How CNC Technology Can Improve the Precision and Consistency of Your Products

CNC machining revolutionizes manufacturing by delivering unmatched precision and consistent quality. Industries like aerospace and energy rely on CNC for its ability to maintain tolerances as tight as ±0.001 inches. The automation eliminates human error, ensuring identical parts across production runs. This consistency enhances efficiency and reduces waste, making CNC a cornerstone of modern manufacturing.

Aspect | Detail |

|---|---|

High Precision and Accuracy | CNC machines maintain tolerances of 0.004 mm or ±0.001 inches. |

Consistency and Repeatability | CNC machines can produce identical parts consistently across production runs. |

Continuous Operation | CNC machines operate continuously, enhancing efficiency and reducing production time. |

Key Takeaways

CNC machines improve accuracy by keeping errors within ±0.001 inches. This is very important for industries like aerospace.

CNC automation removes mistakes made by people. It keeps quality the same and makes sure every product is alike.

Picking the best CNC machines and better programming can save time. It also helps make more products and lowers costs.

Understanding CNC Machining

What Is CNC Technology?

CNC technology, or Computer Numerical Control, transforms digital designs into tangible, precise components. Unlike manual machining, CNC machining relies on automated systems to control tools and processes. This advanced CNC technology ensures high accuracy and repeatability, making it ideal for industries requiring tight tolerances.

The core principles and components of CNC machining set it apart from traditional methods. The table below highlights these key aspects:

Core Principles of CNC Machining | Key Components of CNC Machines |

|---|---|

Transformation of digital designs into precise components | Controller: Interprets digital design and sends commands |

Governed by Computer Numerical Control for accuracy | Machine Tool: Performs cutting, drilling, or milling |

High precision in creating components | Drive System: Powers movement of the machine tool |

Material removal method for tangible parts | Feedback System: Ensures correct path and adjustments |

How CNC Machines Operate

CNC machines follow a systematic process to deliver precision and consistency. The operation begins with a digital design, often created using CAD (Computer-Aided Design) software. This design is converted into a machine-readable code, which guides the CNC machine's movements.

Key operational steps include:

Dimensional Accuracy and Tolerance: Ensures parts meet exact specifications.

Material Hardness and Strength: Determines the best machining techniques.

Roughness and Surface Finish: Achieves smooth surfaces for functionality.

Machining Process Control: Monitors cutting speed and tool wear for quality.

Geometric Tolerance: Maintains precise shapes and dimensions.

Assembly and Fit: Confirms parts align perfectly during assembly.

These steps ensure CNC machines deliver consistent results, even for complex designs.

Types of CNC Machines

CNC machines come in various types, each suited for specific applications. Multi-axis machining, a feature of many CNC machines, allows for intricate designs and complex shapes. The table below outlines common CNC machines and their uses:

CNC Machine Type | Applications |

|---|---|

CNC Router | Machining softer materials like wood, steel, foam, composites, aluminum, and plastic. |

CNC Drilling Machine | Producing cylindrical holes using various types of drill bits for specific applications. |

CNC Lathe Machine | Removing material from rotating workpieces for applications like roughing, finishing, and threading. |

5-Axis CNC Machine | Accessing five out of six sides of a workpiece for complex shapes and sculptures. |

CNC Milling Machine | Shaping workpieces using rotating multi-point cutting tools, available in various orientations. |

CNC Plasma Cutting Machine | Cutting electrically conductive materials like brass, copper, aluminum, and steel. |

