CNC Machining for Jewelry and Artistic Creations

CNC machining has revolutionized how you create fine jewelry and artistic designs. It uses automated software to achieve precise cuts and measurements, ensuring unmatched accuracy. Unlike traditional methods, which rely on manual labor and can introduce errors, CNC minimizes inconsistencies and enhances quality. Artisan jewelers now use CNC to craft intricate patterns with tolerances as tight as ±0.001 inches. This technology also reduces material waste, making it more sustainable. With its ability to work continuously and produce identical pieces efficiently, CNC machining empowers you to push the boundaries of creativity and craftsmanship.

Key Takeaways

CNC machining helps make jewelry with precise and detailed designs.

It makes production faster, saving time and reducing wasted materials.

These machines let you customize designs to match personal preferences.

You can use CNC machines with many materials for creative projects.

Using CNC technology reduces waste and uses materials more efficiently.

What is CNC Machining?

Overview of CNC Machining

CNC machining is a process that uses computer-controlled machines to create precise and intricate designs. It automates the operation of tools like lathes, mills, routers, and grinders. You start by designing a digital model using CAD (Computer-Aided Design) software. This model is then converted into G-code, which acts as instructions for the machine. Once the machine is set up, it follows these commands to shape the material into the desired form.

The process relies on three main components: the computer system, the machine tool, and the cutting tool. Each part works together to ensure accuracy and efficiency. CNC machining stands out because it reduces human error, increases productivity, and works with a variety of materials. Whether you're crafting jewelry or creating art, this technology ensures your designs are executed with precision.

How CNC Machining Enhances Jewelry Making

CNC machining has transformed jewelry manufacturing by enabling you to create intricate and detailed designs that are hard to achieve manually. The precision of CNC machines ensures that every detail is executed perfectly, even for complex patterns. For example, you can craft delicate filigree or engrave tiny text with ease.

This technology also speeds up production. Instead of spending hours carving or shaping by hand, CNC machines complete tasks in a fraction of the time. This efficiency allows you to focus on creativity and innovation. Additionally, CNC machining minimizes material waste, making it a more sustainable choice for jewelry manufacturing.

Importance of CNC in Artistic Creations

For artists, CNC machining opens up new possibilities. It allows you to sculpt materials with exceptional precision, ensuring that even the most complex designs are achievable. Traditional carving methods often lead to variations or inaccuracies, but CNC technology eliminates these issues.

You can use CNC machines to create sculptures with intricate geometries or engrave detailed patterns on various surfaces. This versatility makes CNC machining an invaluable tool for artistic creations. Whether you're working with metal, wood, or other materials, CNC helps you bring your vision to life with unmatched accuracy.

Types of CNC Machines for Jewelry Manufacturing

CNC Milling Machines for Jewelry

CNC milling machines are essential tools for jewelry manufacturing. These machines excel at creating intricate designs and handling metals with precision. You can use them to carve wax for lost-wax casting or to produce master models for consistent mass production. Smaller CNC mills are particularly effective for sectioning metals and crafting detailed components.

Unlike other CNC machines, milling machines can perform grinding and finishing operations. This capability ensures that your jewelry pieces have smooth surfaces and refined details. Whether you are working on delicate filigree or bold geometric designs, CNC milling machines provide the accuracy and versatility you need to bring your ideas to life.

CNC Routers for Artistic Designs

CNC routers are ideal for carving molds and creating artistic designs from softer materials like wax, wood, and acrylics. These machines allow you to experiment with different materials and textures, making them perfect for prototyping or crafting unique jewelry pieces. A CNC router machine can also cut intricate patterns into softer materials, giving you the freedom to explore creative possibilities.

If you want to create molds for wax modeling, CNC routers offer precision and efficiency. They ensure that your molds are free from defects, which is crucial for high-quality jewelry production. By using a CNC router, you can achieve consistent results and reduce the time spent on manual adjustments.

