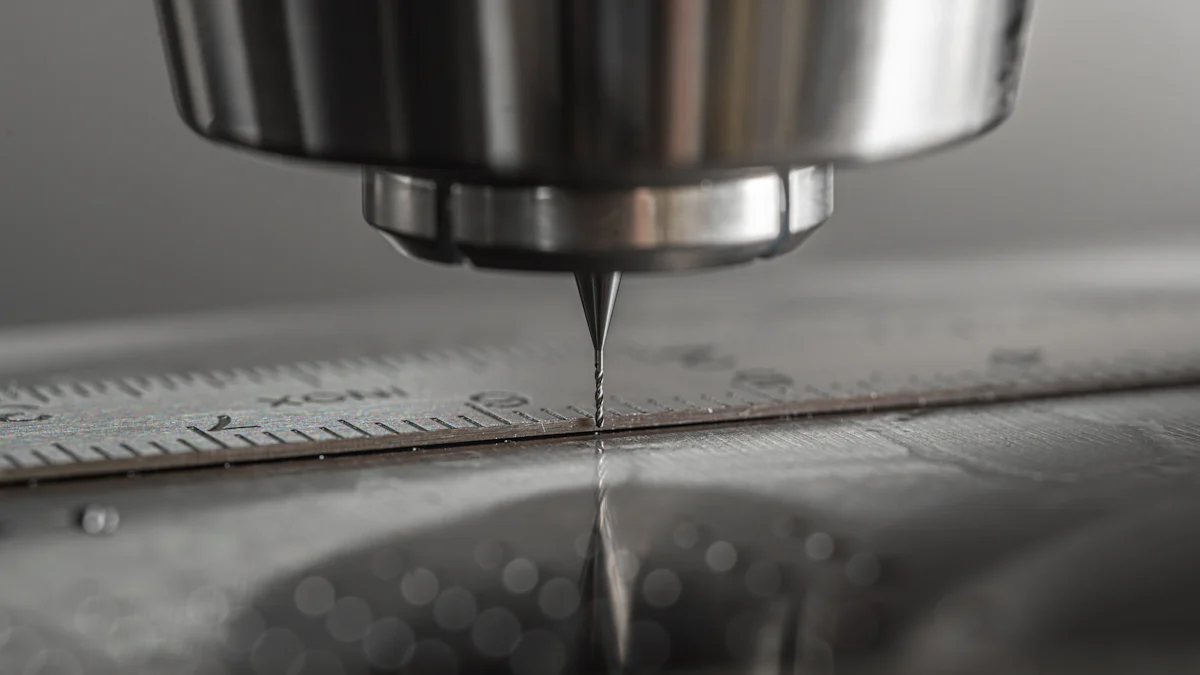

The Role of CNC Machining in Reducing Production Costs

CNC machining plays a vital role in helping you reduce production costs. This technology enhances precision and efficiency, ensuring fewer defects and less rework. By automating processes, CNC machines allow operators to oversee multiple systems, cutting labor costs significantly. The ability to reuse programs and tools further reduces expenses. CNC multi-axis machines streamline complex tasks, saving time and improving productivity. Additionally, precise material removal minimizes waste, contributing to sustainable manufacturing. These advancements in CNC technology lead to cost reduction and overall improvement in manufacturing processes.

Key Takeaways

CNC machines work accurately and quickly, causing fewer mistakes and costs.

Picking cheaper materials and easier designs can cut machining costs.

Better machine paths and smart software make work faster with less waste.

Taking care of CNC machines stops big repairs and keeps quality steady.

Using standard parts makes work easier and avoids special machining needs.

Factors That Influence CNC Machining Costs

Understanding the factors that influence cnc machining costs can help you make informed decisions to optimize your production process. Key considerations include material selection, machine setup and programming, and design complexity.

Material Selection

Impact of material type on machining time and tool wear

The type of material you choose directly affects machining time and tool wear. Softer materials like aluminum and plastic are easier to machine, reducing tool wear and production time. Harder materials, such as stainless steel, require more robust tools and longer machining cycles, which increase costs.

