How CNC Technology Optimizes Material Grain Flow

CNC machining gives you precise control over material grain flow, which directly enhances the strength and durability of components. By aligning the grain structure, you can improve the performance of materials under stress. This process ensures that parts withstand higher loads and last longer in demanding applications.

Grain flow plays a critical role in minimizing the presence of internal defects such as voids and porosity. The aligned grains help fill voids and eliminate weak spots, enhancing the overall structural integrity of the blade.

With CNC, you achieve consistent results that reduce waste and defects, making it an essential tool for precision manufacturing.

Key Takeaways

CNC machines make materials stronger by aligning grain flow. This makes parts tougher and more dependable.

Correct grain alignment lowers flaws and weak areas. This creates better products that last longer.

CNC technology reduces wasted material, cutting costs and helping the environment.

Industries like aerospace and cars gain a lot from CNC. It makes strong parts that handle tough conditions.

Advanced CNC methods, like multi-axis machining, give exact control. This keeps grain flow in the best shape.

Understanding Grain Flow in Forging

What Is Grain Flow?

Definition and its role in material properties.

Grain flow refers to the directional alignment of grains within a metal during the forging process. These grains are microscopic structures that determine the material's mechanical properties. When you forge a component, the grains realign to follow the shape of the part. This alignment enhances the material's strength, ductility, and toughness. Unlike casting, which creates a random grain structure, forging ensures a continuous and uniform grain flow. This deliberate alignment is why forged components often outperform those made using other methods.

Grain flow in forging also plays a vital role in improving fatigue resistance and impact toughness. The repeated heating and deformation during forging allow grains to flow in a specific direction, creating a structure that can withstand stress better. This process ensures that the material performs optimally under demanding conditions.

How grain flow impacts strength, durability, and stress distribution.

The orientation of grain flow directly influences the strength and durability of a component. Favorable grain flow increases tensile properties, making the material less prone to cracking or breaking under stress. When grains align with the direction of applied stress, the material becomes more resistant to fatigue and wear. On the other hand, poor grain flow can lead to reduced strength and increased brittleness, making the component more susceptible to fractures.

Cracks often form parallel to the grain structure. By aligning the grain flow perpendicular to stress, you can minimize the risk of crack propagation. This alignment ensures better stress distribution, which is critical for components subjected to high loads or cyclic stresses.

Importance of Grain Flow in Manufacturing

The role of grain alignment in product performance.

Grain alignment is essential for achieving high-performance components. Properly aligned grains enhance the load-bearing capacity of materials, making them suitable for applications where strength and reliability are critical. For example, in aerospace and automotive industries, grain flow in forging ensures that parts can handle extreme conditions without failure. This alignment also improves the material's resistance to fatigue, extending the lifespan of the product.

Common issues caused by poor grain flow, such as fractures and weaknesses.

Poor grain flow can lead to several manufacturing challenges. Components with misaligned grains often exhibit reduced mechanical properties, such as lower strength and increased brittleness. Cracks and fractures are more likely to occur in these materials, especially under high stress. Additionally, non-uniform grain structures can result in weak points within the component, compromising its overall integrity. Contamination and temperature fluctuations during forging can further disrupt grain flow, leading to defects and inefficiencies in production.

How CNC Machining Optimizes Grain Flow

Precision in Grain Alignment

How CNC machining ensures precise cuts aligned with grain flow.

