How CNC Machining Supports the Renewable Energy Industry with Durable Materials

CNC machining plays a vital role in advancing renewable energy systems. It allows you to create precise components that meet the demanding requirements of energy technologies. Durable materials produced through this process ensure systems last longer and perform reliably under extreme conditions. CNC machining also supports sustainability by optimizing resource use. It minimizes waste through precision cutting and promotes recycling, reducing the need for raw materials. These practices lower environmental impact while maintaining high-quality production standards.

Key Takeaways

CNC machining helps make parts for renewable energy systems accurately. This improves how well they work and how long they last.

Strong materials like stainless steel and carbon fiber make energy systems last longer. This also lowers the need for repairs and saves money.

CNC machining cuts materials precisely, creating less waste. This helps protect the environment and supports green goals.

The technology can grow to make parts for small or big projects. It works for things like wind turbines and solar panels.

New ideas in CNC machining, like robots and smart tech, make it faster. These ideas also help create better renewable energy tools.

CNC Machining and Its Role in Renewable Energy

What is CNC Machining?

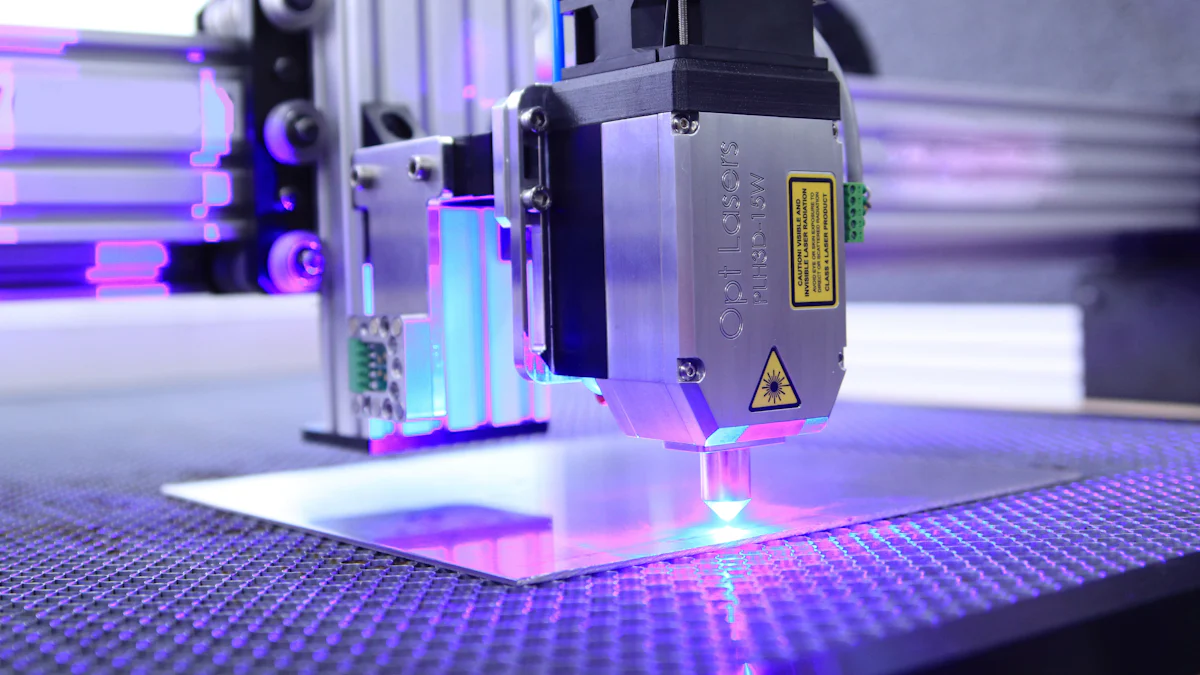

Overview of the CNC machining process

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses pre-programmed software to control machinery. This technology allows you to produce parts with exceptional precision and repeatability. The process involves various techniques, including milling, turning, drilling, and grinding. For example, milling creates turbine components, while turning is essential for manufacturing rotational parts like shafts. Drilling ensures precise holes for assembly, and grinding provides smooth surfaces for tight tolerances. Advanced methods like multi-axis machining enable the creation of complex shapes, which are often required in renewable energy systems.