Material | Cost Range (per pound) | Common Applications |

|---|---|---|

Aluminum | $1 - $6 | Automobile, medical, aerospace, bicycle |

Steel | $0.30 - $6 | Various industries, depending on grade and complexity |

Stainless Steel | $2 - $20 | Medical, food processing, aerospace |

Brass | $3 - $10 | Musical instruments, plumbing fixtures, decorative hardware |

Plastic | $1 - $7 | Electronics, automotive, consumer goods |

Choosing cost-effective materials without compromising quality

Balancing affordability with functionality is essential when selecting materials. Standardizing materials across product lines minimizes waste and improves machining efficiency. Focus on the most critical characteristics of your part, such as strength or heat resistance, to eliminate unsuitable options. This approach allows you to compare costs effectively and select materials that meet your needs without overspending.

Machine Setup and Programming

Time and cost associated with initial setup

Machine setup and programming are significant contributors to cnc machining costs. Factors like part size, complexity, and quantity impact setup time. For example, programming rates for a 3-axis machine average $40 per hour, while 5-axis machines range from $75 to $120 per hour. Skilled operators are essential for efficient setup, but their expertise adds to labor costs.

CNC Programming Rate | Cost |

|---|---|

3-axis | $40/hr |

4-axis | $45-50/hr |

5-axis | $75-120/hr |

Importance of efficient programming for cost savings

Efficient programming reduces cnc machining costs by optimizing tool paths and minimizing waste. Using CAM software, you can visualize and refine the machining process, ensuring faster production and consistent quality. Simplifying designs and adopting lean manufacturing practices further enhance cost reduction.

Design Complexity

How intricate designs increase machining time and costs

Complex designs, such as those with sharp internal corners or deep cavities, require more machining steps and specialized tools. This increases production time and costs. Additionally, intricate geometries often demand multi-axis machines and skilled operators, further driving up expenses.

Simplifying designs to reduce production expenses

Simplifying part designs is one of the most effective ways to reduce cnc machining costs. Evaluate whether all features are necessary or if they can be simplified without compromising functionality. Opt for simpler geometries and avoid unnecessary complexity to streamline production and save money.

Strategies to Reduce CNC Machining Costs

Simplifying Part Designs

Reducing unnecessary features to lower machining time

Simplifying part designs is one of the most effective ways to reduce cnc machining costs. Complex shapes often require additional machining steps and specialized tools, which increase production time and expenses. By eliminating unnecessary features, you can streamline the process and save both time and money.

Simpler geometries reduce machining operations.

Fewer features mean less tool wear and shorter cycle times.

Simplified designs minimize the risk of errors, leading to fewer defects.

Designing for manufacturability to streamline production

Designing for manufacturability (DFM) ensures that your parts are optimized for efficient production. By evaluating functional requirements early, you can avoid unnecessary precision and select materials with good machinability. This approach reduces costs and improves efficiency.

Adjusting tolerances to practical levels lowers expenses.

Choosing machinable materials prevents excessive tool wear.

Collaborating with machinists during the design phase ensures cost-effective production.

Using Standard Components

Benefits of standardization in reducing custom machining

Using standard components simplifies production and reduces the need for custom machining. Standardized parts are readily available, which eliminates the need for custom tooling and shortens lead times.

Standard components ensure consistent quality across machined parts.

They reduce the complexity of manufacturing processes.

Standardization improves efficiency and lowers costs.

Cost savings from readily available components

Readily available components contribute to significant cost savings. These parts eliminate the need for custom designs, reducing machining steps and production time.

Off-the-shelf components streamline assembly processes.

They minimize the need for additional machining operations.

Using standard parts reduces overall production costs.

