How CNC Services Reduce Waste in Material Usage

CNC Machining offers a precise and efficient way to reduce waste in material usage. This technology ensures maximum use of raw materials while extending tool lifespan. Compared to traditional methods, CNC services significantly lower production costs and environmental impact.

You benefit from sustainable practices like recycling leftover materials and using energy-efficient machines. These methods not only reduce emissions but also meet the growing demand for eco-friendly manufacturing. By adopting CNC technology, you contribute to a greener industry while achieving consistent, high-quality results.

Key Takeaways

CNC machines use materials wisely by making exact cuts, reducing waste and saving money.

Automated CNC systems prevent mistakes, ensuring good quality and less wasted material.

Nesting methods arrange materials smartly, cutting down scraps and leftovers, helping the planet and saving money.

Energy-saving CNC machines cost less to run and are better for the environment.

Using CNC tools improves work speed and draws eco-friendly customers, helping your business stand out.

Precision in CNC Machining for Waste Reduction

Accurate Cuts and Measurements

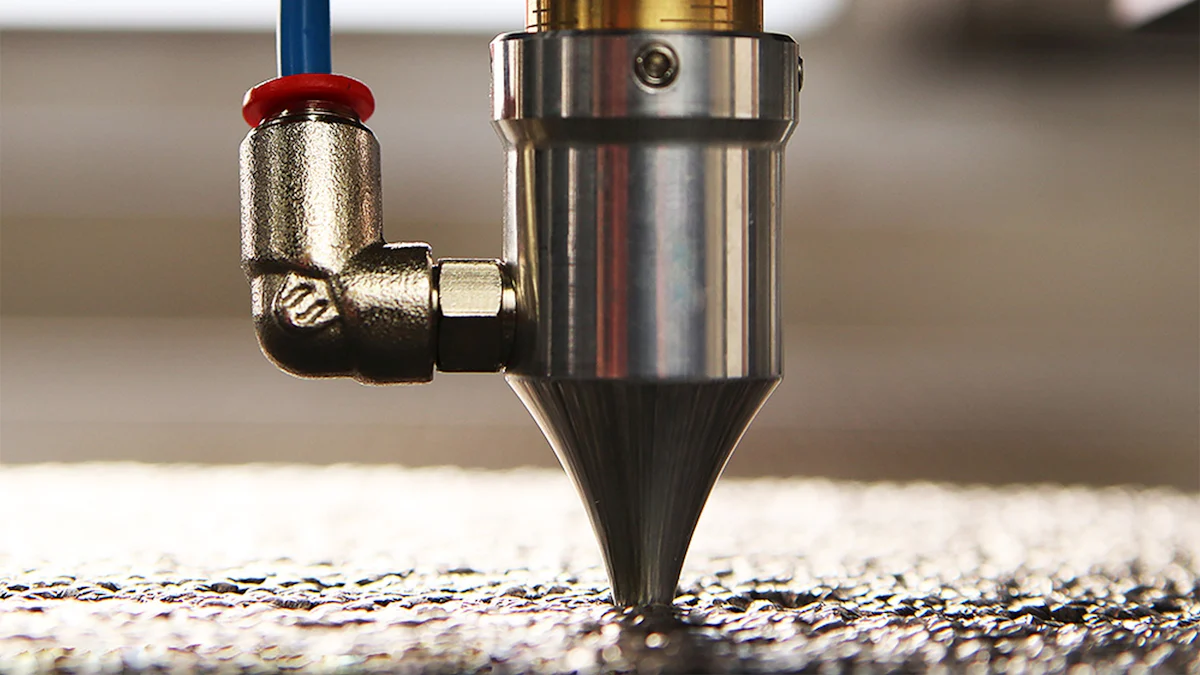

How CNC machines achieve pinpoint accuracy

CNC machines ensure precise cuts and measurements by leveraging advanced technologies. Adaptive toolpaths adjust cutting settings based on the shape of the workpiece, optimizing tool engagement and reducing unnecessary material removal. High-speed machining allows you to achieve accuracy at faster feed rates, while precision machining employs high-tolerance tools to minimize waste. These machines also rely on computer-aided design (CAD) software to program exact movements, ensuring every cut aligns perfectly with design specifications. Automation further eliminates inconsistencies, and real-time monitoring allows operators to make adjustments during production.

Examples of industries benefiting from precise material usage

Many industries benefit from the precision of CNC machining.

Aerospace companies use CNC machines to create lightweight, high-strength components.

Automotive manufacturers rely on accurate cuts for engine parts and body panels.

Medical device makers produce tools and implants with exact specifications.

Electronics industries craft intricate circuit boards and components with minimal material waste.

