Why CNC Services Are Perfect for Expanding Your Manufacturing Capacity

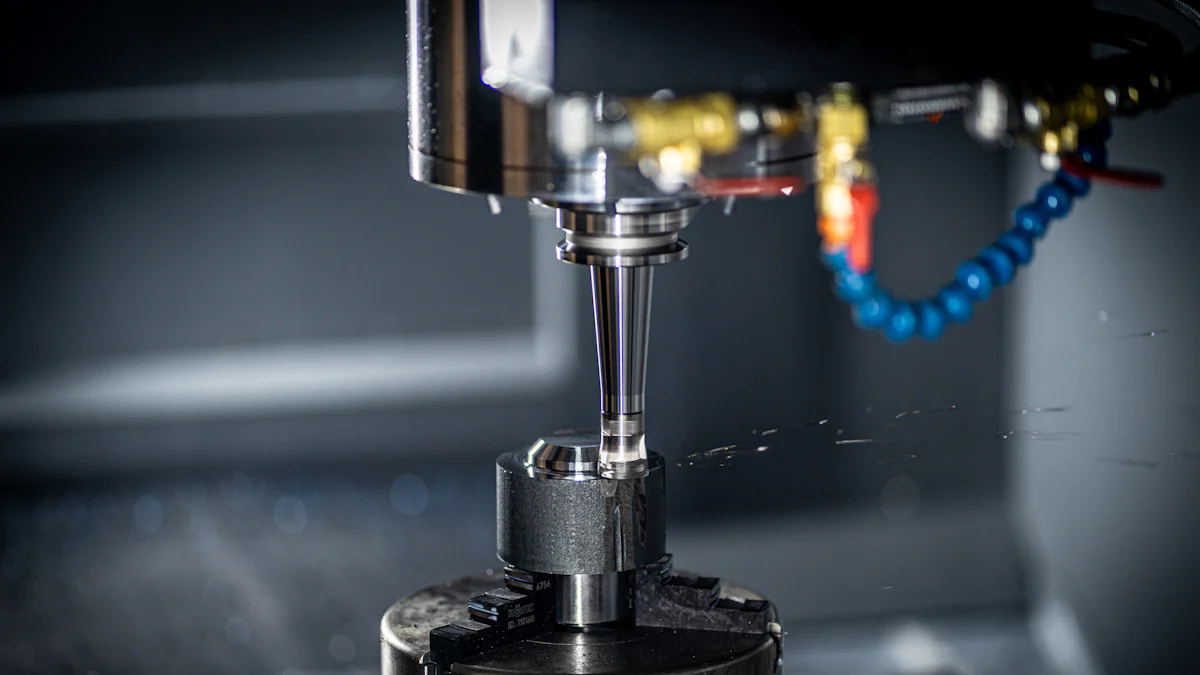

CNC services empower you to scale your manufacturing operations with precision and cost savings. CNC machining automates production, reducing labor costs and material waste. Its high accuracy minimizes defects, ensuring consistent quality. By leveraging CNC technology, you achieve unparalleled production efficiency, enabling faster output and sustainable practices while maintaining competitive costs in today’s industrial landscape.

Key Takeaways

Using CNC services saves money since you don’t need to buy expensive machines. You can still use advanced tools without owning them.

CNC machines make work faster by automating tasks. This lowers labor costs and keeps product quality the same every time.

Working with CNC companies lets you grow or shrink production easily. You can adjust to market needs without buying your own equipment.

Cost-Effectiveness of CNC Services

Reducing Capital Investments

Investing in CNC machinery for in-house operations often requires a significant upfront cost. Purchasing equipment, setting up infrastructure, and maintaining machines can strain your budget. Outsourcing CNC services eliminates these financial burdens. You gain access to advanced CNC machining without the need for large capital investments. This approach allows you to allocate resources to other critical areas of your manufacturing process, such as research and development or marketing.

