How CNC Machining Minimizes Material Waste in 2025

You might not realize how much material waste traditional manufacturing methods generate. These methods often require extensive post-processing, which leads to unnecessary scrap and overproduction. CNC machining changes this by offering unmatched precision and efficiency. It produces less waste when converting raw materials into finished parts. This process uses advanced tools to shape materials accurately, reducing the need for additional adjustments. By minimizing resource consumption, CNC machining ensures you get the most out of every piece of material, making it a game-changer for sustainable manufacturing.

Key Takeaways

CNC machining cuts and shapes materials exactly, wasting less.

Automation removes human mistakes, making products the same every time.

Planning with CAD/CAM software uses materials wisely, leaving little waste.

Recycling systems reuse scraps, helping the environment and saving resources.

Using AI and renewable energy will make CNC machining even better.

Precision and Efficiency in CNC Machining

How CNC Machines Reduce Waste Through Accuracy

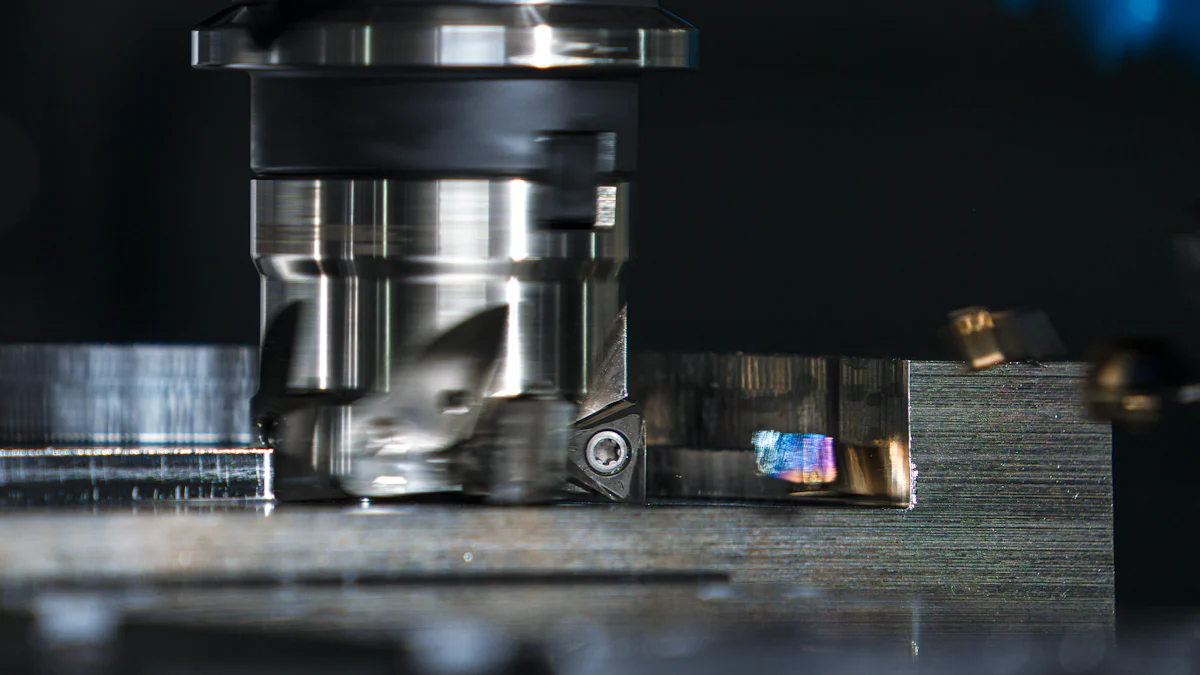

Pinpoint cutting and shaping with minimal excess

CNC machining ensures precise cutting and shaping, leaving little room for material waste. The computer numerical control system guides the cutting process with unmatched accuracy. This precision allows you to achieve the exact dimensions required for your parts without unnecessary trimming or adjustments. By using advanced tools and techniques, CNC machines reduce waste by producing components that meet specifications on the first attempt.

The features of CNC machining that contribute to this precision include optimized machine setups, cutting parameters, and simulation software. These elements work together to ensure every cut is deliberate and efficient.

