How CNC Machining Prototyping Changed the Product Design Process

CNC machining has revolutionized how you approach prototyping. It allows you to create prototypes with unmatched precision and efficiency. By automating processes, CNC prototyping reduces production errors to nearly zero, saving costs and time. This technology bridges the gap between prototyping and production, enabling seamless transitions and fostering innovation across industries.

Key Takeaways

CNC machining makes prototypes quickly, cutting time from days to hours. This helps products get to market faster.

CNC machines are very precise, with accuracy up to ±0.01mm. This ensures prototypes are high-quality and meet strict rules.

CNC machining saves money by lowering labor costs and waste. It also uses the same materials as the final product.

Understanding CNC Machining Prototyping

What Is CNC Machining Prototyping?

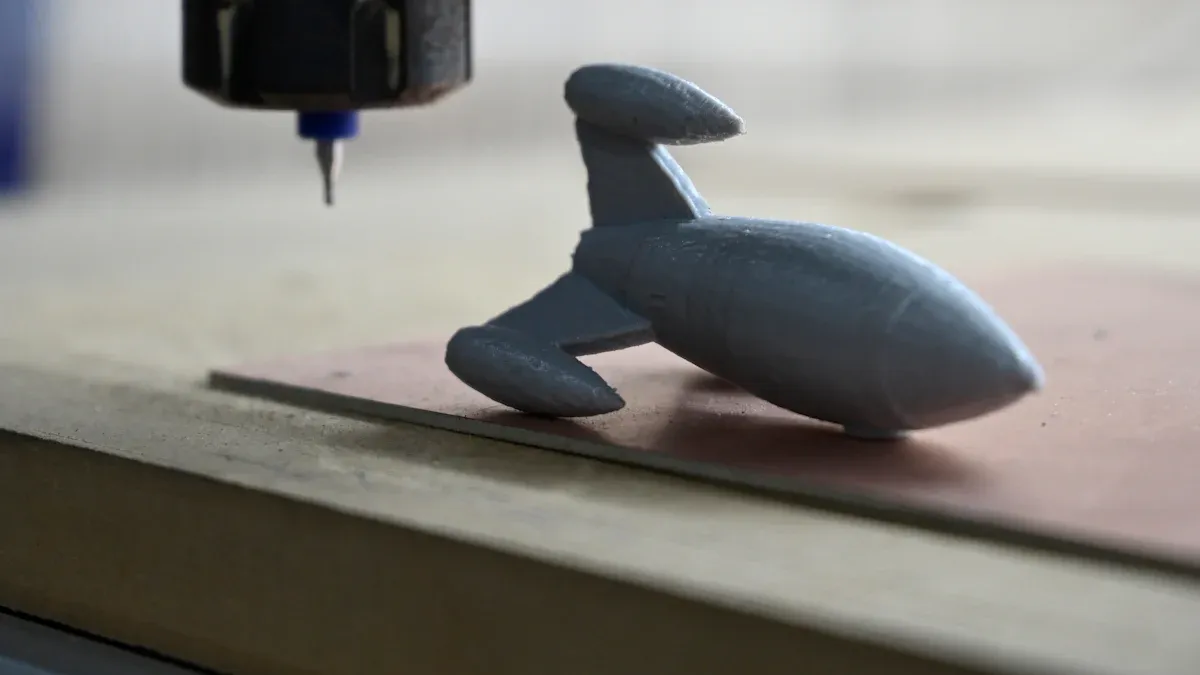

CNC machining prototyping is a modern approach to creating physical models of your designs. It uses computer-controlled machines to carve, cut, or shape materials into precise prototypes based on 3D CAD models. This process allows you to test your designs in real-world conditions before moving to full-scale production. By using CNC prototyping, you can visualize how your digital designs translate into physical products, ensuring functionality and identifying potential flaws early.

The process involves several key steps. First, you draft a CAD model of your design. Then, this model is converted into a 3D file that CNC machines can interpret. Afterward, the manufacturing sequence is determined, and the CNC program is created. Once the material is mounted, the machine fabricates the prototype with high precision. Finally, the prototype undergoes testing to ensure it meets your design requirements.

The Role of CNC Machining in Product Design

CNC machining plays a vital role in modern product development. It allows you to create prototypes quickly and accurately, reducing the time needed for testing and refinement. With its ability to produce small batches, CNC machining minimizes financial risks by identifying defects early. This rapid prototyping capability ensures that your designs are ready for market faster, giving you a competitive edge.

