How CNC Machining Helps Design and Produce Wearable Electronics

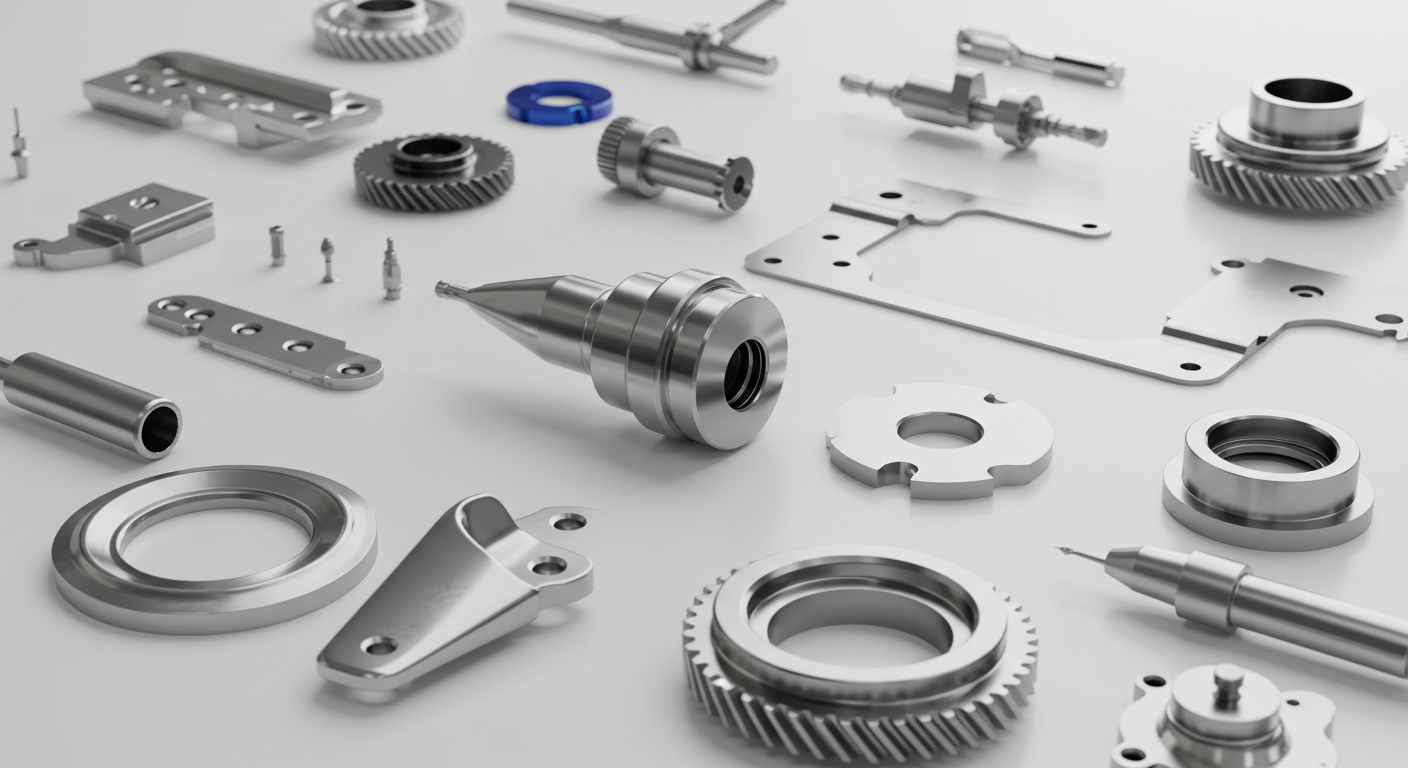

CNC machining transforms how you create wearable electronics by delivering unmatched precision and efficiency. Its ability to achieve tight tolerances ensures intricate designs meet exact specifications. High-speed and multi-axis machining enhance production speed, making CNC ideal for compact, high-performing devices. This technology empowers you to innovate with durable, customized components.

Key Takeaways

CNC machining is very precise, with tolerances as small as +/- 0.0025 mm. This ensures wearable electronics work reliably.

CNC machining allows custom designs and quick prototypes. This helps meet the need for personalized wearable devices.

Lightweight metals and strong plastics used in CNC machining make wearable electronics tough and comfy for daily use.

