The Growing Demand for CNC Precision Parts and its Applications

The demand for CNC precision machining applications has surged across industries due to their unmatched precision and reliability. You see this growth reflected in the global CNC market, which is projected to expand from $67.5 billion in 2023 to $80.4 billion by 2028, driven by automation and high-precision manufacturing. Industries like automotive and aerospace rely on CNC technology to meet the need for intricate, high-quality components. With advancements like AI and IoT, CNC precision machining applications continue to revolutionize production processes, ensuring efficiency and consistency. Its ability to cater to diverse applications makes it indispensable in modern manufacturing.

Key Takeaways

CNC machines automate making things, giving exact results and fewer mistakes. This is very important for fields like airplanes and healthcare.

CNC machines can handle many materials, so they are used for many things, like special implants or tiny electronic parts.

Using CNC machines saves money over time and works faster. They cut down waste and make more products with automation.

Understanding CNC Machining and Its Importance

What is CNC Machining?

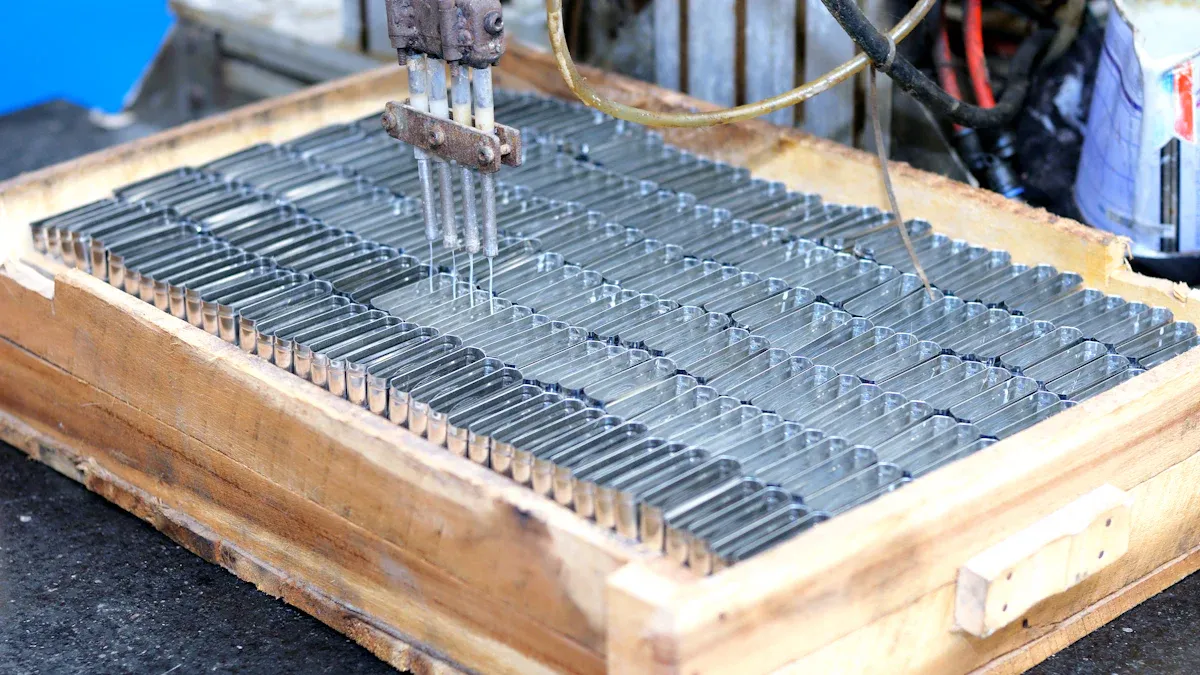

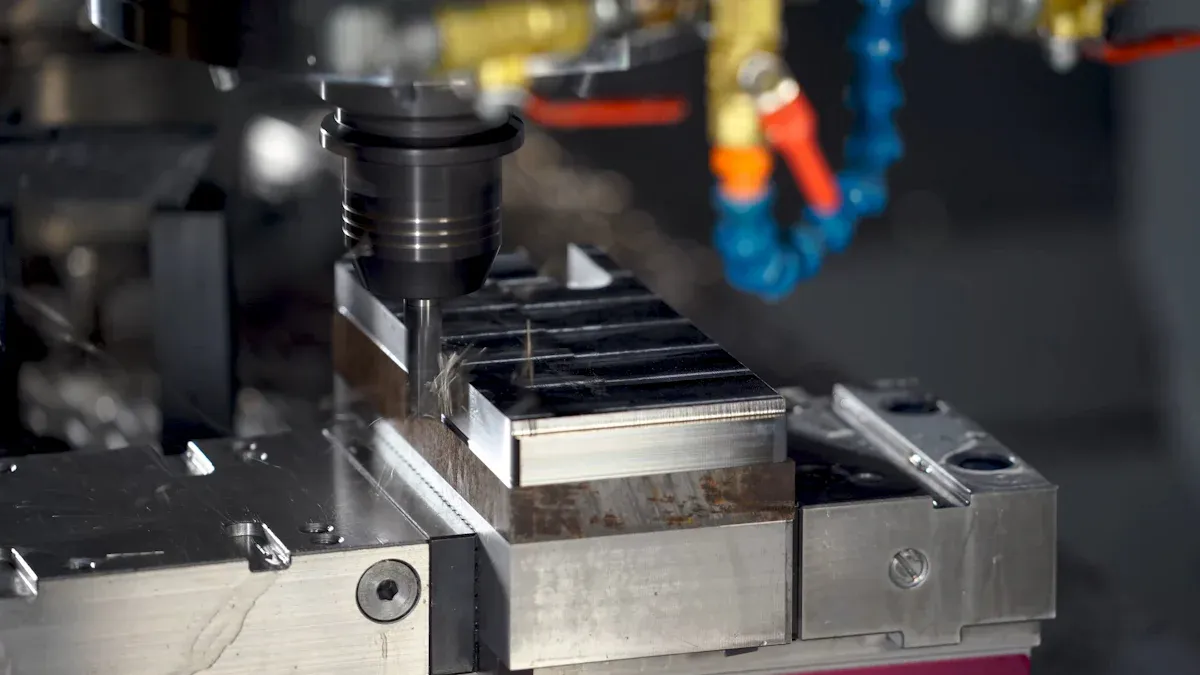

CNC machining, or Computer Numerical Control machining, is a modern manufacturing process that uses computerized systems to control tools and machinery. Unlike traditional methods, CNC machining automates operations, ensuring consistent and precise results. You can use this process to create intricate designs and complex geometries that would be challenging with manual techniques. CNC machining works with a wide range of materials, including metals, plastics, and composites, making it highly versatile for various industries.

Key features that set CNC machining apart include:

Precision: Computerized control minimizes human error, delivering high accuracy.

Material Versatility: It handles harder materials that traditional methods cannot process.

Production Efficiency: Continuous operation reduces downtime and speeds up production.

Cost-Effectiveness: While initial costs are high, it saves money in large production runs.

Lower Skill Requirements: Operators need less expertise compared to traditional machining.

The Role of CNC in Precision Manufacturing

CNC machining plays a vital role in precision manufacturing by producing high-quality parts with tight tolerances. You’ll find it indispensable in industries like aerospace, automotive, and medical, where accuracy is critical. For example, aerospace companies rely on CNC machining to create engine components and airframe structures. In the medical field, it’s used for surgical tools and implants. This process ensures that every part meets exact specifications, reducing errors and improving reliability.

Why CNC Machining is Essential for Modern Industries

Modern industries demand efficiency, precision, and adaptability, and CNC machining delivers on all fronts. Its ability to operate continuously enhances production speed and reduces costs. You can also benefit from its rapid prototyping capabilities, which allow for quick design iterations. Industries like electronics and automotive depend on CNC machining to produce intricate parts, such as circuit boards and engine components. Additionally, its versatility in design enables customization, making it a cornerstone of innovation in manufacturing.

