Ensuring Material Quality with CNC Machining Standards

Material quality plays a vital role in cnc machining. Every component must meet strict specifications to ensure durability and performance. Advanced equipment and thorough inspections help manufacturers achieve this. Standards like ISO 9001 and ASTM guide these processes, ensuring precision and reliability. Certifications also reduce waste and improve cost-efficiency by streamlining workflows. Quality control ensures that even the smallest deviations are caught before production continues. By adhering to these standards, you can maintain consistency and deliver high-quality results every time.

Key Takeaways

Good material quality is very important for CNC machining. Check that materials match project needs to make them strong and work well.

Taking care of CNC machines and checking them often is key. This stops big mistakes and keeps them working smoothly for a long time.

Using smart tools helps check quality better. Sensors and live monitoring find problems early and save time.

Following rules like ISO 9001 helps gain customer trust. These rules keep quality steady and allow access to special markets.

Mixing machine checks with human checks gives better results. This reduces mistakes and makes production faster and better.

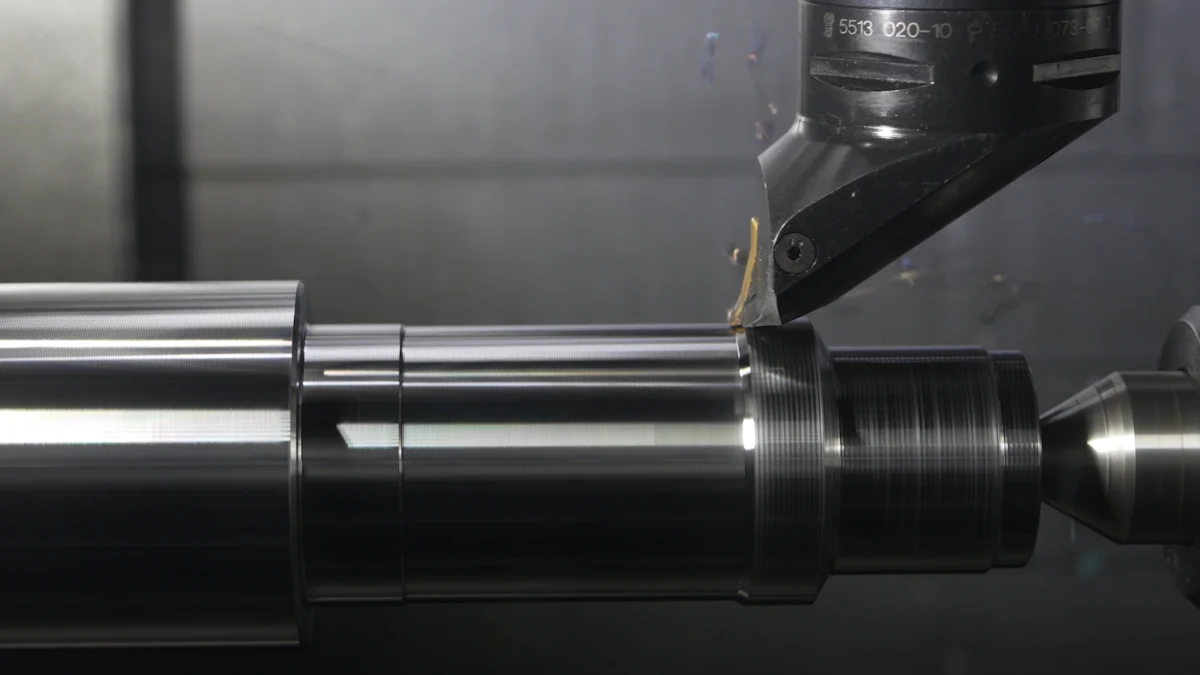

The Role of CNC Machines in Ensuring Material Quality

Selecting the Right CNC Machine

Importance of machine precision and calibration

Precision is the backbone of cnc machining. A machine with high accuracy ensures that every part meets the exact specifications. Calibration plays a critical role in maintaining this precision. Regularly calibrated machines prevent deviations that could compromise quality. For example, a well-calibrated cnc machine ensures that dimensions, tolerances, and surface finishes align with your requirements. This level of accuracy reduces the risk of defects and enhances product reliability.