The Role of CNC Machining in Wearable Electronics

Precision in Electronic Component Production

CNC machining technology delivers the precision required for wearable electronics. Advanced software controls every step of the process, ensuring that each part meets exact specifications. High-quality tooling and meticulous calibration allow CNC machines to achieve tolerances as tight as +/- 0.0025 mm. This level of precision is essential for electronic component production, where even the smallest deviation can affect performance. For example, CNC machining ensures that smartwatches, fitness trackers, and medical sensors function reliably by producing perfectly fitting parts. Regular maintenance of CNC machines further guarantees consistent quality, making this technology indispensable in the electronics industry.

Customization for Unique Wearable Designs

CNC machining empowers you to create wearable devices tailored to individual needs. The technology supports the production of intricate designs, such as engraving unique patterns on smartwatch cases or crafting ergonomic shapes for comfort. CNC machining processes also allow for rapid prototyping and production of custom components, enabling you to test and refine designs quickly. Whether you need a personalized fit or a complex shape, CNC machining ensures high accuracy and flexibility. This capability is particularly valuable in the electronics industry, where consumer demand for unique and functional designs continues to grow.

Efficiency in Prototyping and Manufacturing

CNC machining streamlines the transition from prototyping to full-scale manufacturing. The same processes used to create prototypes can be applied to mass production, ensuring consistency and reducing lead times. Rapid prototyping with CNC machining allows you to test designs quickly, saving time and costs associated with traditional methods. For instance, high-precision CNC milling can produce prototypes with tolerances as precise as 0.0001 of an inch. This efficiency accelerates product development, helping you bring innovative wearable devices to market faster. By minimizing human error and maintaining strict quality standards, CNC machining services provide a reliable solution for the electronics industry.

Materials Used in CNC Machining for Wearable Devices

Lightweight Metals for Durability and Comfort

Lightweight metals play a crucial role in CNC machining for wearable devices. These materials combine strength, durability, and comfort, making them ideal for creating compact and reliable components. Commonly used lightweight metals include:

Aluminum Alloys: Known for their excellent corrosion resistance, machinability, and strength-to-weight ratio.

Magnesium Alloys: One of the lightest structural metals available, offering good strength and damping capacity.

Titanium Alloys: Combines high strength with corrosion resistance and low weight.

These metals enhance the performance of wearable electronics in several ways:

Property | Contribution to Wearable Electronics |

|---|---|

Excellent machinability | Enables the creation of lightweight and durable casings. |

Corrosion resistance | Enhances longevity by protecting devices from environmental damage. |

Thermal conductivity | Facilitates effective heat management, improving comfort and performance. |

By using these materials, you can ensure that your wearable devices remain durable, lightweight, and comfortable for extended use.

Durable Plastics for Versatile Applications

Durable plastics are another essential material in CNC machining for wearable electronics. They offer versatility, strength, and resistance to environmental factors, making them suitable for various applications. Two commonly used plastics include:

Material | Properties | Applications |

|---|---|---|

PEEK | High strength, durability, resistance to electrical currents | CNC machining for electronics |

Nylon | High strength, durability, resistance to electrical currents | CNC machining for electronics |

These plastics allow you to create components that are not only robust but also lightweight and adaptable to different designs. Their resistance to wear and tear ensures that your wearable devices maintain functionality over time.

Hybrid Materials for Advanced Wearable Electronics

Hybrid materials represent the future of CNC machining for wearable devices. These materials combine the benefits of multiple components, enhancing both performance and functionality. Flexible hybrid electronics, for instance, conform to the wearer's body, improving comfort and user experience. They also increase durability, making wearables more rugged and less prone to damage. Additionally, the versatility of flexible circuits allows you to integrate them into various products, from skin patches to clothing. By leveraging hybrid materials, you can expand the possibilities of wearable technology and create innovative solutions tailored to user needs.

Examples of Wearable Components Made with CNC Machining

Casings and Enclosures for Wearable Devices

CNC machining plays a pivotal role in producing durable and precise casings for wearable electronics. You can rely on this technology to create enclosures that protect sensitive components while maintaining a sleek and ergonomic design. For instance:

Smartwatch cases crafted from 7075 aerospace-grade aluminum offer both strength and lightweight comfort.

Custom-fit silicone seals integrated into CNC machined casings ensure water resistance, making devices suitable for various environments.

Type III hard-anodized finishes enhance durability and aesthetics, providing a premium look and feel.

