How CNC Machining Helped a Small Business Scale Production

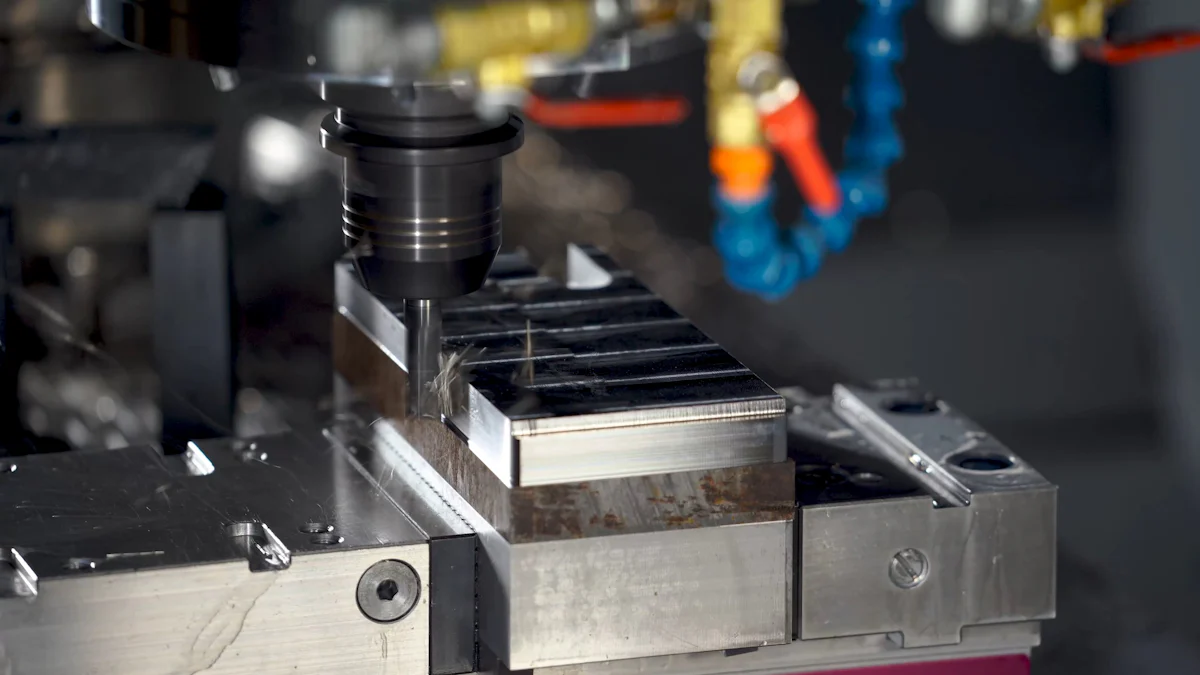

Imagine running a business where every product you create is flawless, consistent, and ready to meet growing demand. That’s the power of CNC machining. By automating production, CNC machines work tirelessly, boosting efficiency and cutting costs. They deliver precision that manual methods can’t match, ensuring every piece meets exact specifications. Whether you’re crafting intricate jewelry or manufacturing vehicle parts, CNC machining transforms your operations. It minimizes waste, speeds up production, and keeps quality high. With reliable CNC machining, you can scale confidently and compete with larger players in your industry.

Key Takeaways

CNC machines do the work automatically, cutting down mistakes and making products the same every time.

Using CNC machines can save money over time by working faster and wasting less material.

CNC machines are flexible, letting small businesses use different materials and make tricky designs easily.

Automation with CNC machines makes things faster, helping businesses finish on time and keep up with customer needs.

Teaching workers to use CNC machines improves their skills and lets them do more important jobs, helping the business grow.

CNC Machining Benefits for Small Businesses

Precision and Consistency

How CNC machining ensures uniformity in production.

When you rely on CNC machining, every product you create meets the same high standards. These machines follow programmed instructions with incredible precision, ensuring each piece is identical to the last. Unlike manual methods, CNC eliminates inconsistencies caused by human error. Whether you're producing ten units or ten thousand, the results remain consistent.

