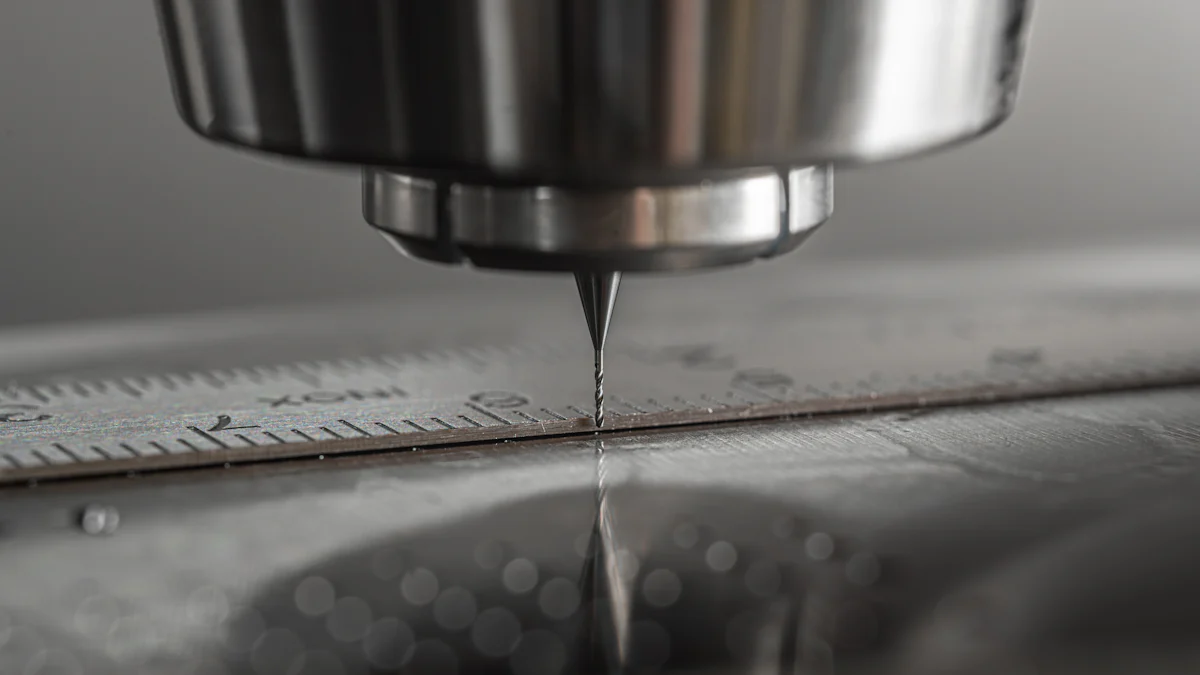

CNC Machining Tolerances for Different Materials

CNC machining tolerances define the allowable variation in part dimensions during manufacturing. These tolerances depend on material properties like hardness, elasticity, and thermal behavior. For example, softer materials such as plastics often allow looser tolerances, around ±0.5 mm for a 20 mm diameter part, while harder materials like steel require tighter tolerances, often ±0.01 mm. Materials with high thermal conductivity, such as aluminum, reduce heat-related deformation, ensuring better dimensional accuracy. Understanding these variations helps you achieve precise fits and maintain functionality in your designs, especially when working with CNC machining processes.

Key Takeaways

CNC machining tolerances depend on the material used. Softer materials like plastic need less precision, but harder ones like steel need more accuracy.

Knowing material properties is very important. Hardness, flexibility, and heat behavior change how materials act during machining, affecting precision.

Balancing accuracy and cost is key. More precision can cost more, so choose tolerances that work well without wasting money.

Checking material datasheets helps pick the right tools and methods. This leads to better results and saves money.

Using standards like ISO 2768 and ASME Y14.5 keeps machining consistent and high-quality. These rules make communication easier and prevent mistakes.

Factors Influencing CNC Machining Tolerances

Material Properties

Hardness and machinability

The hardness of a material directly impacts its machinability and the achievable machining tolerances. Harder materials, such as titanium and hardened steel, cause increased tool wear, which can lead to dimensional errors. On the other hand, softer materials like aluminum and brass offer better machinability, allowing for faster cutting speeds and reduced tool wear. Materials with high machinability also produce smoother surfaces, improving part quality and reducing the need for additional finishing processes.

Elasticity and deformation

Elasticity plays a critical role in determining how a material behaves under machining forces. Flexible materials, such as certain plastics, may deform during machining, making it harder to maintain tight tolerances. Rigid materials, however, resist deformation, ensuring better dimensional accuracy. Understanding a material's elasticity helps you predict and minimize potential deviations in dimensions.

