Comparing CNC Machining of Thermoplastics and Thermosets

CNC machining plays a vital role in modern manufacturing. It follows a structured process: design a digital model, program it into a CNC machine, set up the tools, and execute precise machining. This method ensures accuracy, efficiency, and consistency, making it ideal for creating complex parts across industries.

When choosing materials for CNC machining, you often encounter thermoplastics and thermosets. Thermoplastics are flexible and recyclable, while thermosets are rigid and durable. These differences impact their applications and machinability.

This blog explores how these materials behave during CNC machining, helping you make informed decisions for your product design.

Key Takeaways

Thermoplastics are bendable and reusable, great for light and tricky designs in CNC machining.

Thermosets are strong and tough, good for hot environments, but they can't be reused.

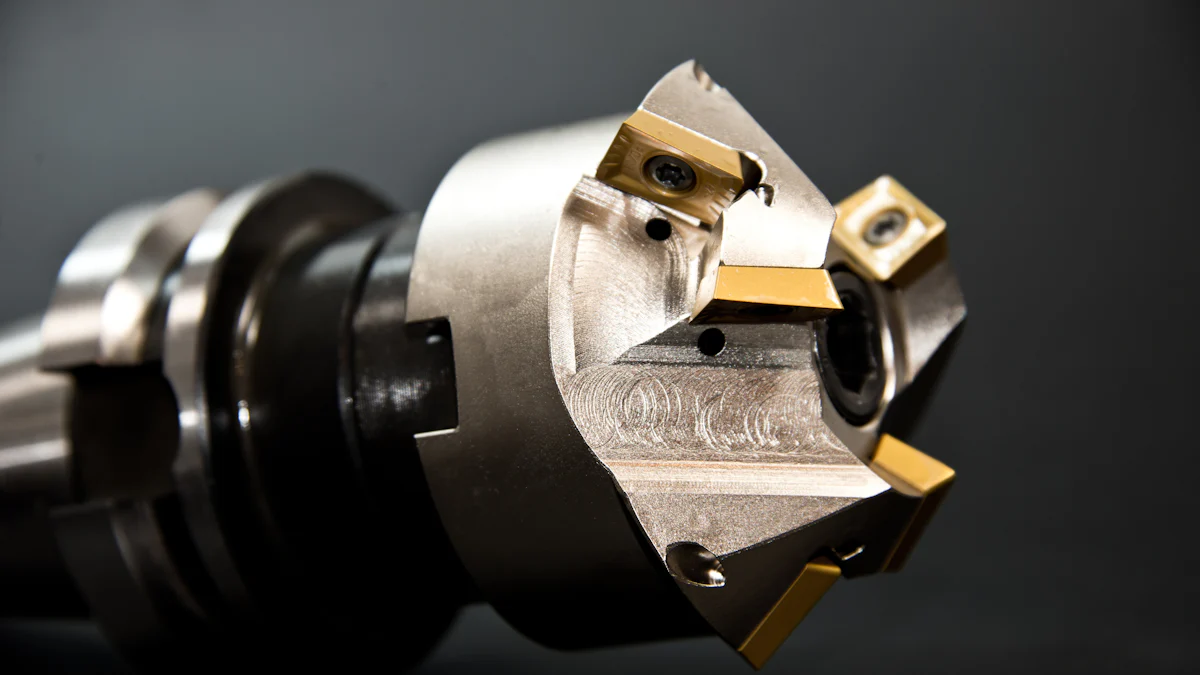

Cutting thermoplastics is simpler and wears tools less, but thermosets need stronger tools because they are harder.

Thermoplastics usually cost less to buy and cut, so they are cheaper for making many parts.

Think about your project: pick thermoplastics for reuse and detailed shapes, or thermosets for strength and heat safety.