Here’s a quick look at how CNC machining benefits your production process:

Benefit | Description |

|---|---|

Reduced Manual Labor | Minimizes human intervention, leading to fewer errors and more efficient use of workforce resources. |

Consistent Output Quality | Ensures each product is identical, enhancing customer trust and brand reputation. |

Lower Production Costs | Automates processes, reducing labor costs and increasing production speed, leading to overall savings. |

Minimal Material Waste | Increases material efficiency, reducing waste and promoting sustainability. |

The role of precision in reducing waste and improving product quality.

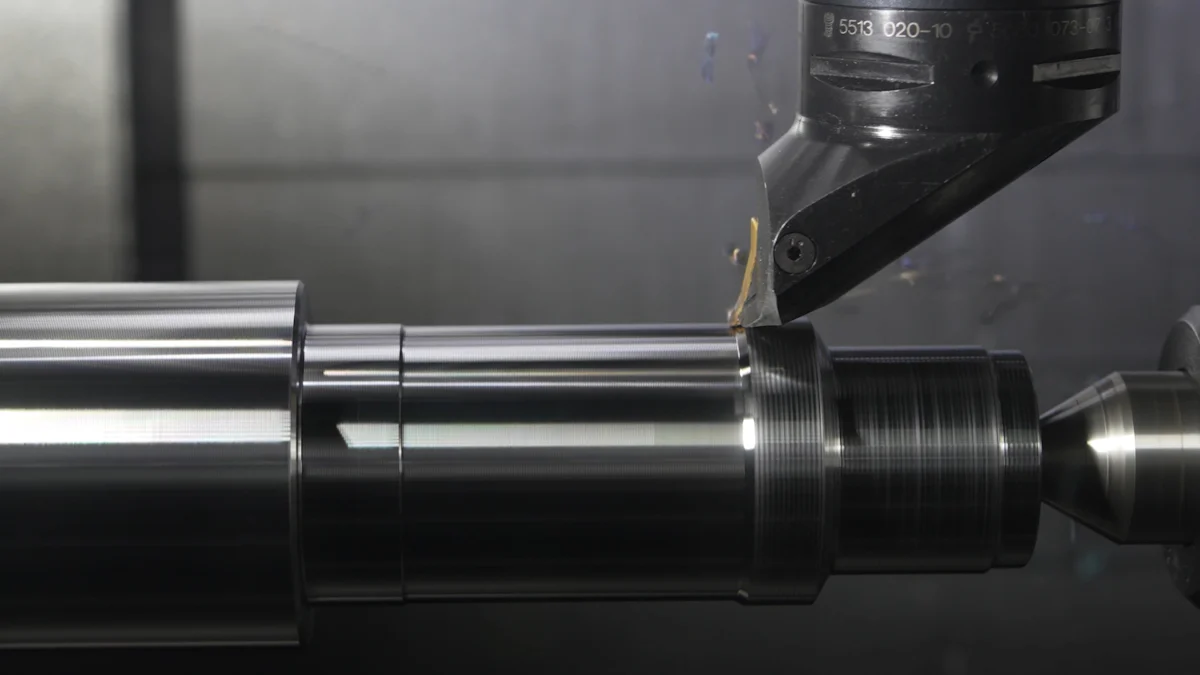

Precision plays a huge role in cutting waste and boosting quality. CNC machines don’t rely on manual tools, which often require advanced skills to operate. Instead, they use exact specifications to make cuts that align perfectly with your design. This means fewer mistakes and less wasted material.

Tolerance control ensures parts meet specific dimensions, reducing defects.

High-quality surface finishes are ideal for industries like aerospace and medical.

Dimensional accuracy guarantees consistent results, no matter the batch size.

Speed and Efficiency

Faster production cycles compared to manual methods.

CNC machining speeds up your production cycles significantly. Traditional methods often involve slow, repetitive tasks. CNC machines, on the other hand, work continuously without breaks. They can handle complex designs faster than any manual process. This means you can meet tight deadlines and keep up with customer demand.

How automation reduces downtime and increases output.

Automation is a game-changer for production efficiency. Tools like bar feeders and robotic arms keep your machines running smoothly. They reduce downtime by automating material loading and repetitive tasks. Rotary tables and tombstones allow you to work on multiple parts simultaneously, boosting output.

