How CNC Machining Reduces Lead Times for Production

You can achieve faster production cycles with CNC machining. This technology uses automation to minimize errors and streamline workflows. Unlike manual methods, CNC machines operate continuously, even without human intervention. This allows for 24/7 production, reducing lead times significantly. Rapid prototyping becomes easier, as CNC machining can create prototypes in days instead of weeks. With higher cutting speeds and the ability to handle multiple parts simultaneously, CNC ensures efficient machining and faster output. By reducing bottlenecks, you can meet tight deadlines and improve overall manufacturing efficiency.

Key Takeaways

CNC machines work all day and night, cutting project time.

Automation in CNC reduces mistakes, making parts accurate and reliable.

CNC helps make prototypes quickly, speeding up new product creation.

Easy setup and switching in CNC save time and boost efficiency.

Using CAD/CAM software with CNC makes work faster and saves time.

Understanding CNC Machining

What Is CNC Machining?

Definition and Core Principles

CNC machining, or computer numerical control machining, automates the operation of machine tools like mills, lathes, and grinders. This technology uses pre-programmed commands derived from digital designs to shape and cut materials with high precision. You can rely on CNC machining to deliver consistent results, as it minimizes human intervention and ensures repeatability.

Here are the core principles that define CNC machining:

It automates the control of machines using software-driven commands.

It integrates CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software for precise tool manipulation.

It enhances productivity by enabling continuous operation with minimal downtime.

By adopting CNC machining, you can achieve greater production efficiency and reduce errors in your manufacturing processes.

Key Components and Tools Used in CNC Machining

CNC machining relies on a variety of tools and components to perform different tasks. Each tool serves a specific purpose, ensuring versatility in the production process. Commonly used tools include:

Drill Bits: Create holes with precision.

End Mills: Cut materials without needing pre-drilled holes.

Face Mills: Prepare flat surfaces for detailed machining.

Thread Mills: Cut internal and external threads.

Fly Cutters: Produce smooth finishes with broad cuts.

The machines themselves also vary based on their functions:

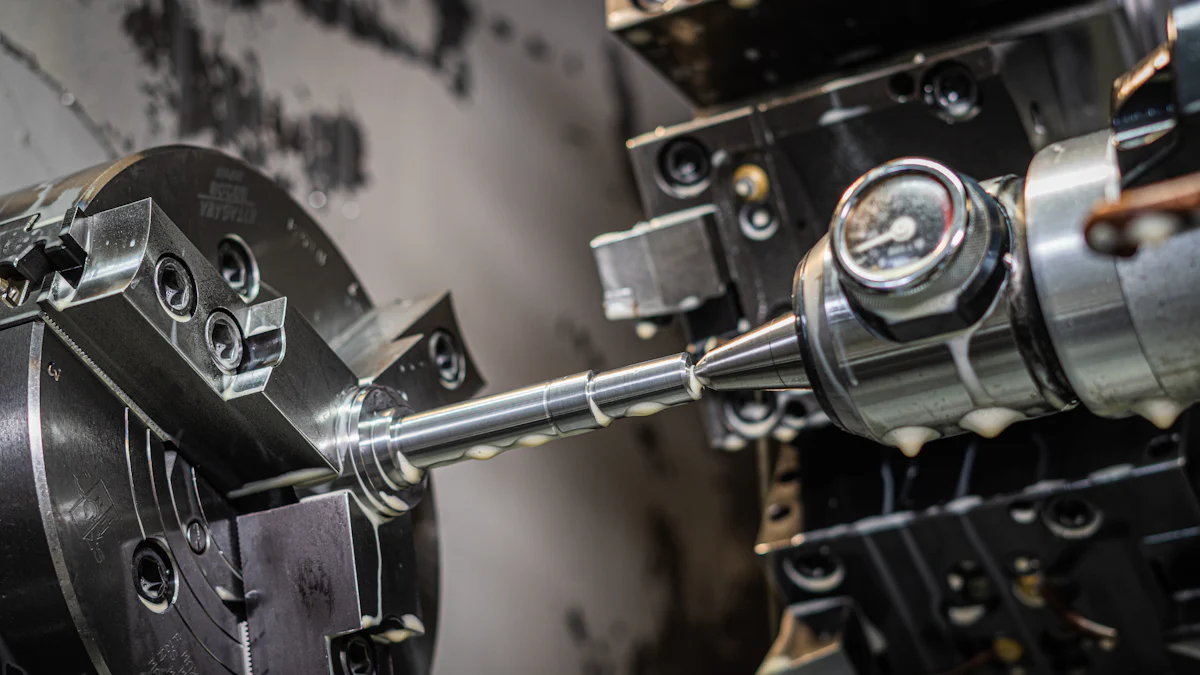

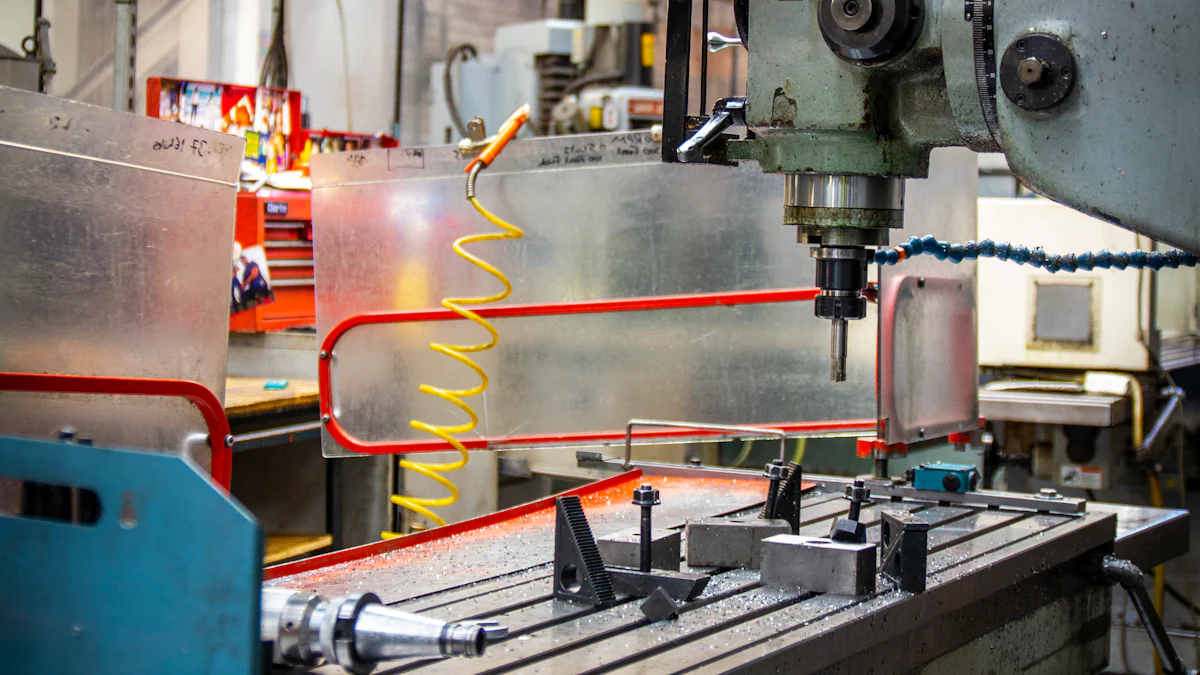

Milling Machines: Shape complex designs using rotating cutting tools.

Turning Machines: Create cylindrical parts by rotating the workpiece.

Grinding Machines: Achieve fine finishes with abrasive wheels.

Five-Axis CNC Machines: Handle intricate designs by moving tools along five axes.

These tools and machines work together to streamline your production process, delivering high-quality results efficiently.

CNC Machining vs. Traditional Methods

Differences in Process and Efficiency

CNC machining stands apart from traditional methods in several ways. Traditional machining relies heavily on manual control, which can slow down the production process. In contrast, CNC machining uses software to automate operations, significantly improving efficiency.

Here’s how CNC machining differs:

Control: CNC machines use computer software, while traditional methods depend on manual adjustments.

Flexibility: CNC machining handles complex designs and materials more effectively.

Labor Requirements: CNC reduces the need for skilled operators, focusing instead on software programming.

Quality: CNC ensures consistent precision, minimizing errors and rework.

By switching to CNC machining, you can save time and resources while maintaining high standards in your production.

Advantages of Automation in Reducing Lead Times

Automation is a key factor in reducing lead times with CNC machining. Unlike traditional methods, CNC machines operate continuously without human intervention. This allows for 24/7 production, minimizing downtime. Automation also speeds up setup and reconfiguration, enabling quicker transitions between tasks.

With CNC machining, you can produce prototypes rapidly, test designs faster, and refine them efficiently. The precision of CNC machines further reduces errors, eliminating the need for time-consuming rework. These advantages make CNC machining an essential tool for meeting tight deadlines and improving overall production efficiency.