Feature | Contribution to Precision and Efficiency |

|---|---|

Machine Setup | Ensures correct tool length, diameter, and configuration for accuracy. |

Cutting Parameters | Fine-tuning feed rate, speed, and cutting depth enhances performance. |

Multi-Axis Machining | Reduces setup changes and cycle times, increasing productivity. |

Quality Cutting Tools | Improves operational efficiency and reduces downtime for tool replacement. |

Material Optimization | Reduces waste and ensures correct final products, saving time. |

Efficient CAD/CAM Programming | Minimizes unnecessary tool changes and optimizes tool paths. |

Simulation Software | Identifies inefficiencies before production, enhancing quality and safety. |

Automation to eliminate human error and overproduction

Automation in CNC machining eliminates the inconsistencies caused by manual processes. You no longer need to worry about errors from miscalculations or fatigue. CNC machines follow programmed instructions with precision, ensuring consistent results. This automation also prevents overproduction by producing only the required quantity of parts. By reducing human error and unnecessary output, CNC machines reduce waste and improve production efficiency.

Optimized Material Usage for Minimized Material Waste

Careful planning of product design and layout

CNC machining relies on careful planning to optimize material usage. Before the machining process begins, CAD/CAM software helps you design and layout parts efficiently. This software ensures that every piece of raw material is used effectively, leaving minimal scrap. By incorporating lean manufacturing principles, CNC machining services streamline workflows and eliminate unnecessary steps. This approach enhances material efficiency and supports sustainable manufacturing practices.

Efficient machining parameters to reduce scrap

Fine-tuning machining parameters plays a critical role in waste reduction. Adjusting feed rates, cutting speeds, and tool paths ensures that the process uses materials efficiently. CNC technology also incorporates recycling strategies, such as reusing scrap materials, to promote sustainability. By implementing a closed-loop system, you can collect and reuse leftover materials, reducing the need for new resources. These practices not only minimize material waste but also contribute to significant cost savings.

Advanced Technologies Driving Waste Reduction

CAD/CAM Software and Toolpath Optimization

Efficient nesting of parts to maximize raw material usage

CAD/CAM software plays a crucial role in improving material efficiency during machining. It automates the creation of optimized toolpaths based on CAD models, ensuring every piece of raw material is used effectively. By nesting parts efficiently, you can maximize the number of components produced from a single sheet of material. This reduces material waste and supports sustainable manufacturing. Intelligent tool selection within the software further enhances efficiency by minimizing tool wear and ensuring precise cutting. Adaptive cutting techniques also allow real-time adjustments to the cutting process, optimizing material removal and reducing waste.

Toolpath planning to minimize scrap and energy consumption

Toolpath optimization refines the paths that cutting tools follow, maximizing production efficiency. This process reduces machining time and material waste while lowering energy consumption. By automating the translation of CAD designs into precise CNC instructions, toolpath planning ensures consistent quality and minimizes errors that could lead to scrap. These improvements not only enhance sustainability but also reduce the environmental impact of CNC machining services.

Recycling and Closed-Loop Systems

Reusing scrap materials to promote a circular economy

Recycling systems in CNC machining promote sustainability by reusing scrap materials. Closed-loop systems allow you to collect, process, and reintegrate waste materials back into the production cycle. This approach minimizes the need for new resources and reduces overall waste. By optimizing cutting patterns, manufacturers can extract the maximum number of parts from a single piece of material, further supporting a circular economy.

Integration of recycling systems in CNC workflows

Closed-loop coolant systems are another example of sustainable practices in CNC machining. These systems recycle and reuse coolant, significantly reducing water demand. Machines equipped with closed-loop systems continuously reuse coolant, lowering overall water usage and contributing to environmental sustainability. Integrating these systems into CNC workflows ensures efficient resource utilization and minimizes waste.

Multi-axis Machining for Complex Designs

Reducing setups and material waste for intricate parts

Multi-axis machining enhances production efficiency by completing complex tasks in a single setup. This reduces the need for multiple fixtures and repositioning of the workpiece, minimizing material waste. Consolidating operations into one setup also lowers cycle times and reduces the need for costly work fixtures. These advantages make multi-axis machining a valuable tool for sustainable manufacturing.