Automation Tool | Contribution to Efficiency |

|---|---|

Bar Feeders | Automate material supply, reducing downtime from manual loading and ensuring continuous operation. |

Robotic Arms | Perform repetitive tasks, increasing throughput and reducing setup times, optimizing workflow. |

Rotary Tables/Indexers | Enable multi-axis machining, reducing setup times and improving accuracy by allowing access to multiple sides. |

Tombstones/Trunnions | Hold multiple workpieces simultaneously, streamlining setup and reducing downtime from part changeovers. |

Versatility in Applications

The ability to handle diverse materials and complex designs.

CNC machining stands out for its versatility. You can work with a wide range of materials, from metals and plastics to wood and foam. It also handles intricate designs with ease, making it perfect for industries that demand precision and creativity.

Here are some materials you can use with CNC machines:

Metals

Plastics

Wood

Glass

Foam

Composite materials

Examples of industries where small businesses benefit from CNC machining.

CNC machining applications span across many industries. If you’re in aerospace, you’ll appreciate the precision needed for turbine engines. Automotive businesses rely on CNC for vehicle parts. Even jewelry makers use it for cutting and engraving precious metals. Other industries include:

Agriculture

Construction

Dental

Electronics

Food and Beverage

Firearms

No matter your field, CNC machining benefits your business by improving production efficiency and expanding your capabilities.

Reducing Costs and Errors with CNC Machines

Lowering Labor Costs

How CNC machines reduce the need for manual labor.

CNC machines can significantly cut down your reliance on manual labor. These machines automate repetitive tasks, which means you don’t need as many workers to handle production. For small businesses, this is a game-changer. You save money on wages while also reducing the risk of errors caused by manual processes. Plus, CNC machining ensures consistent results, so you don’t have to worry about quality slipping due to human fatigue or mistakes.

Although the initial cost of CNC machines might seem high, the long-term savings are worth it. By automating your production, you can operate with a leaner workforce, which is especially helpful if you’re working with a tight budget.

Reallocating workforce to higher-value tasks.

When CNC machines take over repetitive jobs, your team can focus on more strategic roles. Instead of spending hours on manual machining, your employees can work on tasks like product design, quality control, or customer service. This shift not only boosts efficiency but also helps your business grow.

“Automating simpler, more repetitive duties can free up existing employees to do higher value work elsewhere in the business.”

Here’s how CNC machining helps you reallocate your workforce:

It reduces manual labor, minimizing the need for human intervention in production.

Workers spend less time on repetitive tasks and more on innovation.

Your team can focus on improving processes and customer satisfaction.

Minimizing Errors and Waste

The role of automation in eliminating human errors.

Automation in CNC machining eliminates the guesswork. CNC machines follow precise instructions, which means fewer mistakes and higher-quality products. They can handle complex operations with incredible accuracy, ensuring every part meets your specifications. Automated inspection systems also catch defects early, so you can fix issues before they become costly problems.

Here’s why CNC machining reduces errors:

It provides precise control over the manufacturing process.

Automated tools perform tasks with consistency that surpasses human capabilities.

Multi-axis machining ensures identical accuracy for every part.

Cost savings through efficient material usage.

CNC machining is incredibly efficient with materials. These machines use only what’s necessary, which means less waste and lower costs. For small businesses, this efficiency can make a big difference. By reducing material waste, you not only save money but also make your operations more sustainable.

Some ways CNC machining saves materials:

Simplifying part designs minimizes machining time and costs.

Specifying tolerances and finishes helps control expenses.

Standardizing surface roughness values reduces waste.

Long-Term Cost Efficiency

How CNC machining lowers operational costs over time.

CNC machining isn’t just about short-term savings. Over time, it helps you cut operational costs by streamlining production and reducing waste. Effective tooling strategies, like using multipurpose tools, optimize your processes and save money. Lean manufacturing practices also help you eliminate inefficiencies, ensuring your business stays competitive.

The return on investment for small businesses.

