Why CNC Prototyping Reduces Development Costs for Startups and Innovators

CNC Machining empowers you to bring your ideas to life in a cost-effective manner. It combines precision and speed to reduce waste and save money. For example:

A medical device startup created 50 prototypes in 48 hours, meeting a critical investor deadline.

A consumer electronics company cut production costs by 30% using small-batch CNC manufacturing.

Key Takeaways

CNC prototyping helps startups make real models in just days.

It cuts down on wasted materials and saves money on work.

CNC machines handle detailed designs and quick changes, improving products fast.

The Role of CNC Machining in Product Development

What is CNC Machining and How Does It Work?

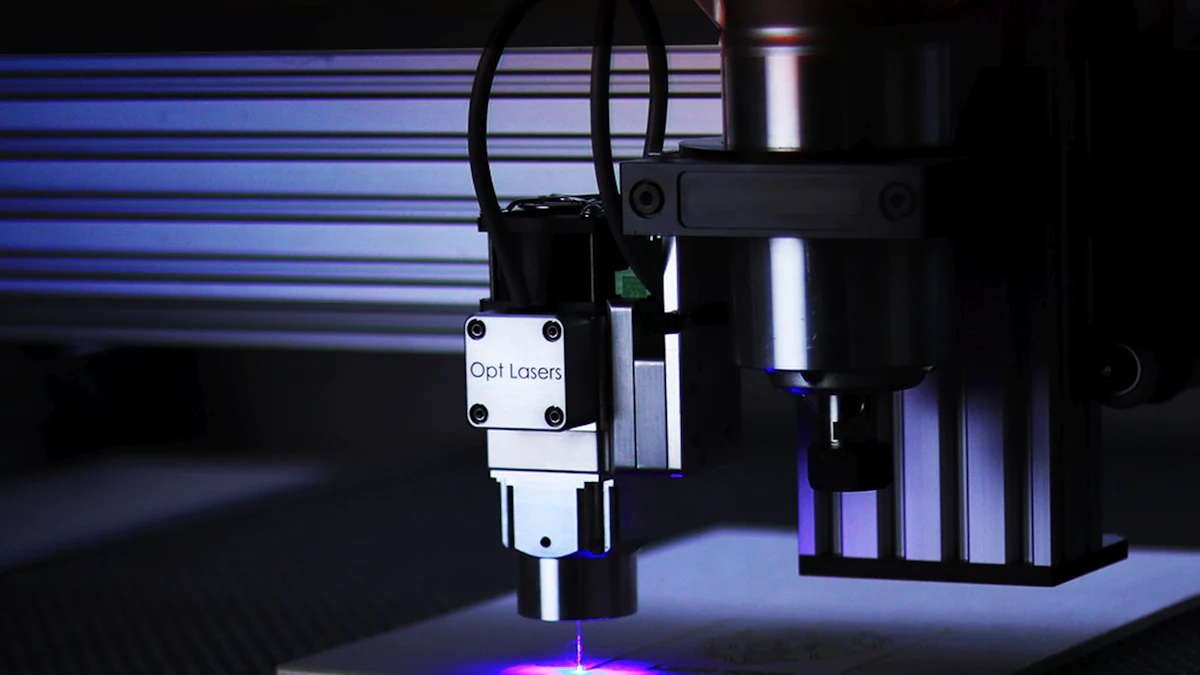

CNC machining is a manufacturing process that uses computer-controlled machines to create precise and consistent parts. You can think of it as a highly automated system where computers guide cutting tools to shape materials like metals, plastics, or wood. This process ensures exceptional accuracy and repeatability, which are essential for modern product development.

CNC machining stands out because it combines automation, precision, and efficiency. These qualities allow you to create complex components with tight tolerances and shorter lead times. Whether you're working in aerospace, automotive, or consumer electronics, this technology helps you meet the demands of high-quality production.

Key principles of CNC machining include:

Precision and Accuracy: Achieve tight tolerances for industries requiring high accuracy.

Consistency and Repeatability: Produce identical parts every time, perfect for scaling production.

Efficiency and Speed: Reduce production time and boost productivity.

Why CNC Machining is Essential for Startups

For startups, CNC machining offers unmatched advantages over traditional manufacturing methods. It provides the flexibility and scalability you need to adapt to changing demands. With CNC machining, you can avoid high upfront costs and minimize the risk of overproducing parts that may require design revisions.