Minimizing Errors and Material Loss

Reducing human error through automated programming

CNC turning eliminates common errors found in manual machining. Automated programming reduces mistakes like incorrect syntax or improper tool selection. Unlike manual methods, CNC machines maintain consistent feed and speed settings, preventing tool wear and poor finishes. Proper maintenance ensures accuracy, as clean and lubricated machines operate efficiently. By automating these processes, you can minimize waste and improve production quality.

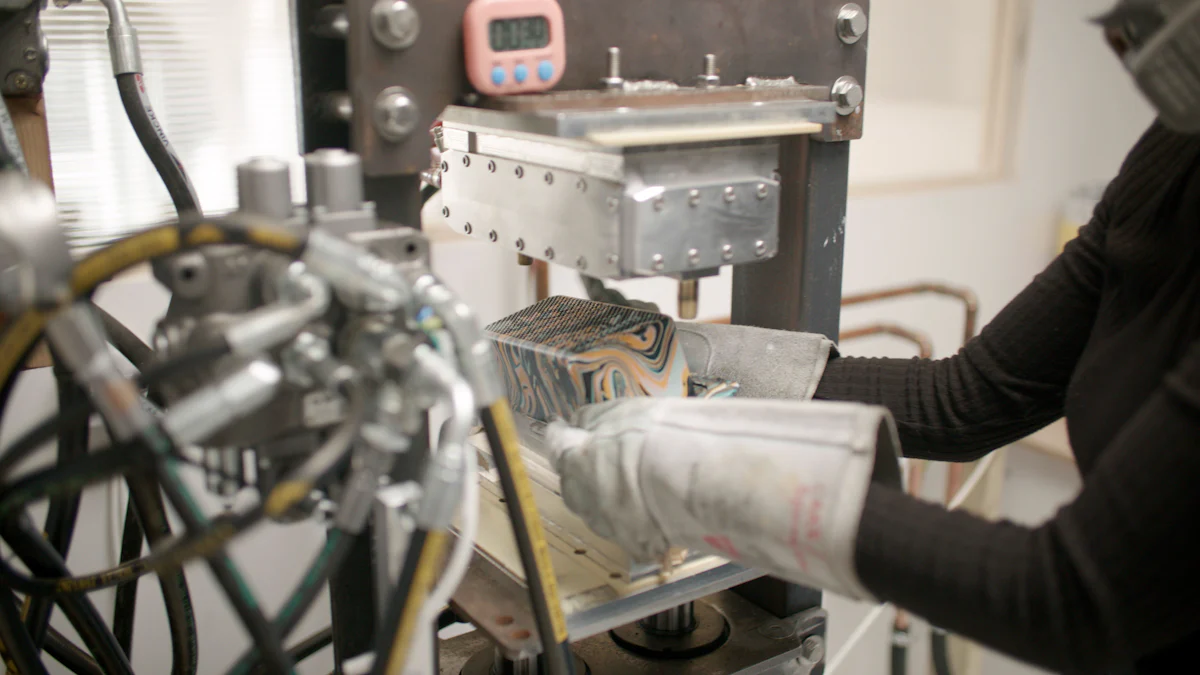

Case studies of waste reduction in manufacturing

Several case studies highlight the impact of CNC machining on waste reduction. For example:

Case Study | Challenge | Solution | Outcome | Economic Impact |

|---|---|---|---|---|

Aerospace client | High-cost complex component | Redesigned using DFM principles | 25% cost reduction, 15% faster production | 10% market share increase |

Medical device maker | Corrosion-resistant tools | Used stainless steel alloy with CNC machining | 30% longer tool lifespan | 20% market share growth |

Marine equipment client | Durable components for harsh environments | Advanced CNC turning with titanium alloy | 30% weight reduction, 50% longer life | 20% lower maintenance costs |

Optimized Material Utilization

Nesting techniques for efficient material layout

Nesting techniques play a vital role in achieving optimal material utilization. Advanced nesting software uses algorithms to arrange parts efficiently. True-shape nesting considers the actual shape of each part, fitting them together like puzzle pieces. Scenario nesting evaluates stock and remnants to maximize usage, while common-line cutting reduces waste by sharing cuts between parts. These techniques ensure you reduce offcuts and make the most of your materials.

Reducing offcuts and scrap material

Reducing offcuts and scrap material offers measurable benefits. It improves environmental impact by lowering waste and carbon emissions. Optimized resource utilization leads to significant cost savings. Additionally, adopting these practices enhances your reputation, attracting eco-conscious clients and boosting revenue. CNC machining helps you minimize waste while maintaining high production standards.

