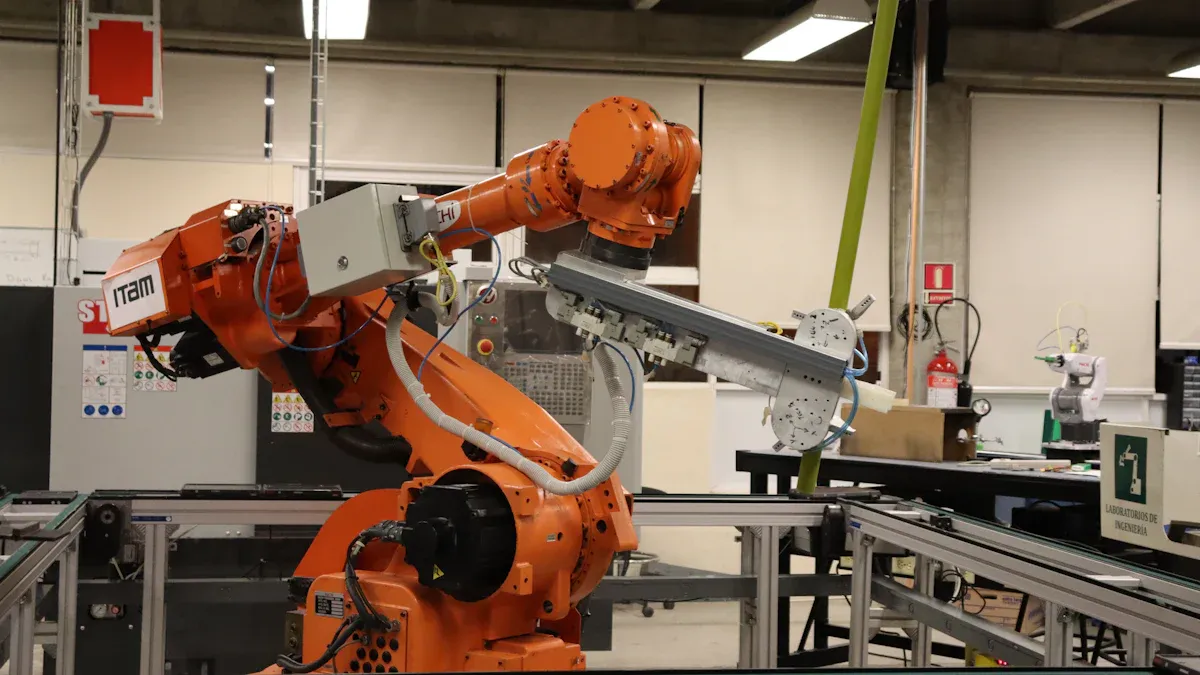

The Role of CNC in the Rise of Smart Factories and Automated Production Lines

CNC machining is transforming manufacturing by enabling unmatched precision and efficiency in smart factories. By integrating IoT and AI, CNC systems allow real-time data monitoring, predictive maintenance, and remote operations. Embedded sensors collect performance data, improving product quality and reducing errors. These advancements make smart manufacturing more adaptable and interconnected than ever before.

Key Takeaways

CNC technology helps automate making things. It ensures accuracy and lowers mistakes, improving product quality and saving money.

Adding IoT and AI to CNC systems helps watch machines in real-time. It predicts problems early, cutting downtime and repair costs.

CNC machines are flexible. They can make complex designs and custom items quickly to meet different customer needs.

Understanding CNC Technology in Smart Manufacturing

What is CNC Technology?

CNC, or Computer Numerical Control, refers to a manufacturing process where pre-programmed software controls the movement of machinery and tools. This technology automates tasks that would otherwise require manual operation, ensuring precision and consistency. In the context of smart manufacturing, CNC machining stands out for its ability to integrate with advanced technologies like IoT and AI. These integrations enable real-time monitoring, adaptive control, and error prediction, making CNC systems a cornerstone of modern production lines. By automating processes, CNC reduces human error and enhances efficiency, aligning with the goals of digital transformation in manufacturing.

The Evolution of CNC in Manufacturing

CNC technology has come a long way since its inception in the 1940s. Early systems relied on punch cards and analog controls, which limited their flexibility. The introduction of digital control systems revolutionized CNC machining, allowing for greater precision and adaptability. In the 1970s, microprocessors further enhanced the programmability and efficiency of CNC machines. Today, CNC systems are integral to Industry 4.0, supporting automation, sustainability, and customization. For example:

Automation reduces labor costs and shortens production times.