CNC Engraving Machines for Intricate Patterns

CNC engraving machines are designed to add fine details and patterns to jewelry. These machines eliminate human error and provide unparalleled precision, making them perfect for engraving wedding bands or adding intricate textures to pendants. You can use a CNC engraving machine to create designs that would be nearly impossible to achieve by hand.

These machines save time while allowing you to produce complex patterns with ease. They also minimize material waste, ensuring that your production process is both efficient and sustainable. Whether you are engraving text, symbols, or decorative motifs, CNC engraving machines help you achieve flawless results every time.

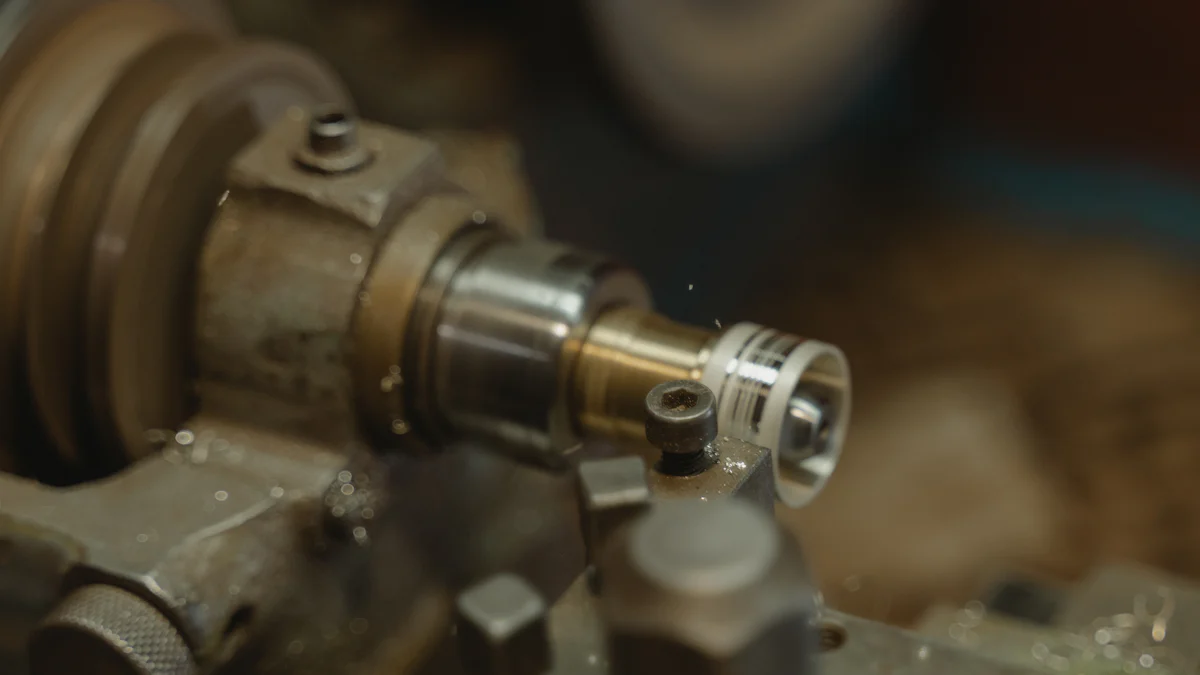

CNC Lathes for Jewelry and Art

A CNC lathe is a powerful tool for crafting unique jewelry and art pieces. It rotates the material while cutting tools shape it into precise designs. This process ensures exceptional accuracy, making it ideal for creating symmetrical components like rings, bracelets, and cylindrical art forms.

You can rely on CNC lathes to achieve intricate detailing. These machines excel at executing complex designs with remarkable precision, which is essential for elaborate jewelry pieces. They also provide unmatched consistency, allowing you to replicate intricate patterns with minimal variation. This consistency ensures high-quality results, even for mass production.