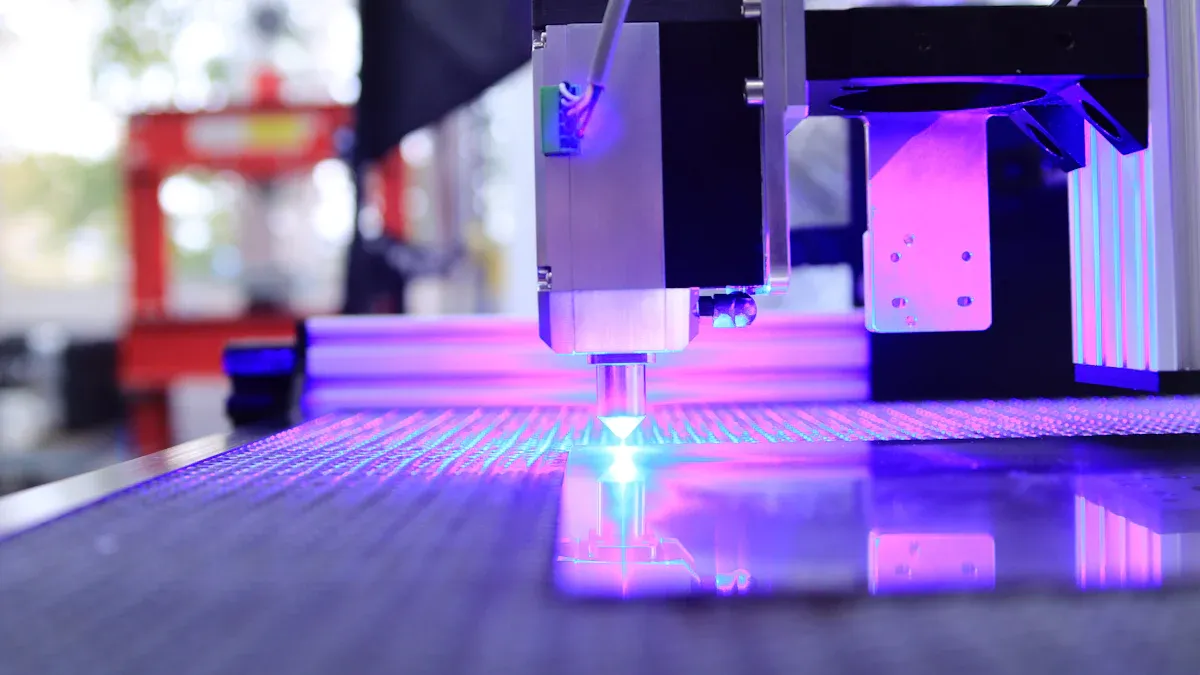

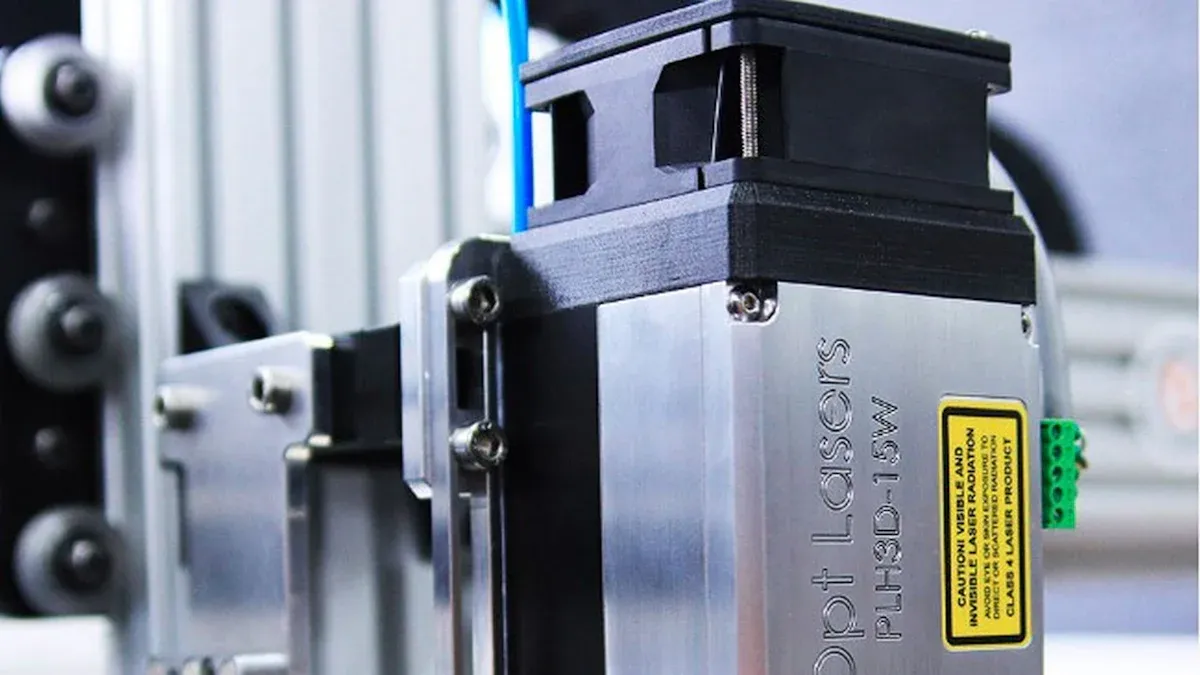

CNC Laser Cutting Machine | Cutting materials using CO2 and solid-state lasers, effective for both non-metal and metal materials. |

Electric Discharge CNC Machine | Reshaping materials using controlled electric sparks. |

CNC Grinding Machine | Precision cutting for components requiring accurate finishes, such as camshafts and bearings. |

CNC Machine with Automatic Tool Changes | Enhancing production rate and efficiency by quickly changing tools. |

By understanding these types, you can select the right CNC machine for your manufacturing needs.

How CNC Technology Improves Precision and Consistent Quality

Eliminating Human Error

CNC machining eliminates human error by automating the manufacturing process. Unlike manual methods, CNC machines rely on precise programming to execute tasks with unmatched accuracy. This automation ensures that every cut, drill, or shape adheres to the exact specifications of the digital design. You no longer need to worry about inconsistencies caused by fatigue or misjudgment.

The feedback systems in CNC machines play a crucial role in maintaining cutting accuracy. Linear scales provide real-time location readings, ensuring precise execution of every movement. Regular calibration of the machine tools further enhances dimensional accuracy, keeping the production process reliable over time. By removing the variability of human intervention, CNC technology delivers consistent quality in every product.

Achieving Tight Tolerances

CNC technology excels at achieving tight tolerances, making it indispensable for industries requiring high precision. These machines can maintain tolerances as tight as ±0.001 inches, ensuring that every component fits perfectly in its intended assembly. This level of precision cutting is vital for applications like aerospace, where even minor deviations can compromise safety and performance.

The table below highlights real-world examples of how CNC machining has improved precision and reduced production inefficiencies:

Case Study Title | Description |

|---|---|

Fastener Reduction Improves Cycle Times | The redesign of a drawer assembly using CNC technology eliminated multiple parts and reduced cycle time by 18%. |

