How CNC Machining Works with Metals: Aluminum, Steel, and More

CNC machining transforms raw materials like metal into precise components using automated tools. This process relies on advanced software and machinery to achieve high accuracy and repeatability. Metals such as aluminum and steel are ideal due to their machinability and versatility. Understanding metal properties like tensile strength and hardness ensures better tool selection and cost efficiency. Easier-to-machine metals, such as aluminum, reduce tool wear and speed up production. Recent trends, including increased automation and sustainability, highlight the growing importance of CNC in modern manufacturing.

🌟 Did you know? The CNC machining market is projected to grow from $95 billion in 2022 to $154 billion by 2032, with a 5% CAGR.

Key Takeaways

CNC machines make metal parts accurately and save time and materials.

Knowing how metals behave helps pick the best one for a job.

Aluminum is light and simple to shape, great for planes and cars.

Steel is very strong but harder to shape; proper tools are key.

Taking care of CNC machines keeps them working well and lasting longer.

CNC Machining and Its Compatibility with Metals

How CNC Machines Work

Precision and automation in CNC machining.

CNC machining relies on advanced automation to deliver unmatched precision. You can achieve intricate designs and tight tolerances by programming the machine to follow exact instructions. The process begins with a computer interpreting CAD models and converting them into G-code. This code directs the machine's movements, ensuring every cut, drill, or contour is accurate. CNC machines operate across multiple axes, allowing you to create complex shapes with ease. Whether you're milling, boring, or drilling, the automation ensures consistent results, reducing errors and waste.

Key components for metalworking.