Automation and Consistency in CNC Machines

Real-Time Monitoring and Adjustments

How sensors and software improve machining accuracy

CNC machines use advanced sensors and software to monitor operations in real time. This technology allows you to observe the production process closely and make necessary adjustments. Deviations from programmed specifications are detected immediately, preventing errors from escalating. Operators can pause production to correct issues, ensuring high-quality output and reducing material waste. Real-time monitoring also optimizes cutting paths and tool engagement, which minimizes waste and prolongs tool life.

Examples of real-time error correction

Adaptive cutting adjusts the tool's path based on real-time feedback, tailoring strategies to the material and reducing waste.

Process optimization automatically modifies parameters like spindle speed and cutting depth, improving machining accuracy and reducing cycle times.

Consistent Quality and Reduced Rework

The impact of automation on product uniformity

Automation in CNC machining ensures consistent quality by achieving tolerances within microns. Every part meets exact specifications, eliminating variations that lead to waste. This level of precision supports industries like aerospace and medical manufacturing, where uniformity is critical.

How reduced rework saves materials and time

CNC machines work faster and more accurately than manual methods. By producing high-quality parts on the first attempt, you avoid rework and the associated material waste. This efficiency through automation not only saves time but also reduces costs, making your production process more sustainable.

Streamlined Production Processes

Integration of CAD/CAM software for efficiency

CAD/CAM software streamlines production by automating tasks and optimizing design parameters. It helps you select the best materials and layouts, minimizing scrap and excess material. The software also enhances collaboration between teams, reducing errors and delays. These practices improve material utilization and energy efficiency, contributing to waste reduction.

Examples of faster production cycles with less waste

Technique/Technology | Benefit |

|---|---|

High-Performance Cutting Tools | Reduces machining time through faster workpiece traversal. |

Adaptive Tool Control Systems | Automatically adjusts settings for optimal machining, minimizing cycle times. |

High-Speed Machining (HSM) Strategies | Allows for faster material removal with larger spindle speeds and feed. |

Automatic Tool Changers (ATCs) | Reduces downtime and enhances machining efficiency through automation of tool swaps. |

These advancements in CNC turning ensure faster production cycles while reducing material waste, helping you meet the demands of on-demand manufacturing without overproduction.

Sustainable Manufacturing Practices in CNC Machining

Recycling and Reusing Scrap Materials

How CNC services handle leftover materials

CNC machining supports sustainable manufacturing by effectively recycling and reusing leftover materials. Recycling metal scraps like aluminum, steel, and brass reduces the need for virgin materials, conserving natural resources. This process also consumes less energy compared to extracting and processing new raw materials. By collecting and processing scrap, you can reintroduce it into the production cycle, minimizing waste and promoting green manufacturing.

To achieve this, you can:

Opt for reused materials whenever possible.

Implement closed-loop systems to collect and reuse waste.

Process scrap materials for reintegration into production.

Examples of recycling programs in manufacturing

Many manufacturers have adopted recycling programs to transform waste into valuable resources. For instance:

Recycling metal scraps during machining conserves raw materials and reduces energy consumption.

Using green materials, such as biodegradable plastics, supports eco-friendly production.

Applying eco-friendly coatings to parts enhances sustainability.

These practices reduce landfill waste and promote optimal material utilization, making your operations more environmentally friendly.

Energy-Efficient CNC Machines

Features of modern CNC machines that save energy

Modern CNC machines incorporate features that enhance energy efficiency. These include:

Regenerative braking systems and energy recovery mechanisms.

Efficient motor designs and variable speed drives for load adjustments.

Advanced cutting tools with improved geometries.

Efficient coolant management systems.

By using energy-efficient machines, you can reduce energy consumption and lower operational costs.

The role of energy efficiency in sustainability

Energy-efficient CNC machines play a vital role in sustainable manufacturing. They reduce energy consumption, which decreases the environmental impact of energy production. Efficient energy use also lowers the carbon footprint of your operations, contributing to climate change mitigation. By conserving finite resources, these machines support sustainability for future generations.

Process Optimization for Sustainability

Reducing waste through lean manufacturing principles

Lean manufacturing principles help you achieve waste reduction and streamline production. These principles include:

Defining value based on customer needs.

Mapping processes to identify and eliminate waste.

Ensuring smooth workflows to avoid delays.

Producing only what is needed to prevent excess inventory.

Continuously improving processes for better efficiency.

By adopting these principles, you can reduce material usage, energy consumption, and waste disposal efforts. This approach enhances your reputation in the eco-conscious market.

Examples of companies adopting sustainable CNC practices

Several companies have successfully implemented sustainable CNC practices. For example:

Beska Mold uses eco-friendly materials, recycling strategies, and advanced technologies to optimize energy usage.

Stecker Machine partners with CNC shops that prioritize sustainability, showcasing their commitment to green manufacturing.