CNC Machining and Plastics

Overview of CNC Machining

CNC machining is a manufacturing process that uses computer-controlled tools to shape materials into precise components. You can program the machine to follow exact specifications, ensuring consistent results. This process is highly versatile, allowing you to work with metals, plastics, and composites. Modern advancements, such as multi-axis capabilities and improved processing power, have made CNC machining even more efficient. For example, 5-axis machines can handle complex designs by machining multiple planes simultaneously. These innovations reduce production time while maintaining accuracy.

Why Plastics Are Commonly Used in CNC Machining

Plastics are a popular choice for CNC machining due to their unique properties. They are lightweight, cost-effective, and easy to machine compared to metals. Many plastics, such as ABS and polycarbonate, offer high impact resistance, making them suitable for demanding applications. Others, like PTFE, provide excellent chemical resistance and low friction, ideal for medical devices and gaskets. Plastics like polyethylene and nylon resist corrosion and perform well in harsh environments. Additionally, machining plastics requires less effort, which helps you achieve intricate designs without excessive tool wear.

Commonly used plastics in CNC machining include:

Acrylonitrile Butadiene Styrene (ABS): High impact strength, used in automotive and electrical applications.

Polytetrafluorethylene (PTFE): Chemical resistance and low friction, ideal for gaskets and medical devices.

Polycarbonate (PC): High impact resistance and clarity, suitable for safety goggles and medical devices.

Polyethylene (PE): Chemical resistance and electrical insulation, used in packaging and automotive industries.

Nylon 66 (Polyamide): Durable and self-lubricating, excellent for gears and bearings.

Key Factors in Machining Plastics

When machining plastics, you need to consider several factors to ensure optimal results. Managing stresses in the material is crucial to prevent warping or cracking. Using sharp cutting tools with appropriate rake angles helps you achieve smooth cuts and reduces heat buildup. Cooling and lubrication play a vital role in maintaining safety and efficiency during the process.

For high-density plastics like HDPE, controlling cutting parameters is essential. Lower cutting speeds combined with higher feed rates improve chip evacuation and minimize heat accumulation. Smaller depths of cut distribute forces evenly, preventing excessive heat generation. Additionally, selecting the right material for your application ensures production efficiency and high-quality results. Consider properties like thermal resistance, rigidity, and electrical insulation when designing your parts.

Thermoplastics in CNC Machining

Key Properties of Thermoplastics

Thermal and Mechanical Characteristics

Thermoplastics offer a range of properties that make them ideal for CNC machining. These materials are lightweight, which is essential for applications requiring reduced weight. They resist wear and tear, making them durable under repeated mechanical stress. Their elasticity provides excellent impact resistance, enhancing their ability to withstand shocks.

Thermoplastics also exhibit high mechanical strength and stiffness, making them suitable for structural components. Their chemical resistance allows them to endure exposure to oils, solvents, and other harsh substances. Additionally, they maintain dimensional stability under varying temperatures and humidity, ensuring precision in CNC-machined parts. These characteristics make thermoplastics a versatile choice for demanding environments.

Recyclability and Reusability

Thermoplastics stand out for their recyclability and reusability. You can remelt and reshape these materials multiple times without significant degradation. This flexibility reduces waste and supports sustainability efforts. Many industries, such as automotive and medical, rely on thermoplastics for their ability to be recycled and reused. Their versatility makes them a practical choice for applications requiring cost-effective and eco-friendly solutions.

Machinability of Thermoplastics

Cutting and Shaping Ease

Thermoplastics are easier to machine compared to metals. Their softer nature allows you to achieve intricate designs with minimal tool wear. CNC machining of thermoplastics often results in smooth surface finishes, reducing the need for additional processing. Properly selected cutting tools and optimized machining parameters further enhance the ease of working with these materials.

Common Challenges in Machining

Despite their advantages, machining thermoplastics presents challenges. These materials expand up to 20 times more than metals when exposed to heat, increasing the risk of localized overheating. Proper heat management is crucial to prevent dimensional shifts and stress cracking. You must also manage stresses in the material to avoid warping or cracking. Using sharp tools, appropriate cutting speeds, and effective cooling systems ensures better results.

