Comparing Raw Materials: Cost vs. Performance in CNC Applications

Choosing the right material is critical in CNC machining. It directly affects the cost, machining efficiency, and final product quality. For example, aluminum offers high machinability and precise finishes, making it ideal for aerospace and automotive applications. On the other hand, stainless steel provides corrosion resistance, perfect for chemical environments. Material selection also influences operational efficiency. Standardizing materials reduces waste and optimizes processes. Balancing affordability with functional needs ensures cost-effectiveness while maintaining quality. By prioritizing these factors, you can achieve better results in your CNC projects.

Key Takeaways

Picking the right material is very important for CNC work. It impacts cost, speed, and product quality.

Think about the price and how easy it is to get materials. This helps avoid delays and keeps costs low.

Using the same materials for projects can cut waste and make machining easier.

Check how easy materials are to machine. This reduces tool damage and saves time and money.

Save money now but also think about long-term needs. This keeps your products strong and reliable.

Key Factors in CNC Material Selection

Cost-Related Factors

Raw material price and availability

The price of raw materials plays a significant role in determining the cost of CNC machining. Materials like aluminum are affordable, with an average cost of just over $1 per pound, making them a popular choice for budget-conscious projects. In contrast, copper is more than three times as expensive, which can significantly increase the cost of CNC. Availability also impacts material cost. Limited supply can lead to delays and higher prices. To avoid these issues, you should consider both price and availability when selecting materials.

Waste reduction and material utilization

Efficient material utilization reduces waste and lowers costs. Standardizing materials across projects can help you minimize scrap and optimize processes. For instance, choosing economical options like aluminum or plastics such as POM (Delrin) can balance material cost with functional requirements. By focusing on waste reduction, you can improve efficiency and control the cost of CNC machining.