CNC machining may have a higher initial investment, but outsourcing proves to be a smart long-term strategy. It reduces the need for ongoing maintenance and ensures you stay competitive without owning expensive equipment.

Lowering Operational Expenses

CNC services streamline the manufacturing process by automating production. This reduces labor costs and minimizes human error. Unlike traditional methods, CNC machining operates continuously without breaks, ensuring consistent production efficiency. Additionally, CNC services optimize material usage, reducing waste and saving costs.

Automation minimizes the need for manual labor.

Regular maintenance schedules ensure machines run efficiently, preventing costly repairs.

Digital simulations and real-time monitoring reduce material wastage.

By outsourcing CNC machining, you avoid the expenses associated with hiring and training specialized staff. This cost-effective solution enhances your bottom line while maintaining high-quality output.

Optimizing Resource Allocation

Outsourcing CNC services allows you to focus on your core competencies. Instead of managing in-house CNC operations, you can direct your resources toward innovation and market expansion. Batch production and automated tool changers further improve efficiency, reducing setup times and maximizing machine utilization.

CNC machining eliminates the need for numerous test runs, as it follows precise software instructions. This accuracy saves time and resources, enabling you to meet production deadlines without compromising quality.

By leveraging CNC services, you achieve cost savings, improved production efficiency, and streamlined operations, making it an ideal choice for expanding your manufacturing capacity.

Scalability with CNC Machining

Adapting to Market Demand

CNC machining offers unmatched flexibility, allowing you to adapt quickly to changing market demands. Whether you need to scale up production for a high-demand product or pivot to a new design, CNC services provide the agility required to stay competitive. By outsourcing CNC operations, you can adjust production volumes without the constraints of in-house equipment. This adaptability ensures you meet customer expectations while maintaining production efficiency.

CNC machines also enable rapid adjustments to manufacturing processes. Operators can modify settings or switch programs seamlessly, ensuring smooth transitions between production runs. This capability is essential for responding to fluctuating market trends and seasonal demands.

Supporting Prototyping and High-Volume Production

CNC machining excels in both prototyping and high-volume production. For prototypes, it allows you to test complex designs with short lead times. Quick modifications and faster turnaround times ensure you can refine your products efficiently. This process minimizes delays and helps you bring innovative solutions to market faster.

CNC machining supports design flexibility, enabling quick adjustments for new prototypes.

Short lead times allow for rapid testing and iteration of prototype parts.

Operators can easily switch between small orders and large-scale production runs.

For high-volume production, CNC machines maintain consistent quality and precision. Automated processes ensure every part meets exact specifications, even in large batches. This dual capability makes CNC machining a versatile solution for your manufacturing needs.

Avoiding Long-Term Equipment Commitments

Investing in CNC equipment ties up capital and limits your ability to adapt. By outsourcing CNC services, you avoid these long-term commitments and associated risks. CNC providers maintain advanced machinery, ensuring consistent quality and precision without requiring you to invest in upgrades.

Outsourcing also offers flexibility in production. You can scale operations up or down based on demand without being locked into specific equipment. This approach reduces the risk of outdated machinery and ensures your manufacturing processes remain efficient and competitive.

CNC services help you focus on growth without the burden of equipment maintenance or replacement. This strategy allows you to allocate resources to other critical areas, such as innovation and market expansion.

Access to Advanced CNC Technology

Utilizing Multi-Axis CNC Machines

Multi-axis CNC machines revolutionize manufacturing by enabling the production of intricate designs and complex geometries. These machines operate along multiple axes simultaneously, allowing you to machine undercuts and hard-to-reach areas with ease. Unlike traditional methods, multi-axis CNC machines minimize manual intervention, ensuring autonomous execution of complex operations. This capability enhances production efficiency and reduces the risk of errors.

The versatility of multi-axis CNC machines extends to various materials, part sizes, and geometries. Their smooth movement improves surface finishes by reducing machining marks, delivering superior-quality parts. Additionally, these machines allow for workpiece setups that handle all milling and turning operations in one go, significantly boosting operational speed. By leveraging multi-axis CNC machining, you can achieve precision and efficiency while meeting the demands of modern manufacturing.