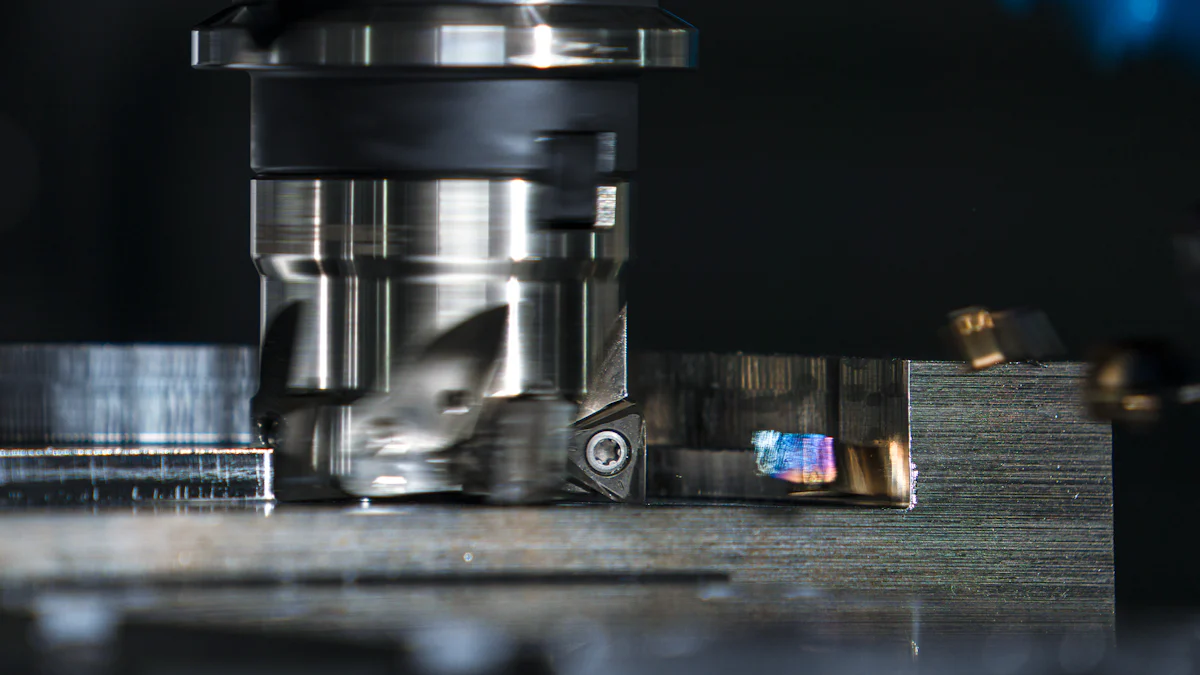

CNC machines use specialized tools to manipulate materials effectively. For metalworking, tools like lathes, milling machines, and plasma cutters play a crucial role. Lathes rotate the workpiece while a stationary cutting tool removes material, making them ideal for cylindrical parts. Milling machines, on the other hand, move the cutting tool across the workpiece to shape it. Plasma cutters use a high-velocity jet of ionized gas to cut through metals like steel and aluminum. These components work together to handle the demands of machining metals with precision and efficiency.

Why Metals Are Ideal for CNC Machining

Versatility and machinability of metals.

Metals are among the most common machining materials due to their versatility and machinability. Aluminum, for example, is lightweight, corrosion-resistant, and easy to machine. It offers a favorable strength-to-weight ratio, making it suitable for various applications. Brass is another excellent choice, known for its ease of machining and aesthetic appeal. While steel and titanium are harder to machine, they provide superior strength and durability. This balance between machinability and performance makes metals indispensable for CNC machining.

Common industries using CNC machining with metals.

CNC machining plays a vital role in many industries. You’ll find it used in aerospace for creating lightweight yet strong components. The automotive sector relies on CNC for precision parts like engine blocks and gears. In medicine, CNC machines produce surgical instruments and implants. Other industries, such as consumer goods, telecommunications, and robotics, also depend on CNC machining for high-quality metal parts. From electronics to the military, CNC machining supports a wide range of applications, showcasing its importance across various fields.

Properties of CNC Machining Materials

Aluminum

Lightweight, corrosion resistance, and machinability.

Aluminum stands out as one of the most popular CNC machining materials due to its unique properties. Its exceptional machinability allows you to create intricate shapes and designs with precision. This characteristic speeds up the machining process while maintaining accuracy, making it ideal for complex components. Aluminum also offers a high strength-to-weight ratio, providing robust structural performance without adding unnecessary weight. This makes it perfect for industries where weight reduction is critical. Additionally, its natural corrosion resistance, thanks to a protective oxide layer, ensures long-lasting durability even in harsh environments. These material characteristics make aluminum a versatile choice for CNC machining.

Common applications in aerospace and automotive.

Aluminum plays a vital role in industries like aerospace and automotive. Its strength-to-weight ratio makes it indispensable for aircraft components, where efficiency and performance are paramount. High corrosion resistance ensures safety and longevity in challenging conditions, such as exposure to moisture or extreme temperatures. Aluminum grades with excellent thermal and electrical conductivity are also used in heat dissipation systems and electrical wiring. Furthermore, its fatigue resistance allows it to endure repeated stress, which is essential for structural integrity in vehicles and aircraft. The malleability of aluminum alloys enables the creation of intricate parts, making it a go-to material for these industries.

Steel

Strength, durability, and challenges in machining.

Steel is another widely used material in CNC machining due to its strength and durability. It offers superior mechanical properties, making it suitable for load-bearing and high-stress applications. However, machining steel presents challenges. Stainless steel alloys, for instance, harden quickly and have a gummy texture, which can make the machining process more difficult. Steel's low thermal conductivity also causes overheating during cutting, which can affect tool life and part quality. Despite these challenges, steel remains a top choice for applications requiring toughness and reliability.

Solutions for machining steel effectively.

To overcome the challenges of machining steel, you can use specific strategies. First, select the right tools and ensure experienced operators handle the CNC machines. Using low-speed tools helps reduce heat generation, preventing overheating. Choosing the appropriate cutting tools can also speed up the machining process, saving time and resources. For achieving a flawless finish, expertise and high-quality tools are essential. Whether you're working with mild steel, alloy steel, or tool steel, these solutions ensure efficient and precise machining.