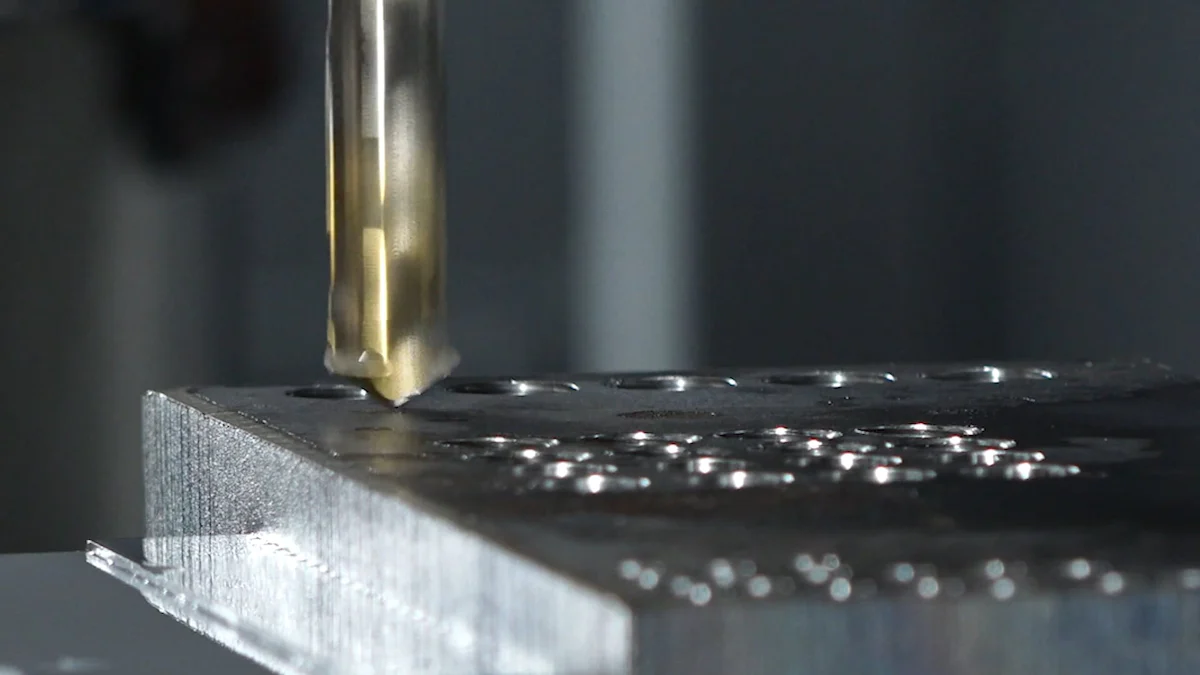

Machining time and tool wear impact

Machining time directly affects the overall machining cost. Longer machining processes increase labor and energy expenses. Tool wear also adds to costs, as frequent replacements disrupt production and raise expenses. Selecting materials with high machinability, like aluminum, can reduce tool wear and machining time. This approach ensures better efficiency and cost control.

Performance-Related Factors

Durability and strength

Durability and strength are critical for ensuring product quality. Materials like steel offer excellent strength, making them ideal for heavy-duty applications. For lightweight yet strong components, aluminum is a reliable choice. Always match material properties to your project’s performance needs.

Machinability and ease of CNC machining

Machinability influences cutting speed, tool life, and overall efficiency. Aluminum 6061, known for its high machinability, is a preferred option for CNC machining. Materials with poor machinability increase machining time and tool wear, raising costs. Choosing machinable materials ensures smoother operations and better results.

Thermal and chemical resistance

Materials exposed to extreme conditions must withstand thermal and chemical stresses. Stainless steel grades like 304 and 316 resist corrosion, making them suitable for chemical environments. For high-temperature applications, Inconel maintains its properties under stress. Selecting materials with the right resistance ensures long-term performance and reliability.

Balancing Cost and Performance

Prioritizing project-specific needs

Balancing cost and performance starts with understanding your project’s requirements. Evaluate factors like strength, weight, and environmental conditions. For example, aerospace components often require lightweight materials like aluminum, while chemical environments demand corrosion-resistant options like stainless steel.

Long-term vs. short-term cost considerations

Short-term savings may lead to higher long-term costs if the material fails to meet performance standards. Investing in durable, high-quality materials can reduce maintenance and replacement costs over time. By considering both immediate and future needs, you can make informed decisions that optimize cost and performance.

Comparing Common CNC Materials

Metals

Aluminum: Affordable, lightweight, and machinable

Aluminum is one of the most commonly used metals in CNC machining. Its low density and high strength make it ideal for industries like automotive and aerospace. You can use aluminum for components such as frames, engines, and structural parts. Its high machinability reduces machining time and tool wear, lowering the overall machining cost. Additionally, aluminum’s corrosion resistance ensures long-term quality, making it a cost-effective choice for many applications.

Steel: Durable and strong, but higher cost

Steel offers excellent strength and versatility, making it suitable for a wide range of applications. Stainless steel provides corrosion resistance, while low-carbon steel is a more affordable option with high strength. You’ll find steel in consumer products like utensils and appliances, as well as in industrial machinery. However, steel’s higher price and machining cost compared to aluminum may impact your budget. Its durability often justifies the investment for heavy-duty projects.

Titanium: High-performance, costly

Titanium stands out for its high strength-to-weight ratio and corrosion resistance. It’s widely used in aerospace and marine industries for structural parts. However, the cost of titanium CNC machining is significantly higher than other metals. Titanium’s lower machinability increases machining time and tool wear, driving up labor and material costs. Specialized tools, significant coolant usage, and additional post-processing steps further add to the cost. Despite these challenges, titanium’s performance makes it indispensable for high-stakes applications.

Plastics

ABS: Cost-effective and easy to machine

ABS is a popular plastic for CNC machining due to its affordability and machinability. It’s lightweight and offers good corrosion resistance, making it suitable for prototyping consumer products. However, ABS has lower strength and hardness compared to metals, limiting its use in heavy-duty applications.

Nylon: Durable with good wear resistance

Nylon provides excellent wear resistance and durability, making it a reliable choice for mechanical components like gears and bushings. Its lightweight nature and ease of machining contribute to lower machining costs. However, nylon’s high thermal expansion may affect dimensional stability in extreme conditions.