Here’s why CNC machining is a game-changer for startups:

Faster turnaround times help you meet tight deadlines and reduce time-to-market.

Superior precision eliminates human error, ensuring high-quality prototypes.

Reduced material waste saves money and supports sustainable practices.

Design flexibility allows you to iterate and improve between production runs.

By leveraging these benefits, you can focus on innovation and bring your ideas to life faster.

Key Features That Support Rapid Product Prototyping

CNC machining is ideal for rapid prototyping because it delivers high precision and supports a wide range of materials. You can create prototypes that closely resemble final products in appearance, quality, and performance. This ensures your product development process stays on track and meets customer expectations.

Some standout features include:

High precision and tight tolerances for accurate prototypes.

Compatibility with diverse materials, from metals to plastics.

Rapid machining for faster iterations and shorter development cycles.

With CNC machining, you can quickly test, refine, and perfect your designs. This efficiency gives you a competitive edge in today’s fast-paced markets.

Cost-Saving Benefits of CNC Prototyping

Reducing Material Waste Through Precision

CNC machining helps you save costs by reducing material waste. Its precision cutting ensures that every piece of material is used efficiently, leaving minimal scrap behind. This is especially important when working with expensive materials like titanium or carbon fiber. By optimizing designs and using automated processes, CNC machining minimizes errors that could lead to wasted resources.

Precise cutting and efficient design practices reduce material waste.

Automation eliminates human error, enhancing cost efficiency.

When you adopt CNC prototyping, you not only save money but also contribute to sustainable manufacturing practices. This approach allows you to focus on creating high-quality products without worrying about unnecessary waste.

Lowering Labor Costs with Automation

Automation in CNC machining significantly lowers labor costs. Automated finishing processes reduce the need for manual intervention, saving you time and money. Efficient tooling strategies also minimize machine wear and operating time, further cutting expenses.

Automated systems reduce labor requirements, making production scalable.

Predictive maintenance prevents costly downtime and extends machinery lifespan.

By leveraging automation, you can optimize resource utilization and achieve cost savings. This makes CNC prototyping an ideal choice for startups aiming to maximize efficiency while keeping expenses low.

Accelerating Product Development with Faster Iterations

CNC prototyping enables rapid iteration, allowing you to refine your designs quickly. This flexibility is crucial for industries like automotive and electronics, where precision and speed are essential. You can test, tweak, and perfect your product designs in record time, leading to faster product launches.

Quick feedback loops and design flexibility support rapid iteration.

In the medical device sector, CNC prototyping helped develop a surgical tool that gained FDA approval through iterative design.

In consumer electronics, rapid prototyping refined a smartphone design to meet user expectations.

With CNC machining, you can stay ahead of the competition by accelerating your product development process. Faster iterations mean you can bring your ideas to market sooner, giving you a competitive edge.

Flexibility and Customization in Rapid Product Prototyping

Adapting to Unique Product Designs

CNC machining offers unmatched adaptability, making it perfect for unique product designs. You can work with a variety of materials, including metals, plastics, and composites, to create prototypes that meet your specific needs. Whether you're crafting lightweight structures or durable components, CNC machining ensures precision and flexibility.

Material Type | Application in Prototyping |

|---|---|

Metals | Aluminum, steel, titanium |

Plastics | Various flexible designs |

Composites | Lightweight structures |

This adaptability allows you to refine your designs quickly. CNC machining supports frequent design changes, ensuring your prototypes align with your vision. You can easily adjust NC programs to accommodate modifications, saving time and resources.

CNC machining empowers you to bring even the most complex ideas to life with precision and efficiency.

Prototyping for Iterative Product Development

An iterative approach to product development is essential for innovation. CNC machining accelerates this process by enabling faster turnaround times. For example, an EV startup tested an aluminum battery enclosure in just two weeks, a task that traditionally takes months.

With CNC machining, you can test and refine your designs repeatedly. High accuracy and surface finishes allow you to conduct real-world testing, such as evaluating water resistance or durability. This iterative approach eliminates the need for expensive tooling, making it cost-effective to implement design changes.

Rapid product prototyping with CNC machining ensures you can gather feedback quickly and perfect your designs efficiently.