Additionally, CNC machining offers unmatched precision and flexibility. Techniques like milling, turning, and multi-axis machining enable you to create complex shapes and detailed components. These capabilities make CNC machining indispensable in industries like automotive, aerospace, and healthcare, where accuracy and reliability are critical.

Transitioning from Traditional Prototyping to CNC Machining

Switching from traditional prototyping methods to CNC machining has transformed the manufacturing landscape. Traditional methods often relied on manual processes, which were time-consuming and required years of training. CNC machining, on the other hand, uses digital models and automated systems, significantly speeding up the prototyping process.

Traditional prototyping could take days or even weeks to produce a single model. CNC machining reduces this timeline to mere hours, allowing you to iterate designs faster. It also offers higher repeatability, ensuring that each prototype meets the same standards of precision and accuracy. While traditional methods excelled in certain areas, CNC machining has become the go-to solution for modern product development due to its efficiency and cost-effectiveness.

Benefits of CNC Machining in Prototyping

Speed and Efficiency in Creating Prototypes

CNC machining offers unmatched speed and efficiency in prototyping. You can create prototypes in hours instead of days, which accelerates product development. This rapid prototyping capability allows you to test and refine designs faster, reducing time-to-market. For example:

In the automotive industry, over 70 components were produced in just two weeks using CNC machining.

Advanced medical devices benefit from expedited prototyping with high accuracy and material variety.

Aerospace turbine blades demonstrate CNC machining's ability to meet tight tolerances essential for safety and performance.

The process begins with a 3D CAD model, which is quickly converted into CAM files. These files guide the CNC machine to produce prototypes with precision and speed. This efficiency makes CNC machining a preferred choice over traditional methods like injection molding.

Achieving Precision and Accuracy in Design

CNC machining ensures exceptional precision and accuracy in prototype creation. You can achieve tolerances as tight as ± 0.01mm, which surpasses traditional methods like 3D printing. This level of precision allows you to fabricate intricate geometries that align perfectly with your digital designs. Fully automated processes eliminate human errors, ensuring consistent quality across prototypes.

For industries like aerospace and healthcare, where performance and reliability are critical, CNC machining delivers components that meet stringent standards. Its ability to produce prototypes with tight tolerances makes it indispensable for high-quality manufacturing.

Cost-Effectiveness and Material Versatility

CNC machining is a cost-effective solution for prototyping. Automation reduces labor costs while minimizing material waste. You also save on upfront costs since CNC machining eliminates the need for expensive molds or dies. Prototypes can be machined from the same materials as the final product, enhancing accuracy and reducing material limitations.

Material | Properties | Applications |

|---|---|---|

Copper | Excellent electrical and thermal conductivity, high corrosion resistance, soft and ductile | Electrical wiring, heat exchangers, marine components |

Titanium | High strength-to-weight ratio, excellent corrosion resistance, biocompatible | Aerospace components, medical devices, marine applications |

Plastics | Lightweight, corrosion-resistant, high chemical resistance, good dimensional stability | Automotive parts, chemical processing seals, optical lenses, high-performance applications in aerospace and medical fields |

This material versatility allows you to create prototypes for diverse industries, fostering innovation and ensuring high-quality results.

Applications of CNC Machining Prototyping

Automotive and Aerospace Advancements

CNC machining has become a game-changer in the automotive and aerospace industries. You can use it to create lightweight materials like aluminum and titanium for aircraft components, such as turbine blades and landing gear. These materials improve fuel efficiency and performance. CNC machining also ensures extreme accuracy in engine components like cylinder heads and engine blocks, which are critical for optimal engine functionality.

The process supports rapid prototyping and customization, allowing you to test new designs quickly. By integrating additive manufacturing, CNC machining enables the creation of intricate parts like engine nozzles. This hybrid approach optimizes material usage and enhances performance, making it essential for innovation in these industries.

Innovations in Healthcare and Medical Devices

In healthcare, CNC machining delivers unmatched precision, achieving tolerances as low as ±0.001 mm. This level of accuracy is crucial for producing orthopedic implants and surgical robotics. You can rely on CNC machining to create patient-specific implants that improve recovery times and treatment outcomes. It also supports the development of surgical instruments and dental crowns, ensuring they meet high safety and functionality standards.