Increased Weld Productivity through Redesign | A 3-piece assembly was reduced to 1 piece, eliminating significant welding and handling, thus improving productivity. |

Elimination of Corner Welds | CNC technology formed tight corners, removing the need for welding and grinding, leading to cost savings and quality. |

These examples demonstrate how CNC machining not only achieves tight tolerances but also enhances overall efficiency.

Ensuring Repeatability

CNC machines ensure repeatability by maintaining consistent performance across production runs. The robust construction of these machines minimizes bending under machining forces, preserving accuracy. Environmental factors like temperature and humidity are also controlled to prevent variations in performance.

To measure repeatability, manufacturers use advanced tools such as Coordinate Measuring Machines (CMM) and laser interferometry. These methods verify that each part meets the required tolerances and dimensional accuracy. The feedback systems in CNC machines further enhance repeatability by making real-time adjustments during operation. This ensures that every product meets the same high standards, regardless of the batch size.

By leveraging CNC technology, you can achieve precise execution, improve precision, and maintain consistency in your manufacturing processes.

Broader Benefits of CNC Machining

Boosting Productivity

CNC machining significantly enhances productivity by automating complex manufacturing processes. Unlike traditional methods, CNC machines operate autonomously, allowing you to focus on other critical tasks. These machines can perform simultaneous operations, such as cutting and drilling, which saves time and boosts production efficiency. Reusable programs further streamline setup, enabling faster transitions between tasks.

With CNC technology, you can achieve enhanced productivity through precision and versatility. These machines handle intricate designs with ease, ensuring high-quality parts every time. They also improve safety by reducing the need for manual intervention. By increasing the volume of production and minimizing setup-changeover time, CNC machining gives you a competitive edge in the market.