The versatility of CNC lathes enables you to explore innovative designs that traditional methods cannot achieve. For example, you can create detailed grooves, textures, or even hollowed-out sections with ease. This capability pushes the boundaries of traditional jewelry-making techniques, giving you the freedom to experiment with new ideas.

Additionally, CNC lathes offer excellent customization options. You can modify your designs to meet specific customer preferences, resulting in unique, personalized jewelry. Whether you are crafting a one-of-a-kind engagement ring or a decorative art piece, a CNC lathe ensures meticulous attention to detail and unmatched craftsmanship.

Specialized CNC Machines for Jewelry Design Precision

Specialized CNC machines take jewelry design precision to the next level. These machines are engineered to handle the intricate demands of modern jewelry manufacturing. They eliminate human error, ensuring that every piece meets the highest standards of accuracy.

With these machines, you can significantly enhance production efficiency. They allow you to create intricate designs faster than traditional methods, saving you time while maintaining quality. For example, advanced CNC machines like the SYIL CNC offer cutting-edge technology that ensures both efficiency and precision in jewelry making.

Customization is another key advantage. Specialized CNC machines enable you to tailor your designs to customer preferences, whether it’s a unique engraving or a complex geometric pattern. This capability allows you to produce personalized jewelry that stands out in the market.

These machines also excel at creating complex shapes and detailed pieces. You can craft designs that would be nearly impossible to achieve by hand. Whether you are working on delicate filigree or bold, modern styles, specialized CNC machines ensure meticulous attention to detail. This technology empowers you to explore innovative designs and elevate your craftsmanship.

Benefits of CNC Machining in Jewelry and Art

Precision and Intricacy in Jewelry Making

CNC machining allows you to achieve unmatched precision in jewelry making. With this technology, you can create intricate shapes and replicate them multiple times without compromising quality. Whether you are designing fine jewelry or crafting detailed engravings, CNC machines ensure every detail is faithfully reproduced.

CNC machines excel at producing complex designs that would be nearly impossible to create manually.

They maintain consistent quality, which is vital for jewelry manufacturing.

From fine engravings to precise stone settings, CNC technology delivers remarkable accuracy.

This precision gives artisan jewelers the ability to push creative boundaries. You can experiment with intricate patterns, delicate textures, and unique designs, knowing the machine will execute your vision flawlessly. The result is jewelry that stands out for its craftsmanship and attention to detail.

Speed and Efficiency in Production

CNC machining significantly improves production speed and efficiency. Fully automated machines reduce manual labor and eliminate human error, allowing you to produce high-quality pieces faster. These machines operate continuously without breaks, ensuring consistent output.

CNC machines can work on multiple parts simultaneously, increasing production speed.

Built-in tool changers and automatic adjustments minimize setup time between tasks.

They reduce the need for secondary operations, saving you time and effort.

This efficiency is especially beneficial in jewelry manufacturing, where time is critical. You can meet tight deadlines without sacrificing quality. Additionally, CNC machines use materials efficiently, reducing waste and lowering production costs. This combination of speed, precision, and sustainability makes CNC machining an invaluable tool for modern jewelry production.

Customization and Personalization in Jewelry Design

CNC machining offers unparalleled flexibility for customization. You can easily adapt designs to suit individual preferences by changing tools or programming specific patterns. This capability allows you to create unique and personalized jewelry that reflects the wearer’s style.

For example, you can engrave intricate patterns, craft custom shapes, or add detailed textures to rings, pendants, and other pieces. CNC technology also enables you to work with various materials, from metals to softer materials like wax. This versatility ensures you can cater to diverse customer demands while maintaining high-quality results.

By embracing CNC machining, you unlock endless possibilities for customization. Whether you are designing one-of-a-kind engagement rings or bold statement pieces, this technology empowers you to bring your creative vision to life.

