How CNC Services Are Incorporating IoT for Enhanced Process Monitoring

The rise of IoT has revolutionized CNC machining, enabling smarter and faster operations. You can now monitor machine performance in real time, reducing downtime and boosting productivity. With IoT-driven systems, CNC machines connect seamlessly, exchange data, and optimize processes. Experts project the CNC market to grow to $140.7 billion by 2029.

Key Takeaways

IoT helps watch CNC machines in real-time. This allows quick fixes, making work faster and stopping delays.

IoT uses predictive maintenance to stop surprise machine problems by 30%. This keeps work smooth and cuts repair costs.

Adding IoT to CNC systems improves automation and accuracy. This makes work better and products the same every time.

IoT and Its Role in CNC Machining

What Is IoT in CNC Machining

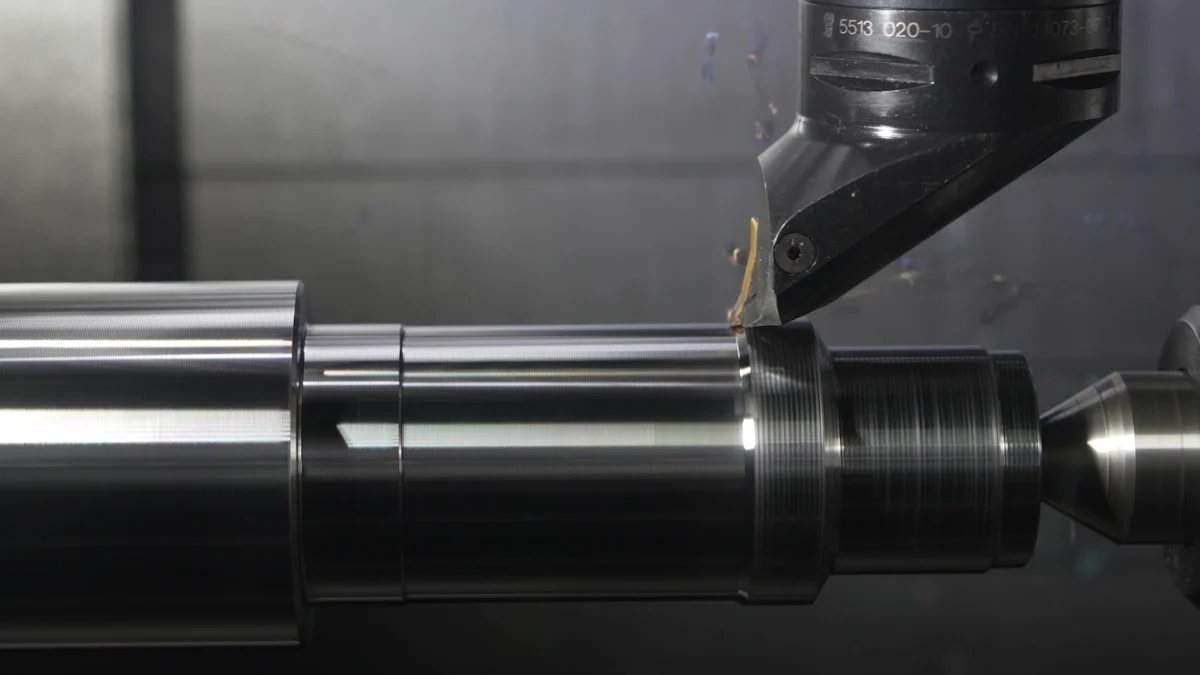

The Internet of Things (IoT) in CNC machining connects machines, devices, and systems to enable seamless communication and data exchange. This integration allows you to monitor and control CNC machines remotely, ensuring real-time oversight of operations. IoT enhances CNC processes by enabling features like predictive maintenance, remote operation, and precision automation. These capabilities streamline manufacturing, reduce downtime, and improve safety on the shop floor.

IoT also brings flexibility to CNC machining. You can customize production processes to meet specific market demands. By leveraging IoT, CNC systems become smarter and more efficient, adapting to the dynamic needs of modern manufacturing.

How IoT Enhances Smart Manufacturing

IoT plays a pivotal role in advancing smart manufacturing. It enables real-time monitoring, allowing you to make immediate adjustments to production activities. Predictive maintenance, powered by IoT, forecasts machine failures and minimizes unexpected downtime. Remote operation capabilities give you the flexibility to manage CNC machines from anywhere.