CNC machining ensures exact dimensions and tolerances, guaranteeing a perfect fit for internal components. This precision protects electronics from environmental factors and daily wear, which is especially critical for medical wearables where reliability is non-negotiable. Whether you need casings for fitness trackers or unibody shells for advanced devices, CNC machining delivers both functionality and visual appeal.

Connectors and Ports for Seamless Functionality

Connectors and ports are essential for wearable devices, enabling reliable signal and power transmission. CNC machining ensures these components meet the highest standards of precision and reliability. The process allows you to produce connectors with complex shapes and exact dimensions, ensuring they fit perfectly within assemblies. This precision supports the seamless functionality of wearable electronics, even under the rigors of daily use. For advanced wearable technology, CNC machining also enables the creation of custom-designed connectors, enhancing both performance and durability.

Heat Sinks and Printed Circuit Boards for Performance

Thermal management is crucial for wearable devices, and CNC machining excels in producing heat sinks that optimize cooling efficiency. These components feature intricate geometries and precise surface finishes, ensuring effective heat dissipation. This helps maintain the performance and longevity of your devices. Additionally, CNC machining supports the production of printed circuit boards with intricate patterns and precise connections. These boards are vital for complex circuits in wearable electronics, enabling high functionality in compact designs. The scalability and customization offered by CNC machining make it an ideal solution for both prototyping and mass production of these critical components.

Advantages of CNC Machining Over Traditional Methods

Superior Precision and Consistency in Production

CNC machining offers unmatched precision and reliability, making it a superior choice over traditional methods. You can achieve tolerances as precise as 0.0001 of an inch, ensuring intricate geometries align perfectly with digital designs. This level of precision eliminates the need for multiple iterations, saving both time and costs. CNC technology also ensures repeatability, producing identical components across large-scale manufacturing runs. Automated inspections and rigorous testing further enhance quality, verifying that each part meets exact specifications. With CNC machining, you can maintain consistent standards, even for complex wearable devices requiring high precision and reliability.

Faster Prototyping and Iteration Cycles

CNC machining accelerates the prototyping process, allowing you to bring ideas to life quickly. By converting digital designs into physical prototypes in record time, you can test and refine concepts without delays. Engineers can make immediate adjustments to CAD models and produce updated prototypes, ensuring alignment with design goals. This rapid iteration process reduces lead times and keeps projects on schedule. CNC machining also eliminates the need for expensive hard tooling, offering significant cost savings. Faster prototyping gives you a competitive edge, enabling quicker market introduction of innovative wearable devices.

Enhanced Quality and Longevity of Wearable Electronics

Wearable electronics demand components that endure daily use while maintaining functionality. CNC machining ensures the durability and reliability of each part, making it ideal for medical wearables and fitness trackers. The precision of CNC processes allows you to create miniaturized components with complex functionality, enhancing both performance and aesthetics. This technology supports the production of customized parts tailored to individual needs, improving user experience. By leveraging CNC machining, you can produce wearable devices that withstand the rigors of everyday life, ensuring long-term reliability and optimal performance.

CNC machining drives innovation in wearable electronics by enabling rapid prototyping, intricate designs, and reliable production. You can leverage advancements like high-speed and 5-axis machining to create precise, high-performing components. This technology ensures wearables meet demanding requirements, offering durability, comfort, and functionality essential for modern devices. Its versatility continues to shape the future of wearable technology.

FAQ

What makes CNC machining ideal for wearable electronics?

CNC machining offers unmatched precision, enabling you to create intricate designs. Its ability to handle diverse materials ensures durable, lightweight, and high-performing components for wearable devices.

Can CNC machining handle rapid prototyping for wearables?

Yes, CNC machining excels at rapid prototyping. It allows you to quickly test and refine designs, reducing development time and accelerating the launch of innovative wearable products.

Which materials are best for CNC-machined wearable components?

Lightweight metals like aluminum and titanium ensure durability and comfort. Durable plastics like PEEK and hybrid materials enhance versatility, making them ideal for advanced wearable electronics.

See Also

CNC Precision Machining Trends Shaping Consumer Electronics in 2024

Understanding CNC Machines and Precision Engineering in Electronics

The Impact of CNC Machining on High-End Manufacturing Processes

Streamlined CNC Machining Solutions for Precision Production Needs

Investigating CNC Machining Services in Precision Manufacturing Sector

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com