Companies integrating AI and machine learning optimize machining processes, reducing material waste and improving efficiency.

These examples highlight how optimized machining processes can lead to a more sustainable production environment.

Economic and Environmental Benefits of Waste Reduction

Cost Savings for Manufacturers

Lower material costs through reduced waste

CNC machining practices help you save on material costs by minimizing waste. Efficient cutting techniques ensure optimal utilization of raw materials, reducing the need for excess stock. This approach not only lowers expenses but also supports waste-reducing practices that enhance your bottom line. Investing in CNC machines provides long-term savings, as their precision reduces errors and maximizes material usage.

Examples of ROI from CNC investments

Adopting CNC technology offers significant returns on investment. You can benefit from:

Precision and accuracy that reduce errors and rework.

Increased production speed, enabling faster cycles and higher profitability.

Cost reduction through automation, which minimizes labor costs and human errors.

Flexibility and versatility, allowing you to adapt to diverse production needs.

Enhanced process optimization using simulation software to improve productivity.

Reduced Carbon Footprint

How CNC services contribute to greener manufacturing

CNC machining supports eco-friendliness by reducing the carbon footprint of manufacturing processes. Recycling metal scraps conserves raw materials and reduces energy consumption. Using eco-friendly materials and closed-loop systems promotes a circular economy. Energy-efficient machines and renewable energy sources further enhance sustainability. Optimizing resource utilization and minimizing waste also play a key role in lowering environmental impact.

The long-term environmental impact of waste reduction

Sustainable CNC machining practices significantly benefit the environment. By reducing material waste and energy consumption, you help conserve natural resources and lower carbon emissions. These efforts contribute to a healthier planet and improve your brand reputation among eco-conscious consumers. Over time, adopting waste-reducing practices ensures a positive ecological impact and aligns your business with global sustainability goals.

Competitive Advantages in Sustainable Manufacturing

How sustainability attracts eco-conscious clients

Sustainability in CNC machining appeals to eco-conscious clients. Recycling metal scraps and using energy-efficient machines demonstrate your commitment to reducing ecological impact. Sustainable practices, such as implementing closed-loop systems and using eco-friendly materials, enhance your brand reputation. Clients value businesses that prioritize eco-friendliness, making sustainability a strategic advantage for future growth.

Examples of businesses leveraging CNC for market differentiation

Many companies use CNC machining to stand out in the market. For example:

Beska Mold utilizes eco-friendly materials and energy-efficient CNC machines.

Businesses implement closed-loop systems to recycle waste and reduce environmental impact.

Companies integrate renewable energy sources, such as solar and wind power, into their operations.

These strategies not only reduce waste but also lower production costs and improve quality control. By adopting sustainable CNC machining practices, you can differentiate your business and attract environmentally conscious clients.

CNC services play a vital role in reducing material waste through precision, automation, and sustainable practices. These machines detect deviations instantly, allowing quick adjustments to prevent waste. They conserve resources by optimizing material usage and reducing energy consumption. By adopting CNC technology, you align with global sustainability goals, such as promoting a circular economy and lowering greenhouse gas emissions. Although the initial investment may seem high, the long-term savings and enhanced brand image make it worthwhile. Embracing CNC technology ensures your business remains competitive while contributing to a greener, more efficient manufacturing industry.

FAQ

What is CNC machining, and how does it reduce waste?

CNC machining uses computer-controlled tools to cut and shape materials with precision. It reduces waste by optimizing material usage, minimizing errors, and automating processes. This ensures you use only the necessary amount of raw materials.

Can CNC machines work with recycled materials?

Yes, CNC machines can process recycled materials like metals and plastics. Using recycled materials reduces the need for new resources and supports sustainable manufacturing. You can integrate these materials into production without compromising quality.

How does automation in CNC machining improve efficiency?

Automation eliminates manual errors and ensures consistent quality. It allows you to monitor production in real time, make adjustments, and streamline workflows. This reduces rework, saves time, and minimizes material waste.

Are CNC machines energy-efficient?

Modern CNC machines include energy-saving features like variable speed drives and regenerative braking. These features lower energy consumption, reduce operational costs, and support eco-friendly manufacturing practices.

What industries benefit the most from CNC machining?

Industries like aerospace, automotive, medical, and electronics benefit greatly. CNC machining provides the precision needed for complex parts, reduces material waste, and ensures consistent quality. This makes it ideal for high-stakes manufacturing.

See Also

Streamlined CNC Machining Solutions for Accurate Manufacturing

Investigating CNC Machining Options for Precise Production

Impact of CNC Precision Processing on Production Expenses

Grasping Material Needs for CNC Precision Machining

Addressing Issues: Improving CNC Prototyping Precision and Speed

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com