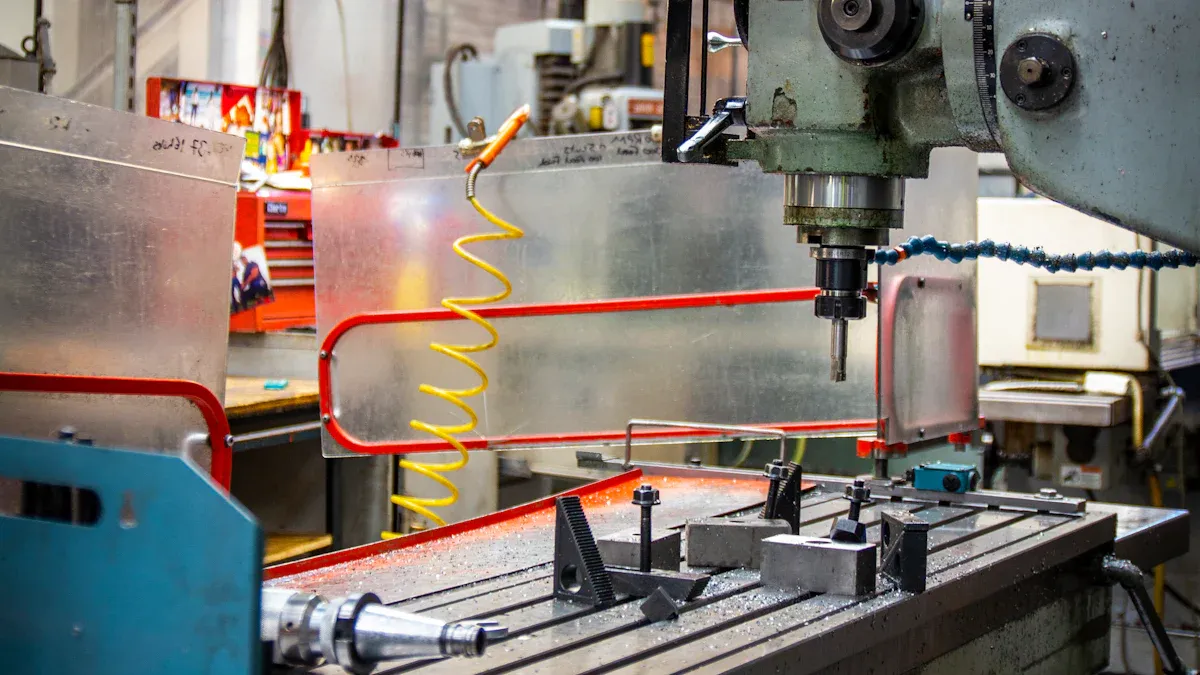

How CNC Prototyping Can Be Used for Complex Plastic Parts

CNC prototyping offers a precise way to create intricate plastic parts. You can achieve designs with complex geometry that traditional methods struggle to replicate. For example, CNC machines use advanced multi-axis systems to produce parts with tight tolerances, often as precise as +0.05mm. This computer-controlled process ensures consistent accuracy while reducing human error.

The demand for CNC prototyping continues to grow. The global plastic prototyping market, valued at USD 3.5 billion in 2023, is projected to reach USD 6.8 billion by 2032, with a 7.5% annual growth rate. This trend highlights its importance in industries requiring high precision and durability.

Key Takeaways

CNC prototyping is very accurate, with tolerances of ±0.005 mm. This makes it important for industries like aerospace and cars.

It creates smooth surfaces, improving how plastic prototypes look and work. This is important for designs that need to look good.

CNC prototyping works with many materials, making strong and useful prototypes. These can meet the needs of different industries.

Benefits of CNC Prototyping for Plastic Parts

High Precision and Accuracy

CNC prototyping delivers unmatched precision, making it ideal for creating plastic prototypes with tight tolerances. You can rely on CNC precision machining to achieve exact dimensions, which is critical for industries like aerospace and automotive. This process operates based on digital models, ensuring extraordinary accuracy and reducing errors compared to manual methods.