Enhancing precision in complex geometries

Multi-axis machining allows cutting tools to move across multiple axes simultaneously, enabling the creation of intricate parts with high precision. This process is ideal for producing complex geometries, such as undercuts and detailed 3D shapes, that would be challenging with traditional methods. By combining several standalone operations into one, multi-axis machining improves accuracy and reduces errors, ensuring superior quality control and efficient use of materials.

Environmental and Economic Benefits of CNC Machining

Sustainability Through Waste Reduction

Lower environmental impact from reduced raw material usage

CNC machining helps you reduce your environmental footprint by optimizing raw material usage. Efficient resource utilization ensures that every piece of material is used effectively, minimizing waste. Energy-efficient CNC machines also lower energy consumption and emissions, contributing to a smaller carbon footprint. By incorporating eco-friendly materials like recycled metals and biodegradable plastics, you can further reduce environmental harm. Closed-loop systems, which collect and reuse scrap materials, promote a circular economy and reduce the need for new resources. These waste-reducing practices not only benefit the environment but also align with sustainable manufacturing goals.

Contribution to sustainable manufacturing practices

CNC machining practices play a vital role in sustainable manufacturing. By optimizing resource use and minimizing waste, you can achieve greater production efficiency. Recycling strategies and energy-efficient technologies further enhance sustainability. Additionally, adopting eco-friendly practices, such as using renewable energy sources and integrating AI for process optimization, ensures that your operations remain environmentally responsible. These sustainable practices not only meet regulatory requirements but also preserve natural resources for future generations.

Cost Savings for Manufacturers

Reduced material costs through efficient resource use

CNC machining services help you save on material costs by maximizing raw material utilization. Effective planning and precise cutting processes ensure minimal waste, reducing the amount of material you need to purchase. Over time, investing in CNC machines leads to significant savings, as these machines are designed to optimize material usage during production. Energy-efficient practices also lower energy costs, further enhancing your overall savings.

Lower waste disposal expenses

Efficient resource use in CNC machining reduces the amount of waste generated, which directly lowers disposal expenses. By implementing lean manufacturing principles, you can scale production to meet demand, preventing excess material waste. Closed-loop systems allow you to collect and reuse scrap materials, minimizing the need for new materials and reducing disposal costs. These strategies not only improve cost efficiency but also support sustainable manufacturing practices.

Improved Operational Efficiency

Faster production cycles with less material waste

CNC machining enhances production efficiency by streamlining workflows and reducing cycle times. Fine-tuning cutting parameters and optimizing machine setups ensure faster production with minimal waste. Preventive maintenance and regular equipment monitoring keep machines running at peak performance, reducing downtime and improving productivity. These improvements allow you to meet production goals more quickly while conserving resources.

Enhanced profitability through resource optimization

Efficient CNC machining practices directly impact your profitability. Waste tracking helps you identify areas for improvement, while quality control minimizes defects and material waste. Preventive maintenance ensures smooth machine operation, reducing unexpected costs. Effective inventory management prevents excess materials, saving you money. By combining these strategies, you can achieve higher profitability while maintaining sustainable manufacturing practices.

Future Trends in CNC Machining for Waste Reduction

AI and Machine Learning Integration

Predictive analytics for material usage and waste reduction

AI is transforming machining by identifying patterns and trends in production processes. You can use AI to analyze data from previous operations, enabling predictive analytics that minimizes waste. For example:

AI adjusts feed rates, cutting speeds, and tool paths based on material properties, ensuring precise machining.

Algorithms detect anomalies in real-time, reducing defect rates by up to 50%.

Predictive maintenance powered by AI optimizes machine performance, preventing unnecessary downtime.

By leveraging these capabilities, you can maximize how you cut metal while reducing material waste and improving efficiency.

Real-time adjustments to optimize machining processes

Real-time feedback systems powered by AI allow you to fine-tune machining parameters during operations. This ensures optimal material usage and reduces waste. Key benefits include:

Adaptive cutting techniques that adjust to material characteristics on the fly.

Monitoring factors like cutting load and surface finish to identify issues early.

