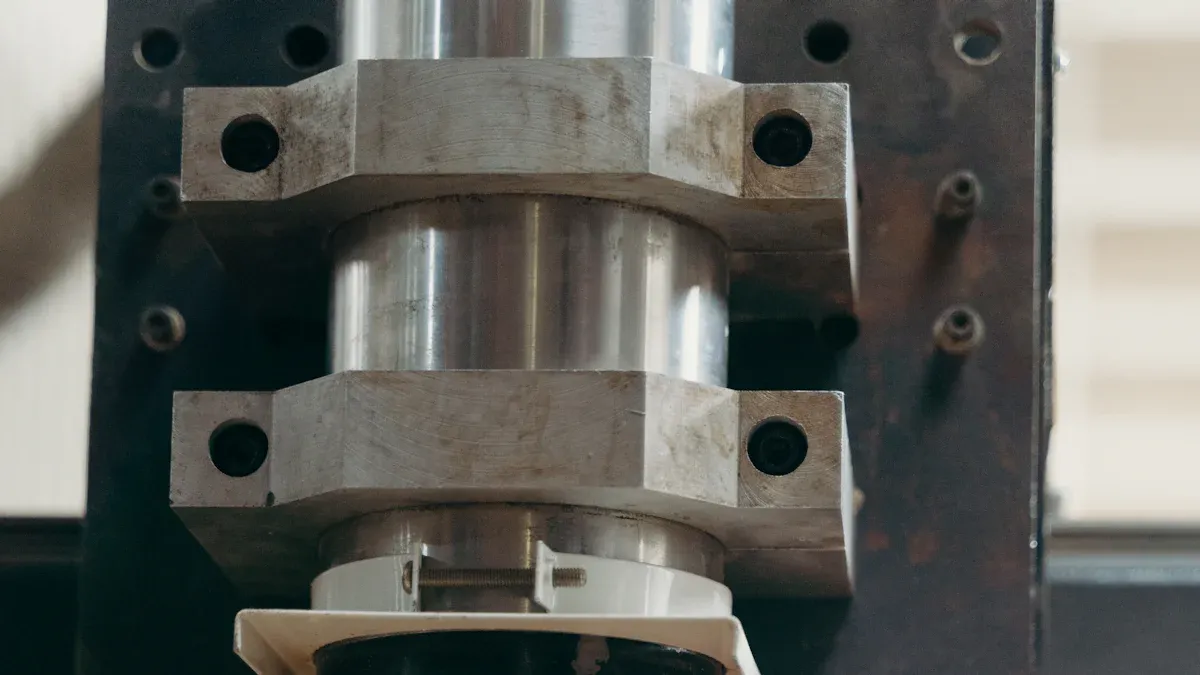

Advanced Tooling and Multi-Axis Machining

Modern advancements in tooling and multi-axis machining have revolutionized CNC robotics. Multi-axis machining centers, such as 5-axis and 6-axis systems, enable you to produce intricate parts with fewer setups. This flexibility improves accuracy and reduces waste, which is essential for robotics systems requiring complex geometries.

Advancement Type | Description |

|---|---|

Multi-axis machining centers | Enable production of complex parts with high precision through 5-axis and 6-axis capabilities. |

Robotic arms for material handling | Automate tool changes and material handling, increasing production speed and consistency. |

Integration with additive manufacturing | Combines precision machining with flexibility of 3D printing, reducing waste and speeding up development. |

These advancements also include hybrid machines that combine CNC machining with additive manufacturing. This combination allows you to create components with intricate designs while optimizing material usage. Predictive maintenance tools, powered by IoT sensors, further enhance the reliability of CNC robotics and automation.

Automation and Reduced Human Error

Automation in CNC robotics minimizes human error and boosts production efficiency. Robots handle repetitive tasks like material loading and tool changes, ensuring consistent results. Automated CNC equipment operates faster and more reliably than manual processes, reducing downtime and increasing output.

You can also benefit from enhanced precision through automation. High-resolution sensors and robotic arms ensure dimensional accuracy, which is critical for robotics systems. By automating these processes, you can achieve higher production rates while maintaining strict quality standards. This level of automation not only improves efficiency but also reduces the need for manual intervention, making CNC robotics and automation a cornerstone of modern manufacturing.

Applications of CNC Machining in Robotics

Industrial Robotics and Manufacturing

CNC machining has become a cornerstone in industrial robotics, transforming manufacturing processes and enabling increased productivity and efficiency. You can see its applications in various industries, where it supports tasks requiring precision and consistency. For example:

Assembly: CNC robots assist in assembling parts with unmatched accuracy.

Machine Tending: They load and unload CNC machines, optimizing workflows.

Quality Inspection: Robots perform detailed inspections, ensuring enhanced quality in machined parts.

Polishing and Finishing: They handle delicate finishing tasks, such as grinding or buffing.

Material Handling: CNC robots move heavy materials into position, reducing manual labor.

These applications demonstrate how CNC machining is transforming manufacturing by automating repetitive tasks and ensuring consistent results. The integration of robot CNC routers further enhances production speed and reliability.

Medical Robotics and Precision Engineering

In medical robotics, CNC machining plays a vital role in creating components that demand extreme precision. This technology allows you to fabricate intricate parts for robotic surgery, improving patient outcomes. Key applications include:

Producing surgical instruments with smooth finishes and exact tolerances.

Customizing medical devices to meet the unique needs of patients.

Ensuring compliance with stringent quality standards for safety and effectiveness.

By leveraging CNC machining, you can achieve enhanced quality in medical robotics, which is essential for precision engineering and personalized treatments.

Innovations in Autonomous Systems

CNC machining drives innovations in autonomous systems by enabling the production of high-precision components. You can rely on CNC to create parts like robot arms, gears, and sensors, which are critical for seamless operation. Some notable applications include:

End Effectors: Precisely machined tools that interact with the environment.

Chassis and Frames: Strong, lightweight structures that support autonomous robots.

Controllers and Sensors: Complex parts that ensure accurate functionality.

These advancements highlight how CNC machining supports the development of lightweight robotics systems, ensuring increased productivity and efficiency in autonomous applications.

CNC machining has revolutionized robotics by delivering precision, efficiency, and adaptability. Industries like aerospace and automotive rely on CNC for complex designs and continuous operation. Emerging trends, such as AI integration and collaborative robots, promise even greater advancements. By embracing these innovations, you can shape the future of robotics and automation with confidence.

🚀 The future of CNC robotics is bright, with AI and IoT driving unprecedented efficiency and adaptability.

FAQ

What makes CNC machining essential for robotic machining?

CNC machining ensures unmatched precision and consistency. It allows you to create intricate parts required for robotic machining, improving functionality and reliability in advanced systems.

How does CNC machining improve productivity in robotics manufacturing?

CNC machining automates repetitive tasks, reduces errors, and speeds up production. This boosts productivity while maintaining high-quality standards, making it ideal for robotics manufacturing.

Can CNC machining integrate with existing systems in robotics?

Yes, CNC machining integrates seamlessly with existing systems. It enhances efficiency and ensures compatibility, allowing you to scale operations without disrupting workflows.

See Also

Exploring CNC Technology's Role in Modern Manufacturing Innovations

The Impact of CNC Machining on Precision Manufacturing Excellence

Key Processes Involved in CNC Precision Machining Explained

Why Precision CNC Machining Is Crucial for Manufacturing Success

Fundamentals of CNC Machining for Component and Part Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com