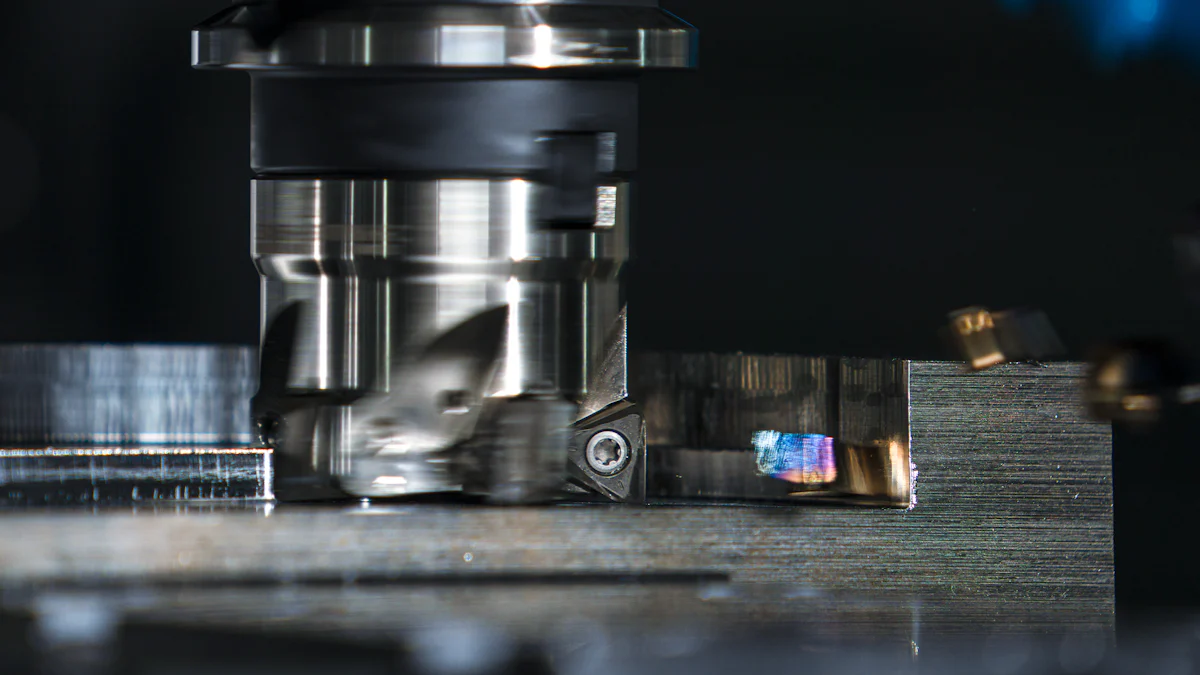

CNC machining gives you unmatched precision when working with materials. By using advanced tools, you can make cuts that align perfectly with the grain structure of the material. This alignment ensures that the grains follow the desired direction, which improves the strength and performance of the final product. Unlike manual methods, CNC eliminates guesswork, allowing you to achieve optimal grain flow every time. This precision is especially important in industries like aerospace and automotive, where even minor misalignments can lead to failures.

The role of toolpath programming in grain flow optimization.

Toolpath programming plays a critical role in optimizing grain flow. By carefully planning the movement of cutting tools, you can ensure that the grains remain aligned throughout the machining process. Modern CNC systems allow you to program toolpaths that follow the natural grain orientation of the material. This approach minimizes stress points and enhances the durability of the component. With the right programming, you can also reduce waste by cutting only where necessary, preserving the integrity of the material.

Automation and Consistency in CNC

How CNC automation minimizes human error in grain alignment.