The versatility of CNC machining allows you to manufacture complex medical devices that comply with stringent regulatory requirements. By integrating robotics and machine learning, the process becomes even more efficient, reducing waste and improving product quality. These advancements make CNC machining a cornerstone of modern healthcare manufacturing.

Consumer Goods and Electronics Development

CNC machining plays a vital role in the consumer goods and electronics sectors. It enables the production of smaller, lightweight, and compact components with high precision and reliability. For example, you can use CNC machining to create circuit boards and advanced professional equipment. This ensures that prototypes fit perfectly and function reliably, meeting the dynamic demands of modern electronics.

Industry | Benefits of CNC Machining Prototyping |

|---|---|

Electronics | Enables production of smaller, lightweight, and compact components with high precision and reliability. |

The cost-effective nature of CNC machining makes it ideal for prototyping in these industries. Its ability to handle tight tolerances ensures that your products meet high-quality standards, fostering innovation and improving product development timelines.

How CNC Machining Enhances the Product Design Process

Faster Iterations and Reduced Time-to-Market

CNC machining accelerates your product development cycles by enabling faster iterations. You can create high-quality prototypes in hours instead of days, allowing you to test and refine designs quickly. This speed reduces the time-to-market for innovative products, giving you a competitive edge.

CNC machining streamlines the prototyping process through automation, minimizing downtime and ensuring continuous operation.

You can respond to customer feedback and market trends more effectively, fostering innovation.

Faster product cycles allow you to explore more design possibilities within the same timeframe.

For example, a consumer electronics company used CNC machining to produce intricate prototypes with tight tolerances. This capability enabled rapid testing and refinement, significantly shortening their product development timeline. By leveraging CNC machining, you can bring your designs to market faster while maintaining high accuracy and precision.

Identifying and Eliminating Design Flaws Early

CNC machining helps you identify and eliminate design flaws during the prototyping phase. By producing high-accuracy and precision prototypes, you can assess functionality and detect potential issues before moving to full-scale manufacturing.

Machined prototypes allow you to conduct functional and market tests, ensuring your designs meet performance expectations.

Correcting defects during prototyping is far more cost-effective than addressing them after production begins.

CNC machining services offer versatility, enabling you to work with various materials while adhering to stringent quality standards.

This proactive approach protects you from costly errors and ensures your final product aligns with your design for manufacturing goals. With CNC machining, you can confidently refine your designs and achieve superior results.

Encouraging Creativity and Experimentation

CNC machining fosters creativity by giving you the freedom to experiment with complex geometries and diverse materials. Its precision allows you to explore intricate designs that would be challenging to achieve manually.

You can create prototypes with unique textures, finishes, and shapes, pushing the boundaries of traditional manufacturing.

CNC machining supports interactive and kinetic designs, enabling you to develop innovative products that captivate users.

The accessibility of CNC technology democratizes the design process, empowering you to bring your creative visions to life.

This versatility inspires innovation across industries, from art to advanced engineering. By embracing CNC machining, you can unlock new possibilities and redefine what’s achievable in product design.

CNC machining has redefined product design by enabling faster, more precise, and cost-effective prototyping. Industries like automotive, medical, and aerospace benefit from its ability to meet tight tolerances and reduce costs. Future advancements, such as AI integration and multi-axis machining, promise even greater innovation, ensuring CNC machining remains a cornerstone of modern manufacturing.

FAQ

What materials can you use with CNC machining prototyping?

You can use metals like aluminum, titanium, and copper. Plastics such as ABS and polycarbonate also work well. Material versatility supports diverse industry needs.

Tip: Always choose materials that match your product's functional and aesthetic requirements.

How does CNC machining compare to 3D printing for prototyping?

CNC machining offers higher precision and better material compatibility. It works well for functional prototypes, while 3D printing excels in creating complex, lightweight designs.

Can CNC machining handle intricate designs?

Yes, CNC machining excels at creating intricate geometries. Multi-axis machines allow you to produce complex shapes with tight tolerances, ensuring your designs meet exact specifications.

Note: Multi-axis CNC machines are ideal for advanced designs requiring high precision.

See Also

Overcoming Obstacles: Improving CNC Prototyping Precision And Speed

Excelling In CNC Machining: Material Choices And Precision Tolerances

The Impact Of CNC Machining On Precision Manufacturing Excellence

Enhancing Product Development Through Effective Prototyping Solutions

Investigating CNC Machining Options For High-Precision Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com