Applications of Thermoplastics

Industries and Use Cases

Thermoplastics find applications across various industries due to their versatility. In the automotive sector, they enhance efficiency and reduce vehicle weight. Aerospace industries use them for high-performance components like PEEK. Medical devices benefit from their flexibility and sterilization capabilities. Thermoplastics also play a role in electronics, where materials like ABS provide excellent insulating properties.

Examples of Thermoplastics

Thermoplastic | Properties | Applications |

|---|---|---|

Acetal (Delrin) | Dimensional stability, low friction | Gears, bushings, bearings |

Nylon (PA) | High tensile strength, toughness | Automotive components, wear strips |

Acrylic (PMMA) | Optical clarity, UV resistance | Signage, display fixtures |

Polycarbonate (PC) | Impact resistance, thermal stability | Safety helmets, electrical enclosures |

PEEK | Chemical resistance, thermal stability | Aerospace components, medical implants |

These examples highlight the diverse capabilities of thermoplastics, making them a preferred choice for CNC machining in various industries.

Thermosets in CNC Machining

Key Properties of Thermosets

Thermal and Mechanical Characteristics

Thermoset plastics exhibit unique properties due to their highly cross-linked molecular structure. This structure gives them exceptional rigidity and strength. Unlike thermoplastics, thermoset materials do not melt when heated. Instead, they degrade, making them ideal for high-temperature applications. Their low coefficient of thermal expansion ensures minimal dimensional changes under heat, which is crucial for precision parts. Additionally, thermoset plastics resist chemical degradation, maintaining their integrity in harsh environments.

Property | Thermosets | Thermoplastics |

|---|---|---|

Molecular structure | Network polymers with strong cross-linking | Linear polymers with weak molecular bonds |

Mechanical | Rigid and strong | Flexible and impact-resistant |

Melting point | Higher than degradation temperature | Lower than degradation temperature |

Solubility | Insoluble in organic solvents | Soluble in organic solvents |

Service temperature | Higher continuous use temperature | Lower continuous use temperature |

Durability and Rigidity

Thermoset plastics are designed for resilience. Their rigidity ensures stability during machining, even under high temperatures. This durability makes them suitable for demanding applications like aerospace and automotive components. However, their hardness can increase tool wear during CNC machining.

Machinability of Thermosets

Challenges in Cutting and Shaping

Machining thermoset materials presents unique challenges. Their rigidity and abrasiveness can lead to significant tool wear. High filler levels in thermosets exacerbate this issue, requiring careful optimization of machining parameters. The grain direction of thermosets also affects processing, influencing compactness and bending.

Tooling and Process Requirements

To machine thermoset plastics effectively, you need robust tools. High-hardness tools withstand the abrasive nature of thermosets. Maintaining sharp cutting edges minimizes wear and ensures precision. Optimizing feed rates and cutting speeds enhances efficiency and reduces tool wear.

Applications of Thermosets

Industries and Use Cases

Thermoset materials play a vital role in various industries. In aerospace, they are used in interior components and structural parts like those in the Boeing 787. Automotive manufacturers rely on thermosets for body panels and high-strength composites. In construction, thermosets are found in sinks, shower stalls, and wall panels. They are also essential in electrical applications, such as printed circuit boards and insulators.

Examples of Thermosets

Thermoset Material | Properties | Applications |

|---|---|---|

Epoxy | High adhesive strength, chemical resistance | Coatings, adhesives, composites |

Melamine | High wear resistance | Laminates, dinnerware, surfaces |

Phenolic Resins | Heat resistance | Electrical insulators, cookware handles |

Polyester | Fiberglass reinforcement | Marine applications |

Polyimide | High-temperature resistance | Aerospace applications |

Thermoset plastics offer unmatched durability and performance, making them indispensable in high-strength and high-temperature applications.