PEEK: High-performance but expensive

PEEK is a high-performance plastic capable of withstanding continuous use temperatures up to 250°C (482°F). It’s easier to machine than polyimides and is ideal for high-temperature applications. However, its high price makes it less suitable for cost-sensitive projects. You should consider PEEK for specialized applications where performance outweighs cost concerns.

Composites

Carbon fiber: Lightweight and strong, but costly

Carbon fiber offers exceptional strength and lightweight properties, making it ideal for aerospace and automotive applications. CNC machining allows you to create complex shapes with minimal waste, which is crucial given carbon fiber’s high price. While its cost may be a barrier, the material’s durability and precision justify its use in high-performance projects.

Fiberglass: Affordable alternative to carbon fiber

Fiberglass provides a more economical option compared to carbon fiber. Its production involves simpler processes, resulting in lower costs. While fiberglass lacks the superior strength of carbon fiber, it remains a reliable choice for applications requiring moderate strength and affordability.

Specialty Materials

Ceramics: High thermal resistance, brittle

Ceramics stand out for their exceptional thermal resistance and electrical insulation. These properties make them ideal for electronic components and high-temperature environments. You can use ceramics in applications where heat or electricity could compromise other materials. For example, ceramic parts often appear in semiconductors and aerospace systems. However, ceramics are brittle, which limits their use in applications requiring high impact resistance. Their machining requires precision and specialized tools, which can increase machining cost. Despite this, ceramics deliver unmatched performance in specific conditions, ensuring long-term quality and reliability.

Exotic alloys: Tailored for specific high-performance needs

Exotic alloys offer unique properties tailored to demanding applications. Titanium alloys, for instance, combine strength and reduced weight, making them indispensable in aerospace. Copper Alloy 101 provides excellent electrical and thermal conductivity, which is essential for electronic components and wiring. Brass, known for its corrosion resistance and machinability, is widely used in plumbing and artistic designs. These materials often come with a higher price due to their specialized properties and limited availability. However, their performance justifies the investment, especially in industries where precision and durability are critical.

Here’s a quick comparison of specialty materials and their unique properties:

Material Type | Unique Properties | Applications |

|---|---|---|

Ceramics | Excellent thermal resistance, electrical insulation | Electronic components |

Titanium Alloys | Reduced weight while maintaining strength | Aerospace applications |

Copper Alloy 101 | High ductility, impact strength, electrical/thermal conductivity | Electronic components, wiring |

Brass | Durable, easily machinable, corrosion resistant | Plumbing, electrical, artistic |

When selecting specialty materials, you should consider the quantity needed and the specific performance requirements of your project. These materials often balance cost and quality, ensuring the final product meets high standards.

Real-World Examples of Material Selection

Aluminum for lightweight automotive parts

Aluminum has revolutionized the automotive industry by enabling lightweight designs. Its low density and high strength make it a preferred material for reducing vehicle weight. This reduction improves fuel efficiency and performance. For example:

The first sports car with an aluminum body debuted at the Berlin International Motor Show in 1899.

In 1901, Karl Benz developed an engine using aluminum components, marking a milestone in automotive engineering.

Audi showcased the aluminum-framed A8 in the 1980s, demonstrating its potential for weight reduction.

Ford adopted an all-aluminum body for the F-150 in 2015, achieving significant weight savings and better fuel economy.

Aluminum’s machinability also lowers the cost of cnc machining. It allows for precise shaping and reduces machining time. These benefits make aluminum an excellent choice for automotive parts like frames, panels, and engine components.

Titanium for aerospace components

Titanium plays a vital role in aerospace engineering due to its unique properties. Its high strength-to-weight ratio makes it ideal for applications where weight reduction is critical. Titanium resists corrosion and withstands extreme temperatures, ensuring durability in harsh environments. For instance:

Its specific strength allows for sleeker designs, enhancing cabin space in commercial airliners.

Military aircraft benefit from titanium’s flexibility, enabling efficient structures and better aerodynamics.

Innovations like sleeker wings rely on titanium’s ability to maintain structural integrity under stress.

However, the cost of titanium cnc machining is higher due to rapid tool wear and specialized processes. Despite this, titanium’s performance justifies its use in critical aerospace components like airframes, engine parts, and landing gear.