Key Ways CNC Machining Reduces Lead Times

Automation and Continuous Operation

24/7 Production Capabilities

CNC machining offers the advantage of continuous operation, enabling machines to run 24/7 without interruptions. Unlike manual methods, where production halts during breaks or shift changes, CNC machines maintain consistent output. This capability significantly increases production capacity and ensures faster production. You can rely on CNC machining to minimize human oversight, reducing errors and maintaining consistent quality in every part produced. By leveraging this around-the-clock operation, you can achieve reduced lead time and meet tight deadlines with ease.

Faster Execution of Complex Tasks

CNC machining excels at handling intricate designs and complex tasks with unmatched efficiency. Machines follow detailed computer programs, ensuring precise adherence to specifications. This precision eliminates errors that often occur in manual machining, saving time and resources.

CNC machining automates tool selection and cutting paths, streamlining the production process.

It produces complex designs with high accuracy, making it ideal for both prototyping and custom orders.

Automated processes reduce setup time and labor costs, further enhancing manufacturing efficiency.

By utilizing CNC technology, you can achieve faster production cycles and improve overall production efficiency.

Rapid Prototyping and Iterative Design

Quick Transition from Design to Prototype

CNC machining simplifies the transition from design to prototype, allowing you to move quickly from concept to creation. CAD files are converted into cutting files within hours, enabling rapid production. This speed eliminates the need for expensive molds or casting tools, making it a cost-effective solution for small production runs. CNC machining supports a wide variety of materials, ensuring flexibility for diverse applications. With tolerances of just a few microns, prototypes meet production standards, ensuring accuracy and functionality.

Faster Testing and Refinement Cycles

CNC machining accelerates testing and refinement cycles during product development. You can produce highly accurate prototypes in days or even hours, enabling rapid evaluation of design iterations. Engineers can validate designs and make adjustments efficiently, shortening the overall development timeline. This approach embodies the "fail fast, learn faster" philosophy, helping you introduce innovative features to the market quickly. By compressing development cycles, CNC machining ensures faster production and quicker turnaround for your projects.

Efficient Setup and Changeover Processes

Pre-Programmed Instructions for Reduced Setup Time

CNC machining uses pre-programmed instructions to streamline setup processes. Machines follow standardized procedures, ensuring tasks are executed efficiently. This reduces the likelihood of errors, which can delay production. Proper documentation and measurement of setup tasks further optimize the process, especially in environments with varied production needs. By reducing setup time, CNC machining enhances manufacturing efficiency and ensures faster production cycles.

Seamless Transitions Between Production Runs

CNC machining facilitates seamless transitions between different production runs. Quick-change tool holders and modular fixturing systems allow for rapid reconfiguration, accommodating various part geometries. Integrated CAM software automates tool selection and cutting paths, minimizing downtime. Built-in tool changers and automatic tool offset adjustments further reduce setup times. This flexibility enables you to switch between products effortlessly, ensuring efficient mass production and consistent quality.

Streamlined Production Workflows

Integration with CAD/CAM Software

Integrating CAD/CAM software into CNC machining workflows transforms the production process. This integration connects the design and manufacturing phases, ensuring a seamless transition from concept to creation. You can eliminate errors and reduce production time by using CAD/CAM software to generate precise toolpaths and cutting instructions. This approach enhances productivity and accuracy while lowering costs.

Here are some key benefits of CAD/CAM integration:

Faster file transfer and overall computing.

Streamlined workflows for improved production efficiency.

Shorter learning curves for operators.

Remote accessibility for enhanced flexibility.

CAD/CAM software also allows you to create intricate designs with ease. By optimizing cutting paths, it minimizes material waste and ensures precision in every part. Whether you're working with five-axis CNC machines or simpler setups, this integration boosts efficiency and supports complex machining tasks.

Tip: Leveraging CAD/CAM software helps you achieve faster production cycles and maintain high-quality standards, making it an essential tool for reducing lead times.

Consistent and Repeatable Processes for Large-Scale Production

CNC machining excels at maintaining consistency and repeatability, which is crucial for large-scale production. Once programmed, CNC machines follow detailed instructions to produce identical parts with minimal variation. This ensures that every component meets exact specifications, a necessity in industries like automotive and aerospace.

Key advantages of CNC machining for large-scale production include:

Continuous operation without human intervention, maximizing efficiency.

Precise adherence to specifications, reducing errors and post-production corrections.

The ability to produce thousands of identical parts, ensuring reliability and safety.