Impact of machine capabilities on material quality

The capabilities of a cnc machine directly influence the quality of the final product. Machines designed for specific applications handle materials more effectively. For instance, selecting a machine based on material properties like hardness or machinability ensures consistent results. Factors such as dimensional stability, electrical conductivity, and operating environment also play a role. By choosing a machine that matches your application needs, you can achieve superior machining quality control and reduce unexpected issues during production.

Maintenance and Calibration of CNC Machines

Regular maintenance to ensure consistent performance

Routine maintenance is essential for keeping cnc machines in top condition. Tasks like cleaning, lubrication, and part replacement help maintain consistent performance. Regular calibration fine-tunes the machine’s settings, ensuring accuracy over time. Proactive maintenance schedules prevent costly errors and minimize downtime. For example, controlling environmental factors like temperature and vibration during calibration ensures precise results. Qualified technicians should handle these tasks to maintain the machine’s reliability.

Consequences of neglecting machine upkeep

Neglecting maintenance can lead to serious consequences. Machines lose precision, resulting in poor product quality and customer dissatisfaction. Unplanned downtime disrupts production and increases costs. Minor issues, if ignored, can escalate into expensive repairs. Additionally, neglected machines pose safety risks to operators and reduce the equipment’s lifespan. By prioritizing maintenance, you can avoid these risks and ensure smooth operations.

Raw Material Quality Inspection in CNC Machining

Pre-Machining Material Testing

Verifying material properties against specifications

Before machining begins, verifying the properties of raw materials ensures they meet your project’s requirements. This step lays the foundation for achieving high-quality results. Material hardness and strength are critical factors to evaluate. Hardness determines a material's resistance to deformation, while strength measures its ability to withstand force. These properties influence the selection of cutting tools and machining parameters. By confirming that materials align with specifications, you can avoid defects and ensure the final product meets durability and performance standards.

Common testing methods for raw materials

Testing raw materials involves several reliable methods to ensure quality control:

Coordinate Measuring Machine (CMM): Measures complex geometries with precision, ensuring dimensional accuracy.

Surface Roughness Testers: Evaluate surface finish quality, which is essential for functionality.

Non-Destructive Testing (NDT): Techniques like ultrasonic testing detect internal flaws without damaging the material.

These methods help you identify potential issues early, saving time and resources during production.

Consequences of Neglecting Raw Material Inspection

Impact on product durability and performance

Skipping raw material quality inspection can compromise the durability and performance of your products. Substandard materials may fail under stress, leading to unreliable components. For example, undetected flaws in the material can result in cracks or deformation during machining. This oversight directly affects the quality of the final product, reducing its lifespan and functionality.

Increased costs due to rework and waste

Neglecting inspection also increases costs. Defective materials lead to rework, wasted resources, and production delays. Repairing or replacing faulty components consumes time and money. Additionally, using poor-quality materials can pose safety risks, further escalating expenses. By prioritizing raw material inspection, you can minimize waste and maintain efficient operations.

Tip: Investing in thorough raw material testing upfront can save you from costly errors and ensure consistent quality control throughout the machining process.