Benefits of CNC Machined Parts

Precision and Accuracy in Manufacturing

CNC machining excels in delivering unmatched precision and accuracy, making it a cornerstone of modern manufacturing. Unlike manual machining, CNC systems achieve tight tolerances of up to ±0.001 inches, ensuring that every part meets stringent tolerances required by industries like aerospace and medical. This level of precision is critical for producing precision-engineered parts, such as custom parts for surgical instruments or intricate components for aircraft engines.

The measurable benefits of CNC machining become evident when comparing it to manual methods. For instance:

Machining Method | Total Units Manufactured | Units Scrapped | Total Cost to get 50,000 QC Passed Units |

|---|---|---|---|

Manual Machine | 56,155 | 6,155 | $202,158 |

CNC Machine | 50,000 | 0 | $172,500 |

CNC machining ensures repeatability and precision, eliminating errors and reducing waste. Advanced software programs the machines, enabling them to replicate parts with identical accuracy, which is essential for industries requiring high-quality components.

Cost-Effectiveness and Efficiency

CNC machining offers significant cost savings and operational efficiency. While the initial investment in CNC systems may seem high, the long-term benefits outweigh the costs. Automation reduces labor expenses by minimizing the need for manual intervention. CNC machines operate continuously, maximizing production output and ensuring consistent quality.

Additionally, CNC machining optimizes material usage. By using advanced cutting paths, it minimizes waste and contributes to sustainable manufacturing practices. For example, adaptive cutting techniques and laser cutting reduce material loss, saving money and resources. This efficiency makes CNC machining an ideal choice for industries aiming to balance cost-effectiveness with high-quality production.

Versatility in Materials and Applications

CNC machining stands out for its versatility in handling a wide range of materials. Whether you need to work with metals like aluminum and titanium, plastics, composites, or even ceramics, CNC machines can process them with ease. This flexibility allows industries to choose the most suitable materials for their applications, enhancing product performance and durability.

Material Type | Examples |

|---|---|

Metals | Aluminum, Titanium |

Plastics | Various types |

Composites | Various types |

Ceramics | Various types |

This versatility benefits industries in multiple ways. You can manufacture rare replacement parts or create custom parts tailored to specific needs. CNC machining also supports non-metal materials like phenolics and rigid foam, further expanding its applications. Its ability to handle diverse materials ensures that you can meet the unique demands of any project, from aerospace components to medical devices.

CNC Precision Machining Applications Across Industries

Aerospace: High-Precision Components for Aircraft

CNC precision machining application plays a critical role in the aerospace industry, where extreme precision and reliability are non-negotiable. You’ll find CNC machined parts in various high-precision components essential for aircraft performance and safety. These include:

Valve components for accurate and secure operations.

Oxygen generation components, which are lightweight yet strong for safety systems.

Shafts for power transmission in aeronautics.

Engine components, landing gear parts, and exhaust nozzles.

CNC machining ensures these parts meet stringent tolerances, often as small as 4μm. Advanced techniques like laser scanning and coordinate measuring machines (CMM) maintain accuracy. By minimizing errors, CNC machining guarantees compliance with strict aerospace standards.

Automotive: Enhancing Engine and Transmission Systems

In the automotive sector, CNC machining enhances the performance and reliability of engine and transmission systems. You can rely on CNC machined parts like gear shafts and transmission housings for smooth operation and durability. The precision in manufacturing ensures these components meet stringent automotive standards, which is vital for vehicle safety and performance.

CNC machining also supports innovation by producing customized parts with intricate geometries. This adaptability allows manufacturers to respond quickly to design changes, keeping pace with the fast-evolving automotive market. The repeatability of CNC machining ensures consistent quality, helping vehicles meet rigorous safety and performance requirements.

Medical: Custom Implants and Surgical Instruments

The medical field benefits immensely from CNC precision machining application. You’ll see its impact in the creation of custom implants and surgical instruments, where precision and accuracy are paramount. CNC machining handles complex geometries, enabling the production of intricate parts for advanced medical applications.

Advantage | Description |

|---|---|

Precision and Accuracy | Ensures strict tolerances for medical devices. |

Repeatability | Guarantees consistent quality for patient safety. |

Flexibility in Material Choice | Allows the use of biocompatible materials for diverse applications. |

Customization | Facilitates personalized implants tailored to individual needs. |

Reduced Production Time | Accelerates the development of new medical devices. |

This process also supports rapid prototyping, meeting the industry’s demand for scalable production.