ABS for consumer product prototyping

ABS is a versatile plastic widely used in prototyping. Its affordability and machinability make it ideal for creating intricate designs. ABS plastic sheets capture fine details, ensuring consistent quality in prototypes. This material is also popular in 3D printing, enabling rapid development and testing of designs. You can make iterative changes quickly and at a low cost.

ABS is durable and easy to process. It offers excellent impact resistance, making it suitable for consumer goods, electronics, and toys. Its ability to handle high precision and complexity ensures reliable results in manufacturing processes like injection molding. For these reasons, ABS remains a top choice for prototyping consumer products.

Balancing cost and performance in medical devices

Medical devices require materials that meet strict performance standards while staying within budget. You must carefully balance cost and performance to ensure the final product delivers both reliability and affordability.

When selecting materials, consider how machinability impacts overall expenses. For example, choosing a material with better machinability, even if it has a higher price, can save money in the long run. Reduced machining time and less tool wear lower machining cost and improve efficiency. This approach ensures you maintain high-quality standards without exceeding your budget.

High-performance materials like titanium often play a critical role in medical devices. Titanium’s biocompatibility and corrosion resistance make it ideal for implants and surgical tools. However, the cost of titanium cnc machining can be significant. Its lower machinability increases machining time and tool wear, driving up expenses. Despite this, titanium’s unique properties justify its use in life-saving applications.

You should also evaluate the quantity of materials needed for production. Bulk purchasing can reduce costs, but only if the material aligns with your performance requirements. For instance, while high-end options like Rogers or polyimide offer superior properties, they may not always fit within budget constraints. Balancing these factors ensures you achieve the desired quality without overspending.

By prioritizing materials that meet both performance and cost goals, you can create medical devices that are safe, effective, and affordable. This careful balance is essential for delivering products that improve patient outcomes while remaining economically viable.

Decision-Making Framework for CNC Material Selection

Step 1: Define project requirements

Performance needs (e.g., strength, thermal resistance)

Start by identifying the specific needs of your project. Consider how the product will be used and the environmental conditions it will face. For example, if the product must endure high temperatures, you might need a material like titanium due to its thermal resistance. Evaluate stress loads, dimensional tolerances, and operating temperatures. If the product requires wear resistance or compatibility with fasteners, include these factors in your analysis. Understanding these requirements ensures the material you choose will deliver the desired quality and performance.

Budget constraints and cost considerations

Budget plays a critical role in material selection. You must balance performance needs with financial limitations. Materials like aluminum or ABS offer cost-effective solutions for many applications. However, high-performance options like titanium can increase the cost of CNC machining. Material availability also impacts price and lead times. Excessive raw material costs can reduce the cost-efficiency of your CNC project. By carefully evaluating your budget, you can maximize material properties while minimizing expenses.

Step 2: Evaluate material options

Compare cost and performance trade-offs

When comparing materials, weigh their cost against their performance. High-performance materials like tool steel or titanium provide exceptional strength but come at a higher price. Alternatives like plastics or aluminum offer good machinability and lower machining costs. For example, aluminum’s machinability reduces production time and tool wear, making it a cost-effective choice. Always align material properties with your project’s needs to achieve the best balance between cost and performance.

Consider material availability and lead times

Material availability can significantly impact your project timeline. Limited stock or special ordering requirements may delay production. Harder or brittle materials often require specialized tooling and slower machining speeds, increasing lead times. For instance, titanium’s hardness and heat sensitivity demand specific handling techniques, which can extend machining time. To avoid delays, choose materials that are readily available and easy to work with.

Step 3: Test and validate materials

Prototype with selected materials

Prototyping helps you test the material’s suitability for your project. Use the same material intended for the final product to ensure accurate evaluation. Keep prototypes simple to reduce costs and complexity. Design with machining efficiency in mind by using default tolerances and optimizing tool geometry. This approach minimizes machining cost while maintaining functionality.

Assess machining efficiency and product quality

Evaluate how the material performs during machining. Check for issues like tool wear, production speed, and dimensional accuracy. For example, titanium’s lower machinability may increase machining time, but its strength and durability often justify the investment. Testing ensures the material meets your performance and quality standards before full-scale production.