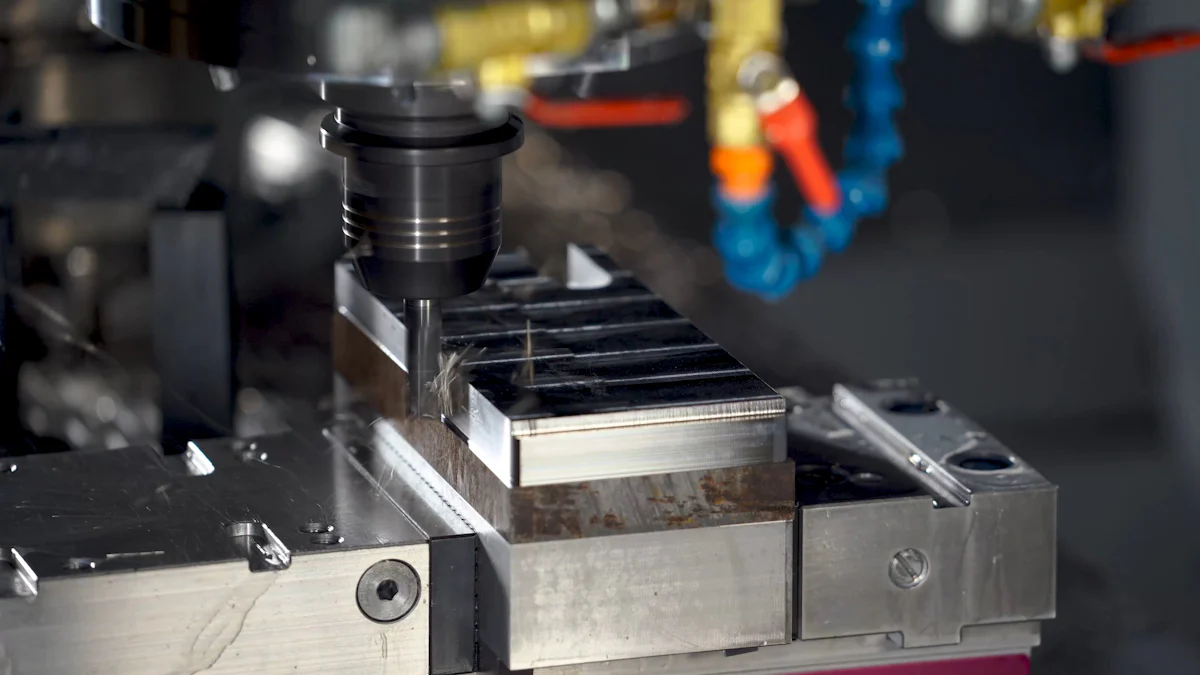

Automation in CNC reduces the risk of human error, ensuring consistent results. When you rely on manual methods, even small mistakes can disrupt grain alignment, leading to weaker components. CNC machines, however, operate with high precision and repeatability. This consistency ensures that every part meets the required specifications, reducing the chances of defects.

CNC machining allows for uniform outputs, ensuring parts fit application specifications.

The precision of CNC machining ensures improved accuracy compared to handmade components.

CNC machines produce parts faster than manual methods, shortening lead times and boosting efficiency.

The use of simulation software to predict and optimize grain flow.

Simulation software enhances the CNC process by allowing you to test and validate designs before production. These tools let you visualize how the grains will align during machining. By identifying potential issues early, you can adjust the toolpaths to achieve optimal grain flow. This virtual testing reduces material waste and ensures that the final product performs as expected. The integration of CAD and CAM software further streamlines this process, making it easier to manufacture high-quality components.

Advanced CNC Techniques for Grain Flow

Multi-axis machining and its impact on grain orientation.

Multi-axis machining expands your ability to control grain orientation. With traditional methods, you might struggle to align grains in complex geometries. Multi-axis CNC machines, however, can approach the material from multiple angles, ensuring that the grains remain aligned even in intricate designs. This capability is crucial for components with curved or irregular shapes, where maintaining grain flow is challenging.

Adaptive machining strategies for complex geometries.

Adaptive machining strategies take CNC to the next level by adjusting the process in real-time. These strategies use sensors and feedback systems to monitor the material and make adjustments as needed. By adapting to the material's properties, you can maintain aligned grains even in challenging conditions. This approach not only improves the performance of the component but also reduces waste by minimizing errors during machining.

Benefits of Optimized Grain Flow in CNC Machining

Enhanced Strength and Durability

How proper grain alignment improves load-bearing capacity.

Proper grain alignment significantly enhances the load-bearing capacity of materials. When grains align with the direction of applied stress, they distribute the load more evenly. This alignment reduces weak points and improves the material's ability to resist fatigue and stress. For example, in CNC machining, aligned grains create components that can handle higher loads without cracking or deforming. This improvement ensures that parts perform reliably in demanding applications.

