Mastering CNC Prototyping: Tips to Overcome Common Issues

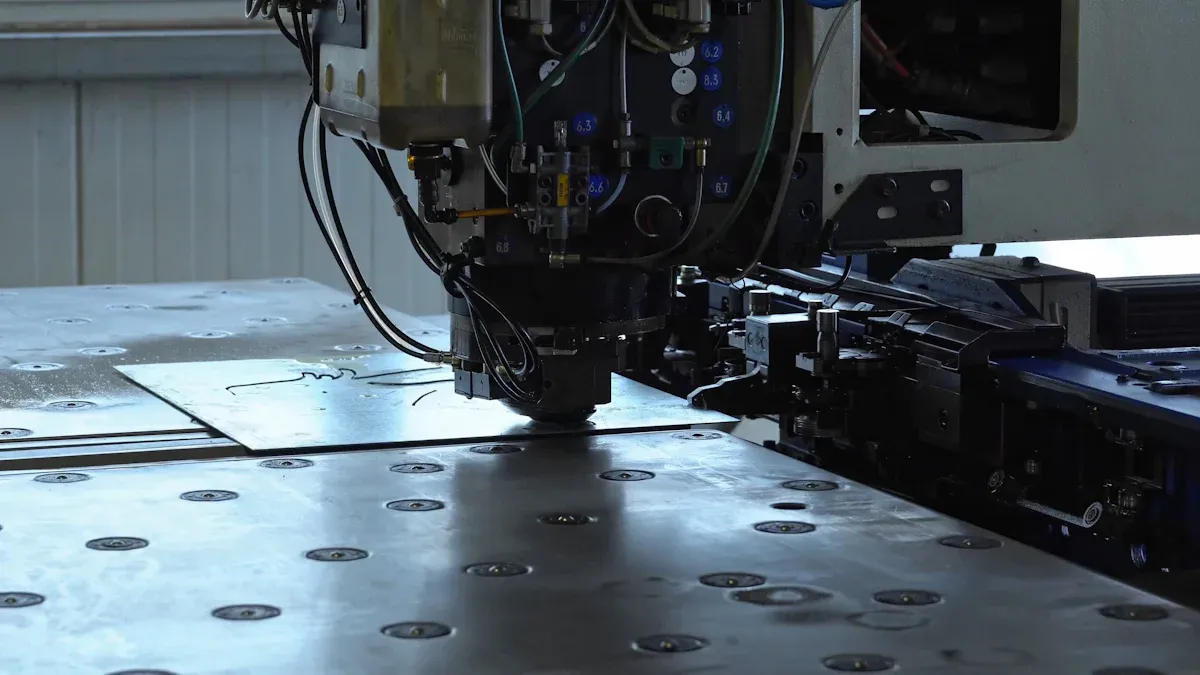

CNC prototyping plays a vital role in modern manufacturing by enabling precise and efficient production of prototypes. However, challenges often arise that can disrupt your workflow. For example, complex geometries increase machining time and costs, while tight tolerances demand significant effort to maintain precision. High-quality fixturing and tooling, along with regular maintenance, are essential to overcome these hurdles. Balancing cost and quality remains a constant struggle, especially with expensive materials and specialized tools. Addressing these issues ensures smoother operations and better results in rapid prototyping.

Key Takeaways

Pick the right material for your CNC prototypes. This improves quality and avoids machining problems. Study material traits to match your project needs.

Make designs simpler to speed up production and avoid mistakes. Keep designs basic to make machining easier.

Use modern CAD software to test tool paths and improve designs. This stops errors and ensures accuracy before starting machining.

Common Challenges in CNC Prototyping

Material Selection and Its Impact

Choosing the right material is critical in CNC prototype manufacturing. However, it often leads to machining challenges if the material is incompatible with CNC methods. For example, harder materials like titanium can wear tools faster, while softer materials may deform under stress. Researching material properties, such as heat tolerance and impact resistance, helps you avoid manufacturability issues. Consulting suppliers ensures you select materials that balance performance and budget. Material cost and availability also play a significant role, especially when producing multiple prototypes.

Material selection directly affects the quality and durability of your prototypes. Each material has unique mechanical properties that influence the machining process and the final product's appearance. For instance, metals like aluminum offer excellent machinability, while plastics provide cost-saving measures for less demanding applications. By understanding these factors, you can optimize your CNC prototyping process for better results.

Design Complexity in CNC Machining

Design complexities often hinder CNC prototype manufacturing. Complex geometries, such as intricate curves or deep cavities, increase machining time and costs. These features also raise the risk of errors, especially when working with tight tolerances. Thin walls, for example, may deform during machining, leading to rework or scrapping.

Challenge | Description | Solution |

|---|---|---|

Complex Geometries | Tool accessibility and movement limitations make intricate designs difficult. | Use advanced CAD/CAM software to simulate and refine designs. |

Tight Tolerances | Maintaining precision across production is challenging. | Regularly calibrate machines and use high-quality tools. |

Thin Walls | Deformation or breakage occurs during machining. | Adjust cutting parameters and reinforce critical areas. |

Difficult Materials | Hard-to-machine materials reduce tool life and speed. | Optimize strategies, such as slowing feed rates or using coolants. |

Simplifying designs where possible improves production speed and reduces machining challenges. Collaborating with experienced engineers ensures your designs are both functional and manufacturable.

Solutions to Overcome CNC Prototyping Challenges

Selecting the Right Material for Optimal Results

Choosing the right material ensures your CNC machining prototype meets performance and budget requirements. Start by understanding the specific needs of your project, such as strength, heat resistance, or flexibility. Compare materials to find options that align with your design specifications. For example, metals like aluminum offer excellent machinability, while plastics can reduce costs for less demanding applications. Evaluate how materials withstand environmental factors like moisture or temperature changes.

Tip: Focus on machinability to save time and reduce tooling wear. Adjust machining strategies based on the material's properties for better efficiency.

Balancing material properties with cost constraints helps you achieve optimal results without overspending. Consulting suppliers can also provide insights into material availability and suitability for rapid prototyping.

Simplifying Designs for Efficient Machining

Simpler designs lead to faster production and fewer errors. Reducing unnecessary features minimizes machining complexity and material waste. For instance, opting for straight lines and shallow cuts makes the process smoother. Standardizing parts and features also reduces the need for unique setups and tool changes, improving efficiency.

Simplify geometries to save time and reduce costs.

Avoid intricate features unless absolutely necessary.

Standardize components to streamline production.

By simplifying designs, you enhance the manufacturability of your CNC machining prototype while maintaining functionality.

Using Advanced Software for Enhanced Precision

Modern CAD tools play a crucial role in CNC prototyping. These tools simulate tool paths, optimize designs, and detect inefficiencies before machining begins. Features like toolpath simulation allow you to visualize cutting tool movements, preventing collisions and ensuring accuracy.

Note: Advanced software enables the creation of intricate 3D models with precision, essential for high-volume CNC machining.

Incorporating these tools into your workflow improves precision and reduces errors, saving time and resources.

Regular Maintenance to Prevent Tool Wear

Preventing tool wear is essential for consistent results in CNC machining. Regularly inspect and replace worn tools to avoid defects. Use coolants and lubricants to reduce friction and extend tool life. Optimize cutting parameters, such as feed rates and speeds, to minimize wear.

Tip: Clean and store tools properly to prevent corrosion and damage.

These practices ensure your tooling remains in top condition, reducing downtime and maintaining quality.

Benefits of Addressing CNC Prototyping Challenges

Higher Product Quality and Consistency

Addressing challenges in CNC prototyping directly improves product quality and ensures consistency. Selecting the right material plays a significant role in achieving this. You can avoid machining issues by ensuring the material is compatible with CNC methods. Researching material properties and consulting suppliers helps you make informed decisions. Adjusting cutting parameters based on material hardness or brittleness enhances machining efficiency.

Engaging with material specialists early in the design phase also ensures optimal material selection. Material libraries provide detailed comparisons, helping you choose the best option for your prototypes. Testing multiple materials under real-world conditions allows you to refine your choices further. These steps lead to better quality control and consistency in your prototypes.

Faster Prototyping Turnaround

When you address design and machining inefficiencies, prototyping becomes faster. Simplifying designs reduces machining time and minimizes errors. Using advanced software to simulate tool paths prevents collisions and ensures precision. Regular maintenance of tools and machines also reduces downtime, keeping production on schedule.

Streamlining processes, such as standardizing components, further accelerates turnaround times. By focusing on efficiency, you can deliver prototypes quickly without compromising quality.

Reduced Costs and Material Waste

Reducing material waste significantly lowers costs in CNC prototyping. Maximizing material usage through nesting strategies minimizes waste and optimizes resources. Sourcing local or recyclable materials cuts transportation expenses and supports sustainability. Selecting cost-effective materials that meet part requirements also enhances savings.

Proper waste management strategies, such as recycling and reusing materials, further reduce expenses. Optimizing tool paths and reducing the number of prototypes needed can also help you save money. These practices ensure cost-effective production while maintaining quality control.

Improved Customer Satisfaction and Trust

Delivering high-quality prototypes on time builds trust with your customers. When you address challenges in CNC prototyping, you ensure consistent results and faster delivery. Customers appreciate reduced costs and sustainable practices, which reflect positively on your business.

By focusing on quality control and consistency, you meet customer expectations and strengthen relationships. Satisfied customers are more likely to return for future projects, boosting your reputation and long-term success.

Addressing challenges in CNC prototyping, such as material selection and design complexity, ensures smoother processes and better results. Simplifying designs, maintaining tools, and using advanced software enhance efficiency. These efforts lead to higher product quality, faster turnaround, and reduced costs. Apply these strategies to foster innovation and improve your prototyping outcomes.

FAQ

What is the best material for CNC prototyping?

The best material depends on your project needs. Metals like aluminum offer machinability, while plastics reduce costs. Evaluate strength, heat resistance, and flexibility to make the right choice.

How can you improve CNC machining precision?

Use advanced CAD software to simulate tool paths. Regularly calibrate machines and maintain tools. Adjust cutting parameters to match material properties for better accuracy.

Why does tool wear occur in CNC machining?

Tool wear happens due to friction, heat, and improper cutting speeds. Use coolants, optimize feed rates, and replace worn tools regularly to prevent defects and maintain quality.

See Also

Overcoming Obstacles: Improving Precision and Speed in CNC Prototyping

Understanding CNC Machining: Key Aspects of Tolerances and Materials

Perfecting CNC Turning: Crafting Accurate Parts for RC Upgrades

Achieving Precision: A Comprehensive Guide to CNC Programming Techniques

CNC Turning Essentials: All You Should Understand for Success

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com