Comparing Thermoplastics and Thermosets in CNC Machining

Machinability

Ease of Machining

Thermoplastics are easier to machine due to their softer nature. You can achieve intricate designs with minimal tool wear. However, managing heat is critical. Excessive heat can cause thermoplastic materials to deform, leading to dimensional inaccuracies. Thermosets, on the other hand, are harder to machine. Their rigidity requires robust tools and precise machining parameters. While thermosets demand more effort, their durability often compensates for the added complexity, especially in high-performance applications.

Tool Wear and Maintenance

Tool wear differs significantly between thermoplastics and thermosets. Thermoplastics are soft, so they cause less wear on cutting tools. This reduces maintenance needs and extends tool life. Thermosets, however, are abrasive. Their hardness and filler content accelerate tool wear, increasing maintenance requirements. The table below highlights these differences:

Machining Factor | Thermoplastics | Thermosets |

|---|---|---|

Cutting Speed | Low to moderate | Moderate to high |

Coolant Requirement | High; prevents softening | Low; reduces friction |

Tool Wear | Low; soft on tools | High; abrasive on tools |

Cost Considerations

Material Costs

Thermoplastics are generally more cost-effective than thermosets. Their faster processing times and lack of curing requirements make them ideal for high-volume production. Thermosets, however, involve higher costs due to their specialized handling and curing processes. This makes thermoset materials more suitable for applications where performance outweighs cost.

Machining Costs

Thermoplastics also offer lower machining costs. Their ease of melting, molding, and recycling minimizes waste and reduces expenses. Thermosets, by contrast, require more time and effort to machine. Their abrasiveness increases tooling costs, and their limited recyclability raises waste disposal expenses. The table below summarizes these cost factors:

Cost Factor | Thermoplastics | Thermosets |

|---|---|---|

Raw Material Cost | Lower; cost-effective in bulk | Higher; limited recyclability |

Processing Time | Faster; no curing required | Slower; requires curing |

Tooling Costs | Lower due to softer material | Higher; wears tools faster |

Waste Disposal Cost | Low; can often be recycled | High; disposal can be challenging |

Overall Production Cost | Moderate to low | Higher in small batches |

Environmental Impact

Recyclability and Waste Management

Thermoplastics excel in recyclability. You can remelt and reuse thermoplastic plastics multiple times, reducing waste and supporting sustainability. Thermosets, however, cannot be recycled due to their cross-linked structure. This makes waste management more challenging for thermoset plastics, especially in industries prioritizing eco-friendly practices.

Energy Consumption

Thermoplastics consume less energy during machining. Their lower melting points and faster processing times contribute to energy efficiency. Thermosets, in contrast, require more energy due to their curing process and higher machining demands. While thermosets perform better in high-temperature environments, their energy-intensive production can increase overall costs.

Summary of Key Differences

Comparison Table

Properties

Thermoplastics and thermosets differ significantly in their properties. Thermoplastics are flexible and impact-resistant, making them ideal for applications requiring elasticity. They melt when heated, allowing reshaping and recycling. Thermoset plastics, however, are rigid and durable. Their cross-linked structure ensures stability under high temperatures but prevents remelting. This makes thermosets suitable for high-strength and high-temperature applications.

Machinability

You will find thermoplastics easier to machine. Their softer nature reduces tool wear and allows intricate designs. However, managing heat is crucial to avoid deformation. Thermosets are harder to machine due to their rigidity and abrasiveness. They require robust tools and precise parameters, which increases machining complexity. Despite this, thermosets deliver excellent performance in demanding environments.

Applications

Thermoplastics are versatile and widely used across industries. Automotive, aerospace, and medical sectors rely on thermoplastics for lightweight and flexible components. Thermosets excel in high-performance applications. Aerospace and automotive industries use thermoset plastics for structural parts and composites. Electrical applications also benefit from thermosets’ insulating properties.