For example, CNC machining is vital for manufacturing automotive components like fuel injection systems and braking mechanisms. These parts require high precision to ensure performance and safety. By automating the production process, CNC machines deliver consistent results, reduce lead times, and enhance overall production efficiency.

Note: The repeatability of CNC machining makes it ideal for mass production, where consistency and precision are non-negotiable.

Additional Benefits Enhancing Production Efficiency

Improved Quality Control

High Precision Reduces Errors and Rework

CNC machining ensures exceptional precision, minimizing errors and the need for rework. You can rely on several quality control measures to maintain high standards:

Material Inspection: Incoming materials undergo thorough checks for defects and dimensional accuracy.

In-Process Monitoring: Cutting speed and tool wear are continuously tracked to ensure consistent results.

Final Inspection: Advanced equipment verifies dimensional accuracy and surface finish.

Statistical Process Control (SPC): Data-driven methods identify trends and variations, ensuring consistent quality.

Regular Machine Maintenance: Scheduled inspections keep CNC machines operating at peak accuracy.

These measures ensure every part meets exact specifications, reducing waste and improving manufacturing efficiency.

Real-Time Monitoring for Consistent Output

Real-time monitoring plays a critical role in maintaining consistent output. By observing cutting load and sound, you can detect tool wear early and make timely adjustments. Continuous performance tracking allows for immediate corrections, preventing defects and scrap production. Monitoring operational speeds and feed rates also ensures adherence to programmed dimensions, delivering reliable results. This proactive approach enhances production efficiency and reduces lead times.

Reduced Material Waste

Optimized Cutting Paths for Minimal Waste

CNC machining employs advanced techniques to optimize cutting paths and minimize material waste:

Adaptive Cutting: Real-time feedback adjusts tool paths, reducing waste and extending tool life.

Laser Cutting: High-speed lasers enhance precision and reduce inaccuracies.

Smaller Cut Widths: Narrower cuts decrease material usage and improve cooling for faster operation.

These methods ensure efficient material usage, lowering costs and improving manufacturing efficiency.

Cost Savings and Faster Material Handling

Reducing material waste directly impacts your bottom line. Precise material removal minimizes the need for raw materials, cutting costs significantly. Reusing materials and implementing closed-loop systems further reduce expenses. Faster processing and shorter cycle times result from optimized resource utilization, enhancing overall production efficiency.

Scalability for High-Volume Production

Efficient Handling of Large Orders

CNC machining is ideal for high-volume production. Automation allows machines to operate continuously with minimal downtime, maximizing output. Once programmed, CNC machines produce components rapidly, maintaining consistent quality. Features like built-in sensors and quick transitions between processes ensure efficiency even for large orders.

Feature | Explanation |

|---|---|

Continuous Operations | Machines run without breaks, increasing output. |

Low Oversight | Minimal human intervention ensures consistent production. |

Quick Transition | Rapid switching between tasks reduces setup time. |

Built-in Sensors | Enhance precision and reliability, ensuring high-quality components. |

Flexibility to Adapt to Production Demands

CNC machining adapts seamlessly to changing production requirements. Real-time monitoring enables dynamic adjustments to spindle speeds and feed rates, ensuring optimal cutting conditions. Modular tooling systems allow for quick tool changes, minimizing downtime. Strategies like just-in-time (JIT) manufacturing align production schedules with demand, reducing inventory costs. This flexibility makes CNC machining a reliable solution for high-volume manufacturing.

Real-World Applications of CNC Machining

Automotive Industry

Faster Production of Custom and Standard Parts

CNC machining plays a vital role in the automotive industry by speeding up the production of both custom and standard parts. You can rely on CNC machines to operate continuously, ensuring faster turnaround times without the delays caused by human fatigue. This technology achieves high precision with tolerances as tight as ±0.001″, which is essential for creating reliable automotive components.

Here’s how CNC machining improves production efficiency in the automotive sector:

Speed: Automated processes reduce lead times, especially for low-volume production.

Accuracy: CNC machines deliver consistent results, minimizing errors and rework.

Flexibility: Quick adjustments accommodate design changes or new requirements.

By leveraging CNC machining, you can meet tight deadlines while maintaining high-quality standards.

Reduced Lead Times for Assembly Line Components

CNC machining significantly reduces lead times for producing assembly line components. Machines operate continuously without human intervention, maximizing efficiency and minimizing idle time. The precision of CNC machining eliminates errors, reducing the need for rework and speeding up production. Rapid prototyping capabilities also allow you to validate and iterate designs quickly, shortening development timelines. These advantages make CNC machining an indispensable tool for automotive manufacturing.