Material Versatility for Artistic Creations

CNC machining offers incredible material versatility, making it a valuable tool for artistic creations. You can work with a wide range of materials, each offering unique properties that enhance your designs. Whether you prefer metals, plastics, or wood, CNC machines allow you to explore endless creative possibilities.

Here’s a quick overview of commonly used materials in CNC machining for artistic projects:

Material | Properties | Common Uses |

|---|---|---|

Aluminum | Lightweight, easy to machine | Industrial and artistic applications |

Brass | Classic look for decorative items | Artistic creations |

Stainless Steel | Corrosion and wear resistance | Outdoor and industrial markings |

Copper | Attractive finish for decorative items | Artistic pieces |

Plastics | Versatile, available in various colors | Signs, prototypes, custom parts |

Wood | Natural aesthetic, varying hardness | Artistic pieces, custom furniture |

Metals like aluminum and brass are durable and ideal for intricate designs. Plastics provide a lightweight and cost-effective option, perfect for colorful engravings or prototypes. Wood, with its natural warmth, is a favorite for creating artistic pieces and custom furniture. This versatility ensures you can tailor your materials to suit the specific needs of your project.

CNC machining also supports customization, allowing you to adapt designs to match the material’s properties. For example, you can engrave detailed patterns on brass or carve complex shapes into wood. This flexibility empowers you to experiment with different textures and finishes, elevating your artistic creations to new heights.

Sustainability and Waste Reduction in Jewelry Manufacturing

CNC machining plays a significant role in promoting sustainability in jewelry manufacturing. Traditional methods often result in excessive material waste, as manual processes lack the precision needed to optimize material usage. CNC technology, on the other hand, ensures precise cutting and shaping, minimizing waste and conserving resources.

By using CNC machines, you can align your production process with environmentally responsible practices. The accuracy of CNC machining reduces scrap metal, ensuring that every piece of material is utilized efficiently. This not only lowers production costs but also supports sustainability by reducing the environmental impact of your work.

Additionally, CNC machines operate with remarkable consistency, eliminating the need for repeated adjustments or corrections. This efficiency further reduces waste, as fewer materials are discarded due to errors. Whether you’re crafting intricate jewelry or creating prototypes, CNC machining helps you achieve high-quality results while maintaining an eco-friendly approach.

CNC machining combines precision, efficiency, and sustainability, making it an essential tool for modern jewelry manufacturing. By embracing this technology, you can create stunning designs while contributing to a greener future.

Applications of CNC Machining in Artistic Creations

Jewelry Design and Manufacturing

CNC machining has become a cornerstone of modern jewelry design. It allows you to create intricate and durable pieces with smooth surfaces and high structural integrity. You can use CNC to produce precise molds for wax modeling, which reduces human error and speeds up production. This technology also enables you to craft master models for consistent mass production, ensuring uniform quality across all pieces.

With CNC, you can design complex filigree patterns or geometric shapes that would be challenging to achieve manually. It also facilitates rapid prototyping, letting you test designs before committing to mass production. Additionally, CNC machines excel at engraving and polishing, enhancing the appearance of your jewelry. For tasks like setting stones or creating prongs, CNC ensures accuracy and minimizes the risk of damage.

Whether you’re crafting a one-of-a-kind piece or producing jewelry in bulk, CNC offers the precision and efficiency you need to bring your designs to life.

Sculptures and 3D Art

CNC technology has transformed the way you create sculptures and 3D art. By using CAD software, you can design intricate models that translate directly into fabrication instructions for CNC machines. This process streamlines production, reducing the time required for sculpting from months to just hours.

CNC machines provide exceptional precision, allowing you to craft complex designs with ease. You can also produce multiple copies of a sculpture with consistent quality, which is nearly impossible with traditional methods. The ability to customize designs during the process gives you greater creative freedom. Whether you’re working with wood, metal, or other materials, CNC ensures your artistic vision is executed flawlessly.