Quality Control Procedures in CNC Machining

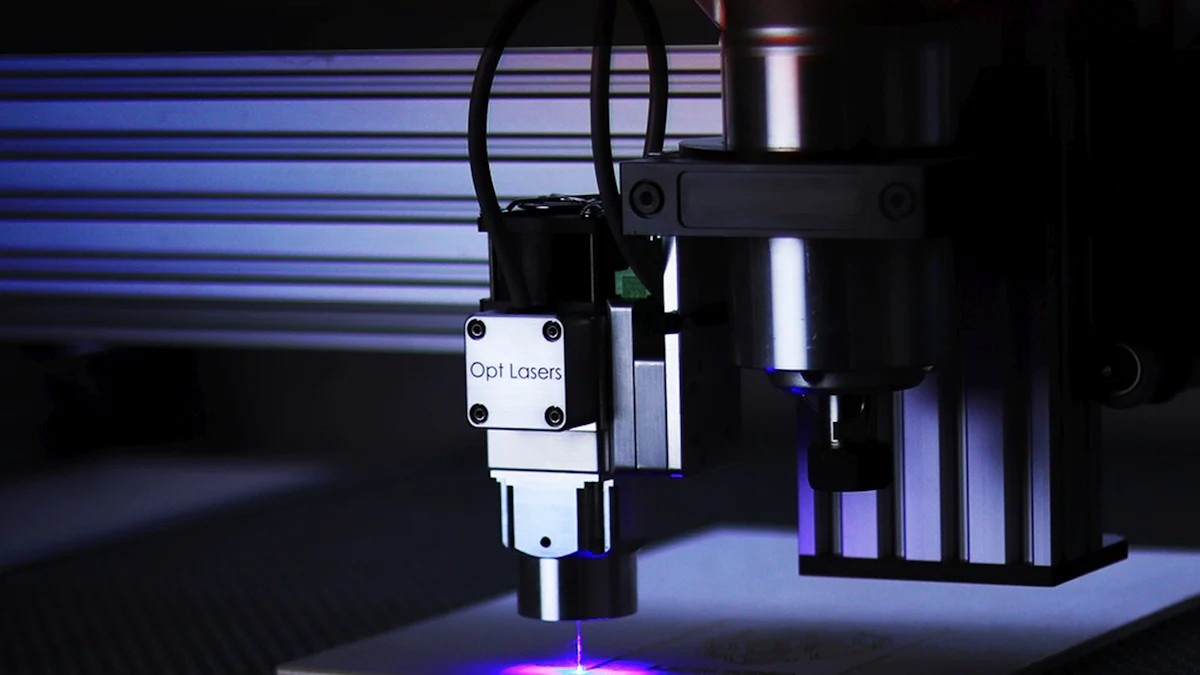

Automated Inspection Techniques

Role of sensors and software in quality assurance

Automated inspection techniques rely heavily on advanced sensors and software to maintain quality assurance. Sensors monitor critical parameters like temperature, pressure, and humidity in real time. These factors directly affect machining precision and material properties. For example, temperature sensors ensure the machining environment remains stable, preventing defects caused by fluctuations. Additionally, CNC machines equipped with feedback systems continuously check tool performance and workpiece accuracy. Automated monitoring systems also assess tool wear and predict tool life, allowing you to make timely adjustments and avoid costly errors.

Benefits of real-time monitoring during machining

Real-time monitoring offers several benefits for machining quality control. On-machine inspection eliminates errors caused by moving parts between stations. This method ensures high accuracy and reduces the time required for quality checks. Statistical process control (SPC) identifies variations in the machining process, enabling immediate corrective actions. Combining SPC with real-time monitoring enhances process stability and prevents defects before they occur. These advancements improve efficiency and ensure consistent quality throughout production.

Manual Inspection Methods

Visual inspections and dimensional checks

Manual inspection methods remain essential for certain applications. Visual inspections help you identify surface defects like scratches or cracks. Dimensional checks verify that components meet specified tolerances. These methods are straightforward and require minimal equipment, making them ideal for small-scale projects or customized parts. For example, a simple caliper can measure dimensions with sufficient accuracy for many tasks.

When manual inspections are most effective

Manual inspections work best for low-volume production or when quick turnaround is needed. They are cost-effective and do not require programming or complex setups. However, they are less suitable for large-scale operations due to slower processing times and the potential for human error. Despite these limitations, manual methods provide flexibility and are easy to implement for specific quality control requirements.

Note: While manual inspections are useful, combining them with automated techniques ensures a more comprehensive approach to quality control.

Combining Automated and Manual Inspections

Achieving comprehensive quality control

Combining automated and manual inspections allows you to leverage the strengths of both methods. Automated systems provide high accuracy and efficiency, while manual methods offer flexibility and adaptability. For instance, integrating on-machine inspection with SPC creates a robust quality control system. This hybrid approach enhances precision and ensures broader process stability. It also enables you to address both large-scale production and customized projects effectively.

Reducing errors and improving efficiency

Using both inspection methods reduces errors and improves overall efficiency. Real-time monitoring identifies deviations immediately, while SPC provides insights into long-term trends. Together, they minimize scrap and rework by ensuring defects are caught early. Predictive capabilities from SPC, combined with immediate corrective actions from on-machine inspection, virtually eliminate issues caused by process drifts. This integrated approach ensures your components meet the highest quality standards, enhancing customer satisfaction and operational efficiency.