Step 4: Finalize material selection

Balance short-term and long-term goals

When finalizing your CNC material selection, you need to weigh immediate project needs against future implications. Short-term goals often focus on reducing machining cost and meeting tight deadlines. For example, choosing aluminum or ABS can help you save time and money due to their high machinability and affordability. However, prioritizing only short-term savings may lead to higher expenses later if the material fails to meet performance standards.

Long-term goals require you to consider durability, maintenance, and operational efficiency. Materials like titanium, while more expensive upfront, offer exceptional strength and corrosion resistance. This makes them ideal for applications where reliability is critical, such as aerospace or medical devices. By investing in high-quality materials, you can reduce repair and replacement costs over time.

To strike the right balance, evaluate factors like the operational environment, expected lifespan, and performance requirements. For instance, if your product will face extreme temperatures or chemical exposure, materials like titanium or stainless steel ensure long-term reliability. Always align your material choice with both immediate and future project goals to optimize cost and performance.

Factor in scalability and future needs

Scalability plays a crucial role in material selection, especially for projects with growth potential. You must consider how material availability and machining efficiency will impact large-scale production. Materials like aluminum and nylon are widely available and easy to machine, making them suitable for high-volume manufacturing. On the other hand, specialty materials like titanium or carbon fiber may face supply chain challenges, increasing lead times and price fluctuations.

Future needs also demand attention. If your design evolves or requires modifications, the chosen material must accommodate these changes. For example, plastics like ABS are versatile and cost-effective for prototyping, but they may not meet the strength requirements of final products. Similarly, titanium’s superior properties make it a reliable choice for high-performance applications, even if its machining cost is higher.

You should also assess the quantity of material required for production. Bulk purchasing can lower costs, but only if the material aligns with your long-term goals. By factoring in scalability and future needs, you can ensure your CNC machining process remains efficient and adaptable as your project grows.

Balancing cost and performance in CNC machining is essential for achieving high-quality results. You can reduce machining cost by selecting materials that align with your project’s functional needs and budget. For example, choosing titanium for aerospace applications ensures durability and strength, even though its price is higher. Simplifying geometries and tolerances also optimizes machining efficiency and minimizes waste.

Aligning material choice with project-specific requirements guarantees better outcomes. Consider factors like stress loads, environmental conditions, and the quantity of materials needed. Using the decision-making framework helps you evaluate options effectively. By defining requirements, testing materials, and balancing short-term and long-term goals, you can ensure your CNC projects meet both performance and cost expectations.

Choosing the right material for CNC machining involves understanding application needs, environmental conditions, and desired properties like strength and thermal resistance. This approach ensures optimal performance and cost-efficiency.

FAQ

What is the composition of CNC machining cost?

CNC machining cost includes raw material expenses, machining time, tool wear, and labor. Additional factors like setup time, quality control and inspection measures, and post-processing also contribute. Understanding these elements helps you manage expenses effectively.

How does the relationship between cost and quantity affect CNC projects?

Producing larger quantities often reduces the per-unit cost. Bulk material purchases and optimized machining processes lower expenses. However, ensure the material aligns with your project’s performance needs to maintain quality.

Why is a cost-benefit analysis of titanium machining important?

Titanium machining involves high costs due to tool wear and longer machining times. A cost-benefit analysis helps you determine if titanium’s strength and durability justify the expense for your specific application.

How can you ensure quality control and inspection measures in CNC machining?

Use precise measuring tools and follow standardized inspection protocols. Regularly check dimensions, surface finishes, and tolerances during production. These measures ensure consistent quality and reduce defects.

What factors influence material selection for CNC machining?

Consider machinability, strength, thermal resistance, and cost. Evaluate how the material performs under stress and environmental conditions. Align your choice with project-specific requirements to balance performance and cost.

See Also

Grasping Material Needs for CNC Precision Machining Success

Key Elements Influencing CNC Precision Parts Processing Costs

How CNC Precision Parts Processing Impacts Production Expenses

Unraveling CNC Milling Costs: Understanding Precision Machining Expenses

Excelling in CNC Machining: Tolerances, Prototypes, and Materials

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com