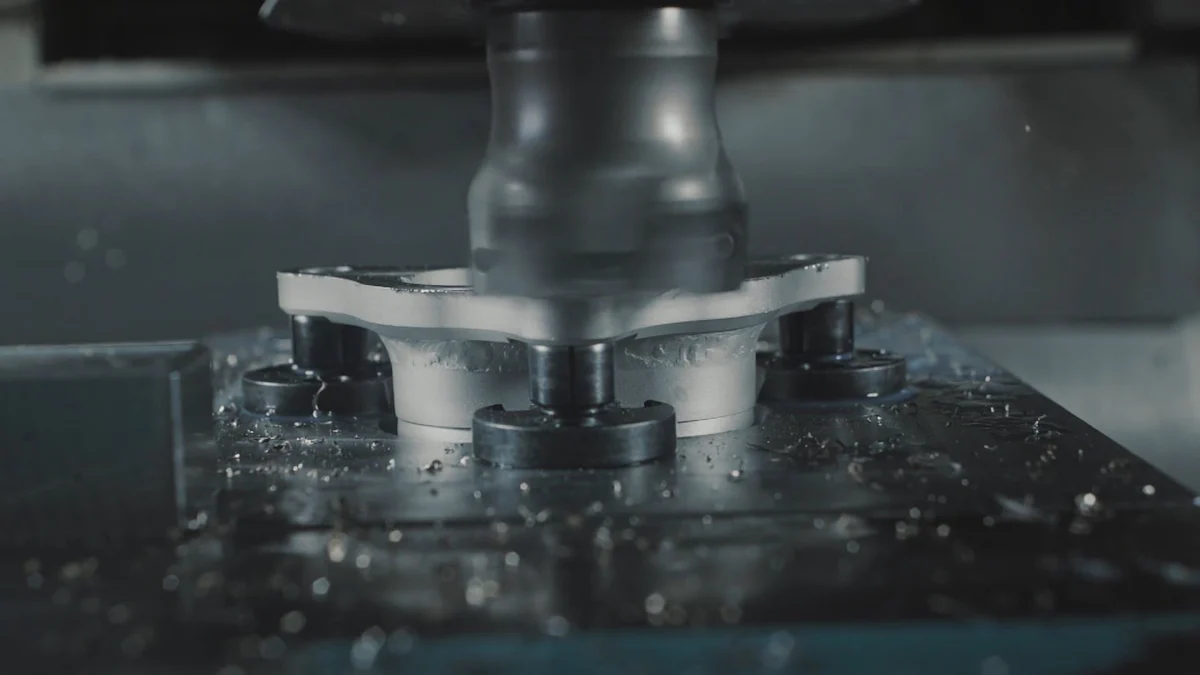

Optimizing Machining Paths

Reducing tool travel to save time and energy

Optimizing machining paths is a key strategy for process optimization. By reducing unnecessary tool travel, you can save time and energy while improving efficiency. Advanced programming techniques help you achieve this goal.

Shorter tool paths reduce cycle times.

Minimizing tool changes lowers production costs.

Efficient paths decrease tool wear and energy consumption.

Leveraging advanced software for efficient path planning

Advanced CAM software enhances machining efficiency by fine-tuning toolpaths and reducing cycle times. Real-time monitoring allows you to make immediate adjustments, preventing errors and improving productivity.

Software optimizes feed rates and machining conditions.

It minimizes unnecessary tool movements, saving time.

Monitoring tools improve overall equipment efficiency.

By applying these cnc machining strategies, you can achieve significant cost reduction while maintaining high-quality production. Simplifying designs, using standard components, and optimizing machining paths are among the best practices for cnc machining cost reduction.

Benefits of CNC Machining for Cost Reduction

Reduced Waste

Precision machining minimizes material waste

CNC machining significantly reduces material waste by delivering high precision. Unlike traditional methods, CNC machines execute exact cuts, ensuring maximum material utilization. Advanced CAD and CAM software optimize cutting processes, allowing parts to be nested efficiently. This minimizes leftover material and ensures you get the most out of your raw materials.

High reproducibility conserves resources.

Optimized part geometry and tool paths avoid unnecessary waste.