The Importance of Certifications and Standards in CNC Machining

Key Certifications for CNC Machining

ISO 9001 and its relevance to CNC machining

ISO 9001 certification plays a crucial role in CNC machining by ensuring that every process follows a well-defined Quality Management System (QMS). This certification focuses on maintaining stringent quality standards, which are essential for high-quality production. It requires you to document and monitor all processes, ensuring consistency and accuracy in every product. Regular internal audits and management reviews help you identify areas for improvement, keeping your operations efficient and reliable. By adhering to ISO 9001, you can enhance customer satisfaction and build trust through consistent quality control.

Other industry-specific certifications

Several other certifications cater to specific industries, further elevating the quality of CNC machining.

AS9100: Designed for aerospace manufacturing, this certification emphasizes risk management and compliance with strict industry standards.

ISO 13485: Tailored for medical device manufacturing, it ensures that your quality management system meets regulatory requirements.

These certifications help you meet the unique demands of specialized markets, ensuring high-quality outcomes in every project.

Benefits of Adhering to Standards

Ensuring consistent material quality

Adhering to standards ensures that your CNC machining processes consistently deliver high-quality outcomes. Compliance involves inspecting raw materials to verify their properties and conducting thorough inspections during and after machining. Techniques like First Article Inspection (FAI) and Statistical Process Control (SPC) help you maintain accuracy and reduce variability. These practices ensure that every part meets stringent quality standards, enhancing durability and performance.

Building trust with clients and stakeholders

Certifications demonstrate your commitment to quality management, fostering trust with clients and stakeholders. They show that your processes meet industry expectations, making you a reliable partner. Certified providers often gain access to specialized markets, such as aerospace or medical industries, where compliance is non-negotiable. This trust translates into long-term partnerships and a competitive edge in the market.

Maintaining Compliance with Certifications

Steps to comply with certification requirements

Maintaining compliance with certifications involves several key steps:

Preparation and Training: Conduct a gap analysis to identify areas needing improvement and train your team on certification standards.

Documentation and Implementation: Develop a QMS and document all processes to ensure transparency and consistency.

Internal and External Audits: Perform regular internal audits to identify non-compliance and prepare for external audits.

Certification and Renewal: Obtain certification and commit to continuous improvement to maintain compliance.

Regular audits and updates to maintain compliance

Regular audits validate your adherence to certification standards. Internal audits help you identify gaps and make necessary adjustments before external evaluations. These reviews ensure that your processes align with quality management requirements, reducing compliance risks. By staying proactive, you can maintain high-quality production and avoid costly disruptions.

CNC machining standards play a vital role in ensuring material quality. They help you maintain consistent product performance, safety, and reliability. By adhering to these standards, you mitigate risks and build trust with clients and stakeholders. Quality control measures, such as real-time monitoring and SPC, reduce waste and improve efficiency. Early error detection minimizes defects, saving time and resources. To stay compliant, focus on regular training, clear accountability, and integrating standards into daily workflows. Prioritizing certifications and quality management ensures your CNC processes deliver superior results every time.

FAQ

What is the most important factor in CNC machining quality?

Material quality and machine precision are the most critical factors. You must ensure that raw materials meet specifications and that CNC machines are calibrated. These steps guarantee accurate machining and consistent results.

How often should you calibrate CNC machines?

You should calibrate CNC machines regularly, depending on usage. For high-volume production, monthly calibration ensures precision. For less frequent use, quarterly calibration may suffice. Always follow the manufacturer’s recommendations.

Why are certifications like ISO 9001 important?

Certifications like ISO 9001 ensure that your processes meet global quality standards. They help you maintain consistency, improve efficiency, and build trust with clients. Adhering to certifications also opens opportunities in specialized industries.

Can automated inspections replace manual inspections?

Automated inspections provide speed and accuracy, but they cannot fully replace manual inspections. You should combine both methods for comprehensive quality control. Manual inspections are ideal for detecting surface defects or handling custom projects.

How does neglecting maintenance affect CNC machining?

Neglecting maintenance reduces machine precision and increases downtime. It leads to poor product quality, higher repair costs, and safety risks. Regular maintenance ensures consistent performance and extends the machine’s lifespan.

See Also

Grasping Material Needs for CNC Precision Machining Success

Enhancing Quality Outcomes Through CNC Precision Machining Techniques

Excelling in CNC Machining: Tolerances, Prototypes, and Materials

Achieving Precision Parts Production Through CNC Machining Mastery

Satisfying CNC Precision Machining Standards for Part Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com