CNC machining ensures consistent quality by maintaining tight tolerances through computerized instructions.

Real-time adjustments to tool paths and machining parameters enhance flexibility and precision.

High-quality CNC machining prototypes meet the rigorous standards required for custom plastic parts.

This level of precision guarantees identical parts, ensuring consistent quality across production runs.

Superior Surface Finishes

CNC machining stands out for its ability to produce superior surface finishes. Plastic prototypes created through this method often feature a clean, smooth texture that enhances their appearance and functionality.

CNC milling machines can achieve surface finishes as smooth as 15Ra, providing a polished look.

Advanced tooling and CNC grinding refine the surface, ensuring precise shaping and smoothing.

These high-quality finishes make CNC prototyping an excellent choice for applications where aesthetics and performance matter.

Material Versatility and Durability

CNC prototyping supports a wide range of materials, showcasing its versatility. Thermoplastics, for instance, are widely used due to their durability and resistance to impact and wear. This makes them suitable for high-stress applications in industries like automotive and medical.

Material Type | Examples | Properties |

|---|---|---|

Plastics | Acrylic, ABS, Nylon, PC, Teflon, PVC | Versatile, durable, impact-resistant |

Composites | Carbon Fiber, Fiberglass | Strong, lightweight, impact-resistant |

Metals | Aluminum, Brass, Stainless Steel | Corrosion-resistant, durable, machinable |

By choosing the right material, you can ensure your prototypes meet the demands of your specific application.

Types of Plastics for Plastic CNC Machining

Common Plastics Used in CNC Prototyping

When it comes to CNC plastic prototypes, certain materials stand out for their unique properties and versatility. These plastics are chosen based on their machinability, durability, and suitability for specific applications.

Plastic Type | Properties | Applications |

|---|---|---|

ABS | Low weight, good machinability, impact resistance | Rapid prototyping, electrical applications |

Polycarbonate | Toughness, electrical insulation, lightweight | Surgical tools, safety goggles, circuit breakers |

PVC | Rigid, lightweight, corrosion resistance | Various industries due to durability and flame resistance |

ABS (Acrylonitrile Butadiene Styrene): This plastic is lightweight and easy to machine, making it ideal for rapid prototyping. Its impact resistance also makes it suitable for electrical applications.

Polycarbonate: Known for its toughness and excellent electrical insulation, this material is often used in medical tools and safety equipment.

PVC (Polyvinyl Chloride): Its rigidity and resistance to corrosion make it a reliable choice for durable plastic prototypes in various industries.

These materials demonstrate how plastic CNC machining can cater to diverse needs, ensuring high-quality results for your projects.

Applications of CNC Plastic Prototypes

CNC plastic prototypes play a crucial role in industries like automotive, medical, and electronics. Their precision and adaptability make them indispensable for creating functional and aesthetic components.

In the medical field, you can find CNC plastic prototypes in orthotic devices, prosthetics, and surgical instruments. They are also used for biopsy tubes, implant holders, and MRI machine components.

Automotive applications include gears, shafts, and engine parts like pistons. These prototypes ensure durability and performance under high-stress conditions.

Electronics benefit from CNC plastic prototypes in safe enclosures and circuit breakers, where precision and insulation are critical.

By leveraging CNC technology, you can produce plastic prototypes that meet the exacting standards of these industries. This approach ensures that your designs are both functional and reliable.

CNC Prototyping vs. Other Methods

CNC Machining vs. 3D Printing

When comparing CNC machining to 3D printing, you’ll notice significant differences in precision, material compatibility, and surface finish. CNC machining excels in creating highly accurate parts with tolerances as tight as ±0.005 mm. In contrast, 3D printing typically offers lower precision, with layer thicknesses ranging from 0.1 mm to 0.5 mm.