Thermal expansion effects

Thermal expansion can significantly affect machining tolerances, especially for materials with low thermal conductivity. Heat generated during machining causes materials to expand, leading to dimensional inaccuracies. Aluminum, with its high thermal conductivity, dissipates heat effectively, reducing thermal deformation. Choosing materials with stable thermal properties ensures consistent tolerances and part quality.

Machining Processes

Cutting speed and tool wear

Cutting speed directly influences machining tolerances. Higher speeds can increase surface roughness and accelerate tool wear, making it harder to maintain tight tolerances. Tool wear reduces the precision of cuts, requiring frequent replacements to preserve accuracy. Balancing cutting speed with tool life ensures consistent production machining tolerance and part quality.

CNC machine precision

The precision of the CNC machine itself determines the achievable tolerance band. Advanced machines with high accuracy can maintain tighter tolerances, while older or less precise machines may require looser tolerances. Regular maintenance and calibration of CNC equipment are essential for achieving standardized tolerances.

Coolant and lubrication

Coolants and lubricants play a vital role in controlling heat and reducing friction during machining. Proper use of these fluids minimizes thermal expansion and tool wear, helping you achieve tighter tolerances. They also improve surface finish, enhancing the overall quality of machined parts.

Design and Application Requirements

Functional requirements

The intended function of a part dictates its machining tolerances. Critical components, such as those used in aerospace or medical devices, require tight tolerances to ensure safety and performance. Less critical parts can tolerate larger deviations without compromising functionality.

Cost and trade-offs

Tighter tolerances often increase production costs due to the need for precise machines, high-quality materials, and additional finishing processes. Balancing precision with cost is crucial to achieving optimal results without exceeding budget constraints.

Industry standards

Industry standards, such as ISO 2768 and GD&T (geometric dimensioning and tolerancing), provide guidelines for acceptable tolerances. These standards ensure consistency and compatibility across different applications. Adhering to these guidelines helps you meet quality requirements and maintain part accuracy.

CNC Machining Tolerances by Material Type

Metals

Aluminum tolerances

Aluminum is highly machinable, making it ideal for achieving tight machining tolerances. Its dimensional stability and high thermal conductivity reduce heat-related deformation during machining. Standard machining tolerances for aluminum are typically ±0.005" (±0.13 mm), making it suitable for high-precision machining in aerospace and automotive industries. You can rely on aluminum for consistent part quality and smooth finishes, even in complex designs.

Material | Standard Tolerance |

|---|---|

Aluminum | ±0.005" or ±0.13 mm |

Steel | Challenging to machine to tight tolerances |

Stainless Steel | Requires careful machining practices |

Titanium | Requires specialized machining techniques |

Steel tolerances

Steel offers excellent strength but presents challenges in maintaining tight tolerances due to its hardness. Factors like tool wear, thermal stability, and surface treatments can affect dimensional tolerancing. High-quality tools and skilled machinists are essential for achieving acceptable dimensional variation. Steel tolerances depend on the grade and machining process, but careful planning ensures compliance with gd&t guidelines.

Titanium tolerances

Titanium's high strength-to-weight ratio makes it a popular choice for critical applications. However, its hardness and low thermal conductivity require specialized machining techniques. Achieving tight tolerances with titanium demands precise tools, controlled environments, and adherence to standardized tolerances. This material is often used in industries where accuracy and durability are paramount.

Plastics

ABS tolerances

ABS is versatile and easy to machine, but its properties require careful control. Temperature and moisture can affect its dimensions, so you must monitor machining conditions closely. ABS tolerances are generally looser than metals, but proper tooling and fixturing help maintain part quality.

Polycarbonate tolerances

Polycarbonate offers superior strength and impact resistance, but it can chip or crack during machining. Adjusting machining parameters and using sharp tools ensures better tolerances. This material is ideal for applications requiring high-precision machining and durability.

Nylon tolerances

Nylon's flexibility and moisture absorption make it challenging to maintain tight tolerances. Proper cooling and humidity control are necessary to stabilize dimensions. You can improve accuracy by using secure fixturing and following tolerancing guidelines.

Composites

Carbon fiber tolerances

Carbon fiber requires specialized tools to handle its unique properties. Machined holes and pockets often end up undersized due to material relaxation. You must account for this behavior to achieve standardized tolerances.

Fiberglass tolerances

Fiberglass shares similar challenges with carbon fiber. Its abrasive nature can wear tools quickly, affecting tolerances. Using high-quality tools and controlled machining processes ensures better accuracy and part quality.