With IoT, automation reaches new heights. Machines operate with enhanced precision, reducing the need for human intervention. This not only improves efficiency but also ensures consistent quality in production. IoT-driven CNC systems empower you to optimize processes, reduce costs, and achieve higher productivity.

Key Technologies Driving IoT in CNC Systems

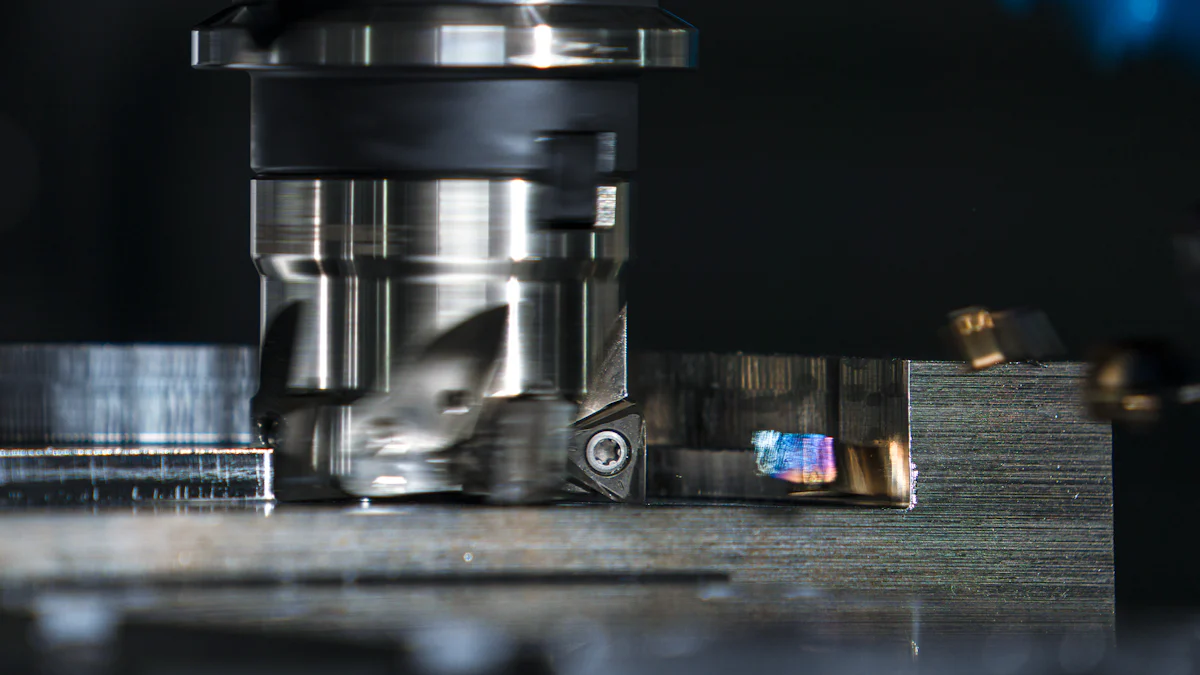

Several technologies enable IoT in CNC systems. Sensors and actuators collect real-time data and adjust operations as needed. Data analytics platforms process this data, helping you make informed decisions. Network connections ensure seamless communication between devices, while user interfaces allow you to interact with IoT-enhanced CNC machines efficiently.

These technologies work together to deliver features like real-time monitoring, predictive maintenance, and enhanced automation. By integrating IoT, CNC systems become more agile, reliable, and capable of meeting the demands of smart manufacturing.

Benefits of IoT for Real-Time Data Monitoring

Real-Time Machine Performance Tracking

IoT enables you to track machine performance in real time, providing instant insights into operational status. This capability saves time and money by allowing you to monitor all machines simultaneously. You can build a performance-driven culture that boosts productivity and profitability. Real-time monitoring also improves production quality and reduces costs by predicting failures before they occur.

Key benefits of real-time tracking include:

Generating actionable data for better decision-making.

Identifying areas for maintenance improvement.

Benchmarking production rates to ensure efficiency.

By leveraging IoT, you can validate existing processes or pinpoint those needing improvement. This approach ensures maximum uptime and consistent output quality.

Predictive Maintenance and Downtime Reduction

Predictive maintenance, powered by IoT, anticipates machine failures before they disrupt operations. This proactive strategy minimizes unplanned downtime by up to 30%, as reported by PTC. It allows technicians to address potential issues early, preventing costly breakdowns. Factories using predictive maintenance have seen a 40% reduction in unexpected failures, leading to increased operational time.