Cost

Thermoplastics are more cost-effective. Their lower raw material costs and faster processing times make them suitable for high-volume production. Thermosets involve higher costs due to their curing requirements and increased tool wear. The table below highlights these differences:

Cost Factor | Thermoplastics | Thermosets |

|---|---|---|

Raw Material Cost | Lower; cost-effective in bulk | Higher; limited recyclability |

Processing Time | Faster; no curing required | Slower; requires curing |

Tooling Costs | Lower due to softer material | Higher; wears tools faster |

Waste Disposal Cost | Low; can often be recycled | High; disposal can be challenging |

Overall Production Cost | Moderate to low | Higher in small batches |

Environmental Impact

Thermoplastics offer better recyclability. You can remelt and reuse them, reducing waste and supporting sustainability. Thermosets, on the other hand, cannot be recycled due to their cross-linked structure. This limits their eco-friendliness. Thermoplastics also consume less energy during machining, while thermosets require more energy for curing. The table below summarizes these environmental factors:

Environmental Factor | Thermoplastics | Thermosets |

|---|---|---|

Recyclability | High; can be reprocessed | Low; limited recycling potential |

Energy Consumption | Moderate; lower energy in molding | High due to curing requirements |

Disposal Impact | Lower; waste management options | Higher; often end up in landfills |

Sustainable Applications | Yes; widely used in green products | Limited; challenging to repurpose |

Understanding the differences between thermoplastics and thermosets helps you make informed decisions for CNC machining projects. Thermoplastics offer flexibility, recyclability, and ease of machining, making them ideal for lightweight components and high-volume production. Thermosets, with their rigidity and heat resistance, excel in heavy-duty applications and electrical insulation.

When selecting a material, consider your project’s specific needs. For example:

Choose thermoplastics for products requiring recyclability or complex shapes.

Opt for thermosets when heat resistance or structural integrity is critical.

Application Requirement | Best Material Choice | Reason |

|---|---|---|

Reusability and recyclability | Thermoplastics | Easy to recycle and reshape |

High strength and rigidity | Thermosets | Durable and retains shape under stress |

Exposure to high temperatures | Thermosets | High heat resistance |

Low-cost production | Thermoplastics | Lower material and processing costs |

Precision parts with complex shapes | Thermoplastics | Easier to machine with CNC |

Electrical insulation | Thermosets | Excellent insulating properties |

For optimal results, consult CNC machining experts. They can guide you in aligning material properties with your product design requirements, ensuring efficiency and performance.

FAQ

What is the main difference between thermoplastics and thermosets?

Thermoplastics can melt and reshape when heated, making them recyclable. Thermosets, however, cannot melt due to their cross-linked structure. This makes thermosets more rigid and heat-resistant but less eco-friendly.

Which material is easier to machine: thermoplastics or thermosets?

Thermoplastics are easier to machine because of their softer nature. They cause less tool wear and allow intricate designs. Thermosets, being harder and more abrasive, require robust tools and precise machining parameters.

Can thermosets be recycled like thermoplastics?

No, thermosets cannot be recycled. Their cross-linked molecular structure prevents remelting. This makes waste management more challenging compared to thermoplastics, which you can remelt and reuse multiple times.

How do I choose between thermoplastics and thermosets for my project?

Consider your project’s needs. Use thermoplastics for lightweight, recyclable, or flexible components. Choose thermosets for applications requiring high heat resistance, rigidity, or durability. Consulting CNC machining experts can help you make the best decision.

Are thermoplastics or thermosets more cost-effective?

Thermoplastics are generally more cost-effective. They have lower raw material costs, faster processing times, and reduced tooling expenses. Thermosets involve higher costs due to their curing process and increased tool wear during machining.

See Also

How CNC Precision Parts Affect Overall Manufacturing Expenses

Addressing Heat Issues in CNC Precision Parts Production

Expertise in CNC Machining: Tolerances, Prototypes, and Materials

Grasping Material Needs for CNC Precision Machining Processes

Investigating CNC Machining Solutions for Accurate Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com