Investing in CNC machines pays off in the long run. While the upfront cost might seem steep, the savings you’ll see in labor, materials, and time make it worthwhile. Plus, the ability to scale production without sacrificing quality gives you a competitive edge. For small businesses, CNC machining is a smart investment that drives growth and profitability.

Scaling Production with CNC Technology

Customization and Rapid Prototyping

How CNC machining allows for on-demand customization.

CNC machining gives you the flexibility to adapt to your customers' needs without breaking a sweat. Whether you’re handling a one-off custom order or tweaking a design for a new product, CNC machines make it easy. They let you adjust parameters quickly, so you can produce unique items without the hassle of retooling. This means you can offer personalized products while keeping your production efficient.

Here’s why CNC machining is perfect for customization:

You can modify digital designs in minutes.

Machines adjust seamlessly to meet specific customer requirements.

Custom orders don’t disrupt your workflow, so you stay productive.

This level of flexibility is a game-changer for small businesses. It allows you to cater to niche markets and stand out from competitors who rely on traditional manufacturing methods.

Meeting unique customer requirements with ease.

Meeting customer demands has never been easier. CNC machining ensures every product matches the exact specifications your clients want. Whether it’s a custom engraving or a complex part design, you can deliver high-quality results without delays. Plus, the precision of CNC machines means fewer errors, so your customers get exactly what they ordered.

Seamless Transition to Large-Scale Production

Transitioning from small batches to large-scale production.

Scaling up your production doesn’t have to be a headache. CNC machining makes the transition from small batches to large-scale production smooth and efficient. Once you’ve perfected your design, the same machine can handle higher volumes without compromising quality. This eliminates the need for additional equipment or extensive setup changes.

Maintaining quality and consistency during scaling.

When you scale up, maintaining quality is crucial. CNC machining ensures consistency by using precise tool settings and real-time monitoring. These features keep your production on track, even as you increase capacity. Rigorous quality control processes, like automated inspections, catch any issues early, so you can maintain the same high standards your customers expect.

Here’s how CNC machining keeps quality intact during scaling:

Precise tool-setting ensures accuracy for every part.

Real-time monitoring allows for adjustments during production.

Automated inspections confirm quality before mass production begins.

Faster Lead Times

How CNC machines enable quicker responses to market demands.

In today’s fast-paced market, speed matters. CNC machining helps you respond quickly to changing demands. Need to launch a new product? CNC machines can produce prototypes in days, not weeks. This rapid turnaround gives you a competitive edge and keeps your customers happy.

Reducing time-to-market for new products.

CNC machining slashes your time-to-market by streamlining the entire production process. Automated tool path generation reduces programming time, while integrated quality control minimizes rework. With optimized scheduling, you can maximize machine utilization and reduce downtime. This means you can bring new products to market faster than ever.

Here’s how CNC machining speeds things up:

Instant quoting helps you plan production quickly.

Automated processes reduce human error and save time.

Access to a global network of suppliers ensures faster turnaround.

By leveraging CNC technology, you can boost your production speed and stay ahead of the competition.

Overcoming Challenges in Adopting CNC Machining

Managing Initial Investment Costs

Exploring financing options for small businesses.

Investing in CNC machining can feel overwhelming when you see the price tag. But don’t worry—there are plenty of financing options to help you get started. You can explore dealer financing, which offers competitive rates but might limit your lender choices. Bank loans are another option, though they often come with strict requirements. If you’re looking for flexibility, leasing could be a good fit. It lowers upfront costs, though it may cost more in the long run.

Other options include equipment financing, where the machine itself serves as collateral, and SBA loans, which offer favorable terms but require a complex application process. Vendor financing is also worth considering, as it provides tailored packages with quick approval. For a more creative approach, crowdfunding can help you raise capital while validating your market.

Calculating the long-term ROI of CNC machining.

When you’re investing in CNC technology, it’s important to think long-term. Start by calculating the return on investment (ROI). Consider factors like acquisition costs, which include the purchase price, installation, and training. Operating costs, such as cycle time and tool life, also play a role. Don’t forget maintenance costs, as unscheduled downtime can eat into your savings.