CNC machining also integrates seamlessly with other technologies, such as additive manufacturing. This combination enhances efficiency and reduces material waste. Whether you need high-volume production or custom components, CNC machining adapts to your specific requirements, making it a versatile solution for renewable energy applications.

Key benefits of CNC machining in manufacturing

CNC machining offers several advantages that make it indispensable for renewable energy systems. First, it delivers unmatched precision, ensuring components perform optimally. Second, it supports a wide range of materials, including metals, plastics, and composites, which are crucial for meeting the durability needs of energy systems. Third, automation reduces labor costs and speeds up production, allowing you to meet tight deadlines. Finally, the process minimizes waste, aligning with sustainable manufacturing practices.

Why CNC Machining is Vital for Renewable Energy

Precision and consistency in energy components

Renewable energy systems rely on components that must function flawlessly under extreme conditions. CNC machining ensures the precision and consistency needed for these parts. For instance, it can create intricate 3D forms, such as rotor blades and gearbox components, which enhance energy absorption and efficiency. The high level of accuracy also reduces the risk of component failure, improving the reliability of renewable energy systems.

Scalability for renewable energy integration

CNC machining excels in scalability, making it ideal for renewable energy projects of all sizes. Whether you are manufacturing large wind turbine blades or small solar panel frames, CNC machining adapts to your needs. For example, it has been used to produce components for offshore wind farms, utility-scale solar farms, and hydroelectric dams. This scalability ensures you can meet growing energy demands while maintaining quality and efficiency. Additionally, the rapid production capabilities of CNC machining reduce lead times, enabling quicker deployment of renewable energy systems.

Applications of CNC Machining in Renewable Energy

Wind Energy Systems

Manufacturing turbine blades and hubs

CNC machining plays a critical role in producing wind turbine components. You can rely on this technology to create precision parts like rotor blades, hub assemblies, and gearboxes. These components require complex shapes and tight tolerances, which CNC machining achieves with ease. For example:

CNC machines carve turbine blades with exact precision, improving aerodynamic efficiency.

Gearboxes are manufactured to handle high mechanical loads with accuracy.

Nacelle components are fabricated to be both lightweight and durable.

This precision ensures that each part fits perfectly into the turbine structure, enhancing performance and safety. By using CNC machining, you can meet the demanding requirements of wind energy systems while maintaining high-quality standards.

Ensuring durability and structural integrity

Wind turbines face harsh environmental conditions, including strong winds, rain, and temperature fluctuations. CNC machining ensures that components like blades and hubs can withstand these stressors. The process allows you to use durable materials and create customized designs tailored to specific operational needs. This approach improves the reliability and lifespan of wind energy systems, reducing maintenance costs and downtime.

Solar Energy Components

Producing panel frames and mounting systems

CNC machining enhances the production of solar panel frames and mounting systems. You can achieve high accuracy in manufacturing, ensuring tight tolerances for structural integrity and proper alignment. This precision is essential for maximizing energy absorption. CNC machining also supports various materials, making it versatile for creating robust and lightweight frames. Automation further reduces production time and labor costs, allowing you to scale up efficiently.

Enhancing efficiency with precision engineering

Solar energy systems depend on precise engineering to optimize performance. CNC machining ensures that photovoltaic cell frames fit perfectly, protecting the cells and dissipating heat effectively. This precision contributes to the overall efficiency of solar panels, helping you generate more energy from renewable sources.