Engraving and Texturing

Engraving and texturing are essential techniques in artistic creations, and CNC machines excel in these areas. Modern CNC engraving methods, such as rotary engraving and laser engraving, allow you to add intricate details to various materials like metal, wood, and plastic. These techniques ensure precision and consistency, making them ideal for creating custom designs or industrial parts.

For high-precision engraving, diamond drag engraving uses a sharp diamond tip to carve delicate patterns without rotating the tool. Advanced methods like 3D engraving let you create relief effects by removing material at varying depths. This adds a unique dimension to your designs, setting them apart from traditional 2D engravings.

By leveraging CNC for engraving and texturing, you can achieve stunning results that elevate your artistic creations.

Mixed-Media Art and Prototyping

CNC machining plays a vital role in mixed-media art and prototyping. It allows you to combine different materials and techniques to create unique, innovative designs. Whether you’re blending metals with wood or incorporating plastics into your artwork, CNC machines give you the tools to bring your vision to life.

One of the biggest advantages of CNC machining is its precision. You can achieve intricate designs that fit together seamlessly, even when working with multiple materials. This accuracy ensures that every component aligns perfectly, which is essential for mixed-media projects. The ability to work with a variety of materials also expands your creative possibilities. Metals, plastics, wood, and even composites can be shaped and combined to explore different textures, colors, and functions.

Here are some ways CNC machining enhances mixed-media art and prototyping:

High precision ensures intricate designs and flawless assembly.

Material versatility lets you experiment with different physical properties.

Quick setup and minimal preparation time allow for rapid design adjustments.

Consistent results make it easier to replicate prototypes or create multiple versions.

CNC machining also speeds up the prototyping process. You can quickly test and refine your ideas without spending hours on manual adjustments. This efficiency helps you iterate designs faster, making it easier to perfect your creations. For example, if you’re designing a sculpture that combines metal and wood, CNC machines let you adjust dimensions or patterns with minimal effort.

By using CNC technology, you can push the boundaries of mixed-media art. It empowers you to experiment, innovate, and create pieces that stand out for their craftsmanship and originality. Whether you’re an artist or a designer, CNC machining gives you the precision and flexibility to turn your ideas into reality.

CNC Machining vs. Traditional Jewelry-Making Methods

Manual Craftsmanship vs. CNC Automation

When comparing manual craftsmanship to CNC automation, the differences are striking. Manual jewelry-making relies on your skill and physical manipulation of tools. It allows for artistic expression but often limits precision and consistency. CNC automation, on the other hand, uses computer-controlled machines to execute designs with unmatched accuracy. This technology ensures that even the most intricate patterns are achievable.

Here’s a quick comparison:

Aspect | Manual Jewelry Machine | CNC Jewelry Machine |

|---|---|---|

Operation | Requires direct human control and physical manipulation. | Automated and controlled by computers. |

Precision | Depends on the skill of the jeweler; can be challenging. | Excels in precision and consistency across multiple pieces. |

Complexity | Suitable for simpler designs; limited by human capability. | Handles complex designs and intricate patterns easily. |

Customization | Labor-intensive for intricate designs. | High degree of customization; efficient programming. |

Speed and Efficiency | Slower and labor-intensive; depends on jeweler's skill. | Faster and more efficient for larger quantities. |

Learning Curve | Requires hands-on experience to develop skills. | Steeper learning curve due to programming requirements. |

CNC automation empowers you to create complex designs faster and with greater precision than manual methods. While manual craftsmanship offers a personal touch, CNC machining ensures consistency and scalability.

Time and Cost Efficiency in Jewelry Manufacturing

CNC machining has revolutionized jewelry manufacturing by improving both time and cost efficiency. Automated machines work continuously without breaks, enabling faster production compared to manual methods. You can also program CNC machines to work on multiple parts simultaneously, further increasing output.

CNC machines streamline production timelines, allowing for quicker turnarounds.

They optimize cutting paths, reducing material waste and saving costs.