Reducing Costs

CNC machining helps you cut costs by optimizing material usage and reducing waste. The precision of CNC machines ensures that every piece meets exact specifications, minimizing errors and rework. Efficient setup and operation also lower labor costs, as fewer skilled operators are required to oversee the process.

Choosing the right material and design complexity can further impact cost savings. For example, simpler designs and high-volume production runs reduce the cost per unit. CNC machining also reduces machine operating time by automating repetitive tasks, which translates to significant savings over time. By delivering consistent product quality, CNC technology ensures you get the most value from your investment.

Enabling Scalability

CNC machining adapts seamlessly to both small-scale and large-scale production needs. Whether you need a single prototype or mass production, CNC machines can handle it all. Automation allows for continuous operation, enabling 24/7 production with minimal supervision.

This scalability is particularly beneficial for industries like automotive, where transitioning from small-batch to high-volume production is essential. CNC technology also allows you to modify designs and production volumes without delays, ensuring operational efficiency. By maintaining consistency across all production runs, CNC machining supports your growth and strengthens your competitive edge.

Practical Steps to Implement CNC Technology

Selecting the Right CNC Machines

Choosing the right CNC machines is crucial for achieving precision and efficiency in your operations. You should evaluate several factors to ensure the best fit for your needs:

Capabilities and Equipment: Look for CNC machines that can handle the materials and complexity of your designs. Advanced inspection tools also help maintain quality.

Quality and Certifications: Check for certifications like ISO 9001 to ensure compliance with industry standards.

Workforce Expertise: Ensure your team has the skills to operate and program CNC machines effectively. Ongoing training is essential for staying updated.

Lead Time and Cost: Assess the machine's ability to meet deadlines and consider the overall value rather than just the price.

Customer Support: Reliable support ensures smooth operation and quick resolution of issues.

By considering these factors, you can select CNC machines that align with your production goals.

Optimizing Programming

Efficient programming is key to maximizing the potential of CNC machining. Start by using CAD/CAM software to create precise designs and minimize unnecessary tool movements. Follow these best practices:

Use adaptive strategies and toolpath optimization algorithms to enhance precision.

Implement simulation software to identify inefficiencies before production.

Optimize tool selection to reduce waste and improve performance.

These steps ensure your CNC machines operate efficiently, saving time and maintaining quality.

Maintaining Quality Control

Quality control measures are essential for consistent results in CNC machining. Regularly monitor cutting speed, feed rate, and tool wear to make real-time adjustments. Use statistical process control (SPC) to track trends and address deviations proactively. Follow these steps to maintain accuracy:

Clean machines routinely to remove debris and lubricate parts.

Inspect components for wear and replace them as needed.

Calibrate tools regularly to ensure precision.

Adhering to these practices helps you maintain high-quality standards and consistent production outcomes.

CNC machining transforms your manufacturing processes by enhancing precision, consistency, and scalability. It eliminates human error, ensures repeatability, and achieves tight tolerances. Manufacturers who adopt CNC solutions benefit from reduced costs, improved productivity, and superior quality. Gradual implementation, continuous training, and strong cybersecurity measures ensure long-term success in leveraging CNC technology.

Many businesses find CNC indispensable for maintaining competitiveness through improved accuracy and production volume.

FAQ

What industries benefit the most from CNC machining services?

Industries like aerospace, automotive, and medical rely heavily on CNC machining services. These sectors demand high precision, tight tolerances, and consistent quality for their components.

How do CNC machining services ensure consistent quality?

CNC machining services use automated systems and advanced programming to eliminate human error. This ensures repeatability and precision across all production runs, regardless of complexity.

Can CNC machining services handle custom designs?

Yes, CNC machining services excel at producing custom designs. Using CAD/CAM software, they transform digital models into precise, tangible components tailored to your specific requirements.

See Also

CNC Machining Innovations Revolutionizing Precision Manufacturing Techniques

The Critical Role of Precision in CNC Machining Processes

Exploring Precision Engineering Through the Lens of CNC Accuracy

Enhancing Manufacturing Quality Using CNC Precision Machining Solutions

Examining CNC Machining Progress in Precision Engineering Developments

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com