Other Metals

Titanium: High strength-to-weight ratio.

Titanium offers an impressive strength-to-weight ratio, making it ideal for applications requiring both durability and lightweight properties. Its corrosion resistance ensures longevity, even in extreme environments. Titanium's machinability allows for the production of precision components, making it a preferred choice in aerospace, medical, and automotive industries.

Brass: Ease of machining and aesthetic appeal.

Brass is known for its excellent machinability, which reduces tool wear and extends tool life. Its aesthetic appeal makes it a popular choice for decorative elements. Brass also provides good corrosion resistance, making it suitable for plumbing and marine applications. Its high thermal and electrical conductivity further enhances its versatility in CNC machining.

Comparing Metals for CNC Machining

Machinability

Factors like hardness and thermal conductivity.

When machining metals, hardness and thermal conductivity play a significant role in determining machinability. Hardness measures a material's resistance to deformation. Harder metals, such as stainless steel, require more effort to cut and can cause rapid tool wear. On the other hand, thermal conductivity affects how well a material dissipates heat during machining. Metals with high thermal conductivity, like aluminum, reduce heat buildup, which helps extend tool life and improves surface finish. Understanding these factors allows you to select the right tools and settings for efficient machining.

Comparison of aluminum, steel, and other metals.

Different metals offer varying levels of machinability:

Aluminum: Soft and thermally conductive, making it one of the easiest metals to machine.

Brass: Known for its excellent machinability and minimal tool wear.

Stainless Steel: Hard and generates high cutting forces, leading to challenges in machining.

Titanium: Strong but has low thermal conductivity, requiring specialized tools and techniques.

By comparing these properties, you can choose the best material for your CNC machining project.

Cost and Performance

Cost-effectiveness of different metals.

The cost of machining metals varies based on their properties and processing requirements:

Aluminum is lightweight, easy to machine, and cost-effective for industries like aerospace and automotive.

Mild steel offers low cost and versatility, making it a popular choice for many applications.

Stainless steel and titanium are more expensive due to their hardness and the need for specialized tools.

Aluminum alloys, such as 7075, also save costs by eliminating the need for additional finishing processes, unlike steel, which often requires treatments like black oxide.

Balancing performance with budget.

Balancing performance and budget involves considering material availability, efficient usage, and machining requirements. For example:

Aluminum provides a balance of low cost, machinability, and corrosion resistance.

Brass combines affordability with aesthetic appeal and functionality.

Mild steel offers strength and versatility at a lower price point.

Selecting a material that naturally meets your design and surface finish requirements can reduce costs by avoiding additional processing.

Application Suitability

Choosing metals based on project needs.

Selecting the right metal depends on factors like mechanical properties, corrosion resistance, and fabrication ease. For example, aluminum is ideal for lightweight structures, while stainless steel works well in environments requiring corrosion resistance. Cost and service life also influence your decision.

Examples of metal selection in various industries.

Industries choose metals based on their specific needs:

Aerospace: Aluminum alloys like 6061 and 7075 for lightweight frames.

Automotive: Aluminum for engine parts and steel for durable components.

Medical: Titanium for implants due to its strength and biocompatibility.

Consumer Products: Stainless steel for its corrosion resistance and aesthetic finish.

These examples highlight how different types of metal materials meet diverse industry requirements.

Selecting the Right CNC Machining Materials

Material Properties

Strength, weight, and thermal conductivity.

When selecting CNC machining materials, you must evaluate their strength, weight, and thermal conductivity. Strength determines how well the material can withstand stress without deforming. For example, steel offers exceptional strength, making it ideal for load-bearing applications. Weight plays a critical role in industries like aerospace, where lighter materials such as aluminum improve efficiency. Thermal conductivity affects heat dissipation during machining. Aluminum, with its high thermal conductivity, reduces heat buildup, ensuring smoother operations and longer tool life. These properties directly influence the performance and machinability of your chosen material.