Continuous operation eliminates downtime, maximizing productivity.

Faster production speeds enable you to meet tight deadlines without compromising quality.

By automating repetitive tasks, CNC machining frees up your time to focus on creativity and innovation. This efficiency not only reduces costs but also enhances your ability to scale production.

Consistency and Quality Control in Jewelry Design

CNC technology ensures consistent quality across all your jewelry designs. Unlike manual methods, which can introduce variations, CNC machines replicate each piece with precision. This uniformity is essential for maintaining high standards in jewelry manufacturing.

CNC machines play a crucial role in maintaining consistent quality in jewelry production. By utilizing computer-controlled technology, manufacturers can execute intricate designs with absolute accuracy, resulting in uniformity across all pieces.

To ensure quality control, you can monitor and adjust parameters like cutting speed and tool wear in real time. Advanced techniques, such as Statistical Process Control (SPC), help you manage machining processes effectively. These measures guarantee that every piece meets your exact specifications, enhancing customer satisfaction.

Challenges and Limitations of CNC Machining

While CNC machining offers precision and efficiency, it also comes with challenges that you should consider before adopting this technology. These limitations can impact your workflow, costs, and creative possibilities.

High Initial Investment: CNC machines require a significant upfront cost. Purchasing the equipment, maintaining it, and hiring skilled operators can strain your budget. For small-scale jewelry manufacturing or artistic projects, this expense may feel overwhelming.

Limited Design Freedom: CNC machines rely on specific tools and programming. This dependency can restrict the complexity of designs you want to create. For instance, intricate patterns or organic shapes may exceed the machine's capabilities, limiting your creative expression.

Environmental Impact: The machining process generates noise, heat, and waste. These byproducts can affect worker health and contribute to environmental concerns. Proper waste management and noise control measures are essential to mitigate these effects.

Despite these challenges, CNC machining remains a powerful tool for jewelry and art. By understanding its limitations, you can make informed decisions and maximize its potential in your projects.

Future Trends in CNC Machining for Jewelry and Art

AI and Machine Learning in Jewelry Manufacturing

Artificial intelligence (AI) and machine learning are transforming how you approach jewelry manufacturing. These technologies analyze vast amounts of data to optimize CNC processes, ensuring precision and efficiency. For example, AI can predict tool wear and recommend adjustments, reducing downtime and improving productivity. Machine learning algorithms also enhance design capabilities by identifying patterns and suggesting innovative solutions.

By integrating AI with CNC machining, you can automate complex tasks like engraving intricate patterns or creating custom designs. This automation allows you to focus on creativity while maintaining consistent quality. Additionally, AI-powered systems adapt to customer preferences, enabling you to offer personalized jewelry that stands out in the market. As these technologies evolve, they will continue to push the boundaries of what you can achieve with CNC.

Advanced Materials for Jewelry and Artistic Creations

The development of advanced materials is expanding your creative possibilities in jewelry and art. CNC machines now work with a wide range of materials, including titanium, resin, ceramics, and precious metals like gold, silver, and platinum. These materials offer unique properties that enhance durability and aesthetics.

For instance, CNC machining produces jewelry with smooth surfaces and high structural integrity. These pieces resist scratches and deformation, making them ideal for everyday wear. You can also explore alternative materials to create innovative designs that combine functionality with beauty.

Common materials used in CNC machining for jewelry include:

Gold

Platinum

18k Gold

Various Silver Products

By experimenting with these materials, you can craft unique creations that cater to diverse customer preferences. This versatility ensures that your designs remain both innovative and timeless.

Miniaturization of CNC Machines for Jewelry Making

Miniaturizing CNC machines is revolutionizing jewelry making by enhancing precision and customization. Smaller machines allow you to create intricate designs with consistent results, eliminating human error. This precision ensures that every piece meets exact specifications, which is essential for quality craftsmanship.