Adjusting feed rates and spindle speeds to balance material removal with surface quality.

These advancements help you achieve consistent results while minimizing scrap and energy consumption.

Renewable Energy in CNC Operations

Solar and wind-powered CNC machines for sustainable manufacturing

Renewable energy sources like solar and wind are becoming integral to CNC machining services. Many manufacturers now power their operations with renewable energy, reducing reliance on non-renewable resources. Benefits include:

Enhanced precision and accuracy for critical components like wind turbine blades.

Increased production efficiency through automation and reduced production time.

Improved component reliability, essential for energy infrastructure.

By adopting renewable energy, you can align your machining processes with sustainable manufacturing goals.

Reducing the carbon footprint of CNC machining

Switching to renewable energy significantly lowers the carbon footprint of CNC machining. Companies like Beska Mold lead the way by integrating solar and wind power into their operations. This shift reduces carbon emissions and demonstrates a commitment to sustainability. By using renewable energy, you can contribute to a greener future while maintaining efficient production cycles.

Innovations in Material Science

Development of recyclable and sustainable materials

Material science innovations are enhancing CNC machining processes. Recyclable metals and biodegradable plastics are gaining popularity for their sustainability. These materials reduce waste and align with environmental regulations. Other advancements include:

Bio-based polymers that support eco-friendly manufacturing.

Advanced composites like carbon fiber-reinforced plastics for durable, lightweight components.

Superalloys and ceramics for high-performance applications in aerospace and medical industries.

These materials not only improve machining efficiency but also promote a circular economy.

Enhanced compatibility with CNC machining processes

New materials require advanced tooling and machining strategies to handle their unique properties. For example, ceramics offer exceptional hardness and heat resistance, while advanced alloys like titanium-aluminum mixes provide strength and lightness. By adopting these materials, you can enhance product design and meet the demands of modern manufacturing.

Innovations in material science ensure that CNC machining remains at the forefront of sustainable production, helping you achieve both environmental and economic goals.

CNC machining offers a transformative approach to reducing material waste. By optimizing material use and energy consumption, you can achieve sustainable manufacturing practices. Lean principles and closed-loop systems ensure efficient resource utilization, while recycled materials further enhance productivity. These strategies not only lower costs but also improve your environmental impact and attract eco-conscious customers.

Future trends like AI and renewable energy will elevate CNC machining services. AI enables predictive maintenance and real-time quality control, reducing downtime and defects. Renewable energy sources, such as solar and wind, power operations sustainably. By embracing these innovations, you can enhance efficiency, minimize waste, and contribute to a greener future.

FAQ

What is CNC machining, and how does it reduce material waste?

CNC machining uses computer-controlled tools to cut and shape materials with precision. It minimizes waste by optimizing material usage, reducing errors, and eliminating unnecessary scrap. You can achieve accurate results on the first attempt, which saves resources and supports sustainable manufacturing.

How does CAD/CAM software improve material efficiency?

CAD/CAM software helps you design parts and plan toolpaths efficiently. It ensures optimal nesting of components, reducing leftover material. By automating these processes, the software minimizes waste and enhances production accuracy.

Can CNC machining handle recyclable materials?

Yes, CNC machining works well with recyclable materials like metals and biodegradable plastics. You can reuse scrap materials in closed-loop systems, promoting a circular economy. This approach reduces waste and supports eco-friendly manufacturing practices.

What are the environmental benefits of CNC machining?

CNC machining lowers your environmental impact by reducing raw material waste and energy consumption. It supports sustainable practices like recycling and using renewable energy. These efforts help conserve resources and reduce carbon emissions.

How does multi-axis machining reduce waste?

Multi-axis machining completes complex tasks in a single setup. This reduces the need for multiple fixtures and repositioning, which minimizes material waste. You can produce intricate parts with high precision while saving time and resources.

See Also

Enhancing Quality Control Through CNC Precision Machining Techniques

Grasping Material Needs for Effective CNC Precision Machining

Streamlined CNC Machining Solutions for High-Quality Production

Excelling in CNC Machining: Tolerances, Prototypes, and Materials

The Impact of CNC Machining on Precision Manufacturing Advancements

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com