Scaling from Prototypes to Small-Batch Manufacturing

CNC machining bridges the gap between prototyping and small-batch manufacturing. Once your prototype is finalized, you can seamlessly transition to producing small quantities without investing in costly molds or tooling. This scalability is ideal for startups and innovators who need to test market demand before committing to large-scale production.

By using CNC machining, you can maintain the same level of precision and quality in small-batch manufacturing as in prototyping. This ensures consistency across all stages of your product development journey.

Scaling with CNC machining gives you the confidence to launch your product while minimizing risks and costs.

Addressing Challenges in CNC Prototyping

Common Challenges Startups Face

CNC prototyping offers immense benefits, but startups often encounter hurdles that can slow progress. One common challenge is balancing cost and quality. You might feel tempted to cut corners, but this can lead to subpar prototypes that fail to meet your expectations. Another issue is the steep learning curve associated with CNC technology. Without prior experience, understanding machine capabilities and material compatibility can feel overwhelming.

Time constraints also pose a significant challenge. Tight deadlines can pressure you to rush through the prototyping process, increasing the risk of errors. Additionally, sourcing reliable manufacturers can be daunting. Not all providers deliver consistent quality or meet project timelines, which can disrupt your development cycle.

Overcoming these challenges requires careful planning, clear communication, and a focus on building strong partnerships with experienced CNC manufacturers.

Partnering with Reliable CNC Machining Manufacturers

Choosing the right CNC machining partner can make or break your project. To ensure success, evaluate potential manufacturers based on their expertise, equipment, and customer support. Look for providers with a proven track record and a commitment to quality assurance.

Key criteria to consider include:

Manufacturer's experience and expertise.

Quality assurance measures and finished product quality.

Timely delivery and adherence to project schedules.

Client testimonials and case studies.

Investment in the latest machinery and technology.

Additionally, assess their ability to handle various materials and complex designs. Strong customer support and clear communication practices are also essential. A reliable partner will work with you to refine your designs and meet your deadlines, ensuring a smooth prototyping process.

Tips for Maximizing Cost Efficiency in CNC Prototyping

You can take several steps to reduce costs without compromising quality. Start by optimizing your designs for manufacturability. Simplify geometries and eliminate unnecessary features to save machining time and material costs. Using standardized materials can also lower expenses and reduce lead times.

Batching multiple parts into a single machining job is another effective strategy. This approach maximizes efficiency and minimizes waste. Clear communication with your manufacturer is equally important. Providing detailed CAD files and specifications ensures they understand your requirements, reducing the likelihood of costly errors.

By implementing these strategies, you can stretch your budget further and focus on bringing your innovative ideas to life.

CNC prototyping empowers you to transform ideas into reality with speed and precision. It reduces costs by minimizing material waste and labor expenses while enabling faster iterations. Startups that embrace this approach gain a competitive edge through rapid product development and shorter time to market.

Key takeaways for startups:

Produces physical prototypes in days, not weeks.

Adapts to intricate designs without costly retooling.

Combines material versatility with high-quality results.

By integrating CNC prototyping into your process, you can refine physical prototypes, test products precisely, and deliver innovation to market faster. This strategy positions you for long-term success in dynamic industries.

FAQ

What industries benefit the most from CNC prototyping?

CNC prototyping benefits industries like aerospace, automotive, medical devices, and consumer electronics. You can create precise, high-quality prototypes for complex designs in these fields.

How does CNC prototyping compare to 3D printing?

CNC prototyping offers higher precision, better material compatibility, and superior surface finishes. You can use it for functional prototypes requiring tight tolerances and durability.

Can CNC prototyping handle complex designs?

Yes! CNC machining excels at producing intricate designs with tight tolerances. You can create prototypes with complex geometries and achieve exceptional accuracy.

💡 Tip: Always consult your CNC manufacturer to ensure your design aligns with their capabilities for the best results.

See Also

Overcoming Obstacles: Improving CNC Prototyping Precision And Speed

Optimizing Product Creation Through Effective Prototyping Solutions

CNC Precision Component Production: Impacting Manufacturing Expenses

Investigating CNC Machining Options For Accurate Manufacturing Processes

Excelling In CNC Machining: Tolerances, Prototyping, And Material Choices

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com