Improvement Type | Description |

|---|---|

Improved Strength and Durability | Optimal grain flow aligns the metal grains along the blade’s contours, enhancing load distribution and resistance to fatigue and stress. |

Enhanced Mechanical Properties | Proper grain alignment improves hardness, toughness, and corrosion resistance, ensuring long-term performance. |

Reduced Risk of Defects | Aligned grains minimize internal defects, enhancing the overall structural integrity of the blade. |

Examples of industries where strength is critical, such as aerospace and automotive.

Industries like aerospace and automotive rely heavily on CNC machining to achieve high-strength components. In aerospace, optimized grain flow ensures that parts like turbine blades and structural components can withstand extreme conditions. Automotive manufacturers benefit from improved production efficiency and product quality, especially for engine and suspension systems. Agricultural machinery also sees enhanced durability and precision through CNC machining.

Reduced Defects and Material Waste

How CNC machining minimizes defects through grain optimization.

CNC machining minimizes defects by ensuring precise grain alignment. Misaligned grains often lead to internal voids and weak spots, which compromise structural integrity. CNC machines eliminate these issues by cutting materials with high precision, preserving the natural grain flow. This process reduces the risk of fractures and enhances the overall quality of the final product.

Cost-saving benefits of reduced material waste.

Reducing material waste directly impacts production costs. CNC machines maximize material usage by cutting only where necessary. This efficiency lowers expenses and promotes sustainable manufacturing. Recycling programs further reduce waste by recovering valuable materials from scrap. These practices not only save money but also contribute to environmentally friendly production methods.

CNC machining helps decrease the environmental footprint by minimizing waste.

Sustainable practices preserve natural resources and reduce pollution.

Although CNC machines require an initial investment, they save money over time by optimizing material usage.

Improved Product Performance

How optimized grain flow enhances fatigue resistance.

Optimized grain flow improves fatigue resistance by aligning grains to counteract stress. This alignment prevents cracks from propagating, even under repeated loading. Components with enhanced fatigue resistance last longer and perform better in high-stress environments. For example, aerospace and automotive parts benefit from this improvement, ensuring safety and reliability.

The role of grain flow in extending product lifespan.

Grain flow plays a crucial role in extending the lifespan of components. Aligned grains enhance mechanical properties like toughness and corrosion resistance. These improvements ensure that parts maintain their performance over time, reducing the need for frequent replacements. CNC machining achieves this level of precision, making it an essential tool for manufacturing durable products.

Key Performance Metric | Improvement Description |

|---|---|

Improved Strength and Durability | Optimal grain flow aligns metal grains, enhancing strength and durability for better load distribution and fatigue resistance. |

Enhanced Mechanical Properties | Proper grain alignment improves hardness, toughness, and corrosion resistance, ensuring long-term reliability. |

Reduced Risk of Defects | Aligned grains minimize internal defects, enhancing structural integrity by filling voids and eliminating weak spots. |

Applications of CNC-Optimized Grain Flow

Aerospace Industry

Importance of grain flow in aircraft components.

In aerospace, grain flow plays a critical role in ensuring the reliability and safety of aircraft components. You need components that can withstand extreme conditions, such as high temperatures and intense mechanical stress. Optimized grain flow aligns the grain structure with the stress requirements of each part, enhancing its mechanical properties. This alignment improves fatigue resistance, ensuring that components perform reliably over long periods. Controlled deformation during forging ensures continuous grain flow, which is essential for the strength of complex geometries like turbine blades and structural supports.

Examples of CNC-machined aerospace parts with optimized grain flow.

CNC machining is vital for producing high-performance aerospace components. Examples include turbine blades, landing gear parts, and structural elements of aircraft. These parts benefit from CNC's ability to maintain precise grain alignment, which enhances their durability and impact resistance. By using CNC, you can manufacture high-quality gas turbine blades that meet stringent aerospace standards, ensuring safety and efficiency in flight.