Corrosion resistance and surface finish.

Corrosion resistance is essential for parts exposed to harsh environments. Materials like stainless steel and aluminum naturally resist corrosion, making them suitable for outdoor or marine applications. Surface finish also matters, especially for components requiring aesthetic appeal or smooth functionality. Brass, for instance, offers a polished finish with minimal effort, while steel often requires additional treatments. By considering these factors, you can ensure durability and visual quality in your CNC projects.

Project Requirements

Load-bearing capacity and environmental factors.

Understanding how your part will be used is key to material selection. For load-bearing components, steel provides the necessary strength and reliability. Environmental factors, such as exposure to moisture or extreme temperatures, also play a role. Aluminum works well in corrosive environments, while titanium excels in high-temperature conditions. Always match the material to the part's functional and environmental demands.

Industry-specific needs and standards.

Different industries follow specific standards for CNC machining materials. For example, aerospace applications often require materials that meet SAE J403 steel grade specifications. Medical devices demand biocompatible metals like titanium. Standards such as ISO 9001 and ASTM ensure quality and performance consistency. Familiarizing yourself with these requirements helps you choose materials that align with industry expectations.

Machining Considerations

Tool wear and cutting speed.

Tool wear and cutting speed significantly impact machining outcomes. Higher cutting speeds improve efficiency but can cause rapid tool wear, especially when working with hard materials like steel. Aluminum allows for faster cutting speeds due to its softness and thermal conductivity. To balance efficiency and tool longevity, you should optimize cutting speeds based on the material's properties. Properly maintained tools also ensure consistent results and reduce downtime.

Importance of proper tooling and settings.

Using high-quality tooling is crucial for precision and efficiency. Tools must match the material being machined. For example, carbide tools work well with steel, while softer metals like aluminum require less robust tooling. Correct CNC settings, including feed rate and depth of cut, further enhance machining accuracy. Regularly inspecting and maintaining your tools ensures they perform at their best, delivering high-quality results every time.

Practical Tips for CNC Machining Metals

Tool Selection and Maintenance

Choosing the right tools for specific metals.

Selecting the right tools is essential for achieving optimal results in CNC machining. You should consider the material being machined and the desired outcome. For example, aluminum and brass are highly machinable and require less robust tooling, while harder materials like steel demand specialized tools with durable coatings. Pay attention to tool geometry, as it directly impacts cutting efficiency. Tools made from carbide or cermet materials often perform better with harder metals, ensuring longer tool life and consistent results.

When choosing tools, evaluate factors such as the workpiece material, production volume, and machine capacity. High-quality tools not only improve machining efficiency but also reduce the risk of damage to CNC machines.

Regular maintenance for precision and longevity.

Regular maintenance ensures your CNC tools and machines operate at peak performance. Routine cleaning and inspections prevent unexpected breakdowns that could disrupt precision. You should check for wear and tear on components and calibrate tools regularly to maintain accuracy. A structured maintenance schedule enhances the lifespan of your CNC equipment, ensuring reliable production output over time. By prioritizing upkeep, you can minimize downtime and maintain high standards in your machining operations.

Optimizing CNC Settings

Adjusting feed rate, speed, and depth of cut.

Optimizing CNC settings is crucial for machining different metals effectively. Each parameter—feed rate, spindle speed, and depth of cut—should align with the material's properties. For example, aluminum allows for higher spindle speeds and deeper cuts, while steel requires slower speeds and shallower depths to prevent tool wear.

Metal | Spindle Speed (RPM) | Cutting Speed (ft/min) | Feed Rate (IPT) | Depth of Cut (inches) |

|---|---|---|---|---|

Aluminum | 3000-6000 | 600-1000 | 0.002-0.005 | 0.04-0.10 |

Steel | 1500-3000 | 100-400 | 0.001-0.004 | 0.02-0.08 |

Adjusting these settings based on the material and tool condition ensures better surface finishes and reduces production costs. Softer materials like aluminum can handle faster feed rates, while harder metals like steel require slower, more controlled machining to avoid excessive tool wear.