Application | Description |

|---|---|

Solar Panel Frames | CNC precision ensures robust frames and correct alignment for maximum energy absorption. |

Photovoltaic (PV) Cell Frames | Frames protect PV cells and improve heat dissipation, enhancing solar panel efficiency. |

Hydropower and Emerging Technologies

CNC-machined parts for hydropower systems

Hydropower systems rely on CNC machining for the production of critical components. You can use this technology to fabricate turbine housings, hydro generators, and large turbines. These parts require precise machining to ensure efficient water flow and minimize energy loss. CNC machining also supports intricate designs, enhancing the performance and reliability of hydropower equipment.

Supporting tidal and geothermal energy innovations

CNC machining contributes to the development of emerging renewable energy technologies like tidal and geothermal energy. For tidal systems, CNC-machined components such as turbine blades and housings improve energy capture from water currents. In geothermal plants, CNC machining produces heat exchangers, high-pressure pumps, and compressors. These components ensure efficient heat transfer and reliable operation under demanding conditions.

Component Type | Function |

|---|---|

Heat Exchangers | Optimized channels for efficient heat transfer |

High-Pressure Pumps | Reliable performance under demanding conditions |

Compressors | Maintains plant efficiency |

By leveraging CNC machining, you can support the growth of innovative renewable energy solutions, driving the transition to a sustainable future.

Durable Materials in CNC Machining for Renewable Energy

Characteristics of Durable Materials

Resistance to wear, corrosion, and extreme conditions

Durable materials used in cnc machining offer exceptional resistance to wear, corrosion, and harsh environmental conditions. These characteristics are essential for renewable energy systems that operate in challenging environments. For example, wind turbines face strong winds and rain, while solar panels endure prolonged exposure to sunlight and temperature fluctuations. Materials like stainless steel and titanium resist corrosion and maintain their structural integrity, ensuring long-term performance. This durability reduces the risk of component failure, enhancing the reliability of renewable energy systems.

Compatibility with renewable energy applications

The compatibility of durable materials with renewable energy applications lies in their ability to meet specific operational demands. Cnc machining provides the precision and high-quality finishes required for components that must endure extreme conditions. The ability to handle complex geometries allows you to produce intricate parts tailored to your needs. Consistent quality ensures reliability, while scalability supports both high-volume production and custom jobs. These features make durable materials ideal for renewable energy technologies.

Examples of Durable Materials

Metals like stainless steel and titanium

Metals such as stainless steel and titanium are widely used in cnc machining for renewable energy systems. Stainless steel offers excellent wear and corrosion resistance, making it suitable for hydropower turbines and offshore wind components. Titanium combines strength with a lightweight structure, ideal for applications like wind turbine blades. Aluminum, known for its high machinability and strength-to-weight ratio, is often used in solar panel frames. These metals ensure durability and efficiency in renewable energy systems.

Advanced composites and polymers

Advanced composites like carbon fiber provide high strength and lightweight properties, making them perfect for wind turbine blades. Polymers, on the other hand, offer flexibility and resistance to environmental stress. These materials enhance the performance of renewable energy systems by reducing weight without compromising strength. Cnc machining enables you to work with these materials, creating components that meet the exact specifications of your projects.

Material Type | Key Characteristics |

|---|---|

High-strength alloys | Resist corrosion, durable for harsh marine environments |

Carbon and stainless steel | Strength under pressure, water damage resistance |

Cost-effective, adaptable for solar panel frames | |

Titanium alloys | Strength without excessive weight |

Carbon fiber composites | High strength, lightweight, suitable for wind turbine blades |

Benefits for Renewable Energy Systems

Increased lifespan and reliability

Using durable materials in cnc machining significantly increases the lifespan and reliability of renewable energy systems. High-precision machining ensures components like heat exchangers and high-pressure pumps can withstand demanding conditions. This durability enhances the overall performance of renewable energy technologies, reducing the likelihood of system failures. By choosing materials like stainless steel or carbon fiber, you ensure your systems remain operational for extended periods, even in harsh environments.