Careful product design planning further reduces material waste.

Recycling scrap materials for additional savings

Recycling scrap materials is another way CNC machining helps you save costs. By minimizing waste and maximizing material utilization, you reduce the need for new raw materials. This approach also lowers disposal costs. Techniques like nesting and optimizing part orientation can further reduce scrap. CNC machines operate under tight tolerances, cutting pieces to exact specifications and leaving little unusable material.

Reduces reliance on new raw materials.

Lowers costs associated with waste disposal.

Ensures efficient use of resources through precise coding.

Faster Production

Automation enables high-speed manufacturing

Automation in CNC machining accelerates production by reducing manual tasks. CNC machines handle loading, unloading, and repositioning materials with minimal human intervention. This efficiency maximizes output and reduces idle time. Modern CNC systems also allow for quick task switching, adapting to diverse production needs.

Aspect | Description |

|---|---|

Efficiency | Automation saves time on material handling and setup. |

Precision | Automated tools ensure consistent quality and reduce errors. |

Flexibility | CNC machines adapt quickly to different tasks, enhancing production speed. |

Consistent quality reduces rework and delays

CNC machining ensures consistent quality, which minimizes the need for rework. High-quality parts meet specifications on the first attempt, saving time and resources. Stringent quality control measures further reduce errors, ensuring smooth production.

High-quality products are less likely to require expensive rework or repairs, and customers are less likely to return defective products.

Scalability and Flexibility

Cost-effectiveness in both small and large production runs

CNC machining offers cost benefits for both small-batch and high-volume production. In small-batch CNC machining, you can achieve high customization without excessive costs. For larger runs, fixed costs spread across more units, reducing per-part expenses. Automation enhances consistency and speeds up production, further lowering costs.

Production Volume | Cost Implications |

|---|---|

Small Batches | Higher per-part costs due to setup expenses dominating total costs. |

Large Batches | Lower per-part costs as fixed charges are spread over more units. |

Flexibility to adapt to changing production needs

CNC machining provides unmatched flexibility. Modern machines switch tasks rapidly, allowing you to respond to market changes. Whether you need small-batch CNC machining for prototypes or high-volume production, CNC systems adapt seamlessly. Flexible manufacturing systems enable quick design changes and production scaling with minimal manual intervention.

Rapid task switching enhances adaptability.

Continuous operation supports both small and large production runs.

Quick reprogramming allows for efficient production of different product variants.

Common Mistakes That Increase CNC Machining Costs

Over-Specifying Tolerances

How unnecessary precision increases costs

Over-specifying tolerances is a common mistake that can significantly increase CNC machining costs. Tight tolerances, such as ±0.0002”, often require specialized tools, longer machining times, and more labor. These factors drive up costs and lead times. Additionally, tighter tolerances increase the likelihood of higher scrap rates, as maintaining such precision consistently is challenging. You should avoid applying tight tolerances to all dimensions. Instead, focus on critical areas like mating or moving parts where precision is essential.

Limit tight tolerances to functional requirements.

Avoid unnecessary precision to reduce material waste and tooling expenses.

Use default tolerances (e.g., ±0.127 mm) for non-critical features.

Balancing tolerances with functional requirements

Balancing tolerances with functional requirements is key to cost reduction. While some parts need tight tolerances, most applications can function well with standard tolerances. Adjusting tolerances to practical levels reduces machining costs and ensures efficient production. Assign numerical values only to features critical to the part’s function. This approach minimizes unnecessary expenses and streamlines the manufacturing process.

Specify tolerances only where necessary.

Avoid over-tolerance to save time and resources.

Collaborate with machinists to determine appropriate tolerances.

Neglecting Design for Manufacturability

Consequences of complex designs on production costs

Ignoring design for manufacturability can lead to costly errors. Complex designs often require additional machining steps, specialized tools, and longer production times. These factors increase costs exponentially, especially if issues arise during later stages of production. For example, fixing a defect during the testing phase costs ten times more than addressing it during the design phase. A single design error can derail your budget and delay product launches.