Other Materials

Ceramic tolerances

Ceramics are known for their hardness and brittleness, which make machining them to tight tolerances a complex task. You must use diamond-coated or carbide tools to handle their abrasive nature. These tools resist wear and maintain precision during cutting. However, ceramics' low thermal conductivity causes heat to build up in the cutting zone. This can lead to microcracks or surface defects if not managed properly. Using coolants effectively helps reduce heat and ensures better dimensional accuracy.

Another challenge is ceramics' tendency to chip or fracture under high cutting forces. To avoid this, you should use slower cutting speeds and lighter passes. These adjustments minimize stress on the material and improve the final part's quality. Despite these challenges, ceramics are ideal for applications requiring high wear resistance and thermal stability, such as in aerospace or medical devices. With careful planning and the right tools, you can achieve tolerances as tight as ±0.001" (±0.025 mm) for ceramic components.

Exotic alloy tolerances

Exotic alloys, such as Inconel and Hastelloy, offer exceptional strength and heat resistance. These properties make them essential for industries like aerospace and power generation. However, machining these materials to tight tolerances presents unique challenges. Their high hardness accelerates tool wear, reducing tool life and precision. You need to select cutting tools designed for high-temperature environments to maintain accuracy.

Poor thermal conductivity in exotic alloys concentrates heat at the cutting zone. This can distort dimensions and compromise tolerances. Using advanced cooling techniques, such as high-pressure coolant systems, helps manage heat effectively. Additionally, these materials often produce irregular chips, which can disrupt machining. Optimizing tool paths and ensuring proper chip evacuation improve process stability.

Exotic alloys also resist deformation, but their stiffness can cause vibrations during machining. You should secure the workpiece firmly and use vibration-dampening tools to maintain dimensional accuracy. With the right approach, you can achieve tolerances of ±0.002" (±0.05 mm) for these materials, ensuring reliable performance in critical applications.

Tip: Always monitor tool wear and machining conditions closely when working with ceramics or exotic alloys. This helps you maintain consistent tolerances and avoid costly errors.

Best Practices for Selecting CNC Machining Tolerances

Understand Material Properties

Research material behavior

Understanding how materials behave during machining is essential for achieving precise tolerances. Each material has unique properties that influence its machinability and the achievable tolerance band. Metals, for instance, generally allow for tighter tolerances compared to plastics. You should also consider the complexity of the part and the CNC machining process being used. Secure clamping and minimizing vibrations during machining are critical for maintaining dimensional accuracy.

Key considerations when researching material behavior:

The relationship between material properties and achievable tolerances.

The impact of material selection on production machining tolerance.

The importance of workpiece stability for accurate dimensions.

Consult datasheets

Material datasheets provide valuable insights into machinability, thermal properties, and other characteristics that affect tolerances. By consulting these datasheets, you can select the right tools and processes for precision machining. This step also helps you balance cost and functionality by adjusting tolerances to meet design requirements.

Benefits of using material datasheets:

Improved understanding of material machinability.

Better selection of tools and processes for achieving gd&t standards.

Cost savings through optimized tolerance specifications.

Balance Precision and Cost

Avoid over-specification

Specifying unnecessarily tight tolerances can increase costs without adding value. Tighter tolerances often require advanced CNC machines, higher-grade materials, and additional inspection time. This can lead to higher scrap rates and extended machining times. Focus on defining tolerances that meet functional requirements without overburdening the production process.

Consider cost implications

Balancing precision and cost is crucial for optimizing CNC machining projects. Tighter tolerances demand more precise equipment, better materials, and enhanced quality control procedures. These factors increase production costs. Efficient setup and material selection can help you reduce expenses while maintaining accuracy.

Cost implications of tight tolerances:

Increased material and tooling costs.

Advanced equipment requirements.

Enhanced quality control procedures.

Higher scrap rates.

Extended machining times.

Collaborate with CNC Experts

Leverage expertise

Working with CNC experts ensures that your machining tolerances align with the capabilities of the equipment and the material properties. Their experience helps you determine feasible tolerances and optimize machining outcomes. Collaborating with experts also saves time and reduces costs by avoiding unnecessary adjustments during production.

Use prototyping

Prototyping allows you to test and refine tolerances before full-scale production. This process helps you identify potential challenges and cost-saving opportunities. Prototypes also ensure that the final product meets functional and dimensional requirements. By addressing issues early, you can streamline production and improve efficiency.

Tip: Prototyping shortens the design cycle and optimizes parts for end-use functionality. It also helps you anticipate challenges and avoid costly redesigns.