Factor | Description |

|---|---|

Acquisition Costs | Includes purchase price, installation, and training. |

Operating Costs | Affects productivity, including cycle time, tool life, part quality, and reliability. |

Maintenance Costs | Unschedulled downtime can erode savings; consider decommission costs and residual value. |

Automation Impact | Increases machine utilization, reduces lead times, and improves part quality with less scrap. |

By evaluating these factors, you’ll see how CNC machining can save you money over time while boosting your business’s efficiency.

Training and Upskilling Employees

Upskilling employees to operate CNC machines.

Introducing CNC machining to your business means your team needs to learn new skills. Upskilling your employees is easier than you think. Many programs cover essential topics like industrial safety, basic machining, and CNC programming. These courses are designed to prepare your team for real-world tasks, and they’re often self-paced, so your employees can learn at their convenience.

Leveraging online resources and training programs.

Online resources make training even more accessible. Many platforms offer flexible payment options, including monthly plans, so you can budget effectively. These programs teach everything from hand tools to advanced CNC technology. By investing in training, you’re not just improving your team’s skills—you’re also setting your business up for long-term success.

Selecting the Right CNC Machine

Factors to consider when choosing a machine for your business.

Choosing the right CNC machine can feel like a big decision, but focusing on a few key factors makes it manageable. Start by evaluating costs, including the initial purchase, programming, labor, and maintenance. Look at the machine’s specifications, such as stroke range and spindle motor power, to ensure it meets your needs. Don’t forget to check the quality and service offered by the manufacturer. Reputable brands often provide warranties and excellent customer support.

Balancing cost, functionality, and scalability.

Balancing cost, functionality, and scalability is crucial for small businesses. CNC machines are incredibly flexible, allowing you to switch between different production batches without needing multiple machines. This saves time and reduces costs. If you’re not ready to invest in your own machine, outsourcing CNC services is a great alternative. It eliminates upfront costs while giving you access to high-quality machining capabilities.

By carefully considering your options, you can find a CNC solution that fits your business’s needs and budget.

CNC machining gives your small business the tools to grow efficiently while keeping quality high and costs low. It reduces manual labor, ensures consistent output, and allows you to meet customer demands with precision. By addressing challenges like upfront costs and employee training, you can unlock its full potential.

Here’s how you can make the most of CNC technology:

Build partnerships to expand your capabilities.

Focus on niche markets for specialized products.

Invest in CNC machines to boost efficiency.

Use digital marketing to attract more customers.

CNC machining isn’t just a tool—it’s a growth strategy. If you’re ready to scale your business and stay competitive, now’s the time to explore this transformative technology.

FAQ

What is CNC machining, and how does it work?

CNC machining uses computer-controlled tools to create precise parts. You program the machine with design instructions, and it automatically cuts, drills, or shapes materials. This process ensures accuracy and consistency, making it ideal for small businesses aiming to scale production.

Is CNC machining suitable for small businesses?

Absolutely! CNC machining helps small businesses by reducing labor costs, improving efficiency, and ensuring consistent quality. It’s perfect for scaling production, handling custom orders, and meeting tight deadlines. Plus, it works with various materials, making it versatile for different industries.

How much does a CNC machine cost?

CNC machines vary in price, ranging from $5,000 for basic models to over $100,000 for advanced systems. Leasing or financing options can help you manage the upfront cost. Consider your production needs and budget to find the right machine for your business.

Do I need to train my employees to use CNC machines?

Yes, training is essential. Employees need to learn programming, safety protocols, and machine operation. Many online courses and resources are available to make training accessible and affordable. Upskilling your team ensures smooth operations and maximizes the benefits of CNC technology.

Can CNC machining handle custom designs?

Yes, CNC machining excels at customization. You can easily modify digital designs to create unique products. Whether it’s a one-off prototype or a personalized order, CNC machines adapt quickly, allowing you to meet customer demands without disrupting your workflow.

Tip: Use CNC machining to explore niche markets and offer specialized products that stand out from competitors.

See Also

Discovering CNC Machining Solutions for Accurate Production

Streamlined CNC Machining Services for Exact Manufacturing

Perfecting CNC Machining Techniques for Precise Component Production

The Impact of CNC Machining on Advanced Precision Production

Recognizing the Significance of Precision CNC Machining in Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com