Complex designs increase machining time and costs.

Late-stage repairs are significantly more expensive.

Poor design planning impacts overall production efficiency.

Collaborating with machinists during the design phase

Collaborating with machinists early in the design phase can help you identify cost-saving opportunities. Machinists can recommend suitable machining processes and materials, ensuring your design aligns with manufacturing capabilities. This collaboration prevents unnecessary precision and reduces production costs. By evaluating functional requirements together, you can create designs optimized for efficient CNC machining.

Early collaboration identifies cost-saving opportunities.

Machinists help select cost-effective machining processes.

Joint planning ensures designs are manufacturable and efficient.

Ignoring Maintenance and Tool Wear

Impact of worn tools on quality and costs

Worn tools can negatively impact both the quality and cost of CNC machining. Dull tools require more cutting force, increasing operational costs. They also reduce part accuracy, leading to higher scrap rates and rework expenses. Poor surface finishes caused by worn tools further escalate costs. Regularly monitoring tool wear ensures consistent quality and minimizes waste.

Impact Type | Description |

|---|---|

Increased Cutting Force | Worn tools require more force, raising operational costs. |

Decreased Accuracy of Parts | Tool wear reduces precision, increasing scrap and rework rates. |

Poor Surface Finish | Dull tools create uneven surfaces, leading to quality issues. |

Decreased Tool Life | Frequent tool changes increase costs and downtime. |

Higher Production Costs | Tool wear raises overall machining expenses and reduces profit margins. |

Importance of regular machine maintenance

Regular maintenance is essential for cost-effective CNC machining. Routine checks prevent unplanned breakdowns, which are often five times more expensive than annual maintenance plans. Proactive maintenance also boosts productivity by reducing downtime. By keeping your machines in optimal condition, you can enhance output efficiency and improve profit margins.

Routine maintenance prevents costly breakdowns.

Regular checks reduce unplanned downtime.

Proactive care enhances productivity and profitability.

CNC machining drives cost reduction by enhancing precision, efficiency, and scalability. Simplifying designs, using standard components, and optimizing machining paths are effective strategies to lower costs. You can also avoid common mistakes, like over-specifying tolerances or neglecting maintenance, to ensure long-term efficiency. Regularly reviewing processes, investing in training, and leveraging advanced software further maximize savings. CNC machining offers unmatched scalability and precision, making it a cost-effective solution for high-quality production. By adopting these practices, you can streamline operations and achieve sustainable manufacturing success.

FAQ

What is CNC machining, and how does it help reduce costs?

CNC machining uses computer-controlled tools to create precise parts. It reduces costs by minimizing waste, improving efficiency, and automating production. This process ensures consistent quality and lowers labor expenses.

How can you simplify designs for CNC machining?

You can simplify designs by removing unnecessary features and using standard geometries. This reduces machining time and tool wear, leading to cost reduction. Collaborating with machinists ensures your design is optimized for manufacturability.

What materials are best for cost-effective CNC machining?

Materials like aluminum and plastic are cost-effective due to their machinability. They reduce tool wear and machining time. Choosing materials based on your part's functional requirements helps balance cost and quality.

How does CNC machining improve scalability?

CNC machining adapts to both small and large production runs. Automation allows quick reprogramming for different tasks, ensuring cost-effectiveness and flexibility. This scalability supports diverse manufacturing needs.

Why is regular maintenance important for CNC machines?

Regular maintenance prevents tool wear and machine breakdowns. It ensures consistent quality, reduces downtime, and lowers long-term costs. Proactive care keeps your CNC machines running efficiently.

See Also

How CNC Precision Parts Affect Overall Manufacturing Expenses

Streamlined CNC Machining Solutions for Accurate Production

Investigating CNC Machining Options for Precision Production

Discovering Seven Advantages of CNC Machining in Modern Manufacturing

Recognizing the Significance of Precision CNC Machining in Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com