Using coolant and lubrication effectively.

Coolants and lubricants play a vital role in CNC machining. They reduce heat buildup, improve tool life, and enhance surface finishes. When machining steel, using a high-quality coolant prevents overheating and ensures smoother cuts. For aluminum, lubrication minimizes friction and prevents material from sticking to the tool. Always choose the appropriate coolant or lubricant based on the material and machining process to achieve the best results.

Ensuring Quality Control

Inspecting parts for accuracy and defects.

Quality control ensures your CNC-machined parts meet design specifications. You should inspect parts for dimensional accuracy and surface defects using tools like calipers and micrometers. Advanced equipment such as Coordinate Measuring Machines (CMM) can verify complex geometries against CAD models. Regular inspections help identify issues early, reducing waste and ensuring consistent quality.

Using advanced measurement tools.

Advanced measurement tools enhance precision in CNC machining. A profilometer measures surface roughness, ensuring finishes meet specified parameters. CMMs provide 3D measurements for verifying intricate designs. For hardness testing, tools like the Rockwell Hardness Tester offer quick and accurate results. By incorporating these tools into your quality control process, you can maintain high standards and deliver reliable products.

CNC machining plays a vital role in transforming metals like aluminum and steel into precise components. It enhances efficiency by reducing setup time and increasing production speed. You can achieve tighter tolerances and minimize waste through automation, making CNC essential for industries like aerospace and automotive. Understanding metal properties ensures better machinability and cost-efficiency.

When selecting the right metal, consider factors like material properties, machinability, and operating environment. For example, aluminum offers lightweight machinability, while steel provides strength for load-bearing applications. Use the table below to guide your decision-making:

Consideration | Description |

|---|---|

Material Properties | Align with the final part’s intended application, operating environment, and required precision. |

Machinability | Determines how easily a material can be cut, shaped, and finished, affecting production costs. |

Operating Environment | Influences material choice based on exposure to extreme temperatures or chemical environments. |

Critical for industries like aerospace; materials must maintain accuracy under stress. | |

Cost Considerations | Material cost is crucial, especially for large production runs. |

By understanding these factors, you can select the optimal metal for your CNC machining project, ensuring both performance and cost-effectiveness.

FAQ

What is CNC machining, and why is it important?

CNC machining uses automated tools to create precise parts from materials like metals. It ensures high accuracy, repeatability, and efficiency. This process is essential for industries requiring complex designs and tight tolerances, such as aerospace, automotive, and medical manufacturing.

How do you choose the right metal for CNC machining?

You should consider factors like strength, weight, corrosion resistance, and machinability. Match the material to your project's requirements, such as load-bearing capacity or environmental conditions. For example, aluminum suits lightweight applications, while steel works well for heavy-duty components.

What are the benefits of using CNC for metalworking?

CNC offers precision, speed, and consistency. It reduces material waste and minimizes errors. You can create intricate designs with tight tolerances, making it ideal for industries like aerospace and automotive. Its automation also lowers production costs over time.

Can CNC machines handle all types of metals?

CNC machines can process most metals, including aluminum, steel, titanium, and brass. However, machinability varies. Softer metals like aluminum are easier to machine, while harder ones like stainless steel require specialized tools and techniques.

How do you maintain quality in CNC machining?

You should inspect parts regularly using tools like calipers or Coordinate Measuring Machines (CMM). Advanced measurement tools ensure accuracy and detect defects. Routine quality checks help maintain high standards and reduce waste in production.

See Also

Benefits of Utilizing Aluminum CNC Machining Services Today

Understanding CNC Machining for Precision Metal Fabrication

Key Processes Involved in CNC Precision Machining Explained

CNC Machining Aluminum Alloys 6061 and 7075: A 2024 Overview

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com