Follow Industry Standards

Adhere to ISO/ASME standards

Following industry standards ensures consistency and precision in CNC machining. Standards like ISO 2768, ISO 286, and ASME Y14.5 provide clear guidelines for machining tolerances. These standards simplify communication between designers and manufacturers, reducing errors and improving part quality.

Standard | Description | Application |

|---|---|---|

ISO 2768 | General tolerances for linear and angular dimensions. Categorized into four classes: fine, medium, coarse, and very coarse. | Used for general-purpose parts unless specific tolerances are required. |

ISO 286 | Tolerances for cylindrical surfaces and parallel planes. Includes various grades like IT6, IT7, and IT8. | Applied based on the precision level needed for specific applications. |

ASME Y14.5 | Guidelines for geometric dimensioning and tolerancing (GD&T). | Ensures parts fit and function correctly through standardized symbols. |

ISO 2768 helps you minimize inconsistencies by providing general tolerances for linear and angular dimensions. It categorizes tolerances into four classes, making it easier to select the right level of precision. ISO 286 focuses on cylindrical surfaces and parallel planes, offering grades like IT6 and IT7 for different precision needs. ASME Y14.5 introduces GD&T, which uses symbols and rules to define geometric tolerances. This ensures that critical features meet functional requirements.

Tip: Use these standards to streamline your design process and ensure compatibility across different applications. They also help you maintain quality while reducing production errors.

Customize for applications

Customizing industry standards allows you to meet the unique demands of specific CNC machining projects. Every sector has distinct requirements, from material selection to environmental considerations. For example, aerospace components often need tighter tolerances and high-strength materials, while consumer products may prioritize cost-effectiveness and sustainability.

You can tailor machining tolerances by considering factors like operating temperature, material properties, and environmental impact. Sustainable materials, such as recycled aluminum or biodegradable plastics, are becoming increasingly important. Custom CNC machining solutions also enable you to create highly specialized components. This level of precision is crucial in industries where even a fraction of a millimeter can determine success.

Key considerations for customization:

Match material grades to application requirements.

Evaluate environmental conditions, such as temperature and humidity.

Opt for sustainable materials when possible.

Note: Customizing standards ensures that your parts meet functional and regulatory requirements. It also helps you optimize performance and reduce waste.

Understanding material-specific tolerances is essential for achieving precision and functionality in CNC machining. Different materials, such as metals, plastics, and composites, react uniquely during machining, influencing the achievable tolerances. For example, parts requiring precise fits or high performance demand tighter machining tolerances, while less critical components can allow for looser specifications. Balancing precision, cost, and functionality ensures optimal results. Tighter tolerances often increase costs due to advanced equipment and materials, but reducing tolerances where unnecessary can save time and expenses. Collaborating with CNC experts and adhering to standards like GD&T simplifies processes, improves part quality, and ensures reliable performance.

FAQ

What is the standard tolerance range for CNC machining?

The standard tolerance range for CNC machining typically falls between ±0.005" (±0.13 mm) and ±0.01" (±0.25 mm). However, this depends on the material, machining process, and application requirements. You should consult with your CNC provider to determine the best tolerance for your project.

How do material properties affect CNC machining tolerances?

Material properties like hardness, elasticity, and thermal conductivity influence tolerances. Harder materials require tighter tolerances due to tool wear, while softer materials allow looser tolerances. Materials with high thermal conductivity, like aluminum, reduce heat-related deformation, improving dimensional accuracy.

Can tighter tolerances increase production costs?

Yes, tighter tolerances often increase costs. They require advanced CNC machines, high-quality tools, and additional inspection time. You can save costs by specifying tolerances that meet functional requirements without over-specifying. Balancing precision and cost ensures efficient production.

Why is prototyping important for CNC machining tolerances?

Prototyping helps you test and refine tolerances before full-scale production. It identifies potential issues, ensures parts meet functional requirements, and reduces costly errors. Prototyping also allows you to optimize designs for better performance and efficiency.

What are the benefits of following industry standards for tolerances?

Industry standards like ISO 2768 and ASME Y14.5 ensure consistency and compatibility. They simplify communication between designers and manufacturers, reduce errors, and improve part quality. Adhering to these standards helps you meet regulatory and functional requirements efficiently.

Tip: Always consult industry standards to streamline your design process and maintain quality.

See Also

Exploring Material Needs for CNC Precision Machining Processes

Expertise in CNC Machining: Tolerances, Prototyping, and Materials

Grasping Tolerances and Surface Finishes for POM Machining

Fulfilling CNC Precision Machining Standards for Component Parts

Achieving Mastery in CNC Machining for Precision Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com