Staying Competitive with Cutting-Edge Tools

Outsourcing CNC machining services gives you access to the latest tools and technologies that keep you ahead in the competitive landscape. Advanced CNC machines, such as 5-axis models, enable the creation of intricate geometries while reducing production time. Hybrid approaches, combining CNC machining with additive manufacturing, further enhance flexibility and production capabilities.

Professional CNC shops also utilize custom cutting tools and sophisticated probing systems to improve dimensional accuracy and reduce scrap rates. Software tools like ShapeSmart streamline toolmaking processes, ensuring predictable results. These cutting-edge advancements allow you to maintain high-quality standards and adapt to evolving industry demands.

Eliminating the Need for In-House Upgrades

Investing in advanced CNC technology often requires significant capital. By outsourcing CNC machining services, you eliminate the financial burden of purchasing and maintaining expensive equipment. Service providers offer access to state-of-the-art machinery and expertise, ensuring your manufacturing processes remain efficient and up-to-date.

Outsourcing aligns with the goals of Industry 4.0 by integrating technologies like IoT and data analytics. These advancements enable real-time monitoring and adjustments, improving product quality and reducing downtime. By partnering with CNC service providers, you can focus on innovation and growth without worrying about costly in-house upgrades.

Risk Reduction Through CNC Services

Minimizing Maintenance and Downtime

CNC services help you reduce maintenance requirements and minimize downtime, ensuring uninterrupted production. Service providers schedule regular maintenance during non-peak hours, preventing unexpected disruptions. Routine inspections and timely part replacements extend the lifespan of CNC machines, protecting your financial investment. Properly maintained machines also reduce scrap rates, improving product quality and production efficiency.

Scheduled maintenance reduces unplanned downtime.

Inspections and part replacements extend machine life.

Well-maintained CNC machines ensure consistent quality.

By outsourcing CNC machining, you avoid the burden of managing maintenance schedules and repairs. This approach allows you to focus on core manufacturing operations without worrying about costly interruptions.

Ensuring Compliance with Industry Standards

CNC service providers adhere to strict industry standards, ensuring your products meet regulatory requirements and maintain high-quality benchmarks. These certifications not only enhance trust but also open doors to specialized markets.

Certification | Industry Focus | Benefits |

|---|---|---|

ISO 9001 | Quality Management | Ensures consistent quality and reduces defects |

AS9100 | Aerospace Manufacturing | Access to specialized markets and elevated trust |

ISO 13485 | Medical Devices | Compliance with regulatory requirements |

By partnering with certified CNC providers, you gain a competitive edge in industries like aerospace and medical manufacturing. This compliance ensures your products meet customer expectations and industry demands.

Reducing Workforce Challenges

CNC services address workforce challenges by leveraging automation and offering innovative training solutions. Automation reduces reliance on manual labor, mitigating the impact of skill shortages. Large CNC shops often collaborate with educational institutions to create training programs, ensuring a steady supply of skilled workers.

Automation modernizes production environments, attracting younger talent.

Online courses and cross-training provide cost-effective skill development.

Collaborative networks allow small shops to share resources and training.

Outsourcing CNC machining also improves workplace culture. Competitive compensation and career growth opportunities help retain skilled employees. By addressing workforce challenges, CNC services enable you to maintain operational efficiency and meet production goals.

Enhancing Production Efficiency and Precision

Achieving Consistent Accuracy

CNC machining ensures consistent accuracy by automating the manufacturing process. Each part produced is identical, eliminating inconsistencies. Advanced CAD and CAM software translate precise designs into machine instructions, minimizing errors. High-precision equipment achieves tight tolerances, which are essential for industries like aerospace and medical device manufacturing.