Energy-efficient designs and waste reduction contribute to sustainability.

Customization capabilities allow manufacturers to meet specific customer demands quickly.

This evolution reflects how CNC technology has adapted to meet the growing demands of smart factories and global markets.

CNC’s Role in Smart Manufacturing Systems

CNC technology plays a pivotal role in smart manufacturing solutions by enhancing automation, precision, and connectivity. It enables machines to operate autonomously, reducing the need for manual intervention. Integration with IoT and IIoT allows CNC systems to collect real-time data, which can be analyzed to optimize production processes. Advanced sensors and AI further enhance these systems by enabling dynamic adjustments and predictive maintenance. For instance, CNC machines can detect potential issues before they cause downtime, ensuring uninterrupted operations. These capabilities make CNC a vital component of Industry 4.0, driving efficiency and innovation in manufacturing.

Key Advantages of CNC in Automation

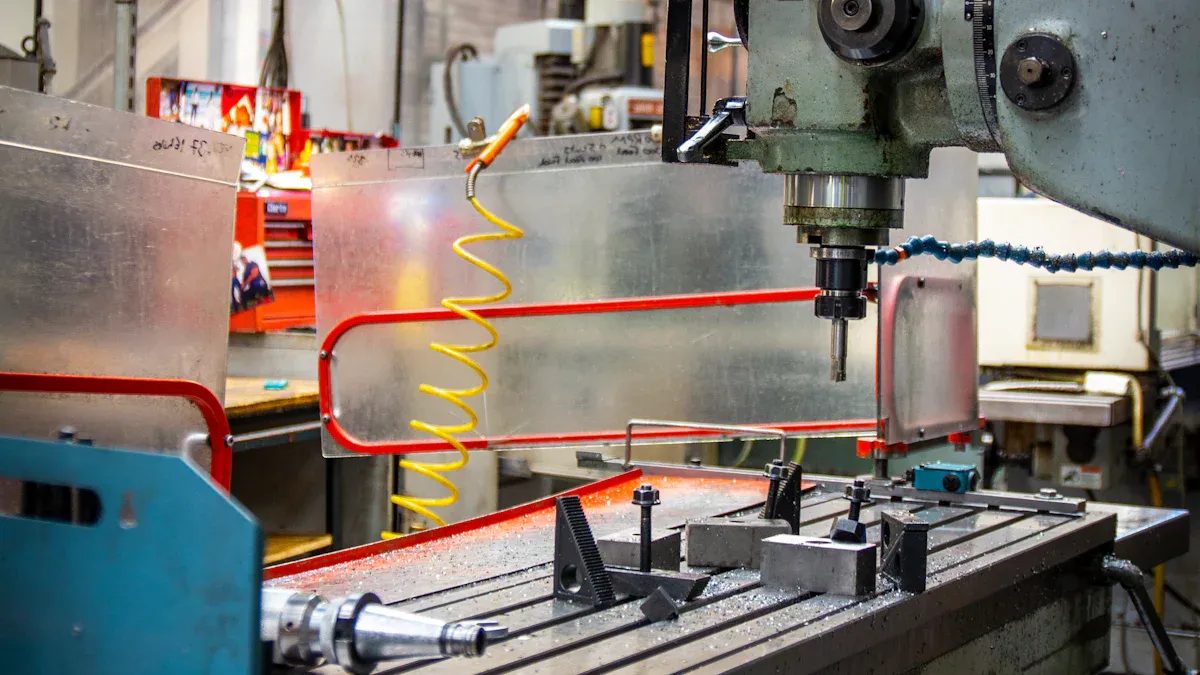

Precision and Accuracy in CNC Machining

CNC machining delivers unmatched precision, which is essential for maintaining quality in automated production lines. You can rely on CNC systems to produce identical parts repeatedly, ensuring reliability and consistency. This level of precision reduces waste and minimizes the need for reworks, saving both time and resources. Additionally, automation in CNC processes accelerates production timelines, enabling you to meet market demands more efficiently.

Tip: By leveraging CNC’s precision, you can achieve higher product quality while reducing operational costs.

