How CNC Machining Increases Production Speed Without Compromising Accuracy

CNC machining transforms manufacturing by automating processes and delivering unmatched precision. Unlike traditional methods, it operates continuously, achieving faster production rates and reducing human error. Industries like aerospace, medical, and automotive rely on CNC Precision Part production to meet strict standards, ensuring consistent quality and efficiency in high-volume manufacturing.

Key Takeaways

CNC machines use automation to make products faster and with fewer mistakes.

Modern CNC tools cut setup time, making switching tasks quicker and boosting efficiency.

Live monitoring helps keep work accurate and steady, creating better products and saving money.

Understanding CNC Machining and Its Core Principles

Key principles of CNC machining

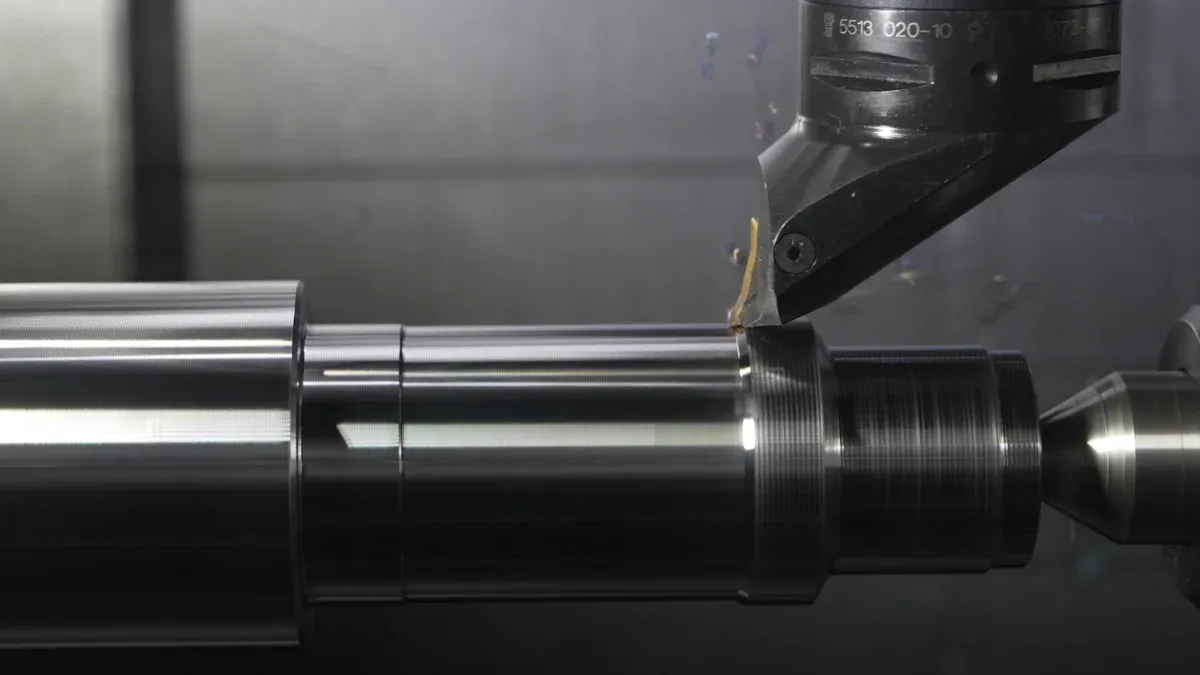

CNC machining operates on a few essential principles that ensure precision and efficiency. First, a computer system interprets CAD (Computer-Aided Design) models and converts them into G-code, which directs the machine's movements. This code acts as the language that tells the machine how to cut, drill, or shape materials. Second, the machine tool, such as a lathe or milling machine, performs the physical operations. Finally, the cutting tool, chosen based on the material and desired finish, shapes the workpiece. These principles work together to deliver consistent results, even for complex designs.

Components of a CNC machine

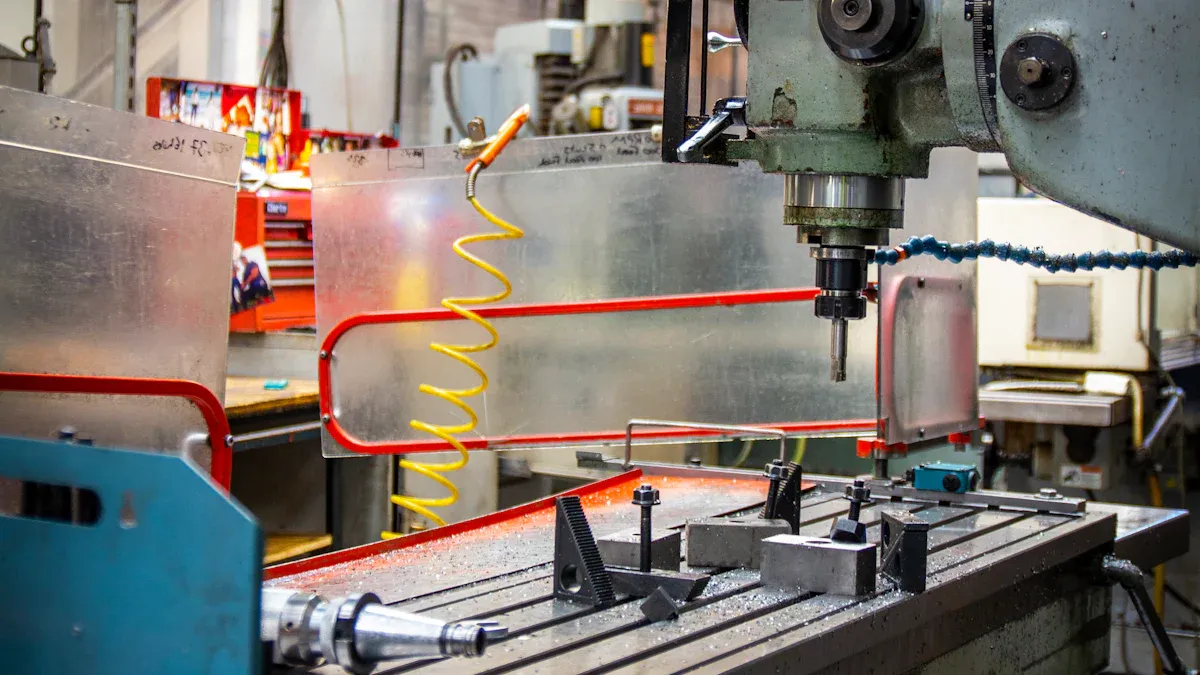

CNC machines consist of several key components that enable their functionality. The control unit serves as the brain, processing the G-code and sending commands to the machine. The machine tool, such as a router or grinder, executes these commands. Cutting tools, like drills or end mills, interact with the material to create the desired shape. Additionally, the worktable holds the material in place, while motors and drives ensure precise movements. Each component plays a critical role in the seamless operation of CNC technology.

Comparison to manual machining processes

CNC machining offers several advantages over manual machining. It provides faster production speeds, higher repeatability, and the ability to handle complex designs. Manual machining, on the other hand, requires no programming and is better suited for unique, low-volume projects. However, CNC machines deliver greater precision and productivity, making them ideal for high-volume manufacturing. While manual machining depends heavily on operator skill, CNC technology relies on programming expertise, ensuring consistent quality.

How CNC Machining Enhances Production Speed

Automation and continuous operation

CNC machining relies on automation to achieve remarkable production speed. By eliminating manual labor, you can reduce human error and streamline machining operations. CNC machines operate continuously, even during nights and weekends, without requiring breaks. This 24/7 capability ensures faster production cycles and consistent output. Additionally, built-in tool changers allow seamless transitions between tasks, minimizing downtime and boosting efficiency.

Automation also enhances precision. Computer-generated programs control every movement of the cutting tools, ensuring accurate machining. This eliminates variability caused by human intervention. With CNC technology, you can meet high production demands while maintaining quality and consistency.

Toolpath optimization and high-speed machining

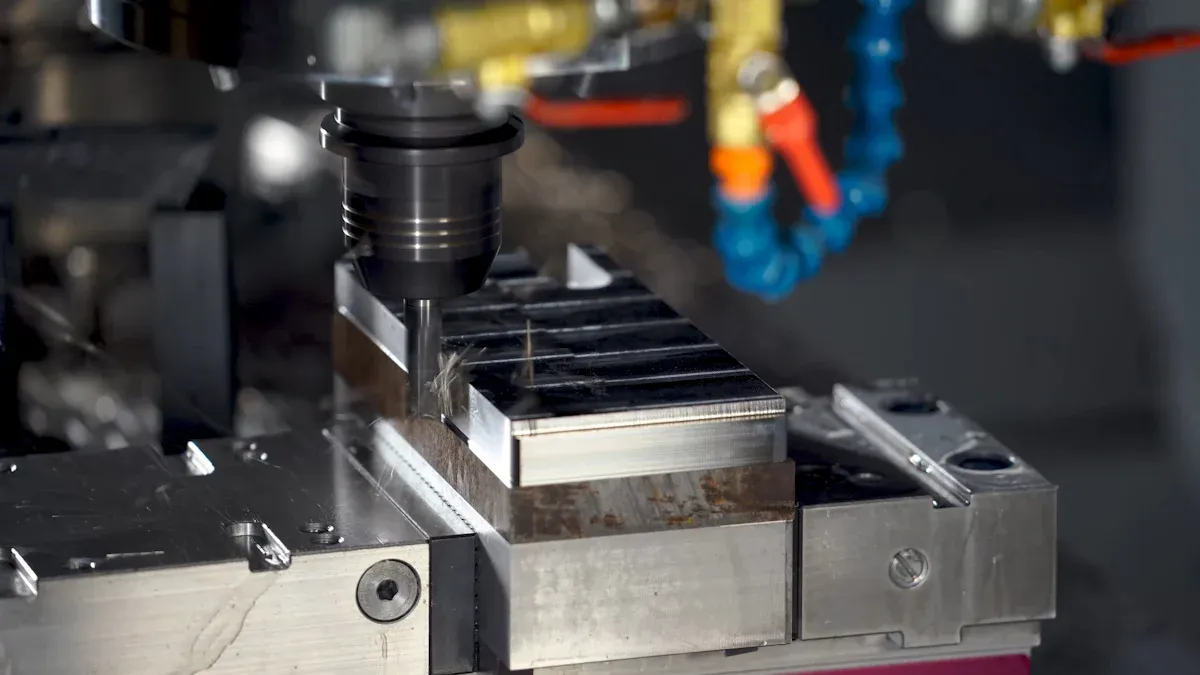

Toolpath optimization plays a critical role in improving machining operations. By determining the most efficient path for the cutting tool, CNC technology reduces machining time and extends tool life. Strategies like adaptive clearing maximize material removal rates while minimizing wear on tools. This approach is especially effective for complex geometries and hard-to-machine materials.

High-speed machining further enhances production speed. It allows CNC machines to perform rapid cutting without compromising surface finish. These advancements ensure faster production cycles and cost savings, making CNC machining a preferred choice for manufacturers.

Reduced setup time with advanced CNC systems

Advanced CNC systems significantly reduce setup time, enabling quicker transitions between production cycles. Features like accurate tracking of setup times provide precise data, helping you identify inefficiencies. Standardized processes ensure consistent quality from the first part produced.

Technology integration also plays a key role. Tools like MachineMetrics offer real-time reporting, allowing you to monitor and optimize setup efficiency. By minimizing downtime, CNC technology ensures faster machining operations and higher productivity.

Mechanisms Behind CNC Precision Part Production

Precision programming and CAD/CAM software

Precision programming forms the backbone of CNC machining. It ensures that CNC machines follow exact instructions derived from CAD models, directly impacting the accuracy of the final product. By using CAD/CAM software, you can automate much of the programming process, reducing setup time and minimizing human error. This automation allows you to achieve machining efficiency while maintaining precision and consistency.

CAD/CAM systems also enable you to create complex 3D models and convert them into machine-readable code. This process ensures that the CNC machine follows a predetermined toolpath, which is crucial for achieving the desired shape accurately. Additionally, techniques like adaptive strategies and toolpath optimization algorithms reduce unnecessary tool changes and movements, further enhancing machining operations.

Advanced cutting tools and materials

The cutting tools and materials used in CNC machining have seen significant advancements. Modern tools are designed to handle high-speed machining and maintain accuracy even under demanding conditions. Materials like carbon fiber reinforced polymers (CFRP) and superalloys such as Inconel and Hastelloy are becoming increasingly popular. These materials offer strength, lightweight properties, and resistance to corrosion, making them ideal for industries like aerospace and automotive.

You can also benefit from the integration of additive manufacturing techniques with CNC technology. This combination allows for the production of complex geometries while optimizing material properties. These advancements not only improve machining efficiency but also expand the enhanced design capabilities of CNC precision part production.

Real-time monitoring and feedback systems

Real-time monitoring systems play a vital role in ensuring precision and consistency during machining operations. Tools like MachineMetrics allow you to track changeovers, parts, and production in real time. By standardizing data across equipment, these systems improve accuracy and ensure timely delivery of parts.

The benefits of real-time monitoring extend beyond precision. For example, manufacturers have reported a 20% increase in Overall Equipment Effectiveness (OEE) and a 6% improvement in On-Time Delivery (OTD). These systems also reduce tooling costs and minimize past dues, helping you optimize production while maintaining high standards of quality.

Benefits of Enhanced Productivity and Manufacturing Efficiency

Cost efficiency and waste reduction

CNC machining offers significant time and cost savings by streamlining production processes. Its automation reduces the need for manual labor, cutting down on labor costs while enhancing operational efficiency. By utilizing CAD software, CNC machines create precise cuts, minimizing material waste. This precision also reduces the likelihood of defects, saving you from reworking materials. Additionally, CNC machines consume only the energy required for each task, lowering energy costs and environmental impact. Features like automatic shut-off further prevent energy waste when idle. These advantages make CNC machining a cost-effective solution for modern manufacturing.

Scalability for high-volume production

CNC machining excels in scaling production to meet high-volume demands without sacrificing manufacturing efficiency. Automation allows you to produce components faster and in greater volumes. Advanced CNC technologies ensure consistent quality across all parts, even in large-scale production. The flexibility of CNC systems enables you to adjust production levels based on demand while maintaining operational efficiency. For example, CNC milling and machining technologies support rapid scaling, ensuring you can meet tight deadlines without compromising on quality. This scalability makes CNC machining ideal for industries requiring high-quality products in bulk.

Consistent quality and tight tolerances

CNC machining ensures consistent quality by automating production processes and maintaining tight tolerances. Advanced programming and real-time monitoring systems allow you to achieve precise measurements and detect errors during production. Skilled operators select high-quality cutting tools and regularly check tool alignment to maintain accuracy. On-machine inspection systems further enhance quality control by verifying machining accuracy in real time. These practices ensure that every part meets specifications, resulting in high-quality products with minimal defects. This consistency is crucial for industries like aerospace and medical manufacturing, where precision is non-negotiable.

CNC machining has transformed manufacturing by combining speed, precision, and efficiency. It reduces waste, enhances scalability, and ensures consistent quality. You can leverage its automation and advanced technology to meet high production demands while minimizing costs. As industries adopt sustainable practices, CNC machining continues to drive innovation and operational excellence.

FAQ

What industries benefit the most from CNC machining?

Industries like aerospace, automotive, and medical manufacturing benefit greatly. CNC machining ensures precision, scalability, and consistent quality, which are essential for these sectors.

How does CNC machining reduce production costs?

CNC machining minimizes waste, reduces labor costs through automation, and optimizes material usage. These factors lower overall production expenses while maintaining high-quality output.

Can CNC machines handle custom designs?

Yes, CNC machines excel at producing custom designs. You can use CAD software to create intricate models, which the machine replicates with precision and accuracy.

💡 Tip: Always ensure your CAD designs are optimized for CNC machining to achieve the best results.

See Also

Enhancing Quality Through Advanced CNC Machining Techniques

Streamlined CNC Machining Solutions for Accurate Production

The Impact of CNC Technology on Precision Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com