Automotive Manufacturing

How CNC machining enhances engine component performance.

CNC machining improves the performance of automotive engine components by enabling the production of complex geometries with tight tolerances. For example, cylinder heads require impeccable precision to ensure optimal engine function. CNC machines allow you to achieve this precision, ensuring uniform flow characteristics and maximizing engine efficiency. Components like engine blocks, pistons, and crankshafts also benefit from CNC machining, as it ensures their reliability and longevity.

Grain flow optimization in safety-critical parts like suspension systems.

Safety-critical parts, such as suspension systems, rely on optimized grain flow for enhanced strength and durability. Proper grain alignment ensures these components can handle high loads and resist fatigue over time. CNC machining ensures precise cuts and consistent grain alignment, reducing the risk of fractures or failures. This precision manufacturing process is essential for meeting the rigorous safety standards of the automotive industry.

Medical Devices and Implants

The role of grain flow in ensuring the reliability of medical implants.

Grain flow is crucial for the reliability of medical implants. Aligned grains improve the mechanical properties of materials, ensuring they can withstand the stresses of daily use. For example, implants like knee replacements and hip joints require exceptional strength and fatigue resistance. Optimized grain flow ensures these devices perform reliably, providing patients with long-lasting solutions.

CNC machining in producing high-precision medical components.

CNC machining is indispensable for producing high-precision medical components. It allows you to create implants, surgical tools, and custom prosthetics with unparalleled accuracy. Examples include orthopedic hardware like plates, screws, and rods, as well as dental tools and medical device prototypes. Each of these components requires precise dimensions and smooth finishes to ensure functionality and patient safety. CNC machining ensures these requirements are met, making it a cornerstone of modern medical manufacturing.

CNC machining plays a vital role in optimizing material grain flow, ensuring precision and consistency in manufacturing. By aligning grains effectively, you enhance material strength, reduce defects, and improve overall product performance. This technology also offers long-term benefits, including reduced waste, lower labor costs, and increased production flexibility. Future advancements, such as AI-driven dynamic tool path optimization and hybrid additive-subtractive manufacturing, promise even greater efficiency and precision. Industries like aerospace, automotive, and medical manufacturing rely on CNC to produce high-quality, durable components, showcasing its indispensable value in modern production.

FAQ

What is CNC machining, and how does it relate to grain flow?

CNC machining is a computer-controlled process that shapes materials with precision. It aligns grain flow by cutting along the material's natural structure. This alignment improves strength, durability, and performance, making CNC essential for high-quality manufacturing.

Why is grain flow important in manufacturing?

Grain flow determines a material's strength and resistance to stress. Proper alignment reduces weak points, enhances fatigue resistance, and extends product lifespan. Misaligned grains can lead to fractures and defects, compromising the component's reliability.

How does CNC machining reduce material waste?

CNC machining uses precise cutting tools and programmed paths to minimize unnecessary material removal. This efficiency reduces waste, saves costs, and supports sustainable manufacturing practices. By optimizing grain flow, CNC also ensures fewer defects, further reducing discarded materials.

Can CNC machining handle complex geometries?

Yes, CNC machining excels at producing intricate designs. Multi-axis machines and adaptive strategies allow you to maintain grain alignment even in curved or irregular shapes. This capability ensures high-quality components for demanding applications.

What industries benefit most from CNC-optimized grain flow?

Industries like aerospace, automotive, and medical manufacturing rely heavily on CNC machining. It ensures durable, high-performance components such as turbine blades, engine parts, and medical implants. These industries demand precision and reliability, which CNC provides.

See Also

Enhancing Manufacturing Quality Through CNC Machining Innovations

The Impact of CNC Technology on Precision Manufacturing Evolution

Exploring Key Processes Involved in CNC Precision Machining

CNC Turning: Key Features of Precision Machining Explained

Exploring CNC Technology Advancements and Their Manufacturing Applications

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com