Enhancing Efficiency and Reducing Downtime

CNC systems significantly enhance efficiency by minimizing errors and optimizing production workflows. For example:

Reduced labor costs and scrap rates lead to substantial cost savings.

Continuous operation maximizes equipment utilization and ROI.

Quick task switching allows you to adapt to changing market needs seamlessly.

Modern CNC machines also reduce setup times, enabling you to complete more jobs on the same equipment. This improved utilization not only boosts cash flow but also ensures higher customer satisfaction. Standardized processes further maintain consistent quality, reducing the likelihood of defects and downtime.

Flexibility for Custom and Complex Designs

CNC systems excel in creating custom and intricate designs. Multi-axis capabilities allow for precise movements, enabling you to handle complex tasks with ease. For instance, modern CNC machines can work on large metal pieces while maintaining safety and accuracy. The evolution from 3-axis to 6-axis CNC machines has expanded the possibilities for intricate designs, making them ideal for industries requiring high customization. This flexibility ensures that you can meet diverse customer demands without compromising efficiency.

CNC and Industry 4.0: Transforming Manufacturing

Real-Time Monitoring with IoT Integration

IoT integration has revolutionized CNC systems by enabling real-time monitoring and seamless connectivity. With IoT, CNC machines can connect to other devices, allowing you to exchange data effortlessly. Advanced sensors collect real-time information on parameters like temperature and vibration, giving you insights into machine health. This data helps you identify potential issues early, reducing downtime and maintenance costs.

You can also monitor and control CNC machines remotely, which enhances operational flexibility. For example, IoT-enabled systems allow you to oversee production and troubleshoot problems from anywhere. Continuous feedback ensures immediate adjustments, improving production efficiency. By leveraging IoT, you can achieve better oversight and optimize your manufacturing processes.

AI-Driven Predictive Maintenance in CNC Systems

AI-driven predictive maintenance takes CNC systems to the next level by preventing unexpected breakdowns. This approach uses machine learning algorithms to analyze data and forecast potential failures. By addressing issues before they occur, you can reduce unplanned downtime by up to 40%. Maintenance costs also decrease by approximately 25%, saving you significant resources.

This proactive strategy extends the lifespan of CNC equipment. Timely servicing ensures fewer replacements, helping you manage capital expenditures more effectively. For instance, a utility company reported a 20% increase in equipment uptime and a 15% reduction in maintenance expenses. AI-driven maintenance not only enhances operational stability but also supports long-term cost savings.

Digital Twins for Process Optimization

Digital twins offer a virtual replica of CNC machines, enabling you to simulate and optimize processes without disrupting production. This technology allows you to test different machining methods, reducing costly errors and downtime. By simulating operations, you can predict outcomes and make informed decisions.

Digital twins also improve efficiency by providing a detailed understanding of the machining process. You can optimize parameters like feed rates and tool paths, enhancing production speed and quality. Additionally, this technology supports better planning, helping you reduce costs and accelerate time-to-market. With projections showing that 75% of industrial companies will adopt digital twins by 2024, this innovation is becoming a cornerstone of smart manufacturing.

Real-World Applications of CNC in Smart Factories

Cost Savings Through Automation

CNC technology helps you achieve significant cost savings by streamlining production processes and reducing material waste. For example, using cost-effective materials like aluminum alloys (6061-T6) and stainless steel (grades 303 and 304) can lower material expenses without compromising quality. Simplifying part designs and incorporating standardized components also reduce manufacturing costs. Optimizing production processes, such as batch production and refining tolerances, further cuts expenses while maintaining efficiency.

Cost-Saving Method | Description |

|---|---|

Use of Cost-Effective Materials | Utilizing materials like aluminum alloys (6061-T6) and stainless steel (grades 303 and 304) reduces material costs. |

Simplified Part Designs | Reducing complexity in designs and using standardized components can lead to significant cost reductions. |

Optimized Production Processes | Implementing batch production and optimizing tolerances and finishes helps in cutting expenses. |

By adopting these strategies, you can maximize your return on investment while maintaining high-quality standards in smart manufacturing.

Boosting Productivity and Scalability

CNC machining enhances productivity and scalability in smart factories by automating complex tasks with precision. Here’s how it boosts your operations:

It ensures high accuracy and repeatability, reducing errors and rework.

It enables the efficient production of intricate geometries, meeting diverse customer demands.