Quality control measures, such as in-process monitoring and post-production inspections, catch deviations early. Skilled operators and engineers oversee operations, making real-time adjustments to maintain high standards. This combination of automation, software, and expertise ensures your products meet exact specifications every time.

Key Benefits of CNC Accuracy:

Automated processes eliminate human error.

Advanced software ensures precise designs.

High-precision machines deliver tight tolerances.

Delivering Superior Surface Finishes

CNC machining produces exceptional surface finishes, enhancing both functionality and aesthetics. Machines achieve roughness levels as low as 0.1 μm Ra, ideal for high-precision components. For general applications, finishes like 1.6 μm Ra meet industry standards. Techniques such as anodizing and bead blasting create uniform, matte surfaces, while powder coating adds durability and corrosion resistance.

Surface Finish | Roughness (Ra) | Description |

|---|---|---|

0.4 μm Ra | 0.4 μm | Extremely smooth, perfect for aesthetic parts. |

1.6 μm Ra | 1.6 μm | Standard finish for most applications. |

3.2 μm Ra | 3.2 μm | Economical choice for functional components. |

Anodizing + Bead Blasting | N/A | Matte, corrosion-resistant finish for aluminum. |

These finishes not only improve product quality but also reduce friction and wear, extending the lifespan of components.

Meeting Tight Deadlines with Automation

CNC automation helps you meet tight production deadlines by minimizing human intervention and maximizing machine uptime. Automated systems operate 24/7, producing identical units with high reliability. Real-time monitoring systems predict failures, preventing downtime and maintaining consistent production quality.

How Automation Enhances Efficiency:

Machines run continuously without breaks.

Optimized machining paths reduce cycle times.

Real-time monitoring prevents unexpected delays.

By leveraging CNC automation, you can accelerate production, reduce errors, and meet customer demands on time. This efficiency ensures your manufacturing processes remain competitive in fast-paced markets.

CNC services offer a streamlined solution for expanding your manufacturing capacity. By outsourcing CNC machining, you gain access to advanced technology, cost-effective production, and scalable operations. A reliable CNC provider ensures high-quality outputs through rigorous quality assurance and expertise. This partnership enhances efficiency, reduces risks, and positions your business for sustainable growth.

Key Takeaways for Choosing CNC Services:

Evaluate the provider’s expertise and technology.

Ensure they meet production demands without compromising quality.

Look for scalability and strict quality control measures.

Factor | Description |

|---|---|

Expertise Level | Assess the provider's ability to handle complex projects with skilled engineers and advanced knowledge. |

Technology Used | Advanced machinery and software ensure precision and accommodate diverse materials. |

Material Options | Efficient sourcing and machining of specific materials enhance product performance. |

Production Capacity | The ability to scale operations while maintaining quality ensures long-term success. |

Quality Assurance | Certifications and inspection methods guarantee high-quality outputs that meet industry standards. |

Partnering with CNC service providers ensures cost-effective manufacturing, high-quality production, and flexibility. Their advanced CNC machining capabilities and wide material options allow you to meet market demands efficiently. This collaboration fosters innovation and long-term success in competitive industries.

FAQ

What industries benefit the most from CNC machining?

CNC machining supports industries like aerospace, automotive, medical, and electronics. Its precision and versatility make it ideal for producing complex parts across diverse manufacturing sectors.

How does CNC machining improve production efficiency?

CNC machining automates processes, reduces errors, and ensures consistent quality. Its advanced technology minimizes downtime, enabling you to achieve higher efficiency and meet tight deadlines.

Can CNC services handle custom manufacturing needs?

Yes, CNC services excel at custom manufacturing. They adapt to unique designs, materials, and specifications, ensuring your products meet exact requirements with precision and reliability.

See Also

Discovering CNC Machining Solutions For Accurate Production

Streamlined CNC Machining Solutions For Precise Manufacturing

The Impact Of CNC Machining On Precision Manufacturing

Understanding CNC Technology: Innovations And Uses In Manufacturing

Unveiling 7 Major Advantages Of CNC Machining In Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com