Electronics: Miniaturized and Complex Parts for Devices

CNC machining is indispensable in the consumer electronics industry, where miniaturization and complexity are key. You can use CNC milling to create intricate geometries and tight tolerances required for components like circuit board frames and device housings. Micromachining enables the production of miniature parts with extreme precision, which is crucial for modern electronic devices.

For example, companies like Apple rely on CNC machining to fabricate high-quality components for products like iPhones and MacBooks. This technology ensures faster turnaround times, minimal tooling costs, and the ability to modify prototypes easily using CAD/CAM software. These advantages make CNC machining a cornerstone of innovation in the electronics industry.

Factors Driving the Demand for CNC Precision Parts

Technological Advancements in CNC Machining

Recent advancements in CNC machining have significantly boosted its demand across industries. You now see the integration of Industry 4.0 technologies, such as IoT, data analytics, and AI, which enhance precision and efficiency. These technologies allow machines to communicate in real-time, improving production control and reducing downtime. Additive manufacturing, like 3D printing, has also emerged as a game-changer. It enables the creation of complex parts with high precision and minimal waste. Additionally, automation and robotics streamline complex processes, making manufacturing faster and more reliable.

The adoption of these advancements ensures that CNC machining remains at the forefront of modern manufacturing. By leveraging these technologies, you can achieve tighter tolerances, faster production times, and improved product quality. This makes CNC machining indispensable for industries requiring high-precision components.

Growing Need for High-Quality and Reliable Components

Industries today demand parts that meet exact specifications without compromise. CNC machining excels in navigating intricate designs and handling complex geometries, such as deep narrow pockets or high-precision threads. This capability ensures that every component meets stringent quality standards. Real-time monitoring further minimizes defects, ensuring reliability and consistency in production.

For example, aerospace and medical sectors rely on CNC machining to produce components with exceptional accuracy. By achieving tighter tolerances and reducing variations, you can deliver products that perform reliably under critical conditions. This growing need for high-quality parts continues to drive the demand for CNC machining.

Automation and Efficiency in Manufacturing Processes

Automation plays a pivotal role in increasing the efficiency of CNC machining processes. By minimizing manual tasks, automation enhances uptime and reduces idle time, leading to higher production output. Automated tools ensure precision and consistency, which is crucial for industries requiring exact specifications. For instance, automated CNC machines can operate continuously with minimal supervision, maximizing production time and reducing labor costs.

You also benefit from optimized material usage, as automation reduces waste through advanced cutting paths. This not only saves costs but also supports sustainable manufacturing practices. With improved cycle times and reduced setup durations, automation ensures that CNC machining remains a cost-effective solution for high-volume production.

CNC machining continues to shape modern industries by delivering precision, efficiency, and versatility. You benefit from its ability to produce high-quality components for diverse applications, from aerospace to medical devices. The future of CNC machining looks promising, with trends like automation, AI, and IoT driving innovation. The global market is projected to reach $129 billion by 2026, fueled by advancements in digital supply chains and reshoring efforts. Emerging technologies, such as cryogenic machining and micromachining, will further expand its capabilities, ensuring CNC machining remains a cornerstone of manufacturing excellence.

FAQ

What industries benefit the most from CNC precision machining?

Industries like aerospace, automotive, medical, and electronics benefit significantly. You’ll find CNC machining essential for producing high-precision, reliable components that meet strict quality standards in these fields.

How does CNC machining ensure high accuracy?

CNC machining uses computer-controlled systems to eliminate human error. Advanced software programs the machines, ensuring consistent results and tight tolerances for every part produced.

Can CNC machines work with different materials?

Yes, CNC machines handle various materials, including metals, plastics, composites, and ceramics. This versatility allows you to choose the best material for your specific application.

💡 Tip: Always consult with your CNC machining provider to determine the most suitable material for your project.

See Also

Understanding CNC Precision Parts Processing in Manufacturing

Excelling in CNC Machining for Precision Part Production

Investigating CNC Machining Solutions for Precision Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com