Automation reduces cycle times, allowing you to complete more jobs in less time.

Additionally, CNC systems integrate seamlessly with IoT and AI, enabling real-time monitoring and process optimization. This connectivity minimizes waste and improves workflows, making your operations more scalable and adaptable to market changes.

Ensuring Consistent Product Quality

CNC systems guarantee consistent product quality by maintaining precision across all production runs. You can rely on these machines to produce identical parts with minimal variation, ensuring reliability and customer satisfaction. Real-time monitoring and feedback mechanisms further enhance quality control by detecting and correcting errors during production.

For example, CNC machining allows you to maintain tight tolerances and achieve superior surface finishes, which are critical in industries like aerospace and automotive. This consistency not only strengthens your brand reputation but also reduces costs associated with defective products. By leveraging CNC technology, you can meet the high standards required in Industry 4.0 and smart factories.

Overcoming Challenges in CNC Integration

Addressing Cybersecurity in Connected Systems

As CNC systems become more connected in Industry 4.0 environments, cybersecurity risks grow significantly. Increased connectivity makes these systems more software-dependent, exposing them to potential attacks. For example:

Outdated operating systems, such as Windows 98, often found in CNC machines, are vulnerable to malware and exploits.

USB devices can introduce malware, leading to data breaches and compliance violations. Poor USB management can even cause cascading effects across the facility's network.

Organizations handling Controlled Unclassified Information (CUI) must comply with strict regulations like CMMC 2.0 and NIST 800-171. A compromised USB drive could threaten compliance, exposing sensitive data and causing financial and reputational damage. To protect your systems, you should implement robust cybersecurity measures, such as regular software updates, restricted USB access, and employee training on secure practices.

Bridging the Skilled Labor Gap

The skilled labor gap in CNC machining poses a challenge for advanced manufacturing. However, several strategies can help you address this issue:

Transition to automated CNC mills to allow robots to handle tasks where labor shortages exist.

Use semi-automated solutions to automate repetitive tasks while still involving human oversight.

Streamline CNC programming with simpler methods, making it easier for less experienced workers to set up machining tasks.

Leverage AI in recruitment to identify suitable candidates more efficiently.

Invest in on-the-job training and use technologies like AR and VR to equip workers with the necessary skills.

By adopting these strategies, you can overcome labor shortages and ensure your operations remain efficient and competitive.

Managing Initial Investment Costs

Integrating CNC systems into smart factories requires a significant initial investment. The cost depends on the type of CNC machine you choose:

Type of CNC Machine | Price Range |

|---|---|

Mid-size CNC machines | $10,000 to $100,000+ |

CNC routers | $5,000 to $50,000 |

While these costs may seem high, the long-term benefits of automation, such as reduced labor expenses and increased productivity, often outweigh the initial expenditure. To manage these costs, you can explore financing options, government grants, or phased implementation strategies. These approaches make it easier to adopt CNC technology without straining your budget.

CNC machining stands as a cornerstone of smart manufacturing, offering unmatched precision, efficiency, and adaptability. Its integration with Industry 4.0 technologies, such as IoT and AI, ensures seamless automation and real-time process optimization. Emerging trends, like additive manufacturing and high-speed machining, further enhance its role in creating sustainable, customer-focused production systems.

By reducing waste, optimizing energy use, and enabling on-demand production, CNC machining contributes significantly to sustainability. These advancements position CNC as a key driver of innovation, ensuring its continued impact on the future of manufacturing.

FAQ

What industries benefit the most from CNC technology?

Industries like aerospace, automotive, and healthcare benefit significantly. CNC technology ensures precision, scalability, and consistent quality, making it ideal for sectors requiring high accuracy and reliability.

How does CNC technology support automated production?

CNC technology automates repetitive tasks, reduces errors, and enhances efficiency. It integrates seamlessly with smart systems, enabling streamlined workflows and boosting productivity in automated production lines.

Is CNC technology environmentally friendly?

Yes, CNC technology reduces material waste and optimizes energy use. Its precision minimizes rework, contributing to sustainable manufacturing practices and supporting eco-friendly production goals.

See Also

Exploring CNC Technology: Innovations and Uses in Manufacturing

Discovering CNC Processing: The Future of Smart Manufacturing

The Revolution of CNC Machining in Precision Manufacturing

CNC Technology Journey: Past Developments and Future Innovations

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com