Aerospace Industry

Precision Machining for Critical Components

The aerospace industry depends on CNC machining for producing critical components with unmatched precision. You can use CNC technology to create intricate engine parts, flight control systems, and landing gear components. This process ensures tight tolerances and consistent quality, which are essential for safety and performance. CNC machining also supports the fabrication of lightweight materials like titanium and advanced plastics, helping reduce aircraft weight and improve fuel efficiency.

Applications of CNC machining in aerospace include:

Machining of engine parts and satellite components.

Fabrication of space shuttle and space station modules.

Production of lightweight interior cabin parts.

By using CNC machining, you can achieve the precision and reliability required for aerospace manufacturing.

Accelerated Prototyping for Innovative Designs

CNC machining accelerates prototyping in aerospace manufacturing, enabling you to test and validate designs quickly. This technology produces precise prototypes that meet strict quality standards, ensuring optimal performance before full-scale production. CNC machining also simplifies adjustments during the iteration phase, allowing you to refine designs efficiently. With its ability to handle complex geometries, CNC machining supports the development of innovative technologies for aircraft and spacecraft.

Medical Device Manufacturing

Rapid Production of Surgical Tools and Implants

CNC machining ensures the rapid production of surgical tools and implants, meeting the medical industry’s demand for timely delivery. You can rely on this technology to produce components with exceptional precision, adhering to strict tolerances required for medical applications. CNC machining also supports a wide range of biocompatible materials, enabling the creation of diverse medical devices.

Advantage | Description |

|---|---|

Precision and Accuracy | Ensures strict tolerances for surgical instruments and implants. |

Repeatability | Delivers consistent quality across production runs. |

Flexibility in Material Choice | Supports biocompatible metals and advanced plastics for diverse applications. |

Customization | Facilitates tailored implants and prosthetics for improved patient outcomes. |

Reduced Production Time | Speeds up the development cycle, ensuring timely delivery of medical devices. |

CNC machining’s ability to replicate parts with exact precision makes it a reliable solution for medical manufacturing.

High-Quality Standards with Quick Delivery

CNC machining maintains high-quality standards while ensuring quick delivery in medical manufacturing. Real-time monitoring and quality testing prevent defects, ensuring every component meets strict specifications. This precision is crucial for surgical tools and implants, which must perform safely within the human body. CNC machining also supports fast production cycles, enabling you to respond quickly to market demands. By combining precision with efficiency, CNC machining helps you deliver high-quality medical devices on time.

CNC machining revolutionizes production by reducing lead times through automation, rapid prototyping, and efficient workflows. You can minimize errors and streamline processes, enabling faster production cycles. Industries like automotive, aerospace, and medical manufacturing rely on CNC for its precision and scalability. Continuous operation and tight tolerances ensure consistent quality, even under tight deadlines. By adopting CNC, you stay competitive in fast-paced environments, handling complex projects with ease. This technology not only accelerates production but also enhances efficiency, making it indispensable for modern manufacturing.

FAQ

What types of materials can CNC machines work with?

CNC machines handle a wide range of materials, including metals like aluminum and steel, plastics, wood, and composites. You can also use them for advanced materials like titanium and carbon fiber, making CNC machining versatile for various industries.

How does CNC machining improve production speed?

CNC machining automates processes, reducing manual intervention. Machines operate continuously, even overnight, and execute tasks with precision. This eliminates delays caused by human error and speeds up production cycles.

Is CNC machining cost-effective for small production runs?

Yes, CNC machining is cost-effective for small runs. It eliminates the need for expensive molds or tooling. You can quickly transition from design to production, saving time and reducing upfront costs.

Can CNC machines produce custom parts?

CNC machines excel at creating custom parts. You can program them to follow precise specifications, allowing for intricate designs and unique geometries. This makes them ideal for prototyping and specialized manufacturing.

How does CNC machining ensure consistent quality?

CNC machines follow pre-programmed instructions, ensuring every part meets exact specifications. Real-time monitoring detects errors early, and automated processes maintain precision. This consistency reduces rework and ensures high-quality output.

See Also

Streamlined CNC Machining Solutions For Accurate Manufacturing

Impact Of CNC Precision Parts Processing On Production Expenses

The Role Of CNC Machining In Advanced Precision Production

Perfecting CNC Machining Techniques For Precision Component Production

Investigating CNC Machining Options For Accurate Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com