Miniaturized CNC machines also offer unmatched flexibility. You can adapt existing designs or create entirely new ones tailored to individual preferences. This capability meets the growing demand for personalized jewelry, helping you stand out in a competitive market.

Benefits of miniaturized CNC machines include:

Enhanced precision for intricate designs

Greater customization options for unique creations

Improved efficiency in small-scale production

As these compact machines become more accessible, they will empower you to explore new techniques and expand your creative horizons. The ability to produce high-quality, personalized jewelry on a smaller scale will redefine the future of jewelry manufacturing.

Integration with 3D Printing and Other Technologies

The integration of CNC with 3D printing and other technologies has transformed how you approach jewelry and artistic creations. By combining these methods, you can achieve designs that were once impossible. Each technology brings unique strengths to the table, and together, they enhance your creative process.

3D printing excels at creating complex internal structures and geometries. It allows you to build intricate designs layer by layer, which is ideal for rapid prototyping. CNC machining complements this by refining the shapes and adding precise surface finishes. This combination ensures your final product meets the highest standards of quality and detail.

Here’s how CNC machining and 3D printing work together:

Integration Aspect | Description |

|---|---|

Additive Capabilities | 3D printing allows for the manufacture of complex internal structures and geometries. |

Precision Processing | CNC machining provides precise shapes and surface finishes. |

Production Efficiency | The combination shortens the production cycle and improves efficiency. |

Rapid Prototyping | 3D printing is used for rapid prototyping, while CNC machining adjusts dimensions for testing. |

This integration also improves production efficiency. You can use 3D printing to quickly create prototypes and test designs. Once the prototype is ready, CNC machines refine the details and ensure accuracy. This process shortens production cycles and reduces material waste, making it both time-efficient and sustainable.

By combining CNC machining with 3D printing, you unlock new possibilities for innovation. You can experiment with intricate designs, test ideas faster, and produce high-quality results. This synergy empowers you to push the boundaries of creativity in jewelry and art.

CNC machining has transformed how you approach jewelry making and artistic creations. It gives you the tools to achieve precision, efficiency, and creative freedom. This technology complements traditional craftsmanship by enhancing your ability to create intricate designs and explore new possibilities. You can now produce high-quality pieces faster and with less waste, making your work both innovative and sustainable. As CNC continues to evolve, it will shape the future of jewelry design and artistic creations, empowering you to push the boundaries of your creativity.

FAQ

What is the main advantage of CNC machining for jewelry making?

CNC machining ensures precision and consistency in every piece. It allows you to create intricate designs that are difficult to achieve manually. This technology also reduces material waste, making it an efficient and sustainable choice for jewelry production.

Can CNC machines work with all types of materials?

CNC machines handle a wide range of materials, including metals, plastics, and wood. You can use them to craft jewelry, sculptures, and mixed-media art. Each material offers unique properties, allowing you to explore diverse creative possibilities.

How does CNC machining compare to traditional methods?

CNC machining automates the process, delivering faster production and higher accuracy than traditional methods. It eliminates human error and ensures consistent quality. While manual techniques offer a personal touch, CNC technology excels in efficiency and scalability.

Is CNC machining suitable for small-scale projects?

Yes, CNC machining works well for small-scale projects. Miniaturized CNC machines allow you to create intricate designs with precision. They are ideal for personalized jewelry or prototypes, offering flexibility and high-quality results.

What skills do you need to operate a CNC machine?

You need basic knowledge of CAD software and programming to operate a CNC machine. Familiarity with materials and tools is also helpful. Many resources and training programs are available to help you learn these skills.

See Also

Creative CNC Jewelry Projects That Inspire Artistic Expression

Discovering CNC Machining Solutions for Accurate Production

Is CNC Milling a Viable Alternative to CNC Engraving?

Achieving Precision in Parts Manufacturing Through CNC Mastery

Streamlined CNC Machining Solutions for High-Precision Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com