By adopting IoT-driven predictive maintenance, you can maintain operational efficiency and strengthen customer relationships. This approach ensures your CNC machining processes remain reliable and uninterrupted.

Data-Driven Process Optimization

IoT facilitates data-driven decision-making by collecting and analyzing real-time data during production. For example, LeClaire Manufacturing implemented machine monitoring, which increased vertical CNC utilization rates by 38 percentage points and generated millions in revenue.

"Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during, and immediately after machining — and a means to act on that data in real time."

IoT systems, equipped with sensors, enable you to optimize processes by reducing variability and improving consistency. This ensures higher productivity and better resource utilization.

Improved Efficiency in CNC Machining

IoT enhances automation in CNC machining, allowing machines to operate with minimal human intervention. Sensors and real-time data monitoring ensure precise adjustments during production. This reduces errors and improves overall efficiency. By integrating IoT, you can streamline workflows, reduce waste, and achieve consistent results.

The Internet of Things transforms CNC machining into a smarter, more efficient process. It empowers you to meet production goals while maintaining high-quality standards.

Real-World Applications of IoT in CNC Machining

Case Studies of IoT-Enabled CNC Systems

IoT has transformed CNC machining by enabling smarter operations and better decision-making. For example, factories using IoT-driven systems have reported significant improvements in machine utilization and efficiency. Real-time data monitoring allows you to make immediate adjustments, ensuring smoother workflows. Predictive maintenance, another common use case, helps forecast potential machine failures, reducing downtime and maintenance costs. Enhanced precision and automation further improve operational accuracy, allowing CNC machines to deliver consistent results.

By integrating IoT, manufacturers have shifted from reactive to proactive strategies. This shift has led to higher productivity and reduced operational costs. These real-world examples highlight how IoT empowers you to optimize CNC machining processes and achieve better outcomes.

IoT Sensors and Devices in CNC Machines

IoT relies on various sensors and devices to collect and analyze data in CNC machines. Commonly used sensors include:

Vision and imaging sensors

Temperature sensors

Proximity sensors

Pressure sensors

Position sensors

Photoelectric sensors

These sensors provide real-time insights into machine performance. For instance, temperature sensors monitor operational heat levels, while position sensors ensure precise movements during machining. By leveraging these devices, you can enhance automation and improve the overall efficiency of your CNC systems.

Enhancing Quality Control with IoT

IoT plays a crucial role in improving quality control in CNC machining. Real-time monitoring collects data points like operational temperatures and vibration patterns. This data allows you to make immediate adjustments, reducing errors and ensuring consistent product quality. Predictive maintenance also enhances quality control by forecasting when machine parts may fail. This proactive approach minimizes unexpected downtime and keeps production running smoothly.

Additionally, IoT enables continuous feedback to CNC machines, allowing them to self-regulate for optimal performance. This automation reduces human intervention and ensures higher precision. By incorporating IoT, you can maintain strict quality standards while boosting productivity.

Challenges in Implementing IoT in CNC Services

Cost and Investment Barriers

Adopting IoT in CNC machining often requires significant financial investment. Upgrading existing systems, purchasing IoT-enabled devices, and implementing new software can strain budgets. Small and medium-sized manufacturers may find these costs particularly challenging. Additionally, ongoing expenses like maintenance, software updates, and data storage add to the financial burden. To overcome this, you should assess your current capabilities and prioritize IoT technologies that align with your business goals. Collaborating with experienced partners can also help optimize costs while ensuring a smooth transition.

Data Security and Privacy Issues

IoT introduces new vulnerabilities to CNC machining environments. Increased connectivity exposes machines to potential cyber threats. Common risks include:

Unauthorized access through networked IT environments.

Exploitation of legacy software with inadequate security measures.

Remote code execution leading to data leaks or intellectual property theft.

Manipulation of machine parameters, causing safety hazards.

To mitigate these risks, you should implement robust authentication protocols, encrypt data exchanges, and conduct regular security audits. Deploying firewalls and intrusion prevention systems further strengthens your defenses.

Integration with Legacy CNC Systems

Integrating IoT with older CNC systems can be complex. Legacy machines often lack the compatibility needed for seamless IoT adoption. To address this, you should:

Assess your current CNC systems and define clear IoT objectives.

Select IoT devices and software that can integrate with existing equipment.

Continuously monitor and maintain the system to ensure optimal performance.

This approach allows you to modernize your operations without replacing all your equipment, saving time and resources.

Workforce Training and Skill Development

IoT adoption requires a skilled workforce capable of operating advanced machines and analyzing data. Training programs are essential to bridge this skill gap. As a manufacturer, you must invest in educating your employees to maximize the benefits of IoT.

"Companies must commit to training their employees, not only to operate these advanced machines but also to analyze and act on the data they provide."

By equipping your team with the right skills, you can ensure a smoother transition to IoT-driven automation and maintain a competitive edge in the industry.

The Future of IoT in Smart Manufacturing

Emerging Trends in IoT and CNC Integration

The integration of IoT into CNC systems is evolving rapidly, bringing exciting trends to the forefront. You can expect to see advanced machine learning and artificial intelligence (AI) enabling CNC machines to make complex decisions autonomously. These technologies will enhance automation and improve manufacturing processes. Augmented reality (AR) is another emerging trend. It can assist technicians with machine maintenance and training, boosting efficiency and reducing errors.

The development of self-diagnosing and self-repairing machine components is also gaining traction. These innovations push predictive maintenance to new heights, ensuring smoother operations. Additionally, the adoption of 5G technology will revolutionize machine-to-machine communication. Faster and more reliable connections will make manufacturing systems more responsive and flexible.

AI and Machine Learning in IoT-Driven CNC Systems

AI and machine learning are transforming IoT-driven CNC systems. Real-time monitoring, enabled by IoT, gives you greater control over manufacturing processes. Machine learning algorithms analyze operational data to optimize tool paths and improve quality control. This reduces setup times and minimizes human error.

Predictive maintenance is another area where AI excels. By analyzing data trends, machine learning can forecast potential faults before they occur. This reduces unexpected downtime and ensures consistent production. Over time, these systems learn from historical data, continuously improving the accuracy of fault predictions.

Long-Term Impact on the Manufacturing Industry

IoT is set to reshape the manufacturing industry in the long term. According to McKinsey, IoT applications could generate an economic impact of $1.2 to $3.7 trillion annually by 2025. This highlights the potential for significant efficiency and productivity gains. Predictive maintenance, powered by IoT, can reduce equipment breakdowns by 70% and lower maintenance costs by 25%, as noted by Deloitte.

Sustainability is another key benefit. For instance, Armal, a manufacturer of portable toilets, used IoT to monitor their production line in real time. This reduced their energy costs by nearly 40%. With the smart manufacturing market projected to grow at a compound annual growth rate (CAGR) of 14.9% from 2023 to 2030, IoT will continue driving innovation and growth in the industry.

IoT is revolutionizing cnc machining by enabling smarter, more efficient, and data-driven process monitoring. Its integration offers transformative benefits, including:

Benefit | Description |

|---|---|

Increased Productivity and Efficiency | IoT-driven CNC machines streamline the manufacturing process, leading to a significant uptick in productivity. |

Reduction in Downtime and Operational Costs | IoT-enabled predictive maintenance ensures that CNC machines are serviced before breakdowns occur, dramatically reducing unplanned downtime. |

Improved Safety and Working Conditions | IoT systems can detect potential safety hazards and trigger alerts before they pose a risk to workers. |

Customization and Flexibility in Manufacturing | IoT-equipped CNC machines can quickly adjust to new specifications and designs, allowing for a wider range of customized products. |

While challenges like cost and security remain, IoT continues to drive innovation. It enables real-time data collection, enhances productivity, and optimizes supply chain operations. As IoT technologies evolve, they will shape the future of smart manufacturing, offering immense potential for growth and sustainability.

FAQ

What is the main advantage of using IoT in CNC machining?

IoT improves efficiency by enabling real-time monitoring and predictive maintenance. This reduces downtime, enhances productivity, and ensures consistent quality in manufacturing processes.

How do IoT sensors improve CNC machine performance?

IoT sensors collect real-time data, such as temperature and vibration levels. This data helps you optimize machine operations, prevent failures, and maintain precision during production.

Is IoT integration in CNC systems expensive?

Initial costs can be high, especially for small businesses. However, IoT reduces long-term expenses by minimizing downtime, improving efficiency, and lowering maintenance costs.

Tip: Start small by integrating IoT into critical machines to manage costs effectively.

See Also

Discovering Digital Manufacturing Through CNC Processing Innovations

A Glimpse at Cutting-Edge Technology in CNC Facilities

Exploring CNC Technology's Role in Modern Manufacturing Advances

Understanding CNC Machining Services for Accurate Production Needs

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com