Reduced maintenance and operational costs

Durable materials also lower maintenance and operational costs. Their long-term reliability minimizes the need for frequent repairs or replacements. For instance, refurbishing worn parts instead of replacing them saves costs and reduces downtime. The consistent quality of cnc-machined components further ensures smooth operation, leading to fewer interruptions. By investing in durable materials, you achieve cost savings while maintaining the efficiency of your renewable energy systems.

Tip: Choosing the right materials for cnc machining not only improves system performance but also supports sustainability by reducing waste and extending the life of components.

Sustainability and Efficiency in CNC Machining

Material Efficiency in CNC Machining

Minimizing waste through precision cutting

CNC machining excels at minimizing waste by using precision cutting techniques. This process ensures that each cut is accurate, reducing excess material. By optimizing cutting patterns, you can produce multiple components from a single piece of material. This approach not only saves resources but also lowers production costs. For example, CNC machining allows you to create intricate parts for renewable energy systems without generating unnecessary waste. This precision aligns with sustainable practices, making it an ideal choice for environmentally conscious manufacturing.

Recycling and reusing materials

Recycling and reusing materials in CNC machining further enhance sustainability. Manufacturers often implement closed-loop systems to collect and reintroduce waste materials into the production cycle. This reduces the need for raw materials and cuts down on waste. You can also manage cuttings and shavings creatively by converting them into resources for other processes, such as metal casting or additive manufacturing. Reusing by-products helps balance material consumption, ensuring that your production remains efficient and eco-friendly.

Energy Conservation in Manufacturing

Reducing energy consumption in CNC processes

CNC machining supports energy efficiency by reducing energy consumption during manufacturing. You can achieve this by using energy-efficient machines equipped with power-saving modes and variable speed drives. Optimizing machining parameters, such as spindle speed and feed rate, also lowers energy demand. Regular maintenance and upgrades ensure that machines operate at peak efficiency, further conserving energy. These strategies not only reduce costs but also contribute to sustainable practices in manufacturing.

Supporting energy-efficient renewable systems

CNC machining plays a vital role in creating energy-efficient renewable systems. Its precision ensures that components like wind turbine blades and solar panel frames perform optimally. The technology minimizes material waste and supports the production of complex parts needed for renewable energy technologies. Automated processes enhance efficiency, reduce production times, and make large-scale projects more cost-effective. By using CNC machining, you can align your manufacturing goals with sustainability.

CNC Machining and the Circular Economy

Designing components for reuse and recyclability

CNC machining aligns with the principles of the circular economy by enabling the design of reusable and recyclable components. You can use this technology to create parts with high precision, reducing mistakes and excess material. Eco-friendly materials, including recycled and biodegradable options, can also be incorporated into the machining process. This approach ensures that your manufacturing practices remain sustainable while meeting the demands of renewable energy systems.

Reducing the environmental footprint of manufacturing

Sustainable CNC machining reduces the environmental footprint of manufacturing by optimizing resource utilization and minimizing waste. High-efficiency machines consume less energy while maintaining productivity. Advanced software like CAD and CAM systems improve accuracy and streamline workflows, saving both time and energy. Additionally, closed-loop systems recycle coolant and conserve water, further enhancing sustainability. By adopting these practices, you can significantly lower the ecological impact of your production processes.

Note: Incorporating sustainable practices in CNC machining not only benefits the environment but also improves the efficiency and cost-effectiveness of your operations.

The Future of CNC Machining in Renewable Energy Integration

Innovations in CNC Technology

Advancements in automation and AI

You are witnessing a transformation in CNC machining as automation and AI reshape the manufacturing landscape. Machine learning algorithms now enable predictive maintenance, helping you avoid unexpected downtimes. These systems analyze real-time data to optimize machining processes, ensuring efficiency and precision. AI-driven design automation also simplifies the creation of complex components, allowing you to focus on functionality and performance. By integrating CNC machining with additive manufacturing, you can minimize waste and conserve resources, aligning with sustainability goals.

Development of new machining techniques

New machining techniques are pushing the boundaries of what CNC machining can achieve. Multi-axis machining allows you to create intricate designs with fewer errors, which is essential for renewable energy components like wind turbine blades. IoT-enabled CNC machines provide real-time monitoring, helping you maintain consistent quality. These advancements enhance the efficiency and cost-effectiveness of renewable energy manufacturing, ensuring you stay ahead in a competitive market.

Expanding Applications in Renewable Energy

Supporting next-generation energy technologies

CNC machining supports the development of next-generation renewable energy technologies. For wind power, you can produce durable components like bearings and large blades with unmatched precision. In hydropower, CNC machining helps you fabricate hydro generators and housing units for large-scale projects. Solar energy also benefits from CNC machining, as it ensures the accuracy and durability of frames and rails. These tailored solutions meet the specific needs of renewable energy systems, helping you achieve scalability and cost-effectiveness.

Enhancing global renewable energy integration

CNC machining plays a critical role in global renewable energy integration. Its ability to produce intricate parts with high accuracy improves the performance of energy systems. You can work with a variety of materials, ensuring compatibility with diverse applications. Automation reduces labor costs and material waste, making production more sustainable. These features make CNC machining an essential tool for advancing renewable energy on a global scale.

Long-Term Impact on Sustainability

Driving the transition to a greener economy

CNC machining helps you transition to a greener economy by reducing waste and improving efficiency. Precision machining allows you to cut intricate designs from a single piece of material, minimizing resource use. The energy-efficient design of CNC machines supports eco-friendly manufacturing practices. By adopting these technologies, you contribute to a sustainable future while meeting economic goals.

Strengthening the reliability of renewable energy systems

The precision and durability of CNC-machined components strengthen the reliability of renewable energy systems. You can reduce the frequency of replacements, lowering maintenance costs and environmental impact. This reliability ensures that renewable energy technologies remain operational for longer periods, supporting the global shift toward sustainability.

CNC machining plays a key role in advancing renewable energy systems. It enables you to produce durable components like turbine blades and solar panel frames with unmatched precision. This precision minimizes material waste, aligning with sustainability goals. Durable materials, such as stainless steel and carbon fiber, ensure the longevity of energy systems, reducing maintenance costs and environmental impact. You can also customize components to meet specific project needs, enhancing efficiency and reliability. As CNC technology evolves, it will continue to drive innovation, supporting the global transition to renewable energy.

FAQ

What makes CNC machining suitable for renewable energy systems?

CNC machining ensures precision manufacturing of components, which is essential for renewable energy systems. It produces parts with high accuracy, improving performance and reliability. The process also supports durable materials, ensuring components withstand harsh conditions.

How does CNC machining contribute to sustainability?

CNC machining minimizes waste through precise cutting and efficient material use. It also supports recycling and reusing materials, reducing the need for raw resources. These practices align with sustainability goals and lower the environmental impact of manufacturing.

Can CNC machining handle large-scale renewable energy projects?

Yes, CNC machining adapts to projects of any size. It supports renewable energy integration by producing components for wind turbines, solar panels, and hydropower systems. Its scalability ensures you can meet growing energy demands efficiently.

What materials are commonly used in CNC machining for renewable energy?

Stainless steel, titanium, and carbon fiber are popular choices. These materials offer durability, corrosion resistance, and strength. CNC machining works with these materials to create components that meet the specific needs of renewable energy systems.

How does CNC machining improve the efficiency of renewable energy systems?

CNC machining ensures components fit perfectly, enhancing system performance. For example, it produces aerodynamic wind turbine blades and precise solar panel frames. This precision boosts energy efficiency and reduces operational costs.

See Also

Streamlined CNC Machining Solutions for Accurate Manufacturing Needs

Investigating CNC Machining Solutions for Precision Production

Comprehending Material Needs for CNC Precision Machining

Grasping Eco-Friendly Methods in CNC Cutting Fluid Management

Discovering Seven Essential Advantages of CNC Machining Techniques

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com