Feature | CNC Machining | 3D Printing |

|---|---|---|

Precision | High precision with tolerances ±0.005 mm | Generally lower precision, layer thickness 0.1 mm to 0.5 mm |

Material Compatibility | Works with metals, plastics, wood, wax | Limited to specific plastics and resins |

Surface Finish | Smooth, often requires little post-processing | Rougher, often requires post-processing |

CNC machining also supports a broader range of materials, including metals, wood, and various plastics. This versatility makes it ideal for creating durable and functional cnc plastic prototypes. On the other hand, 3D printing is limited to specific plastics and resins, which may not meet the demands of certain applications. If you prioritize precision and material flexibility, CNC machining is the better choice.

CNC Machining vs. Injection Molding

CNC machining and injection molding differ significantly in cost-effectiveness for low-volume production. CNC machining has lower upfront costs, making it more suitable for small production runs. Injection molding requires a substantial initial investment to create molds, which can be expensive for limited quantities.

CNC machining allows you to make design changes easily, which is beneficial for projects with evolving requirements.

Injection molding is better suited for high-volume production due to its efficiency once molds are created.

For low-volume projects, CNC machining offers greater flexibility and cost savings.

If your project involves prototype cnc machining or small-scale production, CNC machining provides a more practical and economical solution. Its ability to adapt to design changes ensures your cnc plastic prototypes meet your exact specifications without incurring high costs.

When to Use CNC Prototyping

Evaluating Design Complexity

CNC prototyping is ideal for designs with intricate geometries, but you should evaluate the complexity of your design before proceeding. Complex designs often increase machining costs due to the need for specialized setups and longer machining times. This can delay your project’s time to market.

When assessing complexity, consider factors like the number of angles and undercuts in your design. These features require advanced tool paths and may demand additional machining steps. Tool geometry also plays a critical role. Cutting tools have axial limitations, which can affect their ability to machine certain features. Understanding these constraints during the design phase helps you optimize the prototyping process and reduce unnecessary costs.

By carefully evaluating your design’s complexity, you can ensure that CNC prototyping delivers precise and efficient results for your plastic parts.

Considering Cost and Production Volume

CNC prototyping offers cost-effective solutions for low to medium production volumes. For a single prototype, the cost per piece is higher, but the total cost remains manageable. For example:

Production Volume | Cost per Piece | Total Cost |

|---|---|---|

1 Prototype | $300 | $300 |

10 Prototypes | $120 | $1,200 |

This makes CNC machining an excellent choice for rapid prototyping or small production runs. Unlike injection molding, which requires expensive molds, CNC machining allows you to produce high-quality cnc plastic prototypes without significant upfront investment.

If your project involves low-volume production or frequent design changes, CNC machining provides the flexibility and cost savings you need. Its ability to adapt to evolving requirements ensures that your plastic cnc prototypes meet your exact specifications.

CNC prototyping offers you a reliable way to create complex plastic parts with tight tolerances. Its computerized control ensures consistency and repeatability, producing precise replicas with minimal variation. For example:

CNC machining achieves tolerances as tight as +/- .001, making it essential for industries like aerospace and automotive.

You can rely on its flexibility to create intricate geometries from various plastics, meeting the demands of critical applications.

Projects like turbine blades in aerospace or robotic arm components in automation highlight its success in producing intricate designs. By consulting a trusted manufacturer, you can explore how CNC prototyping can elevate your projects with precision and efficiency.

FAQ

What industries benefit the most from CNC prototyping for plastic parts?

Industries like aerospace, automotive, medical, and electronics benefit greatly. CNC prototyping ensures precision, durability, and adaptability for creating intricate components in these fields.

How does CNC prototyping compare to traditional manufacturing methods?

CNC prototyping offers higher precision, faster production, and better material versatility. It outperforms traditional methods in creating complex geometries and achieving tight tolerances.

Can CNC prototyping handle small production runs?

Yes, CNC prototyping is ideal for low-volume production. It eliminates the need for expensive molds, making it cost-effective for small batches or custom designs.

See Also

Overcoming Obstacles: Improving CNC Prototyping Precision And Speed

Achieving Excellence In CNC Machining For Precise Components

A Comprehensive Guide To CNC Precision Parts Production